Use of Flow Control on Car Dumpers

A Case of Success at Vale

Bruno Eduardo Lopes and Luis Freitas Coutinho

Vale, Departamento de Inovação e Desenvolvimento, Av. Dos Portugueses, S/N, Itaqui, 65085-580, MA, Brazil

Keywords: Car Dumper, Flow Control.

Abstract: The flow control of the car dumper (VV, in Portuguese) used to be done in open loop, i.e., operators used to

manually adjust the speed of the feeders (AL, in Portuguese) to make the actual flow equal to the desired

flow. The problem was that these manual adjustments were not always performed properly and the result

was a loss in productivity and the occurrence of overflow on the feeders. This work demonstrates the

techniques of control, modelling and identification used for the implementation of flow control in closed

loop in the car dumpers at the Ponta da Madeira Maritime Terminal, Vale.

1 INTRODUCTION

The car dumper (VV) is a structure that turns the

wagon at around 160

o

(max 180

o

) on its horizontal

axis. While turning the wagon is locked in its

position by an anchoring system. During the turn,

the iron ore falls into a system called feeder and is

directed to a conveyor belt leading to the material

storage yard or directly to the ship. The use of car

dumpers brings great agility to the process of

unloading wagons in comparison to other methods

used today.

Vale’s unload area at the TMPM (Maritime

Terminal of Ponta da Madeira) is currently

composed of four car dumpers, with a nominal

production capacity of 8,000 ton/h, being able to

unload two wagons simultaneously.

The car dumper installed at the TMPM has the

following systems which operate in an integrated

manner:

Turner

Car Pusher

Winch of the Car Pusher

2 Hoppers

2 Feeders

Reversible Movable Conveyor Belt

Subsystems (hydraulic units, lubrication units,

hydraulic locks, etc.).

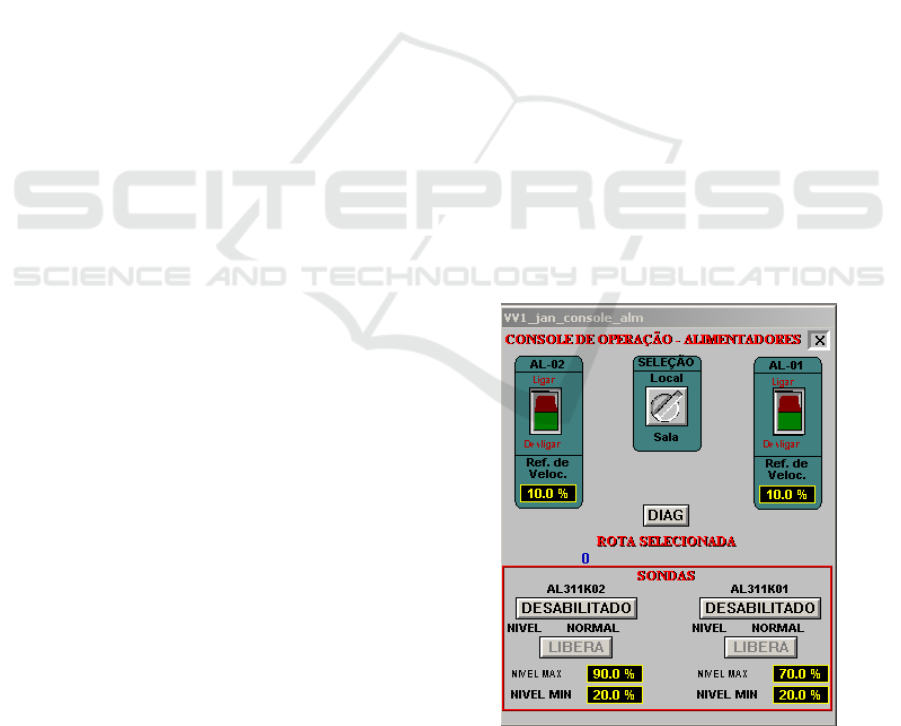

Previously, the flow control of the car dumpers at

TMPM was done in open loop, i.e., to control the

flow the operators had to manually adjust the speed

of the feeder, as shown in Figure 1, until the actual

flow reached the desired value.

Figure 1: Manual adjustment of the feeders speed at

VV01.

However, in order to maintain the levels of the

hoppers under each car dumper close to each other,

the operator had to increase or decrease the

difference in speed between the feeders, and then try

to find a new speed relationship to make the actual

flow equal to the desired setting. The problem was

that these manual adjustments were not always

performed properly, and the end result was a loss in

productivity or the occurrence of overflow at the

580

Eduardo Lopes B. and Freitas Coutinho L..

Use of Flow Control on Car Dumpers - A Case of Success at Vale.

DOI: 10.5220/0003990505800584

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 580-584

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

feeders.

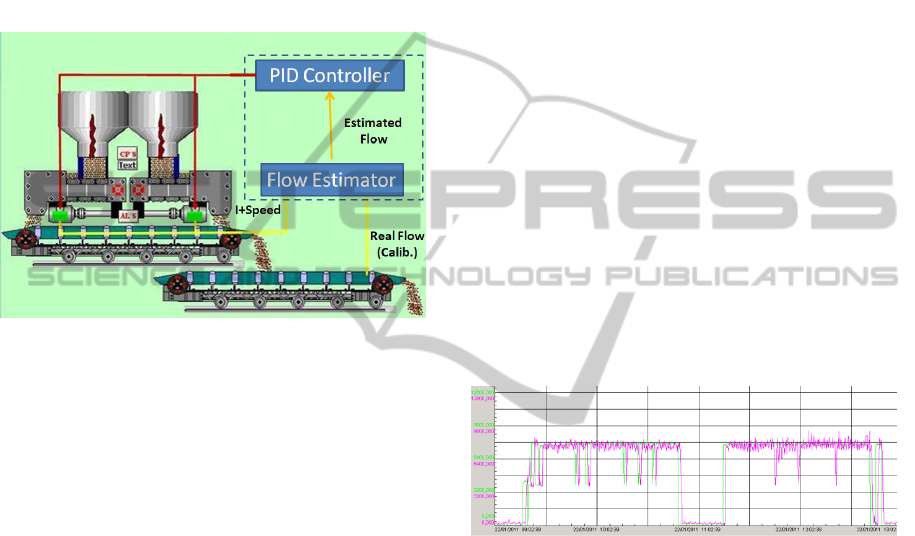

Basically, the flow control implemented in the

car dumpers is a closed loop control, where the

process variable is the estimated flow of the material

at the output of the feeders and the control variables

are the rotational speeds of these feeders. The

estimated flow of material is calculated from the

velocities and currents of the feeders and corrected

with the readings of the existing physical flow scale

at another point in the discharge line. The logic

diagram of the flow control is shown in Figure 2.

Figure 2: Logical diagram of the flow control.

This article demonstrates the theories used to carry

out the implementation of this flow controller and

the results obtained with this implementation.

2 FLOW ESTIMATOR

2.1 Mathematical Modelling

Due to the distance between the car dumper and the

flow scale located at the discharge line, and its

consequent time delay, which would hinder the

implementation of a flow control, it was necessary to

develop a mathematical model that would represent

the flow at the discharge line (estimated flow).

Using the estimated flow as the process variable

(PV) eliminates the effects of the time delay, also

known as dead time (Smith, 1957; Astrom et. Al,

1994; Hagglund, 1992; Astrom et. Al, 1995),

allowing the implementation of the flow control

logic.

For the development of the estimated flow it was

first necessary to perform the data acquisition of the

actual flow (through the flow scale in the discharge

line), current and speed of the feeders. After the

acquisition of the data, a mathematical model

relating the data acquired was created in order to

obtain the estimated flow. In order to

mathematically represent the estimated flow, the

ARX linear model (Aguirre, 2007), was used

together with the Extended Least Squares Method

(Aguirre, 2000) to estimate the parameters. To

determine the order of the model we used the

Method of Analysis of Eigenvalues for linear models

(Lopes et al., 2010).

The mathematical model for the car dumper 01

(VV01), obtained using the least squares estimator is

shown below.

y (t) = (-3.445 * u1 (t)) + (80.31 * v1 (t)) -

(0.5513 * u2 (t)) + (89.11 * v2 (t))

(1)

Where: y= Estimated flow, u1= Current of the

motor powering feeder 01, v1 = speed of the feeder

01, u2 = Current of the motor powering feeder 02

and v2= Speed of the feeder 02.

The model was implemented in a PLC

(Programmable logic controller) controlling the car

dumper VV01 and Figure 3 shows, through actual

data extracted from the PIMS (Process Information

Management System), a comparison between the

estimated flow (Green) and the real flow (Pink). The

analysis of the graphic shows that the estimated flow

is a good representation of the actual flow.

Figure 3: Comparison between estimated and actual flow.

2.2 Reinforcement Learning

To ensure that the estimated flow is corrected over

time, a new technique of reinforcement learning was

implemented. This technique consists of comparing

the results of the estimated flow with the actual flow

to create a correction factor. This correction factor is

then applied to the estimated flow. The

reinforcement learning logic was implemented in the

car dumpers supervisory system.

As shown in Figure 4, each car dumper may

operate on four of the discharge lines and a

discharge line may be used by more than one car

dumper.

The reinforcement learning technique was based

on the following information:

Knowledge of the discharge line being used by

the car dumper;

Use of Flow Control on Car Dumpers - A Case of Success at Vale

581

Figure 4: Car dumpers (VV) and their discharge lines.

Whether there is another car dumper using the

same discharge line. If so, the flow control

should be disabled;

Knowledge of the time delay between the car

dumper and the flow scale at the selected

discharge line.

In order to allow the operator to verify the

estimated flow, the information shown in Figure 5

was made available. The operator may, through the

supervisory system, check the value of the estimated

flow, the value of the calibration factor obtained by

the technique of reinforcement learning and may

also enable/disable the calibration of the estimated

flow.

Figure 5: Information for monitoring the estimated flow.

Figure 6 shows the performance of reinforcement

learning technique. It is possible to verify that there

is an error between the estimated flow (red) and

actual flow (blue) shown by the flow scale. The

moment was activated estimated flow calibration

(using reinforcement learning technique) estimated

corrected flow (Green) is now correctly represent the

actual flow.

Figure 6: Comparison of the actual flow in ton/h (Blue) X

Estimated Flow (Red) X estimated corrected flow (Green).

3 FLOW CONTROL

The flow control needs the operator to inform the

desired flow (SP – Set Point) and a PID controller

adjusts the speed of the feeders (CV - Controlled

Variable) to make the estimated flow equal to the

corrected desired flow.

In addition to informing the desired flow the

operator can adjust through the supervisory system

the speed difference between the feeders. The goal is

to make the level of the hoppers always close to

each other. If the operator activates the level control,

this difference in speed is calculated automatically

by the control system.

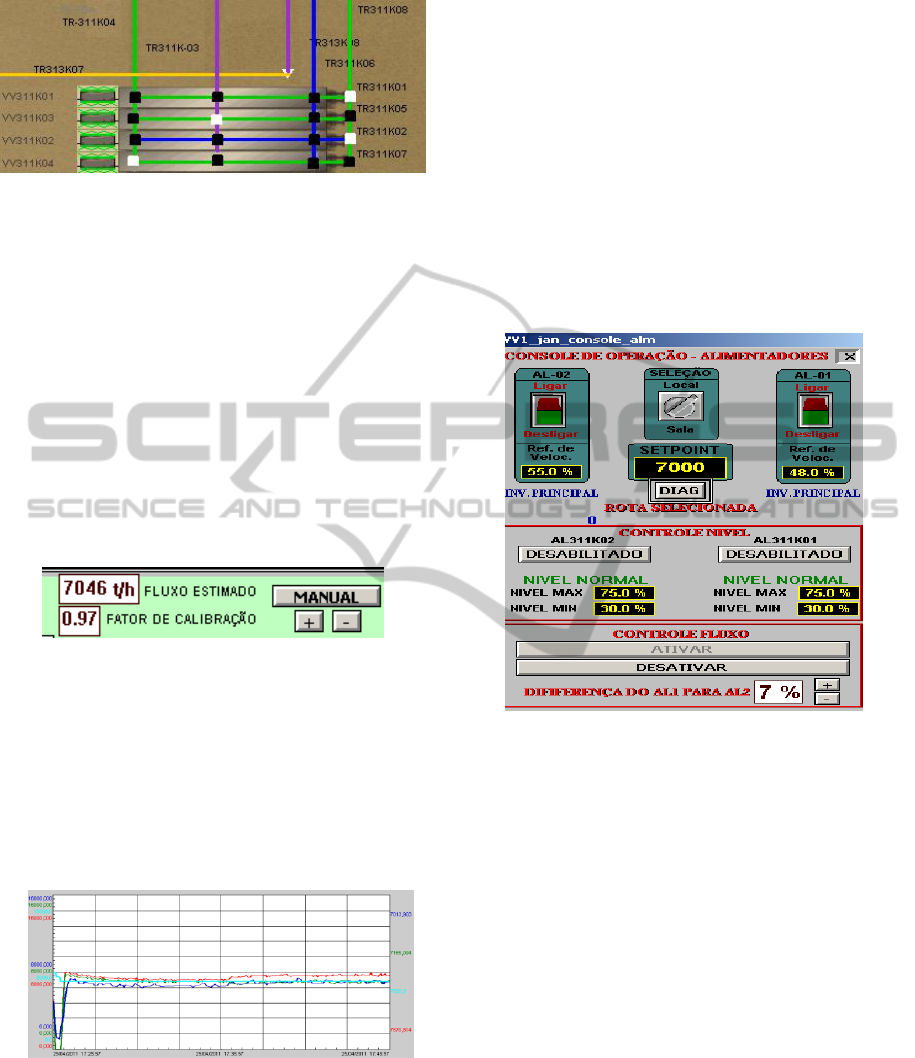

Figure 7 shows the screen that was developed in

the supervisory system for adjusting the set point,

the speed difference between the feeders and to

enable or disable the flow control.

Figure 7: Screen to adjust the set point and speed

difference between feeders.

Both the mathematical model used to estimate the

flow and the PID controller used to control the flow

were implemented on the PLC responsible for

controlling the car dumpers.

3.1 Flow Control Integrated with Level

Control

The car dumper has a hopper that collects the load of

the cars being turned. The hoppers on each side must

have a level transmitter that checks the material that

is unloaded from each wagon.

This system monitors the level of ore in the

hoppers, as shown in Figure 8. The level is measured

during the intervals when the wagons are not being

turned. In order for the level measurement to work,

the following logic must be implemented in the

PLC:

Low level in the hopper: Disable flow control

and reduced speed of feeders;

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

582

Very low level of hopper: Disable flow control

and shutdown of feeders shoe;

Very high level in the hopper: Keep active flow

control and turners blocked for discharge.

Figure 8: Monitors the level of ore in the hoppers.

Using a level transmitter it was possible to

implement a cascade control between the levels of

the hoppers and the discharge flow. The goal is to

control the speed difference between the feeders in

order to maintain the level between the hoppers

always close to each another, keeping the output

flow at the desired value.

4 RESULTS

4.1 Flow Control

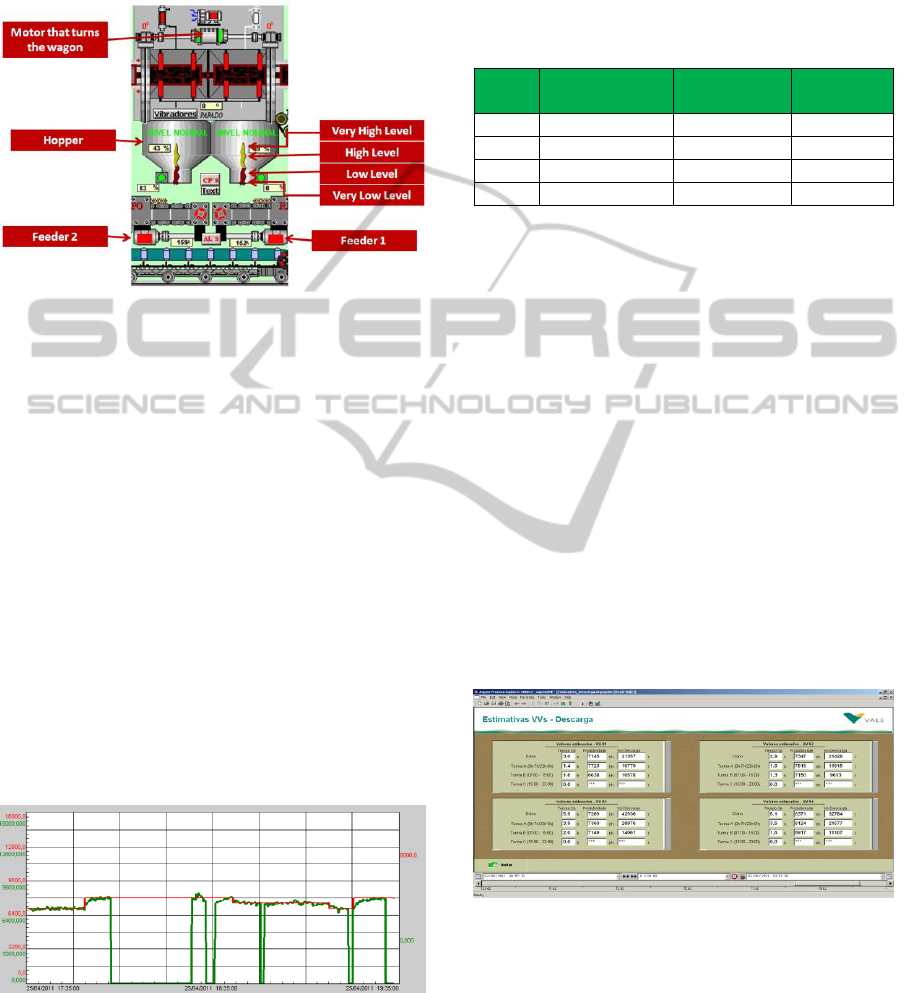

The performance achieved with the implementation

of the flow control can be seen in Figure 10, where

the operator provides different values of set point

(Red) and the controller automatically adjusts the

speed of the feeders to make the estimated corrected

flow (Green) equal to the established set point.

Figure 9: Flow Control Performance.

As can be seen in Figure 9 the flow control

performed well, because every change made to the

set point was rapidly followed by a correct change to

the speed making the flow equal to the estimated set

point.

The main gain with the implementation of flow

control was to reduce the standard deviation and

variability of the average rate (in ton/h) of the

discharge flow. This result is shown in Table 1.

Table 1: Gains obtained with the Flow Control.

Month

Average Rate

(ton/h)

DP Within

(ton/h)

Cpk

April

7698

312

0.21

May

7866

192

0.64

June

7859

170

0.70

July

7894

154

0.85

Using the table we can see that after the

implementation of the Flow Control a 51% reduction

in standard deviation (DP Within) rate and a 303%

reduction in variability (Cpk). With this solution we

have a controller that automatically adjusts the speed

of the feeders to follow the desired flow, thus

eliminating the need for operator intervention. As a

result, a 2.5% increase in the average rate of sinter

feed, which is equivalent to over 8 hours of

operation per month.

Using the estimated flow variable, it was

possible to develop a solution for tracking the

productivity of the car dumpers online. With the

development of this solution was possible to

increase the level of information in the discharge

process, because only then it was possible to obtain

some information online, such as productivity,

volume turned and run time for each day of

operation of the car dumpers. Figure 10 shows this

information being monitored through PIMS.

Figure 10: Screen created for monitoring the estimated

variables.

We conducted a comparison between the estimated

values and data extracted from SGOP (System

developed by Vale to Management of Port

Operations) for car dumper 1 (VV01) during the

month of May 2011 and the result can be seen in

Figure 11. This figure shows that the percentage of

accuracy of the estimated data is close to 100%.

Use of Flow Control on Car Dumpers - A Case of Success at Vale

583

Horas Operadas PIMS vs OEE

0,0

4,0

8,0

12,0

16,0

01/05/2011

08/05/2011

15/05/2011

22/05/2011

29/05/2011

HOP - OEE HOP - PIMS

Toneladas PIMS vs OEE

0

40.000

80.000

120.000

01/05/2011

08/05/2011

15/05/2011

22/05/2011

29/05/2011

VOL - OEE VOL - PIMS

Produtividade PIMS vs OEE

5.000

6.000

7.000

8.000

9.000

01/05/2011

08/05/2011

15/05/2011

22/05/2011

29/05/2011

PRO - OEE PRO - PIMS

94,0%

97,2%

96,7%

Run Time

vs

Horas Operadas Estimadas PIMS

Volume Turned

Productivity

Produtividade Estimadas PIMS

Figure 11: Comparison between data extracted from

SGOP and the estimated values.

It is worth emphasizing that the biggest

difference in the comparisons between the PIMS and

SGOP is in the amount of hours of operation. The

amount of hours informed by operator is always

lower than that calculated by the PIMS. This shows

a possible problem with the appropriation of hours

informed by the operator.

5 CONCLUSIONS

The results presented in this paper showed that the

new standard adopted by Vale to control the

discharge flow of iron ore at the TMPM car dumpers

brought a significant reduction in variability and

standard deviation with a significant increase in

productivity. The reductions were the main gain of

the project, because the constancy of the flow is

healthy for the equipment, as well as for the entire

process route.

Because of the gains obtained with this new flow

control standard developed at the TMPM terminal it

was established as the standard to be used by other

ports of Vale.

REFERENCES

Aguirre, L. A., 2000. A nonlinear dynamical approach to

system identification, IEEE Circuits & Systems

Society Newsletter 11(2): 10-23, 47.

Aguirre, L. A., 2007. Introdução a Identificação de

Sistemas. Técnicas Lineares e Não Lineares Aplicadas

a Sistemas Reais. Editora UFMG, Belo Horizonte -

MG. Brasil, 3a edição.

Lopes, B. E, Corrêa, M. V., Teixeira, R. A. and Moura, J.

P., 2010. Método de Análise dos Autovalores para

seleção de ordem de modelos lineares. Anais do 18º

Congresso Brasileiro de Automática, Bonito MS, pp.

498 — 504

Astrom, K., Hang C., Lim, B., 1994. A New Smith

Predictor for Controlling a Process with a Integrator

and Long Dead Time. IEEE Transaction on Automatic

Control 39(2): 343-345

Hagglund, T., 1992. A Predictive PI Controller for

Processis with Long Dead Time. IEEE, Control

Systems, pp57-60.

Smith, O. J. M., 1957. Closed Control of Loops With

Dead-Time, Chem. Eng. Progress; 53:217-219.

Astrom, K. J., Hagglund T., PID Controllers: Theory,

Design, and Tunning. 2ª Edition, Instrument Society of

America, 1995.

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

584