Fuzzy Control of a Hybrid Renewable Power System based

on Real-time Matlab-PLC Communication through OPC

Isaías González Pérez, A. José Calderón Godoy and Manuel Calderón Godoy

Industrial Engineering School, University of Extremadura, Avenida de Elvas, Badajoz, Spain

Keywords: Hybrid Power System, Renewable Energy, Electrolyzer, Fuzzy Control, OPC, PLC.

Abstract: This paper presents the design of a fuzzy logic controller to operate an electrolyzer of an experimental test-

bed of hybrid wind-solar system with hydrogen storage. This controller runs in Simulink and is linked

through Open Process Control interface with the industrial programmable logic controller responsible of

global management of the installation. Real-time data exchange and control of the process variables have

been successfully achieved and obtained results under real conditions are presented.

1 INTRODUCTION

Hybrid power systems (HPS) refer to all systems

that combine different energy technologies (RES,

hydrogen, biomass etc.) in order to meet the required

electrical and thermal loads of the consumer

(Zervas, 2008). A wind-solar test-bed with hydrogen

support has been developed and installed in the

Industrial Engineering School of the University of

Extremadura in Badajoz. It is a laboratory scale

system for testing the integration and control of a

stand-alone hybrid installation. Its components are

two PV modules, a wind-turbine generator, a lead-

acid gel battery, a PEM (Proton Exchange

Membrane) electrolyzer, a PEM fuel cell, a metal-

hydride system for hydrogen storage, and a

supervisory control and data acquisition system.

This system is based on a Siemens S7-313C-2DP

Programmable Logic Controller (PLC) which

integrates various modules for connecting sensors.

The electrolyzer is used for hydrogen production

from deionized water and electricity provided by the

PV modules. The hydrogen is stored in a set of metal

hydride bottles until feeding the fuel cell to provide

electricity according to the management strategy.

Figure 1 shows the wind-solar generator installed on

the flat roof of the School and the rest of the

elements in the laboratory.

One of the main problems of the HPS is related

to the control and supervision of the energy

distribution. There are power fluctuations because of

the variability of the renewable energy, which cause

disturbances that can affect the quality of the power

delivered to the load. The role of the controller is to

control the interactions of the various system

components and the energy flow within the system

to provide a stable and reliable source of energy.

Figure 1: Wind-solar generator, electrolyzer and

laboratory test-bed.

Literature review reveals that over the last

decades, hybrid systems have grown rapidly and

their technology has proven its competitiveness for

remote area applications. It is observed that

approximately 90% of studies reported are on

design/economic aspects of hybrid systems (Nema,

2009). Research studies about control are, hence,

scarce but there is an increasing interest on control

strategies and systems for hybrid installations.

Different control techniques have been studied for

HPS such as control based on the battery state of

charge (Ipsakis, 2009; Uzunoglu, 2009), logical

15

González Pérez I., José Calderón Godoy A. and Calderón Godoy M..

Fuzzy Control of a Hybrid Renewable Power System based on Real-time Matlab-PLC Communication through OPC.

DOI: 10.5220/0003992300150021

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 15-21

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

control (El-Shatter, 2006; Khan, 2009), sliding mode

control (Battista, 2006; Valenciaga, 2005), fuzzy

control (Bilodeau, 2006; Erdinc, 2011; Erdinc, 2012;

Hajizadeh, 2007; Jeong, 2005; Kyriakarakos, 2012;

Stewart, 2009), optimal control based on genetic

algorithms (Dufo, 2007), predictive control (Wu,

2009; Zervas, 2008), and Petri nets (Calderón, 2010;

Figueiredo, 2008; Lu, 2010).

Lately, Fuzzy Logic Control (FLC) has received

growing attention from researchers. Jeong et al.

(Jeong, 2005) designed and tested a fuzzy controller

for the load management of a fuel cell-battery hybrid

system. El-Shatter (El-Shatter, 2007) applied fuzzy

logic to control the duty cycle of two buck boost

converters of the wind generator into a hybrid wind-

PV-fuel cell system. In (Erdinc, 2011) Erdinc and

Uzunoglu developed and simulated with real

meteorological data a fuzzy controller to manage a

hybrid system consisting of wind-PV generators,

fuel cell, electrolyzer and battery. In (Erdinc, 2012)

Erdinc et al. tested a fuzzy controller in real wind-

PV-battery-fuel cell system for determining the fuel

cell power reference. Hajizadeh and Aliak

(Hajizadeh, 2007) simulated a fuzzy controller as

second control layer for a hybrid fuel cell-battery

system to decide the operating point of the fuel cell.

Bilodeau and Agbossou (Bilodeau, 2006) developed

and simulated a fuzzy logic controller defined using

the Fuzzy Logic Toolbox of Matlab for determining

the power set points of the fuel cell and the

electrolyzer in a stand-alone wind-solar hybrid

system. Stewart et al. (Stewart, 2009) simulated

fuzzy control applied to control the switches of the

battery, the fuel cell and the grid connection of a

hybrid PV-battery-fuel cell system for a residential

installation. Kyriakarakos et al. (Kyriakarakos,

2012) designed and simulated a fuzzy controller

developed using the Fuzzy Logic Toolbox of Matlab

for energy management of a wind-PV-fuel cell-

electrolyzer-battery power system including a

desalination unit.

Furthermore, several authors have reported

successful applications of OPC communication

between Matlab and Simulink environment and a

PLC of S7 series from Siemens (Lieping, 2007;

Linlin, 2011; Manuj, 2011; Mingliang, 2011).

The authors propose a control scheme based on a

six input and one output fuzzy logic controller. It has

been designed and tested for driving the electrolyzer

of the aforementioned renewable energy system.

This controller runs in Simulink and the control data

exchange with the PLC responsible of global

management is carried out in real time through OPC

technology. The rest of the paper is organized as

follows. Section 2 describes the control system, the

FLC features and the integration architecture for

real-time control by means of the PLC. In section 3

the results corresponding to the hybrid test-bed

under real conditions are shown. Finally,

conclusions and further works are outlined.

2 CONTROL SYSTEM

The test-bed monitoring and control system is

implemented by the PLC S7-313C-2DP. It has

electronic modules, Siemens SM331 and SM334

models, for connecting analogue sensors with

voltage and current outputs. Data are displayed and

stored on a TP277B touch panel (Siemens) running a

SCADA (Supervisory Control and Data Acquisition)

application. The touch panel logs the variables of

interest at one minute intervals from the PLC's

memory by a permanent MPI (Multi-Point Interface)

connection.

WinCC flexible is a Human-Machine Interface

(HMI) software. It can solve tasks like visualization,

acquisition and data storage and control of

automated processes. WinCC flexible RunTime is a

HMI based on PC and OPC communication is one of

its functionalities.

MATLAB is a kind of math analysis tool

developed by MathWorks CO, which integrates

OPC Toolbox to facilitate interoperability with other

software which is used as an OPC server.

The fuzzy logic controller has been implemented

with the Fuzzy Logic Toolbox of Simulink/Matlab

environment, which communicates with the

management PLC via OPC technology.

2.1 OPC

Open Process Control (OPC), also known as OLE

for Process Control, is a series of seven

specifications defined by the OPC Foundation for

supporting open connectivity in industrial

automation. OPC uses Microsoft® DCOM

technology to provide a communication link

between servers and clients. It has been designed to

provide reliable communication of information in

process plants, such as petrochemical refineries,

automobile assembly lines, and so on.

The specification of OPC technology contains

Server and Client, using the Client/Server mode.

Server is the supplier of data and Client is the user of

data. They establish a complete set of rules between

hardware supplier and software developer. An OPC

client is able to connect to one or more OPC Servers,

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

16

and several OPC clients are also allowed to

simultaneously connect to the same OPC Server.

A WinCC flexible RunTime software application

has been developed. It runs in the computer

connected to the PLC via Ethernet by using the

communications processor CP-343 Advanced. This

application accesses to data blocks in the PLC

memory where both sensors measurements

(electrolyzer current, pressure, etc.) and calculated

values are stored (battery state of charge, averaged

irradiance, etc.). So, these values are available for

the OPC client. In this case, the OPC Toolbox of

Matlab allows the communication with Simulink

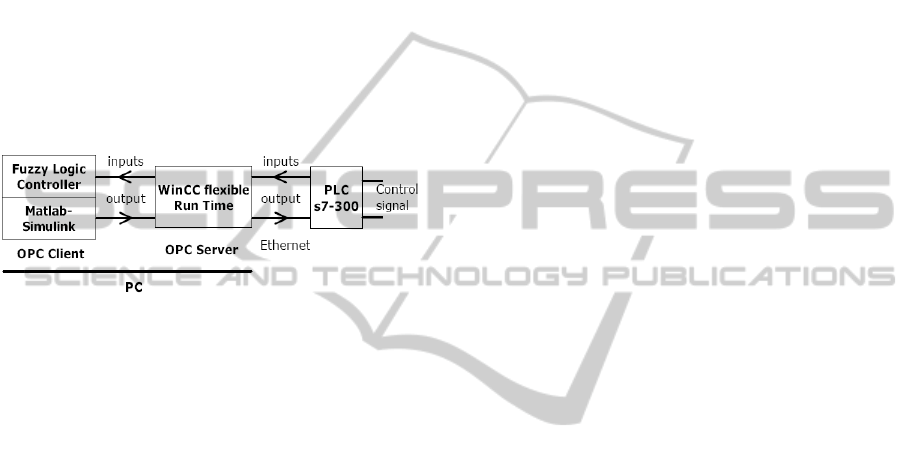

acting as OPC client. Figure 2 shows the

communication structure between the PLC,

Simulink and WinCC.

Figure 2: Diagram of communication structure between

Simulink, WinCC and the PLC.

2.2 Fuzzy Logic Controller

The main advantages of fuzzy logic are the fast

decision capability and that there is no need of

historical data neither mathematical models. Erdinc

and Uzunoglu (Erdinc, 2011) indicate the usefulness

of these features and the suitable structure of fuzzy

logic for the control of power systems.

The control objective of the proposed strategy is

to regulate the operation point of the PEM

electrolyzer depending on the conditions of the

system such as energy availability from PV

generator, from the battery, and others. A dc-dc

converter carries out the conditioning of voltage and

current provided by the PV modules to the

electrolyzer levels. The PLC applies a signal control

to this converter by means of an analogue output of

voltage. This voltage level is generated from the

FLC output.

FLC input variables are: State Of Charge (SOC)

of the battery, solar irradiance, temperature of PV

panel, compromise current, pressure of metal hydride

system, difference between compromise and

electrolyzer currents. This latter is considered as error

signal because it represents the deviation between the

surplus available current and the one delivered to

electrolyzer. This error signal is calculated in

Simulink before entering the FLC block.

Compromise current is defined by the authors as

the possible surplus current that would be produced

in the installation if the PV generator was providing

the maximum possible current. It plays the role of

threshold to decide if the energy surplus is enough

for the electrolyzer operation. It is calculated as the

difference between the maximum current from

modules, Ipmax, and the load current. Ipmax

depends on the panels voltage, Vpan, and the

irradiance, G, according to equation 1 that has been

obtained from experimental data:

Ipmax = 2 * G * (0.0049 – 0.0002 * Vpan) (1)

The battery SOC is estimated in the PLC with

the Ampere-counting method (Piller, 2001) from

values of current and capacity of the battery.

Incident irradiance in the PV modules plane is

used. It is averaged each 5 minutes in order to

reduce the transitory fluctuations due to clouds.

The PV panel temperature is measured with a Pt-

100 probe on the backsurface. This variable is

included in control process because the generation

capacity and the performance of the modules depend

on their temperature. The lower temperature is, the

higher performance will be.

Once the battery is charged enough and the load

demand is being satisfied, the PV modules provide a

surplus current used for hydrogen generation. These

conditions are evaluated by means of the incident

irradiance, the compromise current and the battery

SOC. Furthermore, technological factors must be

taken into account such as the no operation of the

fuel cell and the available capacity for storing in the

metal hydride bottles, i.e., their pressure has to be

under the maximum level.

When such conditions are fulfilled, the voltage

control signal generated by the FLC is applied to the

dc-dc converter that feeds the electrolyzer from PV

modules. This voltage varies with meteorological

and technological changes according to the rules

defined for the controller, so that the current drawn

by the electrolyzer and, hence, the flow of hydrogen

produced are adapted to the availability of energy.

The structure of the FLC has been made as

simple as possible. The fuzzy controller is of

Mamdani type, the And method is Min, the

implication operator is Min, the Aggregation is Max

and the defuzzification strategy is the Centroid of

area. The membership functions have been defined

based on the experience acquired by the research

team through the operation of the test-bed

(Calderón, 2010; Calderón, 2011). Triangular,

trapezoidal, S-shaped and Z-shaped membership

FuzzyControlofaHybridRenewablePowerSystembasedonReal-timeMatlab-PLCCommunicationthroughOPC

17

functions have been used for input and output

variables. These ones conform to the desired design

among those available in the Fuzzy Logic toolbox of

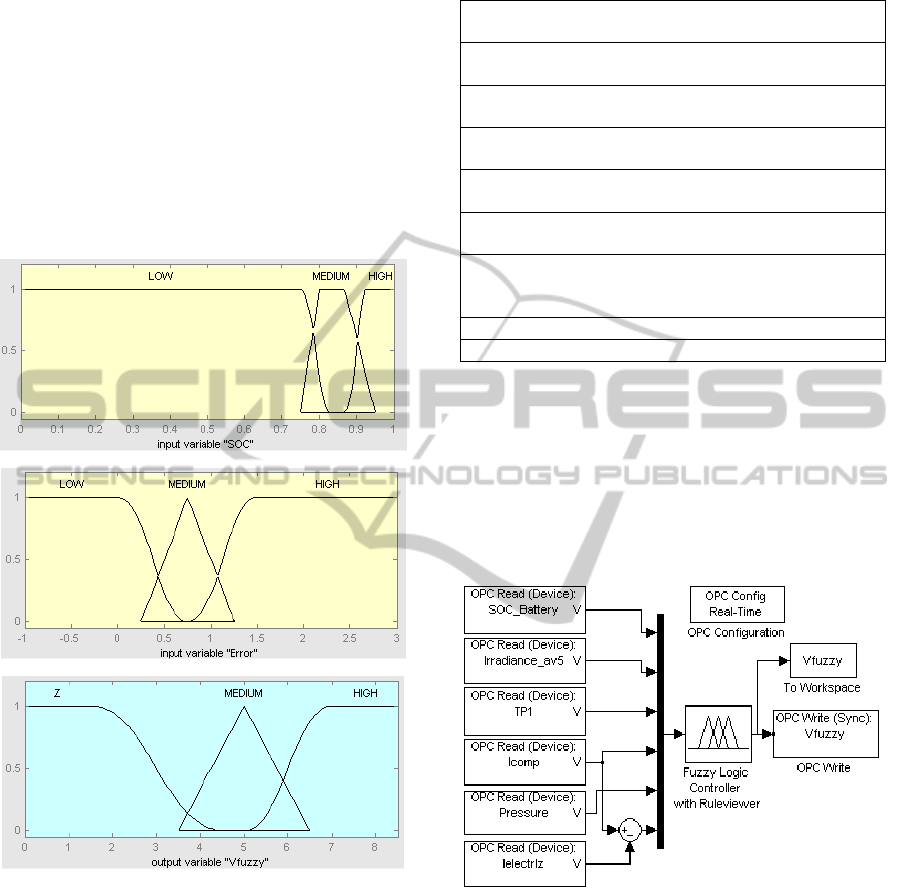

Matlab Membership functions for SOC, error signal

and output variable, Vfuzzy, are presented in Figure

3. Irradiance, compromise current and pressure input

variables have been defined by means of 2 fuzzy

subsets; while SOC, PV module temperature and

error signal use 3 fuzzy subsets. In the case of SOC,

the Low subset has been made larger to avoid

operating on such low values to enlarge the battery

life span.

a)

b)

c)

Figure 3: Membership functions for: a) SOC, b) Error

signal, c) Output signal.

The linguistic variables are Low, Medium and

High for input variables and Z, Medium and High

for output signal. Input ranges depend on the

variable. The narrowest range goes from 0 to 1 for

SOC and the widest one goes from 0 to 1000 W/m

2

for solar irradiance. The range of output signal is 0

to 8’5 V, interval where the electrolyzer behaviour is

lineal. The fuzzy rules define the FLC behaviour.

Table 1 contains the 9 rules that have been

enounced.

Table 1: Rules of the FLC.

If the SOC is High and the irradiance is High and PV

panel temperature is Low then Vfuzzy is High

If the SOC is High and the irradiance is High and PV

panel temperature is Medium then Vfuzzy is High

If the SOC is High and the irradiance is High and PV

panel temperature is High then Vfuzzy is Medium

If the SOC is Medium and the irradiance is High and

PV panel temperature is Low then Vfuzzy is High

If the SOC is Medium and the irradiance is High and

PV panel temperature is Medium then Vfuzzy is High

If the SOC is Medium and the irradiance is High and

PV panel temperature is High then Vfuzzy is Medium

If the SOC is Low or the irradiance is Low or the

compromise current is Low or the pressure is High then

Vfuzzy is Zero

If the error signal is Medium then Vfuzzy is Medium

If the error signal is High then Vfuzzy is High

Figure 4 contains the block diagram of the real-

time control system implemented in Simulink. It

consists of three subsystems: OPC Read blocks for

acquisition of input signals, fuzzy controller block for

control signal generation and OPC Write block for

real-time writing on PLC memory. The

communications parameters are defined with the OPC

Configuration block, so Simulink acts as OPC client.

Figure 4: Simulink block diagram of fuzzy control

scheme.

2.3 WinCC, Simulink and PLC

Integration

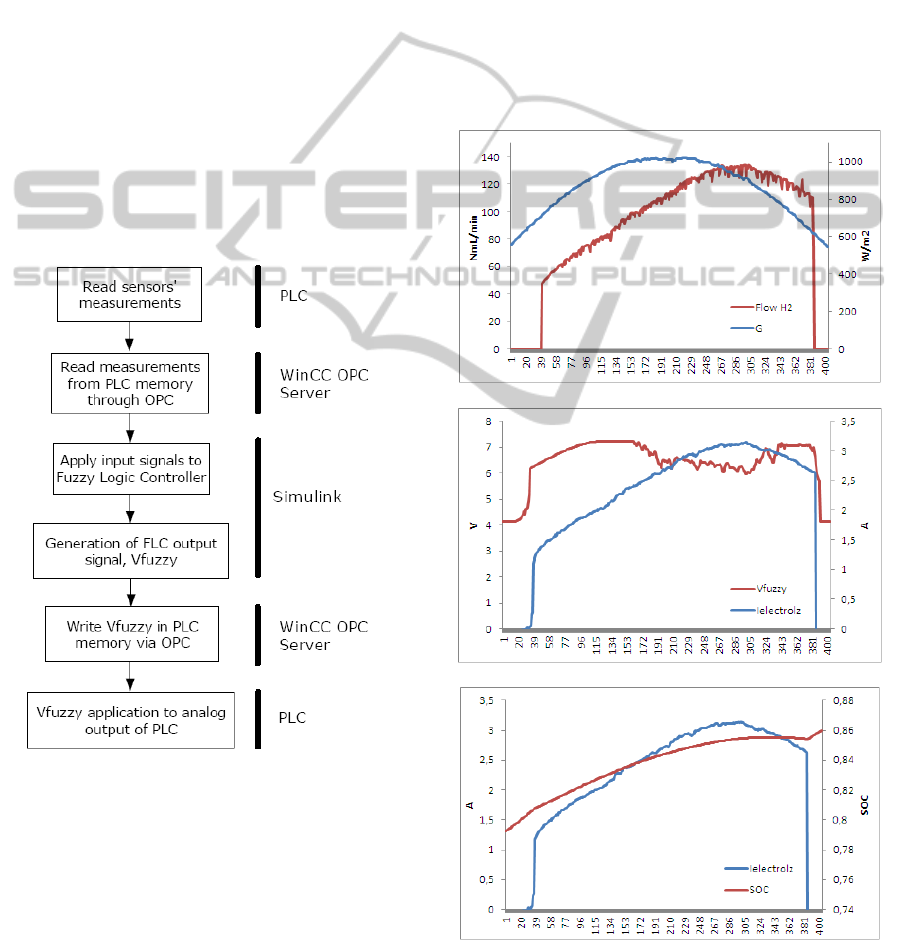

Figure 5 shows the sequence of operations from the

reading of sensors connected to PLC. Those values

are stored in data blocks in the PLC memory. The

OPC server of WinCC flexible RT allows the access

to these memory positions from Simulink by means

of the OPC Read blocks. The same happens to data

calculated by the PLC program and accumulated in

its memory. These signals constitute the FLC inputs,

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

18

which applies the defined control rules to the

fuzzyfied inputs in order to generate a signal output,

that is defuzzyfied. This control signal is written in

the PLC memory by the OPC server of WinCC

using the OPC Write block of Simulink. PLC carries

out the conditioning of the signal Vfuzzy and

transfers it to the analog output connected to the dc-

dc converter of the electrolyzer.

Configured blocks of Simulink access to real-

time process variables and the FLC regulates the

electrolyzer operation point.

The sampling time chosen for OPC blocks and

configuration parameters of Simulink is 10 seconds.

The conditioning and un-scaling of the value Vfuzzy

is carried out by the PLC cyclic interruption block

OB35 every 10 sec. This value is sent to the voltage

analogue output of the module SM334. The PLC

programming software STEP7, the supervision

WinCC software and Matlab software are installed

in the same computer. So, the OPC Server and the

OPC Client are both local machines.

Figure 5: Flowchart of the communication between

WinCC, Simulink and PLC.

3 EXPERIMENTAL RESULTS

The FLC has been tested under real conditions in the

test-bed for several days. The membership functions

and rules were adjusted during trials with different

climatic conditions in order to avoid fluctuations of

the output signal and deviations from the expected

behaviour of the electrolyzer. Figure 6 (a, b and c)

shows the most representative of involved variables

for the system operation during 20

th

February 2012

from 10:00 to 17:00. In Figure 6 a) the irradiation and

the hydrogen production are plotted. In Figure 6 b)

the evolution of the controller output, Vfuzzy, is

shown with the current consumption of the

electrolyzer.

Finally, in Figure 6 c) the battery SOC variation

and the electrolyzer current are shown. As can be

seen, whereas the electrolyzer is producing

hydrogen, the battery SOC is still growing because

the PV modules provide current for both demands.

Low subset has been made larger to avoid operating

on such low values to enlarge the battery life span.

a)

b)

c)

Figure 6: Evolution of: a) incident irradiance and H

2

flow,

b) control signal and electrolyzer current, c) electrolyzer

current and battery SOC for the 20

th

February 2012.

FuzzyControlofaHybridRenewablePowerSystembasedonReal-timeMatlab-PLCCommunicationthroughOPC

19

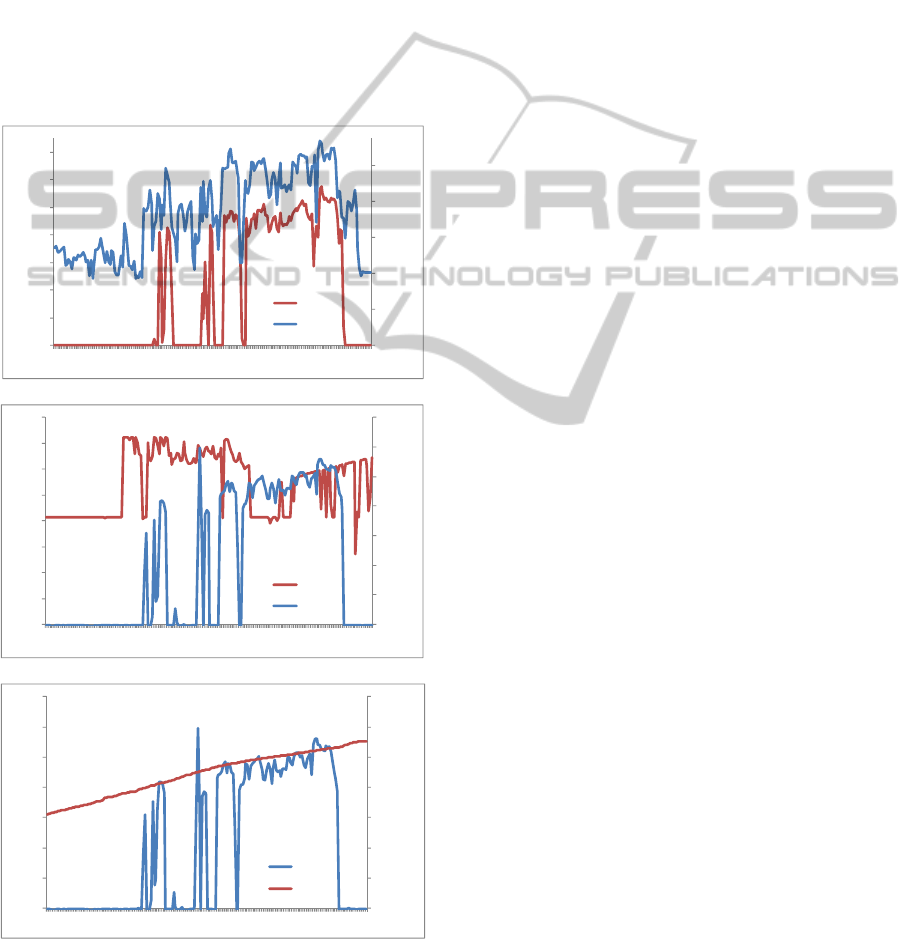

Figure 7 (a, b and c) shows data corresponding to

23rd March 2012 from 10:00 to 13:30, illustrating the

operation of the system during a cloudy day. As can

be seen in Figure 7 a), the hydrogen production

follows the variations of the incident irradiance, so

such production adapts to the power availability. In

Figure 7 b) the effects of the clouds on the output

signal of the FLC, Vfuzzy, and the corresponding

change in the electrolyzer current are showed. Figure

7 c) shows a similar situation to that of 20th February

2012, the battery SOC is incrementing at the same

time that hydrogen is being generated due to the

current delivered by the PV modules. These results

demonstrate the ability of the developed controller to

adjust the control signal to the power availability.

a)

b)

c)

Figure 7: Evolution of: a) incident irradiance and H

2

flow,

b) control signal and electrolyzer current, c) electrolyzer

current and battery SOC for the 23

rd

March 2012.

4 CONCLUSIONS

A fuzzy controller for real-time regulation of the

operation point of a PEM electrolyzer has been

presented. The hydrogen generator constitutes the

core of a hybrid wind-solar test-bed with hydrogen

storage. The fuzzy controller has been designed and

implemented in Simulink and communicated with

the PLC that plays the role of mastermind of the

automation system by means of OPC technology.

The versatility and ability of the proposed

control scheme for being used as a platform for

testing different and advanced control strategies

have been demonstrated and serve as basis for future

works in that sense.

The results under real operating conditions

constitute a proof-of-concept of the validity of the

proposed control structure.

ACKNOWLEDGEMENTS

This work has been supported by grants from

Gobierno de Extremadura (reference GR10157) and

FEDER (Fondo Europeo de Desarrollo Regional,

Una Manera de Hacer Europa)

REFERENCES

Battista, H., Mantz, R. J., Garelli, F., 2006. Power

conditioning for a wind–hydrogen energy system. J.

Power Sources 155, 478–486.

Bilodeau, A., Agbossou, K., 2006. Control analysis of

renewable energy system with hydrogen storage for

residential applications. J. Power Sources 162, 757-764.

Calderón, M., Calderón, A. J., Ramiro, A., González, J. F.,

2010. Automatic management of energy flows of a

stand-alone renewable energy supply with hydrogen

support. Int. J. Hydrog. Energy 35, 2226-2235.

Calderón, M., Calderón, A.J., Ramiro, A., González, J.F.,

González, I., 2011. Evaluation of a hybrid

photovoltaic-wind system with hydrogen storage

performance using exergy analysis. Int. J. Hydrog.

Energy 36, 5751-5762.

Dufo-López, R., Bernal-Agustín, J. L., Contreras, J., 2007.

Optimization of control strategies for stand-alone

renewable energy systems with hydrogen storage.

Renew. Energy 32, 1102–1126.

El-Shatter, T. E., Eskander, M. N., El-Hagry, M. T., 2006.

Energy flow and management of a hybrid

wind/PV/fuel cell generation system. Energy Conv.

Manag. 47, 1264–1280.

Erdinc, O., Elma, O., Uzunoglu, M., Selamogullari, U.S.

Vural, B., Ugur, E., Boynuegri, A.R., Dusmez, S,

2012. Experimental performance assessment of an

0

200

400

600

800

1000

0

20

40

60

80

100

120

140

1

11

21

31

41

51

61

71

81

91

101

111

121

131

141

151

161

171

181

191

W/m2

NmL/min

FlowH2

G

0

0,5

1

1,5

2

2,5

3

3,5

0

1

2

3

4

5

6

7

8

1

11

21

31

41

51

61

71

81

91

101

111

121

131

141

151

161

171

181

191

A

V

Vfuzzy

Ielectrolz

0,74

0,76

0,78

0,8

0,82

0,84

0,86

0,88

0

0,5

1

1,5

2

2,5

3

3,5

1

11

21

31

41

51

61

71

81

91

101

111

121

131

141

151

161

171

181

191

SOC

A

Ielectrolz

SOC

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

20

online energy management strategy for varying

renewable power production suppression. Int. J.

Hydrog. Energy, doi: 10.1016/j.ijhydene.2011.12.042.

Erdinc, O., Uzunoglu, M., 2011. The importance of

detailed data utilization on the performance evaluation

of a grid-independent hybrid renewable energy

system. Int. J. Hydrog. Energy 36, 12664-12677.

Figueiredo, J. M., Sá da Costa, J. M. G., 2008. An

Efficient System to Monitor and Control the Energy

Production and Consumption. Proceedings of the

IEEE 5

th

International Conference on European

Electricity Market, Lisboa, Portugal.

Hajizadeh, A., Aliakbar, M., 2007. Intelligent power

management strategy of hybrid distributed generation

system. Int. J. Electr. Power Energy Sist. 29, 783-795.

Ipsakis, D., Voutetakis, S., Seferlis, P., Stergiopoulos, F.,

Elmasides, C., 2009. Power management strategies for

a stand-alone power system using renewable energy

sources and hydrogen storage. Int. J. Hydrog. Energy

34, 7081-7095.

Jeong, K. S., Lee, W. Y., Kim, C. S., 2005. Energy

management strategies of a fuel cell/battery hybrid

system using fuzzy logics. J. Power Sources 145, 319–

326.

Kyriakarakos, G., Dounis, A., Arvanitis, K., Papadakis,

G., 2012. A fuzzy logic energy management system

for polygeneration microgrids. Renewable Energy, vol.

41, pp. 315-327.

Khan, M. J., Iqbal, M. T., 2009. Analysis of a small wind-

hydrogen stand-alone hybrid energy system. Appl.

Energ. 86, 2429–2442.

Lieping, Z., Aiqun, Z., Yunsheng, Z., 2007. On remote

real-time communication between MATLAB and PLC

based on OPC technology. Proceedings of the 26

th

Chinese Control Conference, Hunan, China.

Linlin, Q., Ping, L., Hongxing, L., 2011. Compound Fuzzy

PID level control system based on WinCC and

MATLAB. International Conference on Measuring

Technology and Mechatronics Automation, Shanghai,

China.

Lu, D., Fakham, H., Zhou, T., François, B., 2010.

Application of Petri nets for the energy management

of a photovoltaic based power station including

storage units. Renew. Energy 35, 1117–1124.

Manoj, R., Janaki, S., 2011. Fuzzy adaptive PID for flow

control system based on OPC. International Journal of

Computer Applications.

Mingliang, W., Mingyong, W., Jiankang, H., Ling, S.,

2011. Intelligent control system of water level for

boiler drum based on OPC and MATLAB.

Proceedings of the 30

th

Chinese Control Conference.

Yantai, China.

Nema, P., Nema, R. K., Rangnekar, S., 2009. A current

and future state of the art development of hybrid

energy system using wind and PV-solar: A review.

Renew. Sust. Energ. Rev. 13, 2096-2103.

Piller, S., Perrin, M., Jossen, A., 2001. Method for state-

of-charge determination and their applications. J.

Power Sources 96, 113-120

Stewart, E. M., Lutz, A. E., Schoenung, S., Chiesa, M.,

Keller, J.O., Fletcher, J., et al., 2009. Modeling,

analysis and control system development for the

Italian hydrogen house. Int. J. Hydrog. Energy 34,

1638-1646.

Uzunoglu, M., Onar, O. C., Alam, M. S., 2009. Modeling,

control and simulation of a PV/FC/UC based hybrid

power generation system for stand-alone applications

Renew. Energy 34, 509–520.

Valenciaga, F., Puleston, P. F., 2005. Supervisor Control

for a Stand-Alone Hybrid Generation System Using

Wind and Photovoltaic Energy. IEEE Transactions on

Energy Conversion, vol. 20, no. 2.

Wu, W., Xu, J. P., Hwang, J. J., 2009. Multi-loop

nonlinear predictive control scheme for a simplistic

hybrid energy system. Int. J. Hydrog. Energy 34

(2009) 3953-3964.

Zervas, P. L., Sarimveis, H., Palyvos, J. A., Markatos,

N.G.C., 2008. Model-based optimal control of a

hybrid power generation system consisting of

photovoltaic arrays and fuel cells. J. Power Sources,

vol. 181, pp. 327–338.

FuzzyControlofaHybridRenewablePowerSystembasedonReal-timeMatlab-PLCCommunicationthroughOPC

21