Risk Prediction of a Behavior-based Adhesion Control Network for

Online Safety Analysis of Wall-climbing Robots

Daniel Schmidt and Karsten Berns

Robotics Research Lab, Department of Computer Sciences, University of Kaiserslautern, 67663 Kaiserslautern, Germany

Keywords:

Genetic Algorithm, Behavior-based, Risk Prediction, Climbing Robot.

Abstract:

Risk analysis in combination with terrain classification is a common approach in mobile robotics to adapt

robot control to surface conditions. But for climbing robots it is hard to specify, how the robotic system

and especially the adhesion is affected by different surfaces and environmental features. This paper will

introduce the climbing robot CROMSCI using negative pressure adhesion via multiple chambers, adaptive

inflatable sealings and an omnidirectional drive system. It presents the used behavior-based control network

which allows the balancing of adhesion force, but fails in extreme situations. Therefore, a risk prediction has

been developed which evaluates behavioral meta-data and allows an estimation of current hazards caused by

the environment. This prediction is used to perform evasive actions to prevent the robot from falling down.

1 INTRODUCTION

A general requirement for robots is safety. Com-

monly, mobile systems have to deal with macro ob-

stacles like persons, furniture, trees or holes depend-

ing on their field of application. In these cases the

results of a crash and requirements to avoid it can be

described well (Kelly and Stentz, 1998) and common

approaches of obstacle detection and avoidance can

be applied. A more difficult challenge is the adap-

tion to environmental features, which can either not

be detected in total or whose impact on the robot is

not known sufficiently. Some use methods of terrain

classification via simple metrics (Castelnove et al.,

2005) or learning methods(Stavens and Thrun, 2006),

others try to get more general information about the

traversability (Kim et al., 2006) of the surface. These

approaches have in common that they collect environ-

mental data, extract key features and derive informa-

tion which will influence robot navigation.

For wall-climbing robots safety is a main require-

ment. The problem of terrain analysis is manageable

if the climbing system uses legs with independent ad-

hesion units which can test the grip at each foot point

(Luk et al., 2001). Other robots use adhesion systems

like magnets (Shang et al., 2008) which are safe by

default. But for wheeled driving on concrete walls

via negative pressure adhesion a prediction of risks is

essential. Here, the robot is permanently exposed to a

drop-off if it is in motion. Unfortunately, not only the

foresighted detection of hazardous features is nearly

impossible due to missing sensor accuracy and/or lim-

ited payload. Also the impact of features like surface

roughness, sheathing defects, porous areas or micro

channels on the adhesion system can not be described

sufficiently (in contrast to macro features).

This paper presents a risk prediction method and

suitable measures to avoid them. Upcoming section 2

will introduce some fundamentals. Section 3 presents

the procedure of risk prediction, section 4 shows how

the needed parameters are determined via training.

The experimental results and safety measures are pre-

sented in section 5, conclusions follow in section 6.

2 FUNDAMENTALS

The research presented in this paper is aimed at the

climbing robot CROMSCI (Schmidt et al., 2011) but

works for similar systems, too. CROMSCI is designed

to be used for inspections of large concrete buildings

as depicted in figure 1. Requirements for this task

are a relatively high velocity even in vertical direc-

tion or overhead for a sufficient fast navigation be-

tween inspection points and the ability of carrying a

high payload in terms of inspection sensors. The most

innovative feature of CROMSCI is the negative pres-

sure system consisting of seven individual adhesion

chamberswhich allowa balancing of downforces. For

high maneuverability and fast continuous motion it is

118

Schmidt D. and Berns K..

Risk Prediction of a Behavior-based Adhesion Control Network for Online Safety Analysis of Wall-climbing Robots.

DOI: 10.5220/0003974701180123

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 118-123

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

security

rope

vacuum

reservoir

wheel

domes

umbilical

cord

Figure 1: Climbing robot

CROMSCI at a concrete wall.

equipped with three unsprung steerable driven stan-

dard wheels. A load cell is integrated into each wheel

to measure forces and torques at the wheel’s contact

point. CROMSCI can be equipped with a movable ma-

nipulator arm to carry inspection sensors. For com-

munication and energy supply it is connected to a

ground station via an umbilical cord. Some key data

of the robot are a maximum velocity of 9.81 m/min,

80 cm diameter, a weight of 45 kg and an additional

payload of about 10kg.

The control software of CROMSCI makes use of

the behavior-based control architecture iB2C (Proet-

zsch et al., 2010) on all abstraction levels reaching

from closed-loop control up to high deliberative func-

tions. In general an iB2C behavior is an algorithmic

element which generates control data based on its in-

puts. All behaviors share a common meta data inter-

face for interaction. Two of these data ports deliver

information about the current state of the behavior

and are important in this context: activity ~a ∈ [0,1]

w

shows the real amountof action the behavior performs

whereas the target rating r ∈ [0,1] represents its sat-

isfaction with the current situation.

The adhesion control system itself consists of a

network of 47 of these behavior elements as published

in (Schmidt and Berns, 2011). The lower part of the

network consists of the chamber controllers which

perform the closed-loop pressure control. Their meta

values are presented exemplarily in equations 1 and 2.

The behavior’s activity a

CC

depends on the actual

valve area A

act

and its maximum A

max

(the larger the

valve opening the more active). The target rating r

CC

uses the control difference of desired p

des

and actual

chamber pressure p

act

compared to a maximum dif-

ference ∆p

max

and therefore is unhappy if the desired

pressure value can not be reached or if it is not acti-

vated (ι

CC

is an internal activation value).

a

CC

= ι

CC

·

A

act

A

max

(1)

r

CC

=

max

0,

min

1,

|p

act

− p

des

|

∆p

max

+ (1− ι

CC

)

(2)

In an outer control loop the downforce is adjusted.

The meta values of all behaviors are calculated in a

similar way as for the chamber controllers. Additional

behaviors analyze the robot state or inhibit chamber

controllers in cases of high leakages to prevent the

complete adhesion system from fail. Nevertheless,

the optimal downforce is not easy to determine be-

cause the robot neither should fall down nor get stuck.

Even if it is in the ideal range at about 2000N there

still exists the chance of the robot to slip or tilt which

could result in a drop off. Some additional measures

like a traction control system have already been devel-

oped to reduce these effects but can not prevent them

completely (Schmidt et al., 2011).

3 RISK PREDICTION

The basic control measures work in general, but are

not able to prevent the robot from a drop-off in cer-

tain situations. Although the robot is equipped with

a light-weighted Hokuyo laser ranger for obstacle

avoidance, these external sensor data have a relatively

low accuracy compared to the micro-features which

need to be detected for a foresighted evaluation of

the terrain. Therefore, internal sensors like the pres-

sure sensors have to be taken into account here. This

approach is possible because of the redundant multi-

ple chamber system which allows the failure of some

chambers for a short period of time without endan-

gering the system. In practice the front chambers in

driving direction are exposed to hazardous features

first which allows a judgement of the upcoming ter-

rain characteristics. First experiments have proven

that pressure values itself are not sufficient for risk

prediction. The idea is to evalute activity and target

rating values of the adhesion behaviors instead. Espe-

cially the different target ratings provide information

about the system state because they represent individ-

ual satisfaction values of controllers.

The intention is now to receive a risk value of

an evaluation function E(~a,~r) which is one or above

if the robot will drop off within the next seconds

(if no evasive action is performed). Of course, this

risk value should indicate a potential drop off early

enough to allow evasion actions. On the other hand it

must stay below one if the robot adhesion is not en-

dangered to avoid false positives.

E(~a,~r) =

n−1

∑

i=0

w

a

i

·a

i

+ w

sa

i

·s(a

i

)+ w

r

i

·r

i

+ w

sr

i

·s(r

i

)

(3)

The current approach uses a weighted sum (equa-

tion 3) E(~a,~r) : [0, 1]

4n

7→ R as evaluation function

RiskPredictionofaBehavior-basedAdhesionControlNetworkforOnlineSafetyAnalysisofWall-climbingRobots

119

based on the meta data of the n behaviors. At this

juncture activity and target rating values a

i

respective

r

i

of behavior i are used in combination with corre-

sponding weights w

a

i

and w

r

i

. In addition also low-

pass filtered meta values s(a

i

) and s(r

i

) with s(x) =

0.3·x+0.7·s

′

(x) and corresponding weights are taken

into account which reduces peaks in the evaluation

function. It is also possible to calculate and use other

values like average, median or variance in the same

way. Recent experiments have shown that these ad-

ditional values may allow a better prediction, but this

enhancement comes with two restrictions: At first one

needs to determine a lot of more weights, at second

there is a higher specialization to certain situations

and parameters like vehicle velocity. The main prob-

lem is now to determine the optimal weights ~w ∈ R

4n

.

It is obvious that this large number of possibilities can

not be set by hand. The next problem is that a forecast

of an adhesion failure is only possible if one knows in

which situations the system will fail.

Therefore, a learning method with training data

needs to be applied to find suitable weights. At first

one needs a measure if the robot fails in a situation

or not and determine important characteristics. The

identification of a drop off is done by an adhesion

score function S

A

(F

z

,x

F

,y

F

) : R

3

7→ [0, 1] which uses

two different indicators as given in equation 4:

S

A

(F

z

,x

F

,y

F

) =

max

S

A

F

(F

z

),S

A

P

(x

F

,y

F

)

(4)

The first indicator is the current downforce value

F

z

(equation 5) measured by the embedded load cells.

If F

z

is below threshold F

min

z

the robot falls down:

S

A

F

(F

z

) = 1−

max

0,

min

1,

F

z

− F

min

z

F

max

z

− F

min

z

(5)

The second measurement unit is the point of

downforce which describes the chance of robot tilt

(equation 6). If the distance of the downforce point

with coordinates x

F

and y

F

from the robot center is

too large (above a threshold d

max

) the robot drops off.

The used threshold values depend on system parame-

ters like weight, wheel distance or friction coefficient.

S

A

P

(x

F

,y

F

) =

max

0,

min

1,

q

x

2

F

+ y

2

F

d

max

(6)

Independent from the type of learning algorithm

one needs some experimental training data. To get

this data, the robot has to be faced with situations in

which the adhesion system reaches its limits and the

robot falls off (S

A

= 1) as well as situations which

are harmless or still manageable by the system (S

A

<

1). Each training set is a double array consisting of

a time value t ∈ {0,m − 1}, all meta data from the

considered behaviors and the adhesion score

1

S

A

(t)

at that timestep. Of course, the size m of the tables

varies from one dataset to another whereas the setup

of behaviors has to be fix.

In literature different learning and optimization

methods exist which can be used in general. There-

fore one needs to find a suitable approach to extract

the needed weight values out of the training data. Ar-

tifical neural networks e. g. are a classic method for

pattern recognition but will not fit in here because

of missing input-output samples. Another approach

is reinforcement learning which tries to optimize a

problem via trial-and-error. Nevertheless it is more

linked to a mapping from situations to actions than

for the given problem. Simulated annealing might be

an appropriate approach, but it does not seems to be a

good idea to follow and optimize only one solution in

the present case. Therefore, the principle of genetic

algorithms is applied to determine the best weights

(Gerdes et al., 2004). The idea is to update the evalu-

ation weights randomly until the desired performance

is achieved.

4 GENETIC ALGORITHM

As usual one needs a population P(s) of individu-

als at step s. Each individual has a chromosome c

with genes which can mutate randomly in a prede-

fined way to optimize the desired function. In this

case one individual consists of a vector of weights

~w = (w

a,0

,w

r,0

,w

sa,0

,...w

sr,n−1

) ∈ [−1, 1]

4n

which is

used for the weighted sum of n behaviors as shown

before. At the beginning of the process a set of indi-

viduals is created with random genes. In each opti-

mization step as illustrated in figure 2 the fitness F(c)

of all individuals is calculated which describes the

chance of an individual to survive. The next gener-

ation P

′

(s) is created by a selection of original indi-

viduals which are updated with certain probabilities

via genetic operations as described in section 4.2.

4.1 Evaluation of Individuals

Of course, the principle of behavior evaluation is not

limited to the given problem. However, the fitness

function is the most difficult part since it describes

the optimization problem and has to be set properly

to achieve the desired results. In this case an indi-

vidual is good if the evaluation function E (with the

1

From now on the results of functions will be shortened

like S

A

(t) = S

A

(F

z

(t), x

F

(t), y

F

(t)) for clarity.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

120

Figure 2: One evolution step with current population, selec-

tion, mutation of survivors and the next generation.

weights) is a good prediction of the adhesion score S

A

in equation 4. As measuring unit, a rating function R

E

is used which compares the evaluation result of an in-

dividual with the adhesion score. At first, the weights

are used to calculate the evaluation value according

to equation 3 for each timestep t of one training set.

One receives a list of evaluation values E(t) over time

which have to be compared to the corresponding ad-

hesion score S

A

(t). The rating of weight evaluation

R

E

is done according to equation 7 and calculated for

each combination of individual and training set.

R

E

= −

m−1

∑

t=0

P

E∆

(t) −

k

∑

t=0

P

unw

E

(t) − M

unw

E

(7)

−

k+∆t

∑

t=k+1

P

des

E

1

(t) −

m−1

∑

t=k+∆t+1

P

des

E

2

(t) − M

des

E

This rating considers three aspects: At first, the

evaluation function E(t) should stay below the adhe-

sion rating S

A

(t), otherwise the rating value is dimin-

ished by a penalty P

E∆

according to equation 8. The

used functions and constants have been determined

carefully for an optimal and balanced rating function.

P

E∆

(t) =

((E(t) − S

A

(t)) · E(t))

3

, if E(t)>S

A

(t)

0 , else

(8)

The second aspect is the avoidance of unwanted

values which produce false alarms. This is split up

into a penalty based on the differences of evaluation

and adhesion rating P

unw

E

according to equation 9 and

a basic mallus M

unw

E

if at least one undesired value

exists (equation 10). S

haz

A

denotes a threshold for a

hazard which is set to 0.9, 10

10

and 10

9

are constants.

P

unw

E

(t) =

(E(t) − S

haz

A

) ·

max

E(t),S

A

(t)

3

·10

10

, if E(t)>S

haz

A

0 , else

(9)

M

unw

E

=

10

9

, if S

A

(t)<S

haz

A

∀t∈[0,k]∧∃E(t)≥S

haz

A

, t∈[0,k]

0 , else

(10)

The value k depends on the type of training set:

If the adhesion rating stayed below S

haz

A

the complete

dataset is processed here (equation 11), otherwise it

considers only the timespan to the timestep t

haz

at

which the adhesion rating reached a hazardous value

minus the double time ∆t. This describes the desired

timespan of the reaction time with ∆t ≤ t

react

≤ 2· ∆t.

k =

m− 1 , if S

A

(t)<S

haz

A

∀t∈[0,m−1]

t

haz

− 2· ∆t , else

(11)

In the same way a mallus and a penalty for miss-

ing desired values are applied, if the adhesion rating

S

A

of this data set is above the threshold at least once

(so that k < m− 1). The evaluation E(t) has to reach

1 within the range [k + 1, k + ∆t] for prediction, oth-

erwise mallus M

des

E

1

(equation 14) is added as well as

penalty P

des

E

1

in equation 12. Penalty P

des

E

2

from equa-

tion 13 tries to push the evaluation function above 1

over the remaining time steps until m− 1.

P

des

E

1

(t) =

(1− E(t))

3

· 10

10

, if E(t)<1∧E(t)<1∀t∈[k+1,k+∆t]

0 , else

(12)

P

des

E

2

(t) =

(1− E(t))

3

· 10

6

, if E(t)<1

0 , else

(13)

M

des

E

=

10

9

, if E(t)<1∀t∈[k+1,k+∆t]

0 , else

(14)

If p training sets are used the mean-square average

of the ratings is determined (equation 15):

R = −

v

u

u

t

1

p

·

p−1

∑

i=0

R

2

E

i

(15)

4.2 Fitness, Selection & Mutation

Based on the final rating value R the fitness F(c) of an

individual can be determined. Equation 16 shows this

calculation based on minimum and maximum values

for the rating value R

min

and R

max

(which can either

RiskPredictionofaBehavior-basedAdhesionControlNetworkforOnlineSafetyAnalysisofWall-climbingRobots

121

be set fix or dynamic based on lowest and highest ac-

tual rating values) and on a basic fitness F

bas

for all

|P| individuals of that population. The chance p(c)

of an individual c to survive depends on the ratio of

individual to population fitness (equation 16, right).

F(c) =

R(c)−R

min

R

max

−R

min

+

F

bas

|P|

1+

F

bas

|P|

, p(c) =

F(c)

∑

i∈P

F(i)

(16)

Since the exploration of the search space is most

important, crossover operations are not considered

here: “If optimality is sought, crossover may be dele-

terious” (Spears, 1993, page 231). In fact three dif-

ferent mutation types are used for adaption: A weight

can be updated with a small random offset. The used

probability p

off

m

is 0.75 that one weight of an indi-

vidual is adapted. Furthermore, an update with a

new random weight with probability p

rand

m

= 0.5 is

possible. Additionally all weights of an individual

can be changed with a random multiplication factor

f ∈ [0.9, 1.1]. The probability p

mul

m

that one individ-

ual is updated inside of the population is 0.1.

Since the values can skitter away it is useful to

keep the best individual inside of the population. On

the other side the population should get the chance

to expand in all directions. Therefore, this approach

additionally uses a kind of elitism function in a way

that there exists a certain chance that the best individ-

ual (that has been found in the past) will be injected

into the population again. Additionally, this chance

decreases over time if no better individual could be

generated to enlarge the evolution space and to reduce

the effect of local minima. The breakpoint R

bp

of the

learning procedure is reached if no rating R

E

i

of the

best individual gained a mallus M

unw

E

or M

des

E

. So far,

the algorithm is stopped manually.

5 RESULTS AND MEASURES

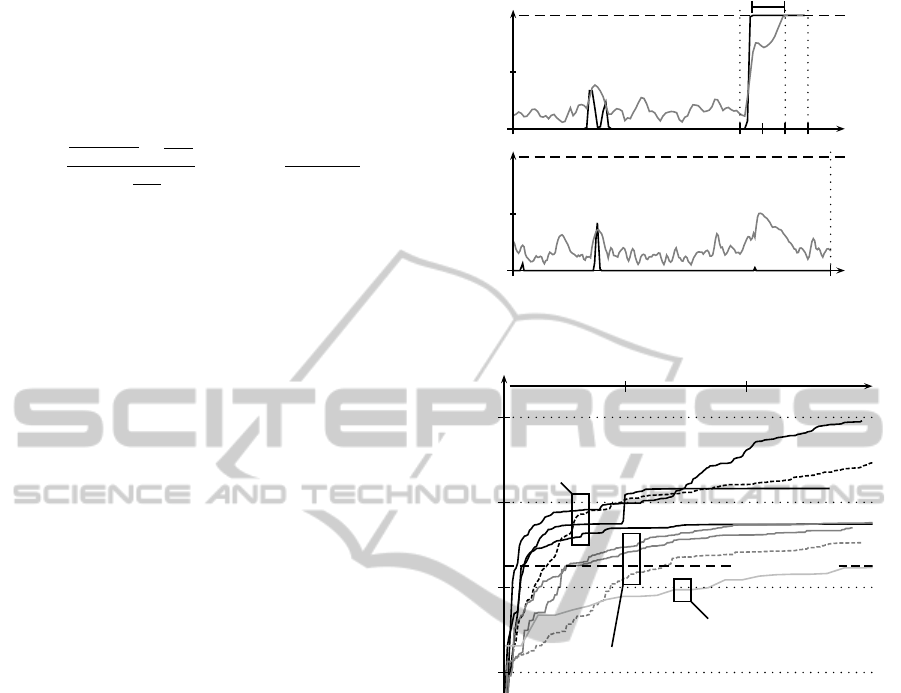

Some exemplary results are given in figure 3. Here

the adhesion scores S

A

(gray) of two different data

sets and final evaluation values E (black) which are

limited to [0, 1] are shown. In the given experiment

10 training sets have been used to determine a set of

90 weights of 45 considered behavior values. In all

cases the robot was driven down a wall but at differ-

ent positions reaching from even and rough surfaces

to patches with deep grooves. The learning algorithm

using 100 individuals was able to train weights which

guarantee a certain reaction time t

react

and avoid false-

positives in the training sets. Figure 4 shows the in-

creasing evaluation values over time which are bet-

ter in cases of small populations (|P| = 100, black)

0.0

1.0

S

A

(t)

E(t)

t

react

t

k

∆t

∆t

t

haz

m-1

0.0

1.0

S

A

(t)

E(t)

t

k

Figure 3: Example for desired results after 1900 evolution

steps (approx. 1330s): If S

A

(t) reaches one E(t) should sig-

nal this beforehand (top).

-10

5

-10

7

R

bp

= −3.16 · 10

8

-10

9

-10

11

R

500 1000

t in [s]

|P | = 100

|P | = 1000

|P | = 10000

Figure 4: Enhancements of the rating value R of the best

individual over time with different population sizes |P|.

performing a faster evolution step compared to larger

populations. The dashed lines indicate experiments

without random multiplication (p

mul

m

= 0.0) with a

slower convergence at the beginning.

To evaluate the learning results the robot again

performs similar trajectories on the structured sur-

face with defects and cracks. Figure 5 shows reaction

times t

react

between detection (E(t) = 1) and drop off

(S

A

(t) = 1) while the robot tries to handle the deep

cracks. Again, evaluation E should signal a drop off

early enough to have enough time for counteractive

measures. The black bars indicate a more uniform

crack in contrast to a complex crack structure (gray

bars). In total, 31 test runs on a cracked structure

have been executed with only one false-negative, two

with a too short reaction time below 0.5s and five

runs with a reaction time larger than 3 s. Further ex-

periments have shown, that the behavioral situation

is completely different if the robot drives upwards so

another set of weights has to be trained for this case.

Beside the correct detection also the avoidance of

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

122

fn

0.5 1.0 1.5 2.0 2.5 3.0

4

2

#

t

react

∆t

2∆t

Figure 5: Reaction time t

react

in [s] and one false-negative

(fn) of examples while facing different cracks.

1.0

0.5

0.0

0.0 0.25

0.5 0.75 S

haz

A

1.0

E

max

S

max

A

◦•

fp

◦

◦

◦

◦

◦

◦

◦

◦

◦

◦

⋆

Figure 6: Maximum evaluation and rating values on differ-

ent rough terrains, ⋆ marks tolerated false-positives (fp).

false-positives is important. Therefore, the reaction

on rough terrain with defects has been tested which

do not lead necessarily to a drop-off. Figure 6 shows

12 test runs with only one false-positive (black circle)

and two detections (E

max

= 1, marked with ⋆) which

are tolerated because of S

max

A

> S

haz

A

. In practice, the

evaluation system has to be trained once and can be

applied to similar situations and setups.

Each detection of safety-critical situations is use-

less without counteractive measures. So far, a re-

versed replay of the robot trajectory is implemented.

The responsible behavior has been embedded into the

control system and is stimulated, if the evaluation

function E reaches a value of 1. In this case, the cur-

rent driving operation is cancelled and the last com-

mands are countervailed. The idea is that the way was

not dangerous so far so the robot should driveback the

same trajectory until a safe position has been reached

and the adhesion system can recover.

6 CONCLUSIONS

This paper presented a risk prediction approach for

wall-climbing robots. Based on training data a ge-

netic algorithm is used to find suitable weights for a

general evaluation function which is used here to pre-

dict an upcoming drop-off. Experiments have proven

the functionality of the approach and the benefit for

robot safety. The next step is to adapt the prediction

system to be able to handle different situations (e.g.

driving up or down) which need to use differing sets

of weights since one-fit-all-weights do not exist.

REFERENCES

Castelnove, M., Arkin, R., and Collins, T. R. (2005). Re-

active speed control system based on terrain rough-

ness detection. In IEEE International Conference on

Robotics and Automation, volume 1, pages 891–896.

Gerdes, I., Klawonn, F., and Kruse, R. (2004). Evolution¨are

Algorithmen. Vieweg Verlag, Germany, 1. edition.

Kelly, A. and Stentz, A. (1998). Rough terrain autonomous

mobility - Part 1: A theoretical analysis of require-

ments. Autonomous Robots, 5(2):129–161.

Kim, D., Sun, J., Oh, S. M., Rehg, J. M., and Bobick, A. F.

(2006). Traversability classification using unsuper-

vised on-line visual learning for outdoor robot navi-

gation. In IEEE International Conference on Robotics

and Automation (ICRA) 2006, pages 518–525.

Luk, B. L., Cooke, D. S., and others (2001). Intelligent

Legged Climbing Service Robot For Remote Inspec-

tion And Maintenance In Hazardous Environments. In

8th Conference on Mechatronics and Machine Vision

in Practice, pages 252–256.

Proetzsch, M., Luksch, T., and Berns, K. (2010). Develop-

ment of complex robotic systems using the behavior-

based control architecture iB2C. Robotics and Au-

tonomous Systems, 58(1):46–67.

Schmidt, D. and Berns, K. (2011). Behavior-based adhesion

control system for safe adherence of wall-climbing

robots. In 14th International Conference on Climb-

ing and Walking Robots (CLAWAR), pages 857–864.

Schmidt, D., Hillenbrand, C., and Berns, K. (2011). Om-

nidirectional locomotion and traction control of the

wheel-driven, wall-climbing robot, Cromsci. Robot-

ica Journal, 29(7):991–1003.

Shang, J., Bridge, B., Sattar, T., Mondal, S., and Brenner,

A. (2008). Development of a climbing robot for in-

spection of long weld lines. Industrial Robot: An In-

ternational Journal, 35(3):217–223.

Spears, W. M. (1993). Crossover or mutation. In Foun-

dations of Genetic Algorithms, volume 2, pages 221–

237.

Stavens, D. and Thrun, S. (2006). A self-supervised terrain

roughness estimator for off-road autonomous driving.

In Conference on Uncertainty in Artificial Intelligence

(UAI), pages 469–476.

RiskPredictionofaBehavior-basedAdhesionControlNetworkforOnlineSafetyAnalysisofWall-climbingRobots

123