Rate-based Simulation of Coke Calcination in Rotary Kilns

E. M. Elkanzi, F. S. Marhoon and M. J. Jasim

Chemical Engineering Department, University of Bahrain, Isa Town, Kingdom of Bahrain

Keywords: Rotary Kiln, Calcining Processes, Rate-based HYSYS Simulation.

Abstract: This paper presents the simulation of the green petroleum coke calcining processes using the simulation

program ASPEN HYSYS. The results are validated using actual industrial data. The present study provides

a detailed description of the rate-based simulation. It considers the rate of physical and chemical phenomena

of interest: the rate of moisture removal, the rate of volatile matter release and combustion, and the rate of

coke dust and sulfur combustion. Data supplied by a local coke calcining kiln in operation are used to

validate the simulation results. It is found that the rate-based simulation can be implemented as a useful tool

to predict the operating conditions needed to control the content of undesirable impurities in the calcined

petroleum coke, namely, sulfur, volatile matter and moisture contents. Except for the metal content, the

simulation shows that it is possible for the kiln operator to process any type of green coke for varying sulfur,

volatile matter and water contents by adjusting the amount of tertiary air and/or fuel.

1 INTRODUCTION

Aluminum industry anodes demand high quality

standard of calcined petroleum coke (CPC). It

requires a coke with no moisture, no volatile matter

and low sulfur contents with an appropriate

crystalline structure. This is achieved through

calcination processes. It is accomplished by gradual

heating of the green coke (GC) at ambient

temperature to a temperature of around 1390°C in a

rotary kiln (calciner). The kiln is operated as a

counter-flow heat exchanger as described by Elkanzi

(Elkanzi, 2007).

The determination of the calciner operation

conditions are based on the following specifications

of the GC: the moisture, the sulfur, the volatile

matter (VM), and the metal contents. If any of these

are not within the specified CPC requirements, then

the operating conditions of the calciner should be

adjusted in order to meet the allowable limit.

However, if the problem in the GC is related to the

metal content, then blending of different GCs is

necessary to meet the desired conditions because

metals cannot be removed by the calcination

processes.

Elkanzi (Elkanzi, 2007) has reviewed different

mathematical models which have been developed to

describe petroleum coke calcination processes in

rotary kilns. Some previous simulators were mainly

written programs to solve the sets of simultaneous

differential equations representing: the material

balances, the energy balances, and the chemical

reactions along the kiln (Li & Friday, 1974; Perron

et al., 1990; Perron et al., 1992; Bui et al., 1993;

Martins et al., 2001).

In a previous publication (Elkanzi, 2007), the

rotary coke calcining kiln processes were simulated

using a commercial simulator. The reactions were

simulated as conversion reactions and the values of

the conversions were obtained from a real kiln data.

The objective of this study is to simulate the

rotary kiln processes based on the rate of these

processes. The rate-based simulation would improve

the prediction of the kiln operating conditions that

control the contents of undesirable impurities in the

calcined coke. The commercial software ASPEN

HYSYS was used for this purpose and the processes

were assumed to take place in mixed reactors in

series along the rotary kiln.

2 RATE OF CALCINATION

PROCESSES

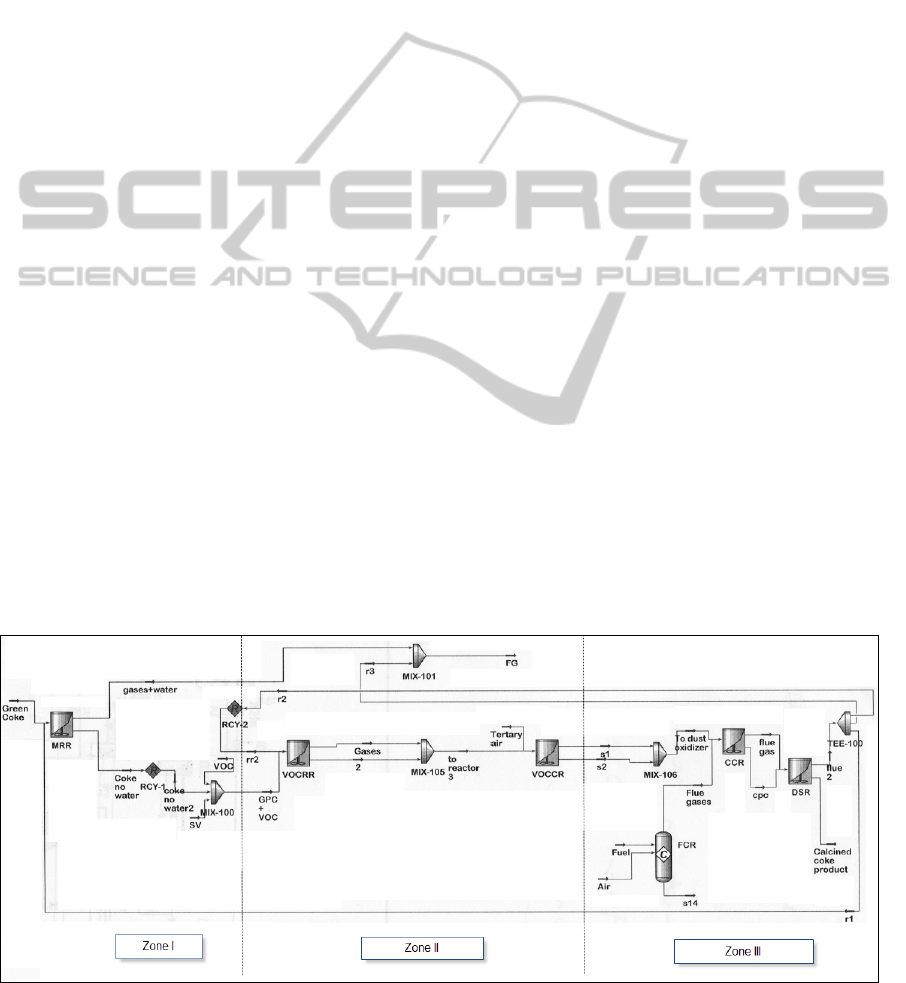

The calcination processes are visualized to take

place in three zones inside the kiln, as illustrated in

Figure 1. In the moisture release zone, the water is

removed from the coke at temperatures up to 400°C,

5

Elkanzi E., Marhoon F. and Jasim M..

Rate-based Simulation of Coke Calcination in Rotary Kilns.

DOI: 10.5220/0004008400050010

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 5-10

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

while the volatile matter (VOC) is driven off the

coke between 400 and 600 °C. Then, the volatile

matter is combusted between 600 and 1000 °C in the

VOC release and combustion zone. Finally, the fuel

is combusted, the coke de-sulfurized and the carbon

oxidized in the temperature range from 1250 to

1400°C in the fuel combustion and calcined coke

zone. All zones are simulated as continuous stirred

tank reactors.

2.1 Moisture Release Rate

The water in the pores of the coke is heated by the

counter flow of the flue gases in the kiln and

evaporated. The evaporation reaction may be

represented by:

2() 2()lg

HO HO→

(1)

However, the use of kinetic reaction in the

HYSYS requires that either water liquid or water

vapour to be represented by a hypothetical

compound having the same properties as that of

water.

The water release rate was described as a first

order reaction (Lyons, et al, 1962) and given by:

()

ERT

cc

www

b

XG

RkX e

MW u A

−

⎛⎞

=

⎜⎟

⎜⎟

⎝⎠

(2)

Where k

w

is a constant equals to 2.549x10

7

s

-1

and E

is the release energy of about 4.1942x10

4

J/mol.

2.2 VOC Release Rates

The VOCs entrained in the pores of the coke are

heated by the counter flow of the flue gases in the

kiln and evolve into the gas phase. De-sorption and

evaporation “reactions” may be represented by:

)(

4

)(

4

g

CH

ad

CH →

(3)

)(

2

)(

2

gad

HH →

(4)

)(

1218)(1218

g

l

HCHC →

(5)

Hypothetical compounds were introduced with

the same properties as that of the real VOCs. The

rate of release of VOCs from the bed to the vapour

phase was obtained from the experimental data of

Dernedde et al (Dernedde, et al, 1986 and reported

by Martins, et al, 2001) and is described by the

following empirical correlation:

()

()

0

0

E

n

cc v

RT

vv v

n

vb

cv

XG X

Rk X e

MW u A

XX

−

⎛⎞

=

⎜⎟

⎜⎟

⎝⎠

(6)

The values of the constants in Eq. (6) are given in

Table 1.

Table1: Empirical constants for evaluating VOC release

rates (Dernedde, et al., 1986).

VOC k

v

(s

-1

) E(J mol

-1

) n

H

2

9.17x10

1

4.37x10

4

1.5

CH

4

1.49x10

6

1.75x10

5

2.0

C

18

H

12

1.09x10

-1

1.25x10

5

1.5

2.3 Combustion of VOC Rates

The combustion of VOCs was simulated by kinetic

expressions in HYSYS. The VOCs released from the

coke bed are oxidized by oxygen in the hot gases

and would combust depending on the amount of

Figure 1: Calcining Processes Zones.

Fuel

Combustion &

Calcined Coke

Zone

VOC Release &

Combustion

Zone

Moisture

Release Zone

Fuel

+Ai

r

CPC

FG

GP

1250-1400 °C

600 - 1000 °C

25 - 600 °C

55 m

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

6

tertiary air entering this zone. The reactions may be

represented by:

OHCOOCH

2224

22 +→+

(7)

OHOH

222

22 →+

(8)

18 12 2 2 2

21 18 6CH O CO HO+→ +

(9)

The rates of combustion of methane and

hydrogen as released from the bed to the gas phase

were obtained from the experimental data of

Srinivasan (Srinivasan, et al., 1998) as:

()()

442

30196

0.5 1.5

11

710

g

T

CH CH o

Ryye

−

−

=×

(10)

[][]

2

20634

0.85 1.42

11

22

2.45 10

g

T

H

RHOe

−

=×

(11)

The rate of combustion of tar can be described

by the empirical equation (Dernedde, et al, 1986;

Howard, et al, 1973):

[][ ][ ]

0.5 0.5

22

E

RT

ch ch

RkchO HOe

−

=

(12)

The values of the constants were as shown in Table 2.

Table 2: Constants of the combustion of Tar rate

expression.

k

ch

(cm

3

/ mole-s)

E

(J/ mole)

Reference

1.8 x10

13

1.32x10

5

Dernedde, et al.,

1986.

1.3 x 10

14

1.25x10

5

Howard, et al.,

1973.

2.4 Desulfurization and Carbon

Oxidation Rates

The de-sulfurization and carbon dust oxidation

reactions were simulated as two reactors. Oxygen

from tertiary air reacts with the sulfur and the carbon

dust to produce SO

2

, CO

2

and CO according to the

following reactions:

22

COOC →+

(13)

COCOC 2

2

→+

(14)

22

SOOS →+

(15)

The rates of entrained coke fines burn-up were

reported in (Li, and Friday, 1974) and described by

the following equations:

[]

2

30800

13

2

6.84 10

g

T

f

CO

SL

ROe

V

−

Δ

⎛⎞

=×

⎜⎟

⎜⎟

⎝⎠

(16)

()

2

62180

0.5

12

1.08 10

12.01 1

24624

2887

g

g

SL

T

f

eP

CO

V

R

CO

P

co

X

T

e

−

⎛⎞

⎜⎟

Δ

⎛⎞

⎜⎟

× ⎜⎟

⎜⎟

⎜⎟

⎝⎠

⎜⎟

⎝⎠

=

⎛⎞

⎛⎞

⎜⎟

⎜⎟

⎜⎟

⎜⎟

+

⎜⎟

⎜⎟

⎛⎞

⎜⎟

⎜⎟

−

⎜⎟

⎜⎟

⎜⎟

⎜⎟

⎝⎠

⎝⎠

⎝⎠

(17)

The rate of carbon monoxide can be simplified by

neglecting the 1 in the dominator since the term

{P

CO

/ (2887 e (-24624/Tg))} is much greater than

one, and hence equation (17) becomes:

()

()

2

86804

0.5

14

1.0

2.62 10

g

CO

T

f

CO

CO

P

SL

Re

V

P

−

Δ

⎛⎞

=×

⎜⎟

⎜⎟

⎝⎠

(18)

The rate of oxidation of sulfur was reported (Lu,

et al., 2004) and is described by:

SV

T

s

CeR

4360

11

101.1

−

−

×=

(19)

Since the units of Csv are in molecule/ cm

3

,

multiplying by Avogadro’s number yields:

SV

T

s

CeR

4360

12

106.6

−

×=

(20)

2.5 Fuel Combustion Rate

The fuel used in the kiln was natural gas and hence

the rate of the fuel combustion is as given by

equation (10). The results of the kinetic equation

(10) were compared with normal conversion

reaction and showed great deal of agreement.

3 HYSYS SIMULATION

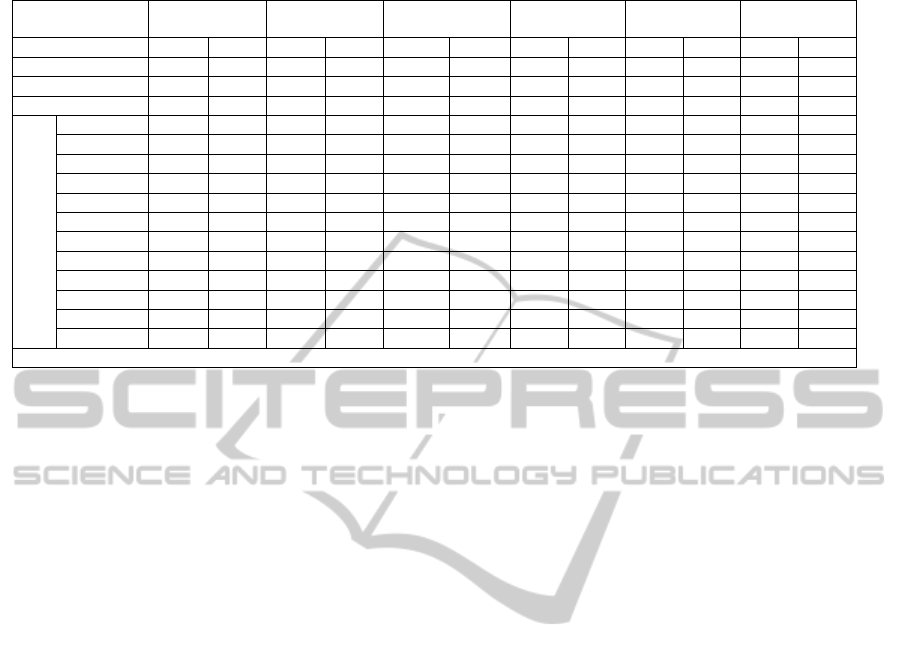

The HYSYS simulation flow sheet of the coke

calcinations processes is depicted in Figure 2 which

shows the three calcination zones. The simulation

was based on actual GC industrial data (ALBA

2010). Process simulation assumes good mixing

inside the kiln; which is accomplished by rotating

the kiln at an inclined position as well as by the

presence of tumblers. Moreover, it was assumed that

the reactions take place effectively in the gas phase.

As a result of these assumptions, the calcination

Rate-basedSimulationofCokeCalcinationinRotaryKilns

7

processes were simulated to take place inside

adiabatic continuous stirred-tank reactors. It is to be

noted that there is no sharp demarcation between

these reactors. In fact part of the VOCs is released in

the moisture release “reactor” and a very little

amount of VOCs is combusted in the VOC release

“reactor” since the release zone is oxygen deficient.

The simulation procedure is similar to the one

used before (Author, 207) featuring the concept of

using “recycle” to simulate counter-current mass

flow that is not allowed by HYSYS. The combustion

of fuel (CH

4

) is simulated by fuel combustion

reactor, FCR, which is a conversion reactor. The flue

gas from the burner is mixed with the outputs from

the VOC combustion reactor (VOCCR) and enters

the carbon combustion reactor (CCR). The CCR is

simulated using equations (16) and (18), for which

the carbon dust was simulated by hypothetical

“carbons” so as not to confuse them with the rest of

the coke carbon that was assumed not to react in the

solid phase. The output from CCR enters the

desulfurization reactor (DSR) that was simulated

using equation (20). The solid output from DSR is

the calcined coke product. The gas output is the

“recycle stream” which is split into three streams:

the first is mixed with the fresh GPC and enters the

moisture release reactor (MRR, simulated using

equation (2), for which the product water was

simulated by a hypothetical water component), the

second is sent to the VOC release reactor (VOCRR),

and the third is mixed with the gas output from the

MRR to form the flue gas that is sent to the

incinerator. It may be noted here that the split ratio

of the recycle stream is determined by trial and error

in order for the temperature in MRR, VOCRR and

VOCCR to fall within the operating range shown in

Figure 1. Since it is assumed that the VOCs and

sulfur are not released in the MRR, they were mixed

and sent to the VOC release reactor (VOCRR) that is

simulated using equation (6) and the data of Table1.

The components in the release equations (3), (4) and

(5) were simulated by hypothetical components. The

output from VOCRR is mixed with tertiary air and

sent to the VOCCR that was simulated using

equations (10), (11), (12), and the data in Table 2.

4 RESULTS AND DISCUSSION

Coke kiln industrial data (ALBA 2010) are

compared with the simulation results using the same

input feed and conditions. At this initial stage of

work, the comparison is made between the

compositions, flow rates, the temperature of the

CPC, and the flue gas streams. The simulation

results are depicted in Table 3 with the industrial

values. There is a good agreement between the

simulation results and the industrial results deviation

of 11%.

The comparison reveals that the prediction of

sulfur in the CPC is exact (zero error). However, the

zero sulfur is an over prediction since oxidation of

sulfur as predicted by equation (20) is considered

only in the vapor phase.

It was found that the predicted CPC temperature

is less than the industrial value by 0.9 %. However,

the CPC real density is a function of temperature

(Ibrahim and Ali, 2004), and hence the

underestimate of the CPC temperature will have

very little effect on the results.

The simulated flue gas temperature was higher

than the actual data by about 11%. This can be

explained by looking into the composition of the

Figure 2: HYSYS Simulation of Kiln Processes.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

8

Table 3: Simulation Results.

Stream GPC CPC FG Tertiary Fuel Fuel Air

Condition 1 2 1 2 1 2 1 2 1 2 1 2

Temperature (K) 293 293 1663 1650 1373 1499 293 293 293 293 293 293

Pressure ( kPa) 120 120 120 120 120 120 120 120 120 120 120 120

Flow Rate (kg/s) 9.7 9.762 7.44 7.27 20.60 20.62 14.0 14.0 0.276 0.276 4.77 4.77

Components Flow Rates ( kg/s)

C 7.925 7.925 - - 0.24 - - - - - - -

C* 0.0 0.062 - - - - - - - - - -

CH

4

0.394 0.394 - - 0.242 - - - 0.276 0.276 - -

H

2

0.528 0.528 - - 0.314 0.4 - - - - - -

C

18

H

12

0.134 0.134 - - 0.072 - - - - - - -

H

2

O 0.51 0.51 - - 3.03 3.41 - - - - - -

N

2

- - - - 14.34 14.34 10.68 10.68 - - 3.66 3.66

CO

2

- - - - 1.84 2.24 - - - - - -

CO - - - - 0.43 0.077 - - - - - -

SO

2

- - - - 0.060 0.069 - - - - - -

S 0.211 0.211 0.169 - 0.0055 - - - - - - -

O

2

- - - - - 0.057 3.24 3.24 - - 11.53 11.53

1 Industrial data , 2 this study , C* carbon dust

flue gas where almost all volatile components and

carbon dust were oxidized adding more heat than

that of the industrial case. Moreover, the assumption

of adiabatic operation would add to the overall rise

in temperature.

5 CONCLUSIONS

This paper addressed the determination and

adjustment of the green petroleum coke calcination

in order to meet the allowable limits of the calcined

coke specifications. The methodology is to simulate

the processes that describe green petroleum coke

calcination. The simulation was based on using

physical and chemical reaction rate equations. The

results of the simulation were compared with actual

industrial rotary kiln data and there was a good

agreement. The methodology of rate-based

simulation described in this study may be used to

predict coke calcining kilns performance regardless

of the green coke composition. The sensitivity of the

kiln performance to changes in green coke

composition, fuel and tertiary air flow rates is left

for future work. Further validations using industrial

data are also necessary.

REFERENCES

ALBA, Private communication.

Bui, R. T., Perron, J., and Read, M., 1993. Model-based

optimization of the operation of the coke calcining

kiln, Carbon. 31; 7; 1139-1147.

Dernedde, E, Charette, A., Bourgeois, T., and Castonguay,

L., 1986. Kinetic Phenomena of the Volatiles in Ring

Furnaces. Light Met. Pcoc. Tech, Sess. AIME 105

th

Annual Meeting. 589.

Elkanzi, E. M., 2007, Simulation of the Coke Calcining

Processes in Rotary Kilns, Chemical Product and

Process Modeling, 2, 3, Article 20.

Howard, J. B., Williams, G. C., and Fine, D. H., 1973.

Kinetics of Carbon Monoxide Oxidation in Post flame

Gases. 14

th

International Symposium on Combustion.

975-985.

Ibrahim, H. A., and Ali, M. M., 2005. Effect of the

removal of sulphur and volatile matter on the true

density of petroleum coke. Periodica Polytechnica Ser

Chem. Eng. 49, 1, 19-24

Li, K. W., and Friday, J. R., 1974. Simulation of Coke

Calciners. Carbon. 12; 225-231.

Lu, C-W, and Wu, Y-J., 2004. Experimental and

theoretical investigations of rate coefficients of the

reaction S (

3

P) + O

2

in the temperature range 298-878

K). Journal of Chemical Physics. 121, 17, 8271-8278.

Lyons, J. W., Min, H. S., Parisot, P. F. and Paul, J. F.,

1962. Experimentation with a Wet-Process Rotary

Cement Kiln via the Analog Computer. Ind. Eng.

Chem. Process Des.Dev. 1; 1; 29-33.

Martins, A. Marcio., Oliveira, Leandro. S., and Franca,

Adriana. S., 1992. Modeling and Simulation of

Petroleum Coke Calcination in Rotary Kilns. Fuel.

80; 1611-1622.

Perron, J., Bui, R. T., and Nguyen, T. H., 1992.

Modelisation du four de calcination du coke de

petrole: 2- simulation du procede. Can. J. Chem.Eng.

70; 1120 - 1131.

Perron, J., and Bui, R. T., 1990. Rotary Cylinders: Solid

transport Prediction by Dimensional Rheological

Analysis. Can. J.Chem.Eng. 68; 61 - 68.

Srinivasan, R. J., Srirmulu, S., and Kulasekaran, S., 1988.

Mathematical modeling of fluidized bed combustion-

2: combustion of gases. Fuel. 77, 9/10, 1033-1043.

Rate-basedSimulationofCokeCalcinationinRotaryKilns

9

APPENDIX

Nomenclature

A area per unit axial length, m.

C species molar concentration, kgmol/m

3

E activation energy, kj/kmol

G mass flow rate, kg/s

k rate constant, s

-1

.

L axial distance along the kiln, m.

MW molecular mass, kg/kmol

P

i

partial pressure of species i, kPa

R

i

rate of reaction of species i, kmol/m

3

. S

Sf total surface area of the coke fines/unit length of

the kiln, m.

T temperature, K.

u velocity, m/s.

V volume of gas in the kiln, m

3

.

X mass fraction, kg/kg.

y mole fraction, kmol/kmol.

Subscripts

b coke bed.

c coke or carbon

ch tar

g gas phase

l liquid phase

o initial

voc volatile organic compound

v volatile

w water

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

10