Developing A New Variables Sampling Scheme for Product

Acceptance Determination

Chien-Wei Wu

1

and James C. Chen

2

1

Department of Industrial Management, National Taiwan University of Science and Technology, Taipei, Taiwan

2

Department of Industrial Engineering and Engineering Management, National Tsing Hua University, Hsinchu, Taiwan

Keywords: Decision Making, Acceptance Sampling, Fraction of Defectives, Quality Assurance.

Abstract: Acceptance sampling is a useful tool for determining whether submitted lots should be accepted or rejected.

With the current increase in outsourcing production processes and the high quality levels required, it is very

desirable to have an efficient and economic sampling scheme. This paper develops a variables repetitive

group sampling (RGS) plan based on the third generation of process capability index. The plan parameters

are determined by minimizing the average sample number (ASN) for inspection and fulfilling the classical

two-point-condition on the operating characteristic (OC) curve. Besides, the efficiency of the proposed plan

is investigated and compared with the existing variables single sampling plan. Tables of the plan parameters

are also provided.

1 INTRODUCTION

Acceptance sampling is one of the most practical

tools in classical quality control and assurance

applications, which deal with quality contracts for

product orders between factories and their

customers. Acceptance sampling plans provide the

producer and the consumer with a general criterion

for lot sentencing. A well-designed sampling plan

can substantially reduce the difference between the

required and the actual supplied product quality

(Pearn and Wu, 2006; Pearn and Wu, 2007).

Unfortunately, it cannot avoid the risk of accepting

unwanted poor product lots, nor can it avoid the risk

of rejecting good product lots without implementing

100% inspection (e.g., Montgomery, D. C., 2009).

The criteria used to measure the performance in an

acceptance sampling plan are usually based on the

operating characteristic (OC) curve, which

quantifies the risks of producers and consumers. The

OC curve plots the probability of accepting a lot

against the actual quality level of the submitted lots.

In other words, the OC curve shows the

discriminatory power of the sampling plan, which

provides the producer and the buyer with a common

base for judging whether the sampling plan is

appropriate.

Sherman (1965) developed a new type of

sampling plan, called the repetitive group sampling

(RGS) plan, for attributes. The operating procedure

of this RGS plan is similar to that of the sequential

sampling plan. Balamurali and Jun (2006) extended

the RGS concept to variables inspection for a

normally distributed quality characteristic. They also

compared the efficiency of the variables RGS plan

with the variables single and double sampling plans.

These results indicate that the variables RGS plan

give the desired protection with the minimum

average sample number (ASN).

It is highly desirable to have an efficient and

economic acceptance sampling scheme, especially

when the required quality level is very high.

Therefore, the main purpose of this paper is to

develop a new variables sampling scheme for

product acceptance determination.

2 PROCESS CAPABILITY

INDICES

Process capability indices (PCIs), including C

p

, C

pk

,

C

pm

and C

pmk

, are convenient and powerful tools for

measuring process performance from different

perspectives. These indices establish the relationship

between actual performance and the specification

limits, and convey critical information regarding

whether a process is capable of reproducing items

satisfying customer requirements. For thorough

589

Wu C. and Chen J..

Developing A New Variables Sampling Scheme for Product Acceptance Determination.

DOI: 10.5220/0003972505890593

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (OMDM-2012), pages 589-593

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

discussions on PCIs and the reviews for the

development of PCIs, refer to Kotz and Lovelace

(1998), Kotz and Johnson (2002), and Wu, Pearn

and Kotz (2009). In addition, Yum and Kim (2011)

summarized the related literature of process

capability analysis from 2000-2009.

In particular, the C

pmk

index is appropriate for

capability measure due to high standard and

stringent requirement on product quality and

reliability.

For a normally distributed process that is

demonstrably stable (under statistical control), Pearn

et al. (1992) suggested using the following

estimator:

2222

ˆ

min ,

3()3()

pmk

nn

USL X X LSL

C

SXT SXT

⎧⎫

−−

⎪⎪

=

⎨⎬

+− +−

⎪⎪

⎩⎭

22

||

3()

n

dXM

SXT

−−

=

+−

,

where

USL and

L

SL are the upper and lower

specification limits,

T is the target value,

()/2dUSLLSL=− is the half-length of the

specification interval and

()/2MUSLLSL=+

is the

midpoint of the specification limits,

1

/

n

i

i

X

Xn

=

=

∑

and

(

)

2

2

1

/

n

ni

i

SXXn

=

=−

∑

are the maximum

likelihood estimators of

μ

and

2

σ

, respectively.

Note that

22

()

n

SXT+−

2

1

()/

n

i

i

X

Tn

=

=−

∑

in the

denominator of

ˆ

p

mk

C is the uniformly minimum

variance unbiased estimator (UMVUE) of

22 2

()[( )]TEXT

σμ

+− = − , which appears in the

denominator of

p

mk

C (Pearn, Kotz and Johnson

(1992) and Pearn and Lin (2002)).

Wright (1998) developed an explicit but rather

complicated expression for the probability density

function (PDF) of

ˆ

p

mk

C . More recently, Pearn and

Lin (2002) rewrote the cumulative distribution

function (CDF) of

ˆ

p

mk

C by taking variables

transformation and the integration techniques similar

to that presented in Vännman (1997). The CDF can

be expressed as

2

/(1 3 )

2

ˆ

2

0

()

() 1

9

()()d,

pmk

bn y

C

bn w

Fy G w

y

wnwnw

φξ φξ

+

⎛⎞

−

=− −

⎜⎟

⎜⎟

⎝⎠

⎡⎤

×+ +−

⎣⎦

∫

for 0y > , where /bd

σ

= , ()/T

ξ

μσ

=− , ()G

⋅

is

the CDF of the chi-square distribution with degrees

of freedom

1n

−

, and

()

φ

⋅

is the PDF of the

standard normal distribution.

3 DEVELOPING A NEW

VARIABLES RGS SAMPLING

SCHEME

If the quality characteristic of interest follows a

normal distribution and has two-sided specification

limits (LSL and USL). It is common to use the AQL

(acceptable quality level) and LQL (limiting quality

level) points on the OC curve to designing an

acceptance sampling plan. This implies that the

probability of acceptance must be greater than

1

α

−

if the quality level of the submitted lot is at

AQLpmk

CC

=

(in high quality). The probability of

acceptance is no more than

β

if the quality level of

the submitted lot is only at

LQLpmk

CC= (in low

quality), where

α

and

β

are commonly called the

producer’s risk and the consumer’s risk,

respectively.

The operating procedure of the proposed

variables RGS plan based on the

p

mk

C index can be

stated as follows.

Step 1. Decide the capability requirements and

the risks for the consumer and the producer (i.e.,

determine the values of

AQL

C ,

LQL

C ,

α

, and

β

).

Step 2. Take a random sample of size

n from the

lot, and calculate the estimated

p

mk

C value,

ˆ

p

mk

C ,

based on these inspected samples.

Step 3. Make a decision based on the following

rules.

(i) Accept the entire lot if

ˆ

p

mk

C

is greater than the

critical value for acceptance

a

k .

(ii) Reject the entire lot if

ˆ

p

mk

C is smaller than

the critical value for rejection

r

k .

(iii) Otherwise, we do not have sufficient

information to determine if the submitted lot meets

the present capability requirement. In this case, we

should take a new sample for further judgment (i.e.,

repeat Step 2).

The definition of the

p

mk

C index can be rewritten

as

21/2

(/ ||)/[3(1 )]

pmk

Cd

σξ ξ

=− + , where

()/T

ξ

μσ

=

− . Further, given

pmk

CC= , /bd

σ

=

can be rewritten as

21/2

3(1 ) | |bC

ξ

ξ

=+ +. The

probability of accepting the lot based on the

p

mk

C

index can be expressed as

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

590

ˆ

()( )

apmk pmk a

PC PC k=≥

2

/(1 3 )

2

2

0

()

()()d.

9( )

a

bn k

a

bn w

Gwwnwnw

k

φξ φξ

+ ⎛⎞

−

⎡⎤

=−++−

⎜⎟

⎜⎟

⎣⎦

⎝⎠

∫

Similarly, the probability of rejecting the lot based

on the

p

mk

C index, ()

rpmk

PC , can be expressed as

ˆ

()( )

rpmk pmk r

PC PC k=<

2

/(1 3 )

2

2

0

()

1()()d.

9( )

r

bn k

r

bn w

Gwwnwnw

k

φξ φξ

+ ⎛⎞

−

⎡⎤

=− − + + −

⎜⎟

⎜⎟

⎣⎦

⎝⎠

∫

So, the OC function of the designed variables RGS

plan based on the

p

mk

C index, ()

Apmk

C

π

, can be

obtained as

()

() .

()()

apmk

Apmk

a pmk r pmk

PC

C

PC PC

π

=

+

As noted before, the parameters of the designed

variables RGS plan should simultaneously satisfy

the following two conditions specified by the

producer and the consumer:

AQL

AQL

AQL AQL

()

() 1

()()

a

A

ar

PC

C

PC PC

π

α

=≥−

+

and

LQL

LQL

LTPD LQL

()

()

()()

a

A

ar

PC

C

PC PC

π

β

=≤

+

,

where

AQL

C and

LQL

C denote the quality levels of

AQL and LQL based on the

p

mk

C index,

respectively.

Three plan parameters

(, , )

ar

nk k must be

determined for the designed variables RGS plan.

There may be several combinations of the plan

parameters that satisfy the above two equations.

The ASN for the proposed variables RGS plan

can be calculated by

ASN( ) .

()()

pmk

apmk rpmk

n

C

PC PC

=

+

It is usual to determine the plan parameters by

minimizing the ASN evaluated at AQL or LQL.

Therefore, the plan parameters

(, , )

ar

nk k of the

proposed VRGS plan based on the

p

mk

C index could

be determined simultaneously by solving the

following optimization problem while the ASN is

the objective function.

AQL

Min ASN( )C

subject to

AQL

()1,

A

C

π

α

≥−

LQL

(),

A

C

π

β

≤

AQL LQL

CC> , 0

ar

kk≥≥,

where

21/2

AQL

3(1)||

A

bC

ξ

ξ

=++ and

21/2

LQL

3(1)||

L

bC

ξ

ξ

=++. If

ar

kk= , the developed

variables RGS plan will reduce to the existing

variables single sampling plan based on the

p

mk

C

index by Wu and Pearn (2008).

4 DETERMINATION OF PLAN

PARAMETERS AND

DISCUSSIONS

Given the producer’s

α

-risk, the consumer’s

β

-risk

and two benchmarking quality levels

AQL LQL

(, )CC,

the plan parameters (

n

,

a

k ,

r

k ), the corresponding

ASN value of the proposed variables RGS plan can

be obtained by solving the above optimization

model.

Tables 1-2 summarize the plan parameters

(

n ,

a

k ,

r

k ) and the corresponding ASN value under

various

α

-risks and

β

-risks = 0.01, 0.05 and 0.10,

with several selected values of

AQL LQL

(, )CC= (1.33,

1.00) and (1.50, 1.00), respectively.

Based on the given tables, the practitioner can

know how large a sample size is required for

inspection and the associated critical values for

acceptance and rejection (

a

k

,

r

k

). For instance, if the

benchmarking quality levels

AQL LQL

(, )CC are set to

(1.33, 1.00) with (

α

,

β

) = (0.05, 0.10) then the plan

parameters will be

(, , )

ar

nk k = (34, 1.297, 1.031).

This implies that the lot will be accepted if the 34

inspected product items yield measurements with

ˆ

pmk

C > 1.297, and the lot will be rejected if

ˆ

pmk

C

<

1.031. Otherwise, a new sample must be

taken for further judgment.

DevelopingANewVariablesSamplingSchemeforProductAcceptanceDetermination

591

Table 1: The values of

n

,

a

k ,

r

k , and the corresponding

ASN for various

α

and

β

with quality levels

AQL LQL

(, )CC= (1.33, 1.00).

α β n k

a

k

r

ASN

0.010 0.010

87 1.278 1.074 124.4

0.050

56 1.275 1.021 82.1

0.100

44 1.271 0.989 65.2

0.050 0.010

78 1.289 1.258 114.2

0.050

45 1.295 1.068 74.2

0.100

34 1.297 1.031 52.8

0.100 0.010

74 1.295 1.159 106.3

0.050

40 1.311 1.099 62.8

0.100

30 1.319 1.059 45.6

Table 2: The values of n ,

a

k ,

r

k , and the corresponding

ASN for various

α

and

β

with quality levels

AQL LQL

(, )CC= (1.50, 1.00).

α β n k

a

k

r

ASN

0.010 0.010

44 1.418 1.127 62.1

0.050

28 1.416 1.050 40.5

0.100

22 1.413 1.003 31.8

0.050 0.010

41 1.433 1.203 57.5

0.050

23 1.447 1.120 35.0

0.100

17 1.455 1.066 26.0

0.100 0.010

39 1.441 1.252 53.7

0.050

21 1.470 1.166 31.5

0.100

15 1.486 1.096 22.6

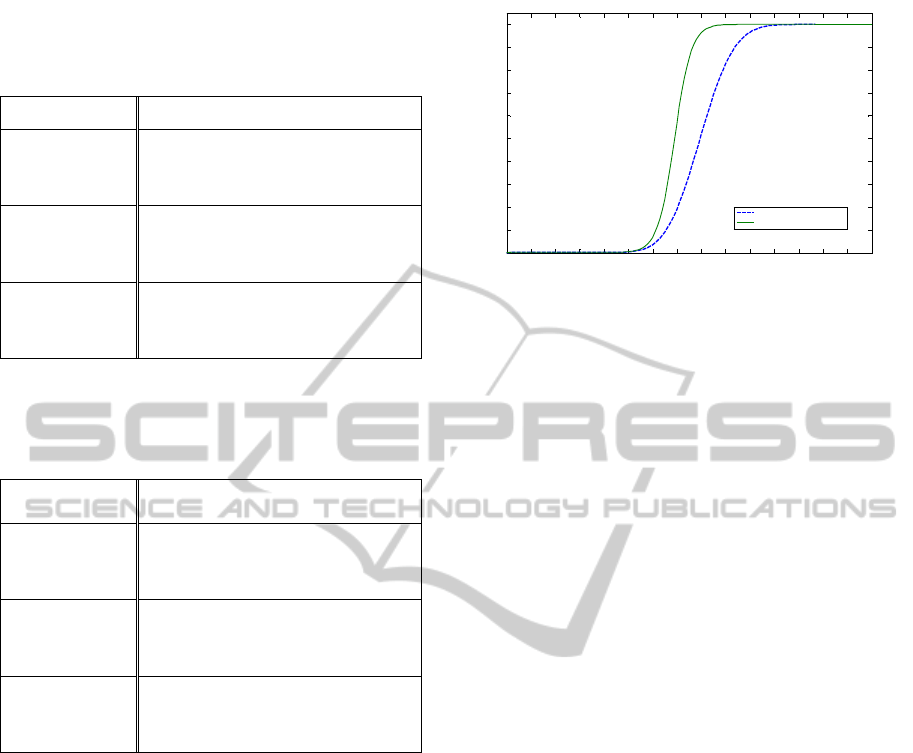

Figure 1 displays OC curves of the variables

single sampling plan and the variables RGS plan

with

n =

100. It can be seen that the OC curve for

the proposed variables RGS plan is more

discriminating than the variables single sampling

plan. This is because a greater slope in the OC curve

represents greater discriminatory power. It provides

a better OC curve than the variables single sampling

plan at good quality levels and protects against the

consumer point of view at poor quality levels.

This implies that the same OC curve can be

achieved by the proposed variables RGS plan with

smaller sample size than required by the existing

variables single sampling plan. Thus, the proposed

variables RGS plan is economically superior to the

variables single sampling plan in terms of sample

size required for inspection. Thus, the proposed plan

will give the desired protection with minimum

inspection, and reduce the cost of inspection greatly.

0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Cpmk

Probability of acceptance

Variables Single Sampling Plan

Variables RGS Plan

Figure 1: OC curves of a variables single sampling plan

and a variables RGS plan with

n = 100.

5 CONCLUSIONS

This paper develops a variables RGS plan based on

the C

pmk

index. The OC curve of the proposed

variables RGS plan is based on an exact sampling

distribution rather than approximation. The sample

size required for inspection and the corresponding

acceptance and rejection criteria are determined by

minimizing the ASN such that two critical

constraints required by the producer and the

consumer can be satisfied. This paper also compares

the efficiency of the proposed variables RGS plan

with the existing variables single sampling plan in

terms of the ASN required for inspection. Results

indicate that the proposed variables RGS plan

requires less sampling for product acceptance

determination than the variables single sampling

plan under the same conditions. It would be useful

when inspection or testing of the product quality

characteristic is costly or destructive.

ACKNOWLEDGEMENTS

This work was partially supported by the National

Science Council of Taiwan under grant no. NSC

100-2628-E-011-013-MY3.

REFERENCES

Balamurali, S. and Jun, C.H. (2009). Designing of a

variables two-plan system by minimizing the average

sample number.

Journal of Applied Statistics, 36(10),

1159-1172.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

592

Kotz, S. and Johnson, N. L. (2002). Process capability

indices – a review, 1992-2000.

Journal of Quality

Technology,

34(1), 1-19.

Kotz, S. and Lovelace, C. (1998).

Process Capability

Indices in Theory and Practice

. Arnold, London, U.K.

Montgomery, D. C. (2009).

Introduction to Statistical

Quality Control

(6th Edition), Wiley, New York.

Pearn, W.L., Kotz, S. and Johnson, N.L. (1992).

Distributional and inferential properties of process

capability indices.

Journal of Quality Technology,

24(4), 216-231.

Pearn, W.L. and Lin, P.C. (2002). Computer program for

calculating the

p-values in testing process capability

C

pmk

. Quality and Reliability Engineering

International

, 18(4), 333-342.

Pearn, W. L. and Wu, C. W. (2006). Critical acceptance

values and sample sizes of a variables sampling plan

for very low fraction of defectives.

Omega – The

International Journal of Management Science

, 34(1),

90-101.

Pearn, W. L. and Wu, C. W. (2007). An effective decision

making method for product acceptance.

Omega – The

International Journal of Management Science

, 35(1),

12-21.

Sherman, R. E. (1965). Design and evaluation of repetitive

group sampling plan.

Technometrics, 7, 11-21.

Vännman, K. (1997). Distribution and moments in

simplified form for a general class of capability

indices.

Communications in Statistics: Theory &

Methods

, 26, 159-179.

Wright, P. A. (2000). The cumulative distribution of

process capability index

C

pm

. Statistics and

Probability Letters

, 47, 249-251.

Wu, C. W., Pearn, W. L. and Kotz, S. (2009). An

overview of theory and practice on process capability

indices for quality assurance.

International Journal of

Production Economics

, 117(2), 338-359.

Wu, C. W. and Pearn, W. L. (2008). A variables sampling

plan based on

C

pmk

for product acceptance

determination.

European Journal of Operational

Research

, 184(2), 549-560.

Yum, B. J. and Kim, K. W. (2011). A bibliography of the

literature on process capability indices: 2000-2009.

Quality and Reliability Engineering International,

27(3), 251-268.

DevelopingANewVariablesSamplingSchemeforProductAcceptanceDetermination

593