Supplier Selection based on Process Yield for LED Manufacturing

Processes

Y. T. Tai

1

and Chien-Wei Wu

2

1

Department of Information Management, Kainan University, Taoyuan, Taiwan, R.O.C.

2

Department of Industrial Management, National Taiwan University of Science and Technology, Taipei, Taiwan, R.O.C.

Keywords: Supplier Selection, Yield, Multiple Characteristics, LED.

Abstract: In today’s fierce competitive business environment, it is very essential to work with right suppliers in the

supply chain systems. Consequently, supplier selection problem is very important and has received

considerable attention. In the supplier selection problem, quality is the most popular criterion. In the paper,

we consider a supplier selection problem of comparing two suppliers and selecting the one that has a

significantly higher process capability for the light emitting diode (LED) assembly process with multiple

characteristics. Testing hypotheses for the LED assembly supplier selection are presented. For practitioners’

convenience, the corresponding critical values for the supplier selection in LED assembly process are

tabulated. For illustration purpose, an application is presented.

1 INTRODUCTION

In today’s fierce competitive business environment,

to provide high-quality products, it is very essential

to work with right suppliers in the supply chain

systems. Consequently, the success of a supplier

chain is highly dependent on selection of good

suppliers (Ng, 2008). In the last decades, the

supplier selection problems have been investigated

extensively. Various decision making approaches

have been proposed to tackle the problem. The first

investigation for the supplier selection problem is

presented by Dickson (1966). He identified over

twenty supplier attributes and ranked their

importance, such as quality, net price, and service.

In addition, Degraeve et al., (2000), De Boer et al.,

(2001) reviewed the literature up to 2000. Recently,

Aissaoui et al., (2007) provided a literature review

that covers the entire purchasing process involving

parts and services outsourcing activities. Ho et al.,

(2010) reviewed the papers from 2000 to 2008 and

provided some recommendations for related future

work among various supplier selection methods.

From the extensive investigations on the supplier

selection problem, Ho et al., (2010) summarized

popular criteria including quality, delivery,

price/cost, manufacturing capability, service,

management, technology, research and development,

finance, flexibility, reputation, relationship, risk, and

safety and environment. It should be noted that

quality is the most popular one for the supplier

selection problem in the investigation of Ho et al.

(2010). In most of high-tech manufacturing

industries, process yield has been the most basic and

common quality criterion for measuring process

performance. Process yield is defined as the

percentage of processed product unit passing

inspection. That is, the process characteristic must

fall within the manufacturing tolerance. Due to

fierce competition on consumption products, the

high-tech manufacturing processes require very low

fraction of defectives in parts per million (ppm).

Consequently, it can be found in the literature

reviewed by Ho et al., (2010), the criterion of

acceptable parts per million is a critical quality

related attribute. However, if we make decision only

based on the values of acceptable parts per million

provided by individual supplier, the unreliable

supplier selection decision may be made.

In this paper, we investigate a case of supplier

selection problem regarding a material part of light

emitting diode (LED) assembly that is the critical

devices in smart phones. It should be noted that the

manufacturing process of LED assembly require

very low fraction of defectives in parts per million

(ppm). Consequently, process capability indices

(PCIs) methods are effective to evaluate the non-

conformation of the units produced from a

594

Tai Y. and Wu C..

Supplier Selection based on Process Yield for LED Manufacturing Processes.

DOI: 10.5220/0003987705940598

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (OMDM-2012), pages 594-598

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

manufacturing process and to obtain the

corresponding process yield.

In this paper, we presented an exact process

capability index with multiple characteristics for the

supplier selection problem in a LED case. The

testing hypotheses for the light emitting diode

assembly supplier selection are presented. For

practitioners’ convenience, the corresponding

critical values for the supplier selection in LED

assembly process are also computed and tabulated.

The supplier selection method which is applied in

the LED assembly process is practical and useful for

practitioners and factory in-plant applications.

2 LIGHT EMITTING DIODE

ASSEMBLY PROCESS

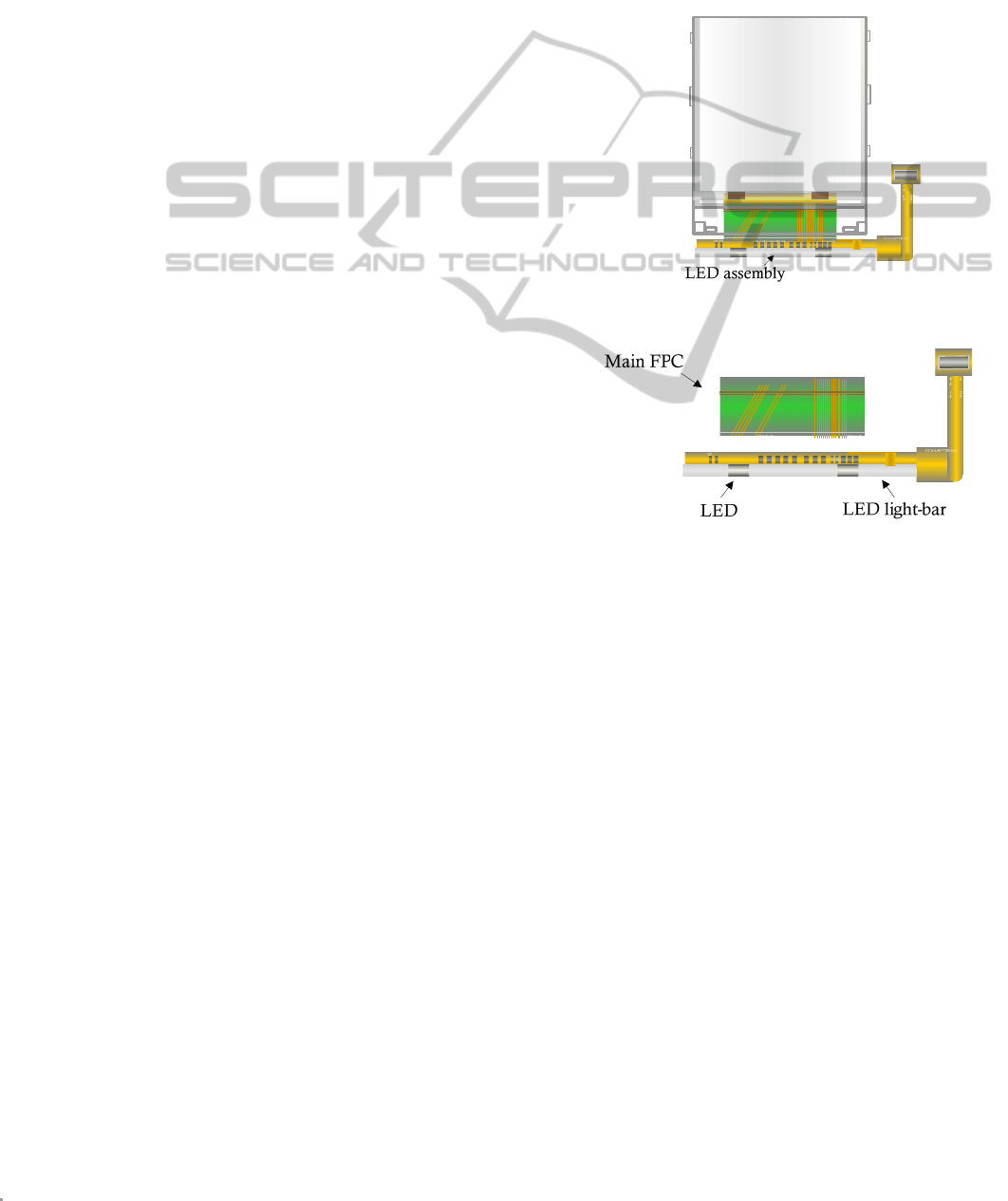

In this case, we provide an effective test to check

whether the new supplier can provide better process

yield than the existing supplier. It should be noted

that LED backlight modules involve many attracting

characteristics such as power-saving, wide color

gamut, high dimming ratio, long lifetime, and high

brightness. They have been widely applied in

portable devices and computer monitors. A LED

backlight module is a critical light source for liquid

crystal display (LCD) panels since LCD panels

cannot luminesce themselves. When the smart phone

manufacturers select their suppliers for the LED

assembly on the LED backlight module (see Figure

1), those popular criteria summarized by Ho et al.

(2010) are considered. However, quality is a very

important consideration in the real selection

processes. It should be noted that the industrial

practitioners commonly use C

pk

to assess the process

capability. The index C

pk

only provides an

approximate rather than an exact measure of the

process yield. In addition, C

pk

is restricted to

processes with single characteristic. However, in

LED assembly process, some critical quality

characteristics are considered simultaneously since

these quality characteristics may affect the yield of

the finished goods. Thus, in the paper, to access

exact process yield measure in supplier selection

process, we consider the application of statistical

selection processes based on the process capability

index with multiple characteristics.

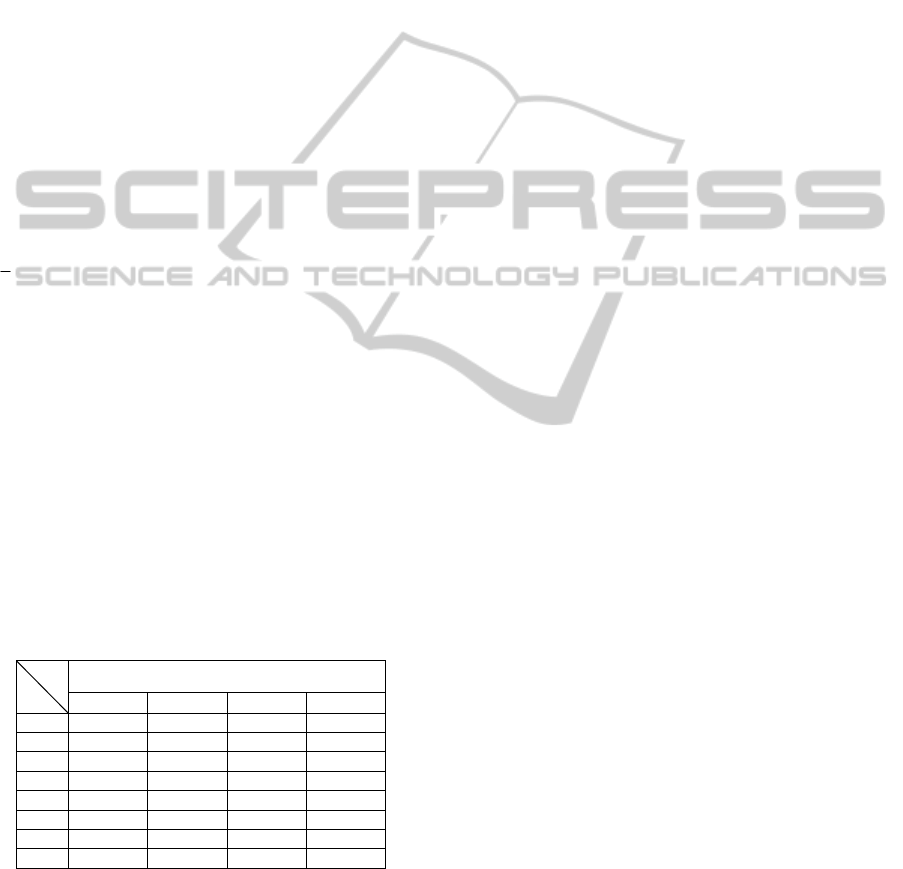

In the LED assembly process, LEDs are bonded

on the FPC (flexible printed circuit) and are referred

to as LEDs light-bar (see Figure 2). It is noted that

there are multiple characteristics are very critical and

should be considered when we evaluate and select

the suppliers. One of the essential characteristics is

the distances between two neighboring LEDs, since

the distance may cause different maximum

uniformities. However, the optical performance

issue is very important. In addition, the LED

assembly is extremely thin and need to connect with

other components. The characteristic of the length of

LED assembly is also critical since it may cause the

situation of unexpected shut-down. Consequently,

the length of the LED assembly should not fall

outside the specification intervals.

Figure 1: LED assembly on a backlight module.

Figure 2: LED light-bar in a LED assembly.

3 SUPPLIER SELECTION BASED

ON PROCESS CAPABILITY

INDEX APPROACH

The most commonly used process capability indices,

C

p

and C

pk

are discussed in Kane (1986). More-

advanced indices C

pm

and C

pmk

are developed by

Chan, Cheng and Spiring (1988) and Pearn, Kotz

and Johnson (1992). Many authors have promoted

the use of various PCIs for evaluating a supplier’s

process capability. Based on analyzing the PCIs, a

production department can trace and improve a poor

process so that the quality level can be enhanced and

the requirements of the customers can be satisfied.

However, the index C

pk

can only provide an

approximation rather than an exact measure on the

SupplierSelectionbasedonProcessYieldforLEDManufacturingProcesses

595

process yield. To obtain an exact measure, Bolyes

(1994) considered a yield index, referred to as S

pk

for normally distributed processes. The index S

pk

is

defined as:

1

11 1

32 2

pk

USL LSL

S

μμ

σσ

−

⎧− −⎫

⎛⎞⎛⎞

=Φ Φ +Φ

⎨⎬

⎜⎟⎜⎟

⎝⎠⎝⎠

⎩⎭

,

where

USL and LSL are the upper and the lower

specification limits, respectively,

μ

is the process

mean, and

σ

is the process standard deviation.

To make more reliable supplier selection

decision, some existing research works have been

presented to perform the effective test. Pearn et al.,

(2004) presented a supplier selection procedure

based on the index C

pm

which can tackle a process

with single characteristic. Wu et al., (2008) applied

the bootstrap method and recommended a procedure

for assessing capability index C

pk

to solve supplier

selection problems. Pearn et al., (2011) provided an

effective powerful test for one-sided supplier

selection problem. Lin and Pearn (2010) considered

the process selection problem by using the yield

index S

pk

to compare two production processes and

select one that has higher process yield. However,

factory practitioners usually consider a process with

multiple characteristics for supplier selection

decisions, particularly, in the LED assembly process.

In this paper, we consider the exact yield index

T

p

k

S and apply the proposed supplier selection

method with multiple characteristics for the light

emitting diode assembly process to help the

participators to make more reliable decisions for

supplier selections.

3.1 Supplier Selection Bases on

T

pk

S

To obtain accurate yield assessment for processes

with multiple characteristics, multiple characteristics

should be considered simultaneously for the LED

assembly processes. In the paper, we apply the

process capability index

T

p

k

S which was proposed by

Chen et al., (2003) and can be defined as follows.

1

1

11

(2 (3 ) 1) 1 ,

32

v

T

pk pki

i

SS

−

=

⎧⎫

⎡⎤

=Φ Φ −+

⎨⎬

⎢⎥

⎣⎦

⎩⎭

∏

where

p

ki

S denotes the

p

k

S value of the ith

characteristic for i= 1, 2, . . . , v, and v is the number

of characteristics. The index can be viewed as a

generalization of the single characteristic yield

index,

p

k

S

.

Since the index

T

p

k

S

provides an exact measure

on the process yield of multinormal processes in

which the characteristics are mutually independent

(Pearn and Cheng, 2010). Pearn and Cheng (2010)

displayed various commonly used capability

requirements and the corresponding production as

well as non-conformities in ppm in Table 1.

Table 1: Various commonly used capability requirements

and the corresponding production as well as non-

conformities in ppm.

T

p

k

S

Yield NCPPM

1.00 0.997300204 2699.796

1.20 0.999681783 318.217

1.40 0.999973309 26.691

1.60 0.999998413 1.587

1.80 0.999999933 0.067

2.00 0.999999998 0.002

3.2 Statistical Test for Supplier

Selection

In this paper, we apply a powerful approach for

supplier selection. Suppose that the process yield

requirement by

T

p

k

S for given processes is C, and the

current supplier has reach the yield requirement. In

real applications, the supplier replacement is time

consuming and costly since the validation of a new

process is complicated. Consequently, when we find

a new supplier to compete with the current supplier,

we can consider the following hypothesis testing to

test whether the new supplier can provide

convincing information to claim that its process

yield is higher than the current supplier. The

considered hypothesis testing for comparing the two

T

p

k

S values: H

0

:

1

T

p

k

S ≥

2

T

p

k

S versus H

1

:

1

T

p

k

S <

2

T

p

k

S

(or equivalently, H

0

:

2

T

pk

S −

1

T

p

k

S ≤ 0 versus H

1

:

2

T

pk

S

−

1

T

p

k

S >0). The test statistic W can be

expressed as

2

ˆ

T

pk

S

−

1

ˆ

T

p

k

S .

4 A LED APPLICATION

To demonstrate the applicability of the supplier

selection method, we consider a case for light

emitting diode assembly process. In the case, two

essential quality characteristics are considered

simultaneously. As described in Section 2, the

distances between two neighboring LEDs and the

length of LED assembly are the two critical quality

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

596

characteristics for supplier selection. In the case, the

LED assembly products require a minimal

capability. The minimal requirement of the LED

assembly characteristic is

T

p

k

S = 1.20.

For the product type we investigated, the upper

and lower specification limits of the distance

between LEDs are set to 12.2 and 15.4 millimeter. In

addition, the upper and lower specification limits of

the length of LED assembly are set to 19.5 and 21.5

millimeter. The millimeter is used as the unit for the

two specifications.

To determine whether the new Supplier (Supplier

II) provides a better process capability of the LED

assembly products than current Supplier (Supplier I),

we perform the hypothesis testing:

02 1

:

TT

p

kpk

H

SS≤

versus

12 1

:

TT

p

kpk

H

SS> . We collected two data sets

from suppliers I and II with

1

n =

2

n =100. Based on

the observations, we compute the sample estimate

ˆ

T

p

k

S of

T

p

k

S

for both suppliers. The sample average

(

j

x

), sample standard deviation (

j

s

) and

ˆ

p

kj

S for

each characteristic are also calculated. Thus, we can

obtain that

1

ˆ

T

p

k

S = 1.104 and

2

ˆ

T

p

k

S =1.415.

We calculated the test statistic W =

2

ˆ

T

pk

S

−

1

ˆ

T

p

k

S =

0.311 for the proposed supplier selection method. In

the paper, we used a commercial computation

software to compute the critical value (see Table 2)

that is very useful to help us to make the decision for

the hypothesis testing.

The input parameters of the

program involving the values of

1

T

p

k

S

,

2

T

p

k

S

,

the

corresponding sample sizes n

1

, n

2

, C, and α.

Table 2: Critical values for rejecting

21

TT

p

kpk

SS≤ with

12

nn= =30(10)100 and

α

=0.05.

n

12

TT

pk pk

SSC

=

=

1.0 1.2 1.4 1.6

30 0.3003 0.3604 0.4204 0.4805

40 0.2601 0.3121 0.3641 0.4161

50 0.2326 0.2791 0.3257 0.3722

60 0.2123 0.2548 0.2973 0.3398

70 0.1966 0.2359 0.2752 0.3146

80 0.1839 0.2207 0.2575 0.2942

90 0.1734 0.2081 0.2427 0.2774

100 0.1645 0.1974 0.2303 0.2632

In the case, we use the Pearson-Correlation test

to justify the correlation. The result shows the

relationship among the two characteristics can be

regarded as independent. In addition, we run the

developed program with

1

n =

2

n =100,

12

TT

p

kpk

SS= =1.20, and α= 0.05 to obtain the critical

value as 0.1974 for the presented supplier selection

method (it also can be found in Table 2).

Since the testing statistic W = 0.311 > 0.1974, we

can conclude that the new supplier is superior than

the current supplier with 95% confidence level.

5 CONCLUSIONS

Supplier selection problem in light emitting diode

assembly process is very important and frequently

occurred. Since the multiple characteristics should

be considered in the light emitting diode (LED)

assembly process for supplier selection, in the paper,

we presented and applied a supplier selection

method based on process yield index to provide

exact measures on process yield with multiple

characteristics. For users’ convenience in applying

the supplier selection method in LED assembly

process, the critical values of the hypothesis testing

with various sample sizes are presented and

tabulated. The supplier selection method which is

applied in the LED assembly process is very useful

for factory in-plant applications.

ACKNOWLEDGEMENTS

The authors would like to express their gratitude to

the anonymous referees for their valuable comments

and careful readings, which greatly improved the

presentation of this paper. This paper was supported

in part by the National Science Council, Taiwan,

ROC, under the contracts NSC 100-2410-H-424-011

and NSC 100-2628-E-011-013-MY3.

REFERENCES

Aissaoui, N., Haouari, M., Hassini, E., (2007). Supplier

selection and order lot sizing modeling: A review.

Computers & Operations Research, 34, 3516-3540.

Boyles, R. A., (1994). Process capability with asymmetric

tolerances. Communication in Statistics: Simulation

and Computation, 23(3), 615-643.

Chan, L. K., Cheng, S. W., Spiring, F. A., (1988). A new

measure of process capability Cpm. Journal of Quality

Technology, 20(3), 162-175.

Chen, K. S., Pearn, W. L., Lin, P. C., (2003). Capability

measures for processes with multiple characteristics.

Quality and Reliability Engineering International,

19(2), 101-110.

Degraeve, Z., Labro, E., Roodhooft, F., (2000). An

SupplierSelectionbasedonProcessYieldforLEDManufacturingProcesses

597

evaluation of supplier selection methods from a total

cost of ownership perspective. European Journal of

Operational Research, 125(1), 34-58.

De Boer, L., Labro, E., Morlacchi, P., (2001). A review of

methods supporting supplier selection. European

Journal of Purchasing and Supply Management, 7(2),

75-89.

Dickson, G. W., (1966). An analysis of vendor selection

systems and decisions. Journal of Purchasing, 2, 5-17.

Ho, W., Xu, X., Dey, P. K., (2010). Multi-criteria decision

making approaches for supplier evaluation and

selection: A literature review, European Journal of

Operational Research, 202, 16-24.

Kane, V. E., (1986). Process capability indices. Journal of

Quality Technology, 18(1), 41-52.

Lin, C. J., Pearn, W. L., (2010). Process selection for

higher production yield based on capability index Spk.

Quality and Reliability Engineering International, 26,

247–258.

Ng., W. L., (2008). An efficient and simple model for

multiple criteria supplier selection problem. European

Journal of Operational Research, 186, 1059-1067.

Pearn, W. L., Cheng, Y. C., (2010). Measuring production

yield for processes with multiple characteristics.

International Journal of Production Research, 48(15),

4519-4536.

Pearn, W. L., Kotz, S., Johnson, N. L., (1992).

Distributional and inferential properties of process

capability indices. Journal of Quality Technology,

24(4), 216-233.

Pearn, W. L., Wu, C. W., Lin, H. C., (2004). Procedure for

supplier selection based on Cpm applied to super

twisted nematic liquid crystal display processes.

International Journal of Production Research, 42(13),

2719-2734.

Pearn, W. L., Hung, H. N., Chuang, Y. S., Su, R. H.,

(2011). An effective powerful test for one-sided

supplier selection problem. Journal of Statistical

Computation and Simulation, 81(10), 1313-1331.

Wu, C. W., Shu, M. H., Pearn, W. L., Liu K. H., (2008).

Bootstrap approach for supplier selection based on

production yield. International Journal of Production

Research, 46(18), 5211-5230.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

598