CFD in the Capillary Rheometry of Polyethylene Melts

Evan Mitsoulis

1

and Savvas G. Hatzikiriakos

2

1

School of Mining Engineering and Metallurgy, National Technical University of Athens, Zografou, Athens, Greece

2

Department of Chemical and Biological Engineering, The University of British Columbia, Vancouver, BC, Canada

Keywords: Capillary Rheometery, Polyethylenes, Entrance Pressure, Viscous.

Abstract: The capillary flow of a commercial LDPE melt was studied both experimentally and numerically. The

excess pressure drop due to entry (Bagley correction), the compressibility, the effect of pressure and

temperature on viscosity on the capillary data analysis have been examined. It was found that only the

viscoelastic simulations (using the K-BKZ constitutive relation) were capable of reproducing the

experimental data well, while any viscous modeling always underestimates the pressures, especially at the

higher apparent shear rates and L/D ratios.

1 INTRODUCTION

Capillary rheometry is extensively used in both

industry and academia to assess the rheological

behaviour of polymer melts at high shear rates

(Dealy and Wissbrun, 1990). When such a flow is

used and the raw data are collected, a number of

important corrections should be applied before the

rheological data can be compared with

corresponding data from a rotational rheometer

(Laun 2003; 2004).

First, capillary flow involves flow through a

contraction of a certain angle, known as entrance

pressure or Bagley correction [Bagley, 1957]. This

pressure is required in order to calculate the true

shear stress. Many studies have previously attempted

to examine the origin of entrance pressure and its

prediction for low-density polyethylenes (LDPEs)

(Feigl et al., 1994); (Barakos and Mitsoulis, 1995a);

(Beraudo et al., 1996); (Guillet et al., 1996);

(Hatzikiriakos and Mitsoulis, 1996; 2003);

(Mitsoulis et al., 1998). Only just recently the

problem of predicting the Bagley correction for

LDPE was solved satisfactorily at extremely high

shear rates (up to 1000 s

-1

) for the first time (Ansari

et al., 2010) by taking into account the effect of

pressure on the viscosity.

The effect of pressure on the viscosity is very

important for some polymer melts, including LDPE.

Using capillary data from dies of various length-to-

diameter (L/D) ratios, the dependence of viscosity

on pressure can be assessed (Couch and Binding,

2000); (Park and Dealy, 2006); (Carreras et al.,

2006); (Son, 2009); (Aho and Syrjala, 2010); (Koran

and Dealy, 1999). As a first approximation, the

following Barus equation can be used to determine

the parameter,

p

β

, known as the pressure coefficient

of viscosity:

()

0

exp

pp

p

ηη β

=

(1)

where

η

is the viscosity at pressure p, and

0p

η

is

the viscosity at ambient pressure. For the LDPE (of

main interest in the present work) a value between

8

1.3 10

−

×

Pa and

8

4.9 10

−

×

Pa has been reported by

various authors (Liang, 2001); (Cardinaels et al.,

2007; Park et al., 2008).

The analysis of the dependence of viscosity on

pressure is complicated by viscous dissipation

(viscous heating) effects. Viscous heating in the

capillary extrusion of polymer melts has been the

subject of several reviews and studies over the past

decades (Winter, 1977); (Ybarra and Eckert, 1980);

(Dihn and Armstrong, 1982); (Milthorpe and

Tanner, 1987); (Mitsoulis et al., 1988); (Warren,

1988); (Ko and Lodge, 1991); (Rosenbaum and

Hatzikiriakos, 1997).

It is the main objective of this work to study the

capillary flow of a LDPE melt numerically and

experimentally by considering all possible capillary

effects, combined and separately. Namely, the

effects of Bagley correction, compressibility,

pressure dependence of viscosity, and viscous

heating will be considered in order to assess the

significance of each effect.

291

Mitsoulis E. and G. Hatzikiriakos S..

CFD in the Capillary Rheometry of Polyethylene Melts.

DOI: 10.5220/0003963602910296

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 291-296

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2 EXPERIMETAL

The experimental data used in the present

simulations have been obtained for a typical LDPE

melt in order to address the effects of pressure,

temperature and compressibility on its capillary

flow.

The viscoelastic moduli were determined over a

wide range of temperatures from 130 to 230

o

C.

Master curves were obtained using the time-

temperature superposition principle (TTS), and the

results are presented at the reference temperature of

160

o

C. The polymer was also rheologically

characterized in simple extension using the SER-2

Universal Testing Platform from Xpansion

Instruments (Sentmanat, 2003).

An Instron capillary rheometer (constant piston

speed) was used to determine the entrance pressure

(known also as Bagley method) and the viscosity as

a function of the wall shear stress,

σ

W

, and apparent

shear rate,

3

/32 DQ

A

πγ

=

&

at 160

o

C, where Q is the

volumetric flow rate and D is the capillary diameter.

3 GOVERNING EQUATIONS

We consider the conservation equations of mass,

momentum and energy for weakly compressible

fluids under non-isothermal, creeping, steady flow

conditions. These are written as (Tanner, 2000);

(Mitsoulis and Hatzikiriakos, 2009):

()

0uu

ρρ

⋅∇ + ∇⋅ =

(2)

0 p

τ

=−∇ +∇⋅

(3)

2

:

p

Cu T k T u

ρτ

⋅∇ = ∇ + ∇

(4)

where

ρ

is the density,

u

is the velocity vector, p is

the pressure,

τ

is the extra stress tensor, T is the

temperature, C

p

is the heat capacity, and k is the

thermal conductivity. For a compressible fluid,

pressure and density are connected as a first

approximation through a simple linear

thermodynamic equation of state (Mitsoulis and

Hatzikiriakos, 2009):

()

0

1

c

p

ρρ β

=+

(5)

where

β

c

is the isothermal compressibility with the

density to be ρ

0

at a reference pressure p

0

(=0).

To evaluate the role of viscoelasticity in the

prediction of Bagley correction, it is instructive to

consider first purely viscous models in the

simulations. Namely, the Carreau-Yasuda model

was used to fit the shear viscosity data of the LDPE

melt. The Carreau-Yasuda model is written as:

1

0,

1(||)

C

n

C

α

α

ηη λγ

−

⎡

⎤

=+

⎣

⎦

&

(6)

where

η

0,C

is the Carreau zero-shear-rate viscosity,

λ

is a time constant, n

C

is the Carreau power-law

index, and

α

is the Yasuda exponent (=2 for the

simple Carreau model). The parameters of the model

are listed in Table 1.

Table 1: Parameters for Eq. 6 at 160

o

C.

Parameter Value

η

0,

C

617,230 Pa⋅s

λ

17.727 s

n

C

0.221

α

0.215

For the capillary flow simulations the effect of

pressure on viscosity can be taken into account by

multiplying the constitutive relation with a pressure-

shift factor, a

p

, defined by the Barus equation, that is

(Son, 2009); (Carreras et al., 2006):

()

0

exp

pP

p

ap

η

β

η

≡=

(7)

where

P

β

is the pressure coefficient and p is the

absolute pressure, as discussed above.

Viscoelasticity is included using the K-BKZ

equation proposed by Papanastasiou et al. (1983)

and modified by Luo and Tanner (1988):

exp

() + ( 1 )

( )+ ( ) d

t

N

k

k = 1

- k k

a

1t t

=

1 3 + I I

ttt

α

θλ λα β β

θ

∞

′

−

−

−−−

′′′

⎛⎞

⎜⎟

⎝⎠

⎡⎤

⎣⎦

∑

∫

τ

-1

C

C

-1

tt

CC

(8)

where λ

k

and a

k

are the relaxation times and

relaxation modulus coefficients, α and β are material

constants, and I

C

, I

C

-1

are the first invariants of the

Cauchy tensor

C

t

and its inverse C

t

-1

, the Finger

strain tensor. Figure 1 plots the master dynamic

moduli G' and G'' at 160

o

C and the model

predictions (Kajiwara et al., 1995). The parameters

are listed in Table 2.

Table 2: Parameters for the K-BKZ (Eq. 8) at 160

o

C.

α

=7.336

k

λ

k

(s )

a

k

(Pa)

β

k

1 1.28x10

-4

4.50x10

5

1

2 2.51x10

-3

98,795 1

3 2.06x10

-2

48,899 0.18

4 1.62x10

-1

22,089 0.45

5 1.224 8,842 0.049

6 6.733 3,397 0.026

7 43 948.5 0.024

8 248 287 0.014

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

292

LDPE

T=160°C

Angular Frequency, ω (rad/s)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

Dynamic Moduli, G', G" (Pa)

10

1

10

2

10

3

10

4

10

5

10

6

Fit

G'

G''

Figure 1: Experimental and model predictions of G′ and

G′′ for the LDPE at 160

o

C.

Figure 2 plots a number of calculated and

experimental material functions for the LDPE melt

at the reference temperature of 160

o

C.

First Normal Stress Difference

,

N

1

(

Pa

)

Shear (Elongational) Rate,

γ (ε)

(s

-1

)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

Shear (Elongational) Viscosity,

η

S(E)

(Pa.s)

10

2

10

3

10

4

10

5

10

6

10

7

η

S

η

Ε

Ν

1

LDPE

T=160

o

C

.

.

Figure 2: Experimental data (solid symbols) and model

predictions of shear viscosity, η

S

, first normal stress

difference, N

1

, and elongational viscosity, η

E

, for the

LDPE melt at 160

o

C using the K-BKZ model (Eq. 12)

with the parameters listed in Table 3.

3.1 Non-isothermal Modeling

For the non-isothermal calculations it is necessary to

derive a non-isothermal constitutive equation from

the isothermal one. This has done by applying the

time-temperature shifting concept as explained by

Luo and Tanner (1987; 1988) and will not be

presented here. For LDPE melts, the following

temperature-shifting function has been found to be

adequate for the dependence of rheological

properties on temperature (Tanner, 2000);

(Meissner, 1975):

00

11

() exp

T

g

E

aT

RTT

η

η

⎡

⎤

⎛⎞

== −

⎢

⎥

⎜⎟

⎢

⎥

⎝⎠

⎣

⎦

(9)

In the above,

η

0

is a reference viscosity at T

0

, E is

the activation energy constant, R

g

is the ideal gas

constant, and T

0

is a reference temperature (in K).

The activation energy constant can be determined

from zero-shear-rate viscosity data (Meissner, 1975).

All these properties needed for the non-

isothermal simulations are gathered together in

Table 3.

4 METHOD OF SOLUTION

The solution to the above conservation and

constitutive equations is carried out with two codes,

one for viscous flows (u-v-p-T-h formulation) and

one for viscoelastic flows (Barakos and Mitsoulis,

1996); (Luo and Mitsoulis, 1990). The boundary

conditions for the problem can be found in our

earlier publications (Mitsoulis et al., 1998);

(Mitsoulis and Hatzikiriakos, 2003).

Table 3: Values of the various parameters for the LDPE

resin at 160

o

C.

Parameter Value

β

c

0.00095 MPa

-1

β

p

0.015 MPa

-1

m

0.65

1

GPa

p

n −

(0.11

1

MPa

p

n −

)

n

p

0.75

ρ

0.7828 g/cm

3

C

p

2.25 J/(g·K)

k 0.0017 J/(s·cm·K)

E 64,100 J/mol

R

g

8.3143 J/(mol·K)

T

0

160°C (433 K)

5 EXPERIMENTAL RESULTS

5.1 Entrance (End) Pressure

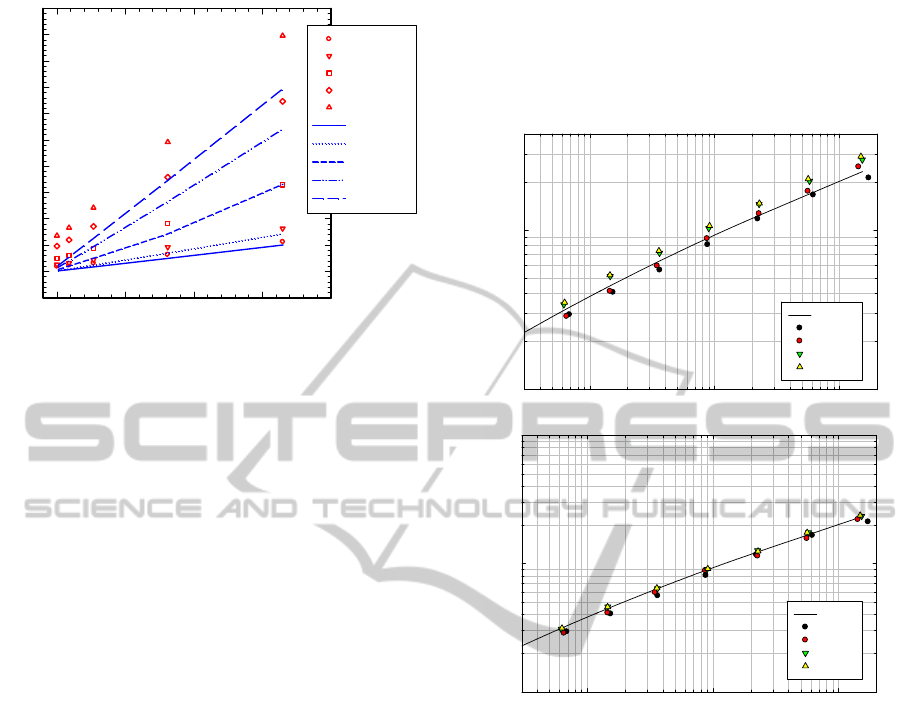

Figure 3 plots the entrance pressure (or end pressure

due to L/D=0) of LDPE at 160

o

C as a function of the

die length L/D for an extended range of values of the

apparent shear rate from 5 s

-1

to 1000 s

-1

. This plot is

also known as the Bagley plot. The data from an

orifice die are also plotted. The data show a

curvature with concavity pointing upwards

consistent with Eq. 1 (effect of pressure on

viscosity). These results are for a contraction angle

2

α

=90°.

CFDintheCapillaryRheometryofPolyethyleneMelts

293

L / D

0 10203040

Δ

P (MPa)

-5

0

5

10

15

20

25

30

35

40

45

50

γ

A

=5 s

-1

γ

A

=11 s

-1

γ

A

=64 s

-1

γ

A

=390 s

-1

γ

A

=1000 s

-1

γ

a

=5 s

-1

γ

a

=11 s

-1

γ

a

=64 s

-1

γ

a

=390 s

-1

γ

a

=1000 s

-1

LDPE,

T=160

o

C

symbols=exp.

Carreau lines

.

.

.

.

.

.

.

.

.

.

Figure 3: The effect of L/D on the pressure for the LDPE

melt at 160

o

C at various values of apparent shear rate (all

effects accounted for). Simulations with the Carreau-

Yasuda model (Eq. 6).

5.2 the Flow Curves

Figure 4a plots the flow curves of LDPE at 160

o

C

obtained with capillary dies having lengths of

L/D=2, 5, 16, and 33. The Bagley and Rabinowitsch

corrections have been applied to the data. Also

plotted are the linear viscoelastic data at 160

o

C,

which agree well with the data at L/D=2 and 5. The

data clearly shows that there is an effect of pressure

on viscosity. Using this set of data the

p

β

(which is a

shear-rate-dependent pressure coefficient) can be

obtained. In our case,

β

p

shows a power-law

dependency on pressure, according to the following

equation:

p

n

p

mp

β

−

=

(10)

where m=0.62

1

GPa

p

n −

and n

p

=0.75, with the

pressure p given in GPa. The pressure-corrected data

for the LDPE are plotted in Fig. 4b. The data

superposes well and the capillary data agrees well

with the LVE data.

6 NUMERICAL RESULTS

6.1 Viscous Modeling

It is instructive to perform first calculations with a

purely viscous model, so that the effect of

viscoelasticity will become evident later. The

numerical simulations have been undertaken using

the viscous Carreau-Yasuda model (Eq. 6). This

constitutive relation is solved together with the

conservation equations of mass and momentum

either for an incompressible or compressible fluid

under isothermal or non-isothermal conditions

(conservation of energy equation) with or without

the effect of pressure-dependence of the viscosity.

Shear Rate

(

s

-1

)

10

1

10

2

10

3

Wall Shear Stress (MPa)

10

-2

10

-1

LVE

L/D = 2

L/D = 5

L/D = 16

L/D = 33

T = 160°C

D = 0.787 mm

2α = 180°

Shear Rate

(

s

-1

)

10

1

10

2

10

3

Wall Shear Stress (MPa)

10

-2

10

-1

10

0

LVE

L/D=2

L/D=5

L/D=16

L/D=33

T = 160°C

D = 0.787mm

2α = 180°

β

p

(1/GPa)=0.62xP

-0.75

Figure 4: The flow curves of LDPE at 160°C determined

in capillary rheometry with dies having L/D ratios from 2

to 33. The data at the small L/Ds agree well with the LVE

data obtained from a rotational rheometer at ambient

pressure. The capillary data have been corrected by

applying both the Bagley and Rabinowitsch corrections

(top) and the effect of pressure on viscosity (bottom).

Collecting all the pressure results together for the

5 dies with L/D=0.2, 2, 5, 16, 33 and 5 apparent

shear rates

A

γ

&

gives in Fig. 3 the well-known

Bagley plot. The experimental results are shown as

symbols while the numerical results here and in the

subsequent graphs are shown as lines. The results

are below the experimental data, and this is mainly

due to the inability of a viscous model to capture the

end correction (for L/D=0). As it was found out in

[Ansari et al., 2010], a purely viscous model for

LDPE gives end corrections one order of magnitude

lower than the experimental ones. It is then at this

point that we turn our attention to the viscoelastic

results.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

294

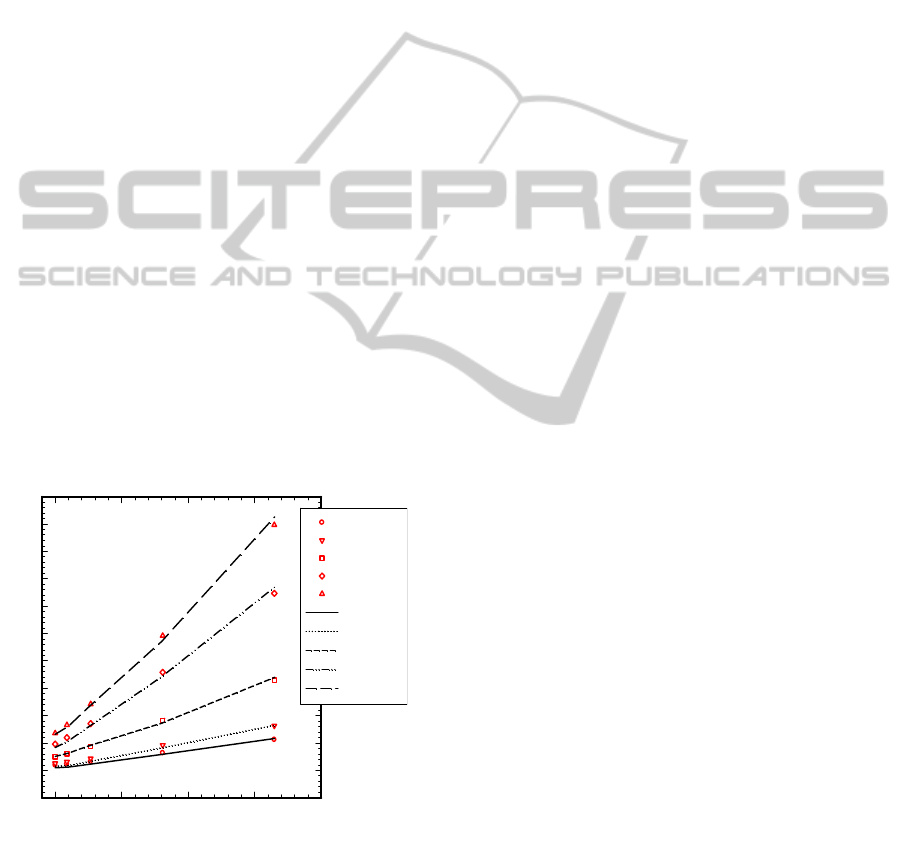

6.2 Viscoelastic Modeling

It is again instructive to compare individual

distributions of pressure and temperature between

the viscous and the viscoelastic models. This is done

in Fig. 5, where we show the pressure results from

the K-BKZ models for the several pressure drops as

in Fig. 3. The viscoelastic pressures are markedly

higher than the viscous ones, and in fact they predict

the experimental data very well. More detailed

simulation results for various cases have shown that

the K-BKZ equation is capable of capturing all

important effects including the effects of

compressibility, pressure, viscous heating and

entrance pressure on the overall pressure required in

the capillary flow of LDPE.

7 CONCLUSIONS

A commercial low-density polyethylene melt

(LDPE) has been studied in entry flows through

tapered dies with different L/D ratios. The

experiments have shown a distinct pressure-

dependence of viscosity with a pressure coefficient

to be a power-law function of pressure. Full

rheological characterization was carried out both

with a viscous (Carreau-Yasuda) and a viscoelastic

(K-BKZ) model. All necessary material properties

data were collected for the simulations.

L / D

0 10203040

Δ

P (MPa)

-5

0

5

10

15

20

25

30

35

40

45

50

γ

A

=5 s

-1

γ

A

=11 s

-1

γ

A

=64 s

-1

γ

A

=390 s

-1

γ

A

=1000 s

-1

γ

A

=5 s

-1

γ

A

=11 s

-1

γ

A

=64 s

-1

γ

A

=390 s

-1

γ

A

=1000 s

-1

LDPE,

T=160

o

C

symbols=exp.

K-BKZ lines

.

.

.

.

.

.

.

.

.

.

Figure 5: The effect of L/D on the pressure for the LDPE

melt at 160

o

C at various values of apparent shear rate.

Non-isothermal simulations with the K-BKZ model with

pressure-dependence of the viscosity (variable

β

p

).

The viscous model was found to underestimate

the extrusion pressures. The viscoelastic model

showed a very good agreement with the

experimental results, which appears to be the first in

the literature for the elastic LDPE melt. The

simulations showed that: (a) compressibility is not

important in these steady flows; (b) viscous

dissipation is important, especially for the more

severe conditions (high L/D and apparent shear

rates); and (c) the pressure-dependence of viscosity

is very important and its correct function has to be

found experimentally. This is the first time that all

these effects are taken into account in a viscoelastic

simulation.

ACKNOWLEDGEMENTS

Financial assistance from the Natural Sciences and

Engineering Research Council (NSERC) of Canada

and the programme “PEBE 2009-2011” for basic

research from NTUA are gratefully acknowledged.

REFERENCES

Aho J., Syrjälä S., J. App. Polym. Sci., 117, 1076-1084

(2010).

Ansari M., A. Alabbas, E. Mitsoulis, S.G. Hatzikiriakos,

Intern. Polym. Proc., 25, 287-296 (2010).

Dealy, J. M., Wissbrun, K. F., Melt Rheology and its Role

in Plastics Processing - Theory and Applications, Van

Nostrand Reinhold, New York (1990).

Bagley, E. B., J. Appl. Phys., 28, 193-209 (1957).

Barakos, G., Mitsoulis, E., J. Non-Newtonian Fluid Mech.,

62, 55-79 (1996).

Barakos, G., Mitsoulis, E., J. Rheol., 39, 193-209 (1995a).

Barakos, G., Mitsoulis, E., J. Non-Newtonian Fluid Mech.,

58, 315-329 (1995b).

Béraudo, C., Coupez, T., Fortin, A., Demay, Y., Vergnes,

B., Agassant, J.-F., Proc. XIIth Int. Congr. Rheology,

Eds. A. Ait-Kadi, J.M. Dealy, D.F. James, M.C.

Williams, Quebec City, Canada, pp. 417-418 (1996).

Cardinaels R., Van Puyvelde P., Moldenaers P., Rheol.

Acta, 46, 495-505 (2007).

Carreras, E. S., El Kissi, N., Piau, J.-M., Toussaint, F.,

Nigen, S., Rheol Acta, 45, 209–222 (2006).

Couch M. A., Binding, D. M., Polymer, 41, 6323-6334

(2000).

Dinh, S. M., Armstrong, R. C., AIChE J., 28, 294-301

(1982).

Feigl, K., Öttinger, H. C., J. Rheol., 38, 847-874 (1994).

Guillet, J., Revenue, P., Béreaux, Y., Clermont, J.-R.,

Rheol. Acta, 35, 494-50 (1996).

Hatzikiriakos, S.G., Mitsoulis, E., Rheol. Acta, 35, 545-

555 (1996).

Laun H. M., Rheol. Acta, 42, 295–308 (2003).

Kajiwara, T., Barakos, G., Mitsoulis, E., Int. J. Polymer

Analysis & Characterization, 1, 201-215 (1995).

CFDintheCapillaryRheometryofPolyethyleneMelts

295

Ko, Y. S., Lodge, A. S., Rheol. Acta, 30, 357-368 (1991).

Koran F., and J. M. Dealy, J. Rheol., 43, 1279-1290

(1999).

Laun H. M., Rheol. Acta., 43, 509-528 (2004).

Liang J.-Z., Polymer, 42, 3709-3712 (2001).

Mitsoulis, E., Hatzikiriakos, S.G., Christodoulou, K.,

Vlassopoulos, D., Rheol. Acta, 37, 438-448 (1998).

Luo, X.-L., Tanner, R. I., Rheol. Acta, 26, 499-507

(1987).

Luo, X.-L., Tanner, R. I., Int. J. Num. Meth. Eng., 25, 9-22

(1988).

Luo, X.-L., Mitsoulis, E., Int. J. Num. Meth. Fluids, 11,

1015-1031 (1990).

Meissner, J., Pure Appl. Chem., 42, 551-612 (1975).

Milthorpe, J. F., Tanner, R. I., Int. J. Num. Meth. Engng.,

24, 263-270 (1987).

Mitsoulis, E., Wagner, R., Heng, F. L., Polym. Eng. Sci.,

28, 291-310 (1988).

Mitsoulis, E., Hatzikiriakos, S. G., J. Non-Newtonian

Fluid Mech., 157, 26-33 (2009).

Mitsoulis, E., Hatzikiriakos, S. G., Rheol. Acta, 42, 309-

320 (2003).

Park, H. E., Lim, S. T., Laun, H. M., Dealy, J. M.,

Macromolecules, 47, 1023-1038 (2008).

Park, H. E., Dealy, J. M., Macromolecules, 36, 5438-5452

(2006).

Papanastasiou, A. C., Scriven, L. E., Macosco, C. W., J.

Rheol., 27, 387-410 (1983).

Rosenbaum, E. E., Hatzikiriakos, S. G., AIChE J., 43,

598-608 (1997).

Sentmanat, M. L., Goodyear Co., U.S. Patent No.

6,578,413 (2003).

Son, Y., J. Polym. Res., 16, 667-671 (2009).

Tanner, R. I., “Engineering Rheology”, 2

nd

Edition,

Oxford University Press, Oxford, UK (2000).

Ybarra, R. M., Eckert, R. E., AIChE J., 26, 751-762

(1980).

Warren, R. C., Viscous Heating. Rheological

Measurement, Elsevier, London, 119-149 (1988).

Winter, H. H., Adv. Heat Transfer, 13, 205-267 (1977).

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

296