Elastomeric Seismic Isolators Behavior at Different Pads Thickness

Gabriele Milani

1

and Federico Milani

2

1

Politecnico di Milano, Piazza Leonardo da Vinci 32, 20133, Milan, Italy

2

Chem. Co Consultant, Via J. F. Kennedy 2, 45030, Occhiobello (RO), Italy

Keywords: Elastomeric Isolators, Hardness/Young’s Modulus, Elastic Modulus/Thickness, Stretch-stress and Shear

Behavior under Large Deformations, Numerical Simulations, Finite Element Method.

Abstract: A seismic isolator has the main function to be extremely deformable for horizontal forces, but at same time

sufficiently stiff when loaded with vertical actions. These properties may be strongly influenced by both the

isolator geometry (i.e. overall dimensions, number and thickness of rubber pads and steel laminas) and the

mechanical properties of rubber pads. Mechanical properties of the pads, especially Young modulus, may be

evaluated as a function of hardness, by means of consolidated empirical formulas. In this work, the

influence of rubber pads thickness and hardness on both vertical and horizontal stiffness of realistic seismic

isolators is discussed. Three full 3D Finite Element models referred to three different seismic isolators

having different slenderness are analysed in detail in both vertical compression (elastic analysis) and simple

shear in large deformations. Uniaxial and shear response of the seismic devices obtained numerically are

finally critically compared, with the aim of evaluating the best compound to be used in practice.

1 INTRODUCTION

In the recent past, seismic isolation technology has

been applied almost entirely to large buildings in

high seismicity countries, where seismic events are

expected to be relevant. One of the most diffused

technology for seismic isolation is the utilization of

elastomeric multilayer bearings. Until now, the high

cost of production reduces the use of seismic

isolation mainly for important buildings. Their cost

is due to the preparation of the steel plates, which

are used to provide vertical stiffness, and the

assembly of the rubber sheets. From a technical

point of view, the rubber has the main function to be

extremely deformable for horizontal forces, but at

the same time sufficiently stiff when loaded with

vertical actions. Each individual elastomeric layer in

the bearing deforms according to two kinematic

assumptions, i.e. that (1) horizontal planes remain

planar and (2) points on vertical lines lie on a

parabola after loading.

This is obtained thanks to the incompressibility

of the rubber sheets (Amin et al., 2002; 2006, Gracia

et al., 2010) and the introduction of the thin

reinforcing steel plates, interspersed between 10-30

mm thick rubber pads (Moon et al., 2002; 2003).

Kelly and co-workers (e.g. Tsai and Kelly, 2002)

have demonstrated that theoretically it is possible to

substitute reinforcing elements of multilayer

elastomeric isolation bearings, which are normally

steel plates, by fiber reinforcement. This solution

goes to a drastically reduction in the weight and

probably in the reduction of the cost in the assembly

of the items. Milani & Milani (2012) have described

a numerical approach to predict the macroscopic

behavior of parallelepiped elastomeric isolators

undergoing large deformations. In that work, the

actual behaviour of elastomeric sheets as a function

of the typology of rubber used and their compounds

were discussed. Following the original approach

proposed in Milani & Milani (2012), in the present

work, with the aim of reducing the production cost,

we have theoretically considered the opportunity to

increase the thickness of the rubber sheets and

decrease the steel plates. This geometrical

rearrangement provides a decrease of the vertical

stiffness but at the same time a good performance

under horizontal loads. When the rubber pad

thickness is increased up to 3.5 cm, it would be

necessary to consider the kinetic of vulcanization of

the rubbers sheets, in order to obtain mechanical-

elastomeric characteristics as homogeneous as

possible in any point of the rubber pad. This would

allow to obtain responses for horizontal forces of the

17

Milani G. and Milani F..

Elastomeric Seismic Isolators Behavior at Different Pads Thickness.

DOI: 10.5220/0004012000170023

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 17-23

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

isolator similar to those obtained with thin sheets. As

it is known, the mechanical elastic behavior can be

correlated to the density of the cross-link, that is

function of the thickness, the dimensions, the type of

rubber and the compound. For these reasons, it is

necessary to optimize the vulcanization in terms of

time/temperature in such a way that in all points of

the items there are similar mechanical-elastomeric

characteristics and in order to obtain pads with a

hardness directly proportional to pad thickness. As a

matter of fact, mechanical properties of the pads,

especially Young modulus, at a first attempt and

without the possibility to perform expensive

mechanical simulations, may be evaluated as a

function of hardness, by means of consolidated

empirical formulas. In this work, the influence of

rubber pads thickness and hardness on both vertical

and horizontal stiffness of realistic seismic isolators

is discussed. Three full 3D Finite Element models

referred to three different seismic isolators having

different slenderness (and hence thickness of the

rubber pads) are analysed in detail in both vertical

compression (elastic analysis) and simple shear in

large deformations. Uniaxial and shear response of

the seismic devices obtained numerically are finally

critically compared, with the aim of evaluating the

best compound to be used in practice.

2 CURED RUBBER

MECHANICAL PROPERTIES

AS A FUNCTION OF

HARDNESS

At present, the influence of pads thickness in the

seismic isolation performance of rubber bearings is

not completely understood in terms of types of

elastomers, optimal recipe, ingredients of

vulcanization to be used to increase both the

mechanical performance and reduce costs. In this

paper, three different thicknesses of rubber pads are

considered and the vertical stiffness of the isolators

so obtained is evaluated in conjunction with the

shear behavior.

As a matter of fact, the utilization of thick pads

provides a decrease of the vertical stiffness, which

obviously depends on the elastic modulus of the

rubber used.

In general, the so-called static modulus of a

rubber compound is obtained in standard stress-

strain tests in which the samples are extended at the

rate of 20 in/min. The dynamic modulus is measured

while the sample is oscillated about some given

strain or stress, usually under some fixed

superimposed load. Hardness is a modulus measured

at very small deformations, commonly obtained by

means of the use of indenter devices.

The static moduli at 300% extension, the

dynamic moduli and the hardness data have been

extensively studied by Studebaker & Beatty (1978).

Usually modulus and hardness of a stock are

increased through the use of fillers. As a

consequence, both modulus and hardness depend on

the so called filler “structure” (or more specifically

on carbon black structure) and cross-linking density.

Dealing with commercial compounds, which are

rather random and heterogeneous, it is difficult to

collect data regarding Young modulus and hardness

and draw any generalization.

The standard test method to have an idea of

rubber mechanical properties still remains

ASTMD2240, which deals with the penetration of a

specified indentor forced into the material under

specified conditions. The test is called “durometer

test”.

Durometer, like many other hardness tests,

measures the depth of an indentation in the material

created by a given force on a standardized presser

foot. This depth is dependent on the hardness of the

material, its viscoelastic properties, the shape of the

presser foot, and the duration of the test. ASTM

D2240 durometers allows for a measurement of the

initial hardness, or the indentation hardness after a

given period of time. The basic test requires

applying the force in a consistent manner, without

shock, and measuring the hardness (depth of the

indentation). If a timed hardness is desired, force is

applied for the required time and then read. The

material under test should be a minimum of 6.4 mm

(.25 inch) thick.

There are some empirical formulas that correlate

indentation hardness to penetration, elastic modulus

and viscoelastic behavior of the material.

For instance, the following external force-

hardness empirical law holds for a so called type A

durometer:

A

HN 075.0550.0:Force +=

(1)

where H

A

is the hardness read on a type A

durometer.

Conversely, for a so called type B durometer the

following formula may be used:

D

HN 4445.0:Force =

(2)

where H

D

is the hardness reading on a type D.

The difference between type A and type D

durometers stands exclusively on the geometry of

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

18

the device.

Type A durometer is a hardened steel rod with

diameter 1.1- 1.4 mm, with a truncated 35° cone of

diameter 0.79 mm. Type D durometer is a hardened

steel rod having a diameter of 1.1- 1.4 mm, with a

30° conical point and 0.1 mm radius tip.

Under small deformations rubbers are linearly

elastic solids. Because of the high modulus of bulk

compression, about 2000MN/m

2

, compared to the

shear modulus G, about 0,2-5MN/m

2

(Tobolsky and

Mark, 1971), they may be regarded as relatively

incompressible. The elastic behavior under small

strains can thus be described by a single elastic

constant G, being Poisson’s ratio very near to ½ and

Young’s modulus E equal to 3G with very good

approximation.

In order to have the possibility to evaluated the

relation between hardness and Young’s modulus,

first of all we have taken into consideration a semi

empirical relation between the shore hardness and

Young’s modulus for elastomers that has been

derived by Gent (1958; 1978). This relation has the

following form:

()

()

S54.2254137505.0

S62336.7560981.0

−

+

=E

(3)

where E is the Young’s modulus in MPa and S is the

shore hardness. This relation gives a value of E

equal to infinite at S=100, but departs from

experimental data for S lower than 40.

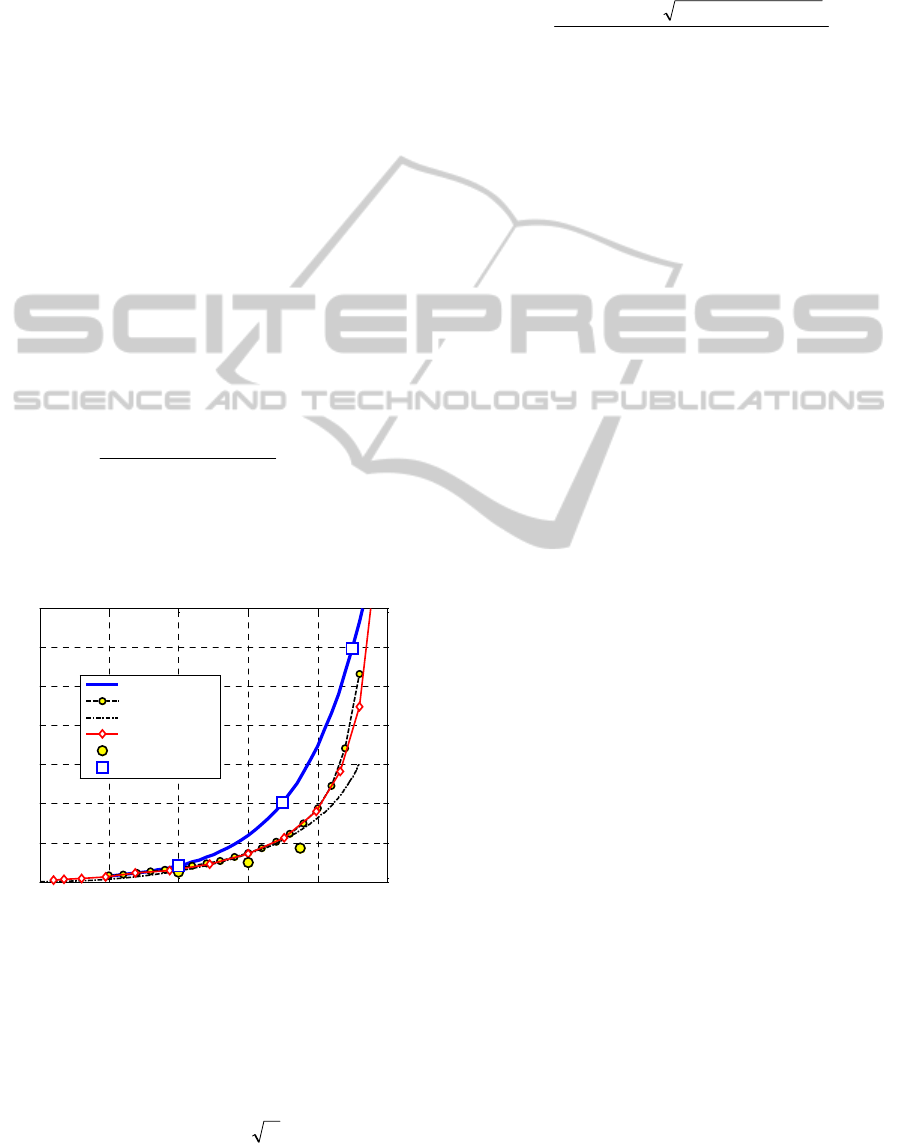

Figure 1: Empirical dependence of the rubber elastic

modulus in terms of international hardness (formula

(6).

Circle, square and triangle denote elastic moduli used in

the numerical simulations.

Another relation that fits experimental data

slightly better is the following and is reported into

British standards (BS 1950, BS 1957):

(

)

Eerf

4

10186.3100S

−

×=

(4)

where erf is the error function and E is in units of

Pa. A first order estimate of the relation between

shore D hardness and the elastic modulus for a

conical indenter with a 15 degree cone is:

(

)

E

E

D

88.78136.6113188.7820

100S

++−

−=

(5)

where S

D

is the shore D hardness and E is in MPa.

Another linear relation between the shore

hardness and the natural logarithm of Young’s

modulus is applicable over a large range of shore A

and shore D hardness (Qi et al., 2003). This relation

has the form:

6403.0S0235.0)ln( −=E

(6)

Where S= S

A

for S

A

between 20 and 80 and S=

S

D

+50 for S

D

between 30 and 85, being S

A

the shore

A hardness, S

D

the shore D hardness and E the

Young’s modulus in MPa.

In our theoretical work, we have considered an

ideal rubber item with different hardness and have

calculated the corresponding Young’s modulus.

From that value, we have deduced the influence of

the thickness of the compounding rubber materials

for the optimal stiffness vertical resistance.

However, hardness is a superficial determination and

for this reason it is necessary to optimize also the

density of cross-linking at same recipe. While this

latter issue is extremely important, our work focuses

on the possibility to increase the thickness of rubber

pads to optimize the elastic properties of the items,

such as initial compression modulus and shear

behavior under large deformation.

The typical dependence of rubber Young

modulus E with respect to hardness S, obtained by

means of the empirical formulas discussed above is

schematically represented in

Figure 1.

As it is possible to notice and as expected, there

is a quite large scatter of the results for rubbers with

big hardness. However, formulas suggested by

ASTM 1415 and BS 903 provide very similar results

in a wide range, also for S near 80. Despite the fact

that Qi et al., (2003) formula seems less

conservative for hard rubbers, authors adopted such

approach to evaluate Young modulus to use in the

numerical simulations, being Qi et al., (2003)

approach based on a convincing experimental and

theoretical framework.

0 20 40 60 80 100

0

5

10

15

20

25

30

35

Hardness S

Young Modulus [MPa]

Qi et al. (2003)

Gent (1958)

BS 903 (1957)

ASTM 1415

FIP experimental

Present data

ElastomericSeismicIsolatorsBehavioratDifferentPadsThickness

19

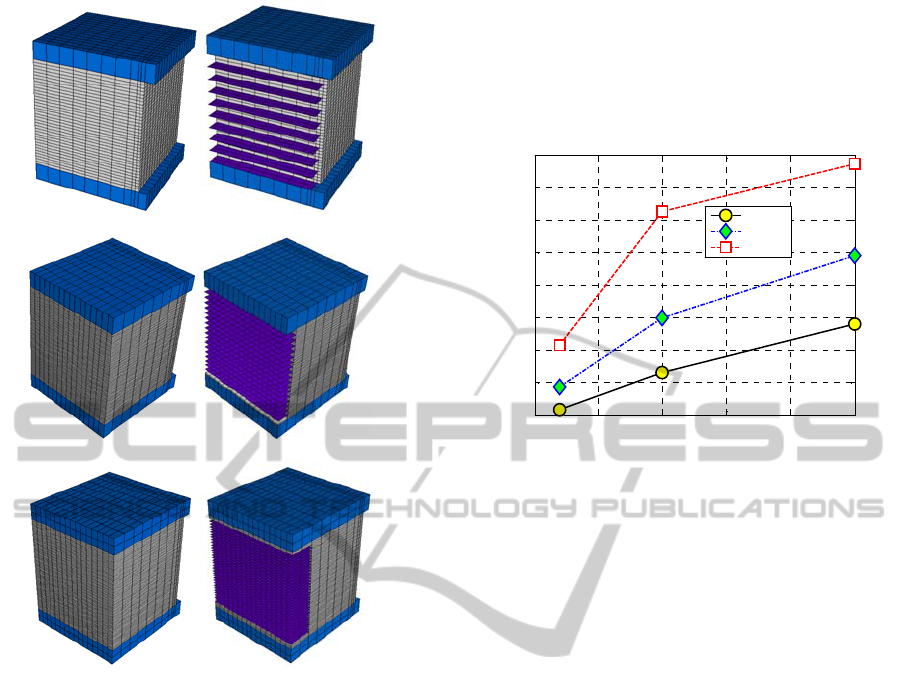

Figure 2: FE discretization of the seismic isolators studied.

3 NUMERICAL FINITE

ELEMENT SIMULATIONS ON

ELASTOMERIC ISOLATORS

One of the key parameters having a fundamental

role in the determination of overall isolator

compression elastic modulus E

c

is the so called

shape factor S

F

(or primary shape factor), defined as

the ratio between the loaded area and the lateral

surface free to bulge. Since the shape factor refers to

the single rubber layer, it represents a measure of the

local slenderness of the elastomeric bearing.

Experimental tests have shown that low shape factor

bearings, characterized by values of S

F

greater than

5 and less than 20 (in the present case S

F

=7), provide

an isolation effect in both the horizontal and vertical

directions whereas high shape factor bearings,

characterized by values of S

F

greater than 20, only

provide a good isolation in the horizontal direction.

It is even obvious that low values of the shape factor

define thick rubber layers and, hence, provide

bearings characterized by high deformability. As a

rule, in seismic isolation applications the need to

have a device with a high vertical stiffness and low

shear stiffness requires that S assumes values greater

than 5 and less than 30.

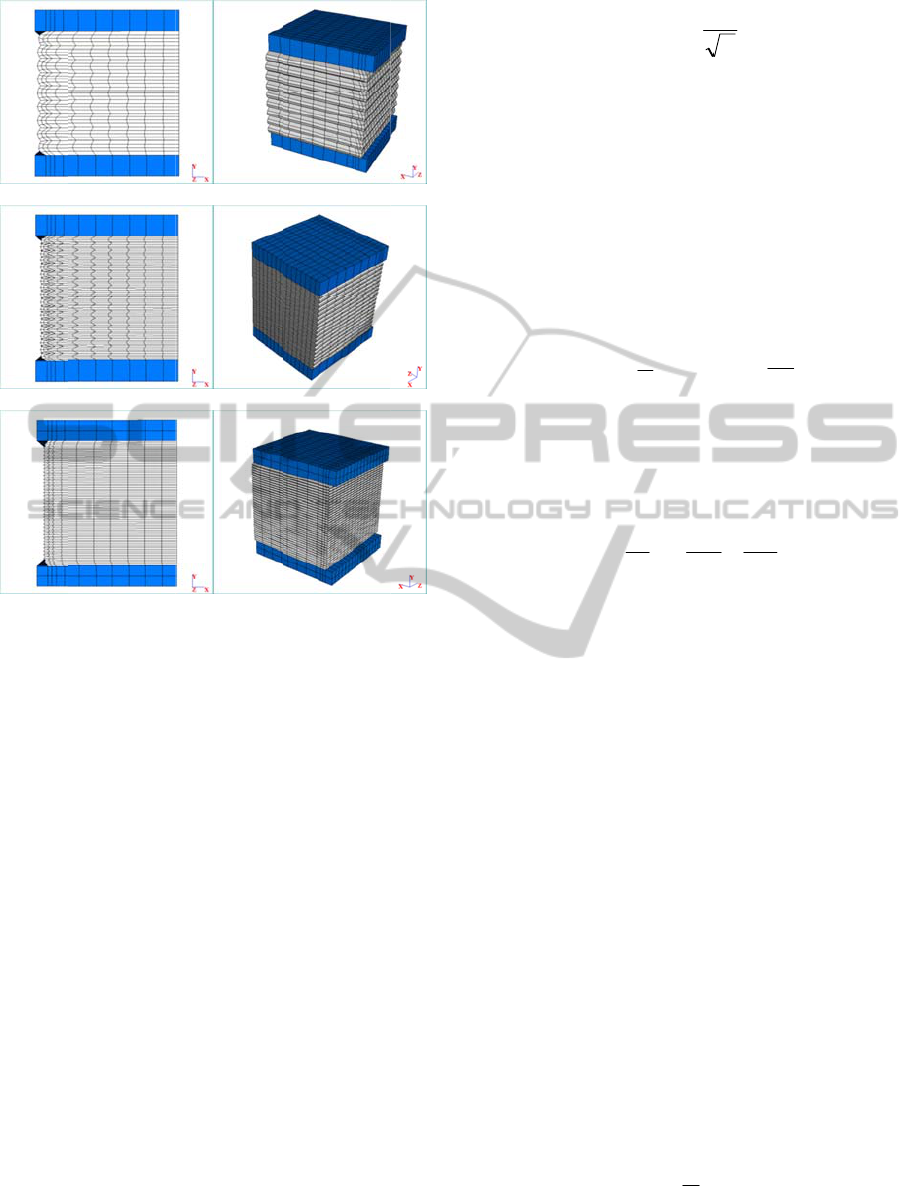

Figure 3: Isolator vertical elastic modulus varying shape

factor and rubber hardness.

Three geometric cases corresponding to shape

factors S

F

equal to 7, 15 and 30 are hereafter

considered. In these cases, the thicknesses of the

single pad are approximately respectively equal to 5,

8.5 and 18 mm, assuming a width of the isolator

equal to 500 mm (square isolators) and a total

thickness equal to 250 mm. Assuming in the first

case a thickness of steel laminas equal to 1 mm, in

the second 2 mm and in the third 3 mm, the number

of steel plates to be used on such devices is

respectively equal to 38, 19 and 9.

Three refined discretizations are adopted in the

numerical simulations discussed in this Section, as

depicted in Figure 2. For rubber, eight-noded bricks

elements are used, whereas for steel laminas four-

noded plate and shell elements are adopted, to

properly take into account both the in-plane and the

out-of-plane effect induced by steel bending.

Obviously, the isolator with shape factor S=30

requires several elements, due to the reduced

thickness of the pads, namely 12224 bricks, 5328

plates and 14501 nodes.

Elastic analyses under small deformations are

performed to characterize the vertical elastic

modulus in compression, which is represented in

Figure 3, at different values of the shape factor

and for the three blends represented in

Figure 1 with

squares.

5 10 15 20 25 30

0

2000

4000

6000

8000

10000

12000

14000

16000

First shape factor

E

eq

[MPa]

Soft

Medium

Hard

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

20

Figure

Obv

i

factor a

n

elastic

m

b

etween

shape f

a

should

b

soft bl

e

p

rogress

lower s

h

In

F

isolators

role pla

y

p

articul

a

To

s

under la

r

Rivlin

m

Defi

n

length i

n

length i

n

stretch i

n

corresp

o

stresses

32

=

σσ

incompr

e

4: Deformed s

h

i

ously elastic

n

d is maximu

m

oduli of a

1500 and 7

5

a

ctor equal to

b

e used. Con

v

e

nds could

h

ively decreas

e

h

ape factors h

a

F

igure 4, d

e

under vertic

a

y

ed by the si

n

a

rly evident.

s

tudy the sh

e

r

ge deformat

i

m

odel is utiliz

e

n

ed the stre

t

n

the deform

e

n

the undefo

r

n

the directio

n

o

nding stres

s

are zero, sin

c

0=

. For

e

ssibility con

d

h

apes for verti

c

modulus inc

r

m for the ha

r

seismic isol

a

5

00 MPa, m

e

15, a mediu

m

v

ersely, for hi

g

h

ave the b

e

e

vertical stif

f

a

rd blends are

e

formed sha

p

a

l compressi

o

n

gle rubber p

a

e

ar behaviou

r

i

ons, a two c

o

e

d in what fol

l

t

ch as the r

a

e

d configurati

o

r

med state, l

e

n

of elongati

o

s

. The othe

r

c

e no lateral

f

constancy

o

d

ition

321

λλλ

c

al compressio

n

r

eases with s

h

r

d blend. Usu

a

tor should r

a

e

aning that

f

m

or a soft b

g

her shape fa

c

e

neficial rol

e

f

ness, wherea

s

preferable.

p

es of the

t

n are shown.

a

d free to bul

g

r

of the isol

a

o

nstants Moo

n

l

ows.

a

tio between

o

n divided b

y

e

t

λλ

=

1

be

o

n and

σ

σ

=

1

r

two prin

c

f

orces are ap

p

o

f volume,

1=

gives:

n

s.

h

ape

u

ally,

a

nge

f

or a

b

lend

ctor,

e

to

s

for

t

hree

The

g

e is

a

tors

n

ey-

the

y

the

e

the

σ

the

c

ipal

p

lied

the

M

o

W

h

det

e

tes

t

hol

d

un

s

uni

a

de

n

uni

a

dis

p

p

ri

n

ax

e

gra

d

de

fo

as

for

ha

v

The strain

e

o

oney-Rivlin

m

=W

where

2

1

1

λ

=I

h

ere

1

C

and

e

rmined for i

n

t

.

In uniaxial t

e

d

and therefo

r

λ

1

=I

The engine

e

s

trained area

a

xial tensile

t

n

sity as follo

w

⎜

⎝

⎛

= 12'S

In simple s

h

a

xial compr

e

p

lacement do

e

n

cipal stretch

e

s. Due to app

d

ient tensor

fo

rmation tens

⎢

⎢

⎢

⎣

⎡

=

00

10

1

γ

F

Consequentl

y

21

3== II

Cauchy stres

s

2

12

T =

γ

In pure she

v

e the followi

n

λλ

32

==

n

ergy functi

o

m

odel is:

()

3

21

+−

C

IC

2

3

2

2

2

1

λλ

++

an

d

2

C

are mat

e

n

stance by a

s

e

nsion or co

m

r

e:

λ

λ

2

2

+

1

=I

e

ring stress

o

f cross-sect

i

t

est may be

e

w

s:

⎜

⎜

⎝

⎛

∂

∂

⎟

⎠

⎞

−

1

3

1

I

W

λ

λ

h

ear deformat

e

ssion, the

e

s not coinci

d

e

s; rather it

i

l

ied shear str

a

F

and th

or

B

are de

s

⎥

⎥

⎥

⎦

⎤

1

0

0

⎢

⎢

⎢

⎣

⎡

=

1

B

y

, the strain i

n

2

γ

+

,

3

=I

s

becomes:

/[

1

IW +∂∂

γ

a

r deformati

o

n

g form:

1

1

3

2

1

=

=

=

λ

λ

λ

λ

λ

λ

1

o

n for a tw

o

()

3

12

−I

C

d

2

12

−

+=

λ

λ

I

e

rial paramet

e

s

imple uniaxi

a

m

pression equ

a

2

1

2

λ

λ

+

'S

(force

i

on) in the c

a

e

valuated fro

m

⎟

⎟

⎠

⎞

∂

∂

+

2

1

I

W

W

t

ion and diff

e

direction o

f

d

e with the di

r

involves a r

o

a

in

γ

, the de

f

h

e left Cau

c

s

cribed as:

+

100

0

1

0

1

2

γ

γγ

n

variants are

e

1

and the e

x

]/

2

IW ∂∂

o

n

p

rincipal

(7)

o

constats

(8)

2

3

2

2

−−

+

λ

λ

.

e

rs to be

a

l tension

a

tions (7)

(9)

per unit

a

se of an

m

energy

(10)

e

rently to

f

applied

r

ection of

o

tation of

f

ormation

hy-Green

⎥

⎥

⎥

⎦

⎤

0

0

(11)

e

xpressed

x

pression

(12)

stretches

(13)

ElastomericSeismicIsolatorsBehavioratDifferentPadsThickness

21

Consequently, the strain invariants are expressed

as

1/1

22

21

++==

λλ

II

and the expression for

Cauchy stress becomes:

()

⎟

⎠

⎞

⎜

⎝

⎛

−−−=− 1

1

212

2

2

2

13311

λ

λσσ

CC

()

⎟

⎠

⎞

⎜

⎝

⎛

−+−−=− 1

1

212

2

1

2

23322

λ

λσσ

CC

()

⎟

⎠

⎞

⎜

⎝

⎛

−+=−

2

2

212211

1

2

λ

λσσ

CC

(14)

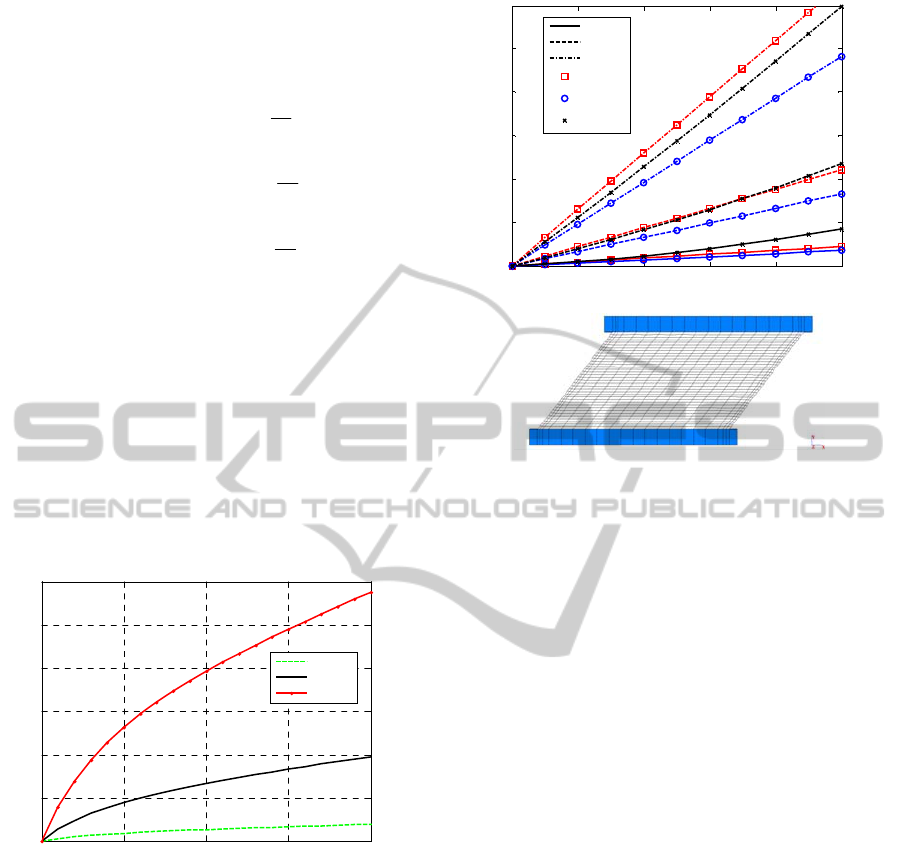

The normal behaviour under large deformations

of the single pad is shown in

Figure 5

. Such a response under large

deformations is fully determined once known the

two Mooney-Rivlin constants

1

C

and

2

C

. However,

the initial Young Modulus gives only one

information on such constants (G=2(

1

C

+

2

C

)). In

what follows we therefore assume

1

C

=G/2 and

2

C

=0, in absence of experimental data on constituent

materials, which corresponds to a Neo-Hookean

material.

Figure 5: Stretch-stress behaviour of a single rubber pad

(top) and pure shear behaviour under large deformations

(bottom).

Having at disposal

1

C

and

2

C

constants, a

standard large deformation software is utilized to

plot the response of the whole isolator in shear, as

sketched in Figure 6.

Figure 6

is particularly important for practical

purposes, because the curves may be implemented at

a structural level to study entire base-isolated

buildings in the dynamic range.

Figure 6: Force-displacement curves in shear under large

deformations and corresponding deformed shape (S=7).

As it is possible to notice, the utilization of

different hardness rubber pads in conjunction with

slender or less slender isolators may considerably

change the macroscopic response of the isolator and,

hence, the effectiveness of the device inserted in a

large case structure may be variable.

4 CONCLUSIONS

The important matter of the role played by the

thickness of rubber pads within seismic isolators is

not well covered in the literature. From our

theoretical investigation, it is shown that a proper

calculation is needed when the item involves a high

thickness and a large volume of the elastomer

compounds. Hardness is a very important parameter

to define rubber initial Young’s modulus, that is the

main parameter to define the possibility that a

predetermined thickness of the rubber pad is able to

suitably support the vertical load. As it is known, the

hardness determination, in general, is done on the

surface of the items and this is function, at same

recipe and rubber type, of the cross-link density. For

this reason it will be required to deepen such

preliminary results considering a particular rubber

type, an experimental recipe and a mathematical

approach to define the optimal vulcanization

time/temperature and subsequently link these

parameters with the hardness, to evaluate an optimal

1 1.5 2 2.5 3

0

10

20

30

40

50

60

Stretch

λ

[ ]

Engineering stress S' [MPa]

Soft

Medium

Hard

0 100 200 300 400 500

0

1000

2000

3000

4000

5000

Horizontal displacement [mm]

F shear force [kN]

Soft

Medium

Hard

S

F

=7

S

F

=15

S

F

=30

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

22

cross-link density in any point of the items,

especially for isolators with big dimensions.

Another important parameter that will be

investigate is the hysteresis loss and thermo-

mechanical behavior that, as known, can be

correlated to the dynamic behavior based on cross-

link structures. Finally, it will be considered the

aging or the stability of the rubber items, that in

general depends on the structure of the elastomer

used. In our theoretical work it is shown that a

proper calculation is needed when a product

involves a large volume of the rubber items in the

seismic isolators. It is suggested to consider the

following steps for a choice of the optimal thickness

of the pads as a function of predetermined hardness,

which also allows to increase the volume of rubber

and decrease the number of the steel plates:

1) Calculation of the Young’s modulus from

hardness.

2) Calculation of the maximum vertical stiffness

supported.

3) Determination of the stretch-stress behaviour

of the single rubber pad.

4) Determination of the shear behaviour of the

whole isolator under large deformations.

5) Utilization of the stretch-stress and the shear

behaviour in order to define the best solution for a

single building.

6) Combination of the technical characteristics

of the rubber pads and the steel laminas to minimize

the cost, in order to introduce the seismic isolation

technology in large buildings in high seismicity

countries. The authors are convinced that this

approach could be in the future the normal routine to

design new buildings.

REFERENCES

Amin, A. F. M. S., Alam, M. S., Okui, Y., 2002. An

improved hyperelasticity relation in modeling

viscoelasicity response of natural and high damping

rubbers in compression: experiments, parameter

identification and numerical verification. Mech. Mater.

34: 74-95.

Amin, A. F. M. S., Wiraguna, I., Bhuiyan, A. R., Okui, Y.,

2006. Hyperelasticity Model for Finite Element

Analysis of Natural and High Damping Rubbers in

Compression and shear. Journal of Engineering

Mechanics ASCE, 132(1): 54-64.

British Standard 903, 1950, 1957. Methods of testing

vulcanized rubber, Part 19 (1950) and Part A7 (1957).

Gent, A. N., 1958. On the relation between indentation

hardness and Young’s modulus. Institution of Rubber

Industry – Transactions, 34: 46-57.

Gent, A. N., 1978. Rubber elasticity: basic concepts and

behavior. In: Science and Technology Rubber (Ed.: F.

R. Eirich), Academic Press, NY, San Francisco,

London.

Gracia, L. A., Liarte, E., Pelegay, J. L., Calvo, B., 2010.

Finite Element simulation of the hysteretic behavior

on industrial rubber. Application to design rubber

components. Finite Elements in Analysis and Design

46: 357-368.

Milani, G., Milani, F., 2012. Stretch-stress behavior of

elastomeric isolators with different rubber materials. A

numerical insight. Journal of Engineering Mechanics

ASCE, in press.

Moon, B. Y., Kanga, G. J., Kanga, B. S., Kim, G. S.,

Kelly, J. M., 2003. Mechanical properties of seismic

isolation system with fiber-reinforced bearing of strip

type. International Applied Mechanics, 39(10): 1231-

1239.

Moon, B. Y., Kanga, G. J., Kanga, B. S., Kim, G. S.,

Kelly, J. M., 2002. Design and manufacturing of fiber

reinforced elastomeric isolator for seismic isolation.

Journal of Materials Processing Technology, 130-131:

145-150.

Qi, H. J., Joyce, K., Boyce, M.C., 2003. Durometer

hardness and the stress-strain behavior of elastomeric

materials. Rubber Chemistry and Technology, 72(2):

419-435.

Studebaker, M. L., Beatty, J. R., 1978. The rubber

compound and its composition. In: Science and

Technology of Rubber (Ed.: F.R. Eirich), Academic

Press, NY, San Francisco, London.

Tobolsky, A. V., Mark, H. F., 1971. Polymer Science and

Materials. Chap.13 (Ed.: Wiley) New York.

Tsai, H. S., Kelly, J. M., 2002. Stiffness Analysis of Fiber-

Reinforced Rectangular Seismic Isolators. Journal of

Engineering Mechanics ASCE, 128(4): 462-470.

ElastomericSeismicIsolatorsBehavioratDifferentPadsThickness

23