Dynamic Model of a 7-DOF Whole Arm Manipulator and Validation

from Experimental Data

Zaira Pineda Rico, Andrea Lecchini-Visintini and Rodrigo Quian Quiroga

Department of Engineering, University of Leicester, University Road, Leicester, U.K.

Keywords:

Whole Arm Manipulator Model, Friction Model, Friction Identification.

Abstract:

The present paper describes the design of the dynamic model of a 7 degrees of freedom whole arm manipulator

implemented in SimMechanics. The friction phenomena of the manipulator is identified, represented through

a fitted model and included in the system model with the aim of increment the accuracy of the model with

respect to the real system. The characteristics of the model make it suitable to test and design control strategies

for motion and friction compensation in MATLAB/Simulink.

1 INTRODUCTION

The computation of the dynamic model of a robot ma-

nipulator plays an important role in simulation of mo-

tion, analysis of the manipulator’s structure and de-

sign of optimal control algorithms. The inclusion of

the effects of friction in a mechanical system model

when simulating control strategies, helps to improve

the performance of the controller to be implemented

in the real system (Kostic et al., 2004; Indri, 2006;

Bompos et al., 2007). Most of the whole arm manip-

ulators mathematical models are based in the com-

putation of multi-links serial robot’s mathematical

equations. These equations are obtained using the

Newton-Euler recursive method to calculate the Cori-

olis, centrifugal and inertial forces observed when the

end-effector is in motion. Moreover, a Jacobian ap-

proach may be implemented in parallel for mapping

between Cartesian and joint space, in order to mini-

mize singularity conditions that increase the computa-

tion load of the control algorithm (Lau and Wai, 2002;

Sousa et al., 2009). This methodology involves both

operational and joint forces.

In most cases these mathematical models are

implemented using high level computing languages

as MATLAB (Corke, 1996), C/C++ or Fortran.

Nevertheless, in order to avoid significant com-

putation time, some authors have found in MAT-

LAB/SimMechanics a comfortable tool to design me-

chanical systems used for experimental verification.

The capability of this tool yields appropriate results

when working with joints with 1 DOF and when

all the manipulator’s inertial parameters are known

(MathWorks, 2011).

Section 2 offers a brief description of the real ma-

nipulator system. Section 3 gives insights on the de-

sign of the model and shows the importance of exper-

imental data in the development of the friction model.

In Section 4 the response of the real system is com-

pared to that of the model when simulating some ex-

periments. Finally, section 5 presents some conclu-

sions related to this work.

2 THE REAL SYSTEM

The real system is a 7-degrees-of-freedom whole arm

manipulator (WAM) from Barrett Technology Inc. It

is a joint torque controlled manipulator equipped with

configurable PD/PID control and gravity compensa-

tion. The information related to the joints configu-

ration, joint motor drives and the body part masses,

centre of gravity and inertia matrix is provided by the

manufacturer in the WAM ARM User’s Manual (Bar-

rett Technology Inc, 2008). Figure 1 shows the con-

figuration and attached frames of the 7-DOF system

with a grasper. All the joints of the manipulator are

1 DOF revolute joints. An image of the real system

is shown in Figure 2, consisting in a Barret 7-DOF

Whole Arm Manipulator with an attached BH8-series

BarrettHand.

For the developmentofthis projectthe 7-DOF ma-

nipulator is configuredwithjoint PD control and grav-

ity compensation given by Equation (1), where the

joint torque τ is expressed as the sum of the difference

217

Pineda Rico Z., Lecchini-Visintini A. and Quian Quiroga R..

Dynamic Model of a 7-DOF Whole Arm Manipulator and Validation from Experimental Data.

DOI: 10.5220/0004013002170222

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 217-222

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

Z4

X3,X4

Z3

J4

J1,J3

Z0,Z2

X0,X1,X2

Z1

J2

Zbase

Xbase

Xtool

Ztool

X5,X6

X7

J5,J7

Z6,Z7

Z5

J6

Figure 1: WAM 7-DOF Denavit-Hartenberg architecture

with attached frames as shown in (Barrett Technology Inc,

2008).

Figure 2: The Barret 7-DOF Whole Arm Manipulator with

the BH8-series BarrettHand.

between the reference and measured position, namely

position error ˜q, multiplied by a constant proportional

gain K

P

, the derivative of the error

˙

˜q multiplied by a

respective derivative gain K

D

and the compensation

for gravity g, which is a function of the joint position.

τ = K

P

˜q+ K

D

˙

˜q+ g (1)

The WAM joint PD control block diagram is shown

in Figure 3. The control loop uses the reference sig-

nal r(t), namely a joint trajectory, and the measured

position y(t) to compute the present error. Then the

derivative of the error is calculated, and the gravity

compensation is added to conform the joint torque

u(t) to be applied to the manipulator’s joint.

_

+

lIr(t)

lIy(t)

P

+

lu(t)

K

P

Ks

D

+

+

I

I

g( )y(t)

+

ie(t)

Figure 3: Configuration of the joint PD control with grav-

ity compensation. r(t) is the reference trajectory, e(t) is

the response error, P represents the manipulator, g(y(t)) is

the gravity compensation, K

D

and K

P

are the derivative and

proportional gains, respectively.

3 THE MODEL

The 7-DOF WAM model is built by four blocks:

• Seven modules that compute the joint reference

trajectories.

• The dynamic model of the system.

• Fitted friction models for each joint of the manip-

ulator.

• Joint PD controllers configured and tuned as those

implemented in the real system.

The dynamic model of the manipulator is based on

the configuration and physical characteristics of the

real system, the parameters of the friction model are

determined through the identification of the joint fric-

tions whilst the joint trajectory and joint controller are

emulations of those existent on the real system.

3.1 Trajectory Generation

The reference signal used to perform every joint ro-

tation is a linear segment parabolic blend (LSPB) tra-

jectory defined as follows. Up to a time t

c

the trajec-

tory is parabolic with linear velocity, at tc the trajec-

tory chances to linear with constant velocity and zero

acceleration, finally after a time (t

f

− t

c

) the trajec-

tory changes to parabolic again and the velocity de-

creases linearly until reaching zero. The motion pro-

duced when applying this velocity profile to any joint

is translated in a rotation from the initial joint posi-

tion q

i

of the manipulator to q

f

radians. Equation (2)

defines the described trajectory, where q

i

is the initial

position, q

f

is the final position reached in a time t

f

,

˙q

c

= ¨q

c

t

c

is the value of the constant velocity exhib-

ited from time t

c

to time (t

f

− t

c

) and ¨q

c

is the value

of the desired constant acceleration.

q(t) =

q

i

+

1

2

¨q

c

t

2

0 ≤ t ≤ t

c

1

2

(q

f

+ q

i

− ˙q

c

t

f

) + ˙q

c

t t

c

< t ≤ t

f

−t

c

q

f

−

1

2

¨q

c

(t

f

−t)

2

t

f

−t

c

< t ≤ t

f

(2)

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

218

0 1 2 3 4 5 6 7

-0.6

-0.4

-0.2

0

[rad]

[s]

Position

0 1 2 3 4 5 6 7

0

0.05

0.1

[s]

Velocity

0 1 2 3 4 5 6 7

-0.1

0

0.1

[rad/s

2

]

[s]

Acceleration

[ rad/s]

l

Figure 4: Example of a trapezoidal velocity profile when

the values of the variables are set as follows q

i

= −0.55,

q

f

= −0.05 rads, ¨q

c

= 0.083 rads/s, t

f

= 7s and t

c

= 1.

An example of the trajectory given by Equation (2)

can be seen in Figure 4 where a rotation of 0.5 rads is

performed.

In order to generate the LSPB joint trajectory, the

real system sets the value of the time of change tc as

1, and the velocity ˙q

c

and acceleration ¨q

c

are calculated

using Equations (3) and (4), taking into account the mea-

sured values of the initial and the final joint position q

i

and q

f

.

In simulations, the joint trajectory is emulated by the

model considering the experimental values of the initial

joint position q

i

, the final joint position q

f

and the exe-

cution time t

f

. The value of t

c

is set as 1 and the velocity

and acceleration are also calculated using Equations (3)

and (4). Finally, taking all the parameters previously es-

timated, the joint trajectory is generated using Equation

(2).

˙q

c

=

4(q

f

− q

i

)

t

2

f

− (−2(t

c

− 0.5t

f

))

2

(3)

¨q

c

= ˙q

c

(4)

3.2 The Dynamic Model

The dynamic model equation for a robot manipulator is

generally written in the form (Siciliano et al., 2009):

B(q) ¨q+C(q, ˙q) ˙q+ G(q) + F = τ (5)

where q, ˙q, ¨q are the position, velocity and acceleration

vectors of all the joints that shape the manipulator, B(q)

is the inertial matrix, C(q, ˙q) ˙q is the Coriolis-Centrifugal

matrix, G(q) is the gravity vector and F is the vector of

friction, which is usually obtained using a fitted friction

model.

The dynamic model of the WAM Arm was designed

and simulated using MATLAB/SimMechanics, and most

of the inertial data provided by the manufacturer had to

be adapted according to the inertial reference system.

The MATLAB/SimMechanics toolbox is a block dia-

gram modelling environment like Simulink, created by

MATLAB, to design and simulate mechanical systems.

The toolbox contains several modules that represent par-

ticular bodies and which inertial properties can be spec-

ified by the user.

A great advantage of using SimMechanics in mod-

elling mechanical systems is that the toolbox is prompt

to be used with Simulink so that control routines can be

added with ease in order to analyse the behaviour of the

system’s dynamics under motion constraints.

700 800 900

-1

-0.5

0

0.5

1

1.5

2

DataforfrictionmodellingJ1

Position[rads]

Samples(T=0.01s)

0 50 100 150 200 250 300 350 400

0.3

0.32

0.34

0.36

0.38

0.4

Samples(T=0.01s)

.Id

_

.idt

0 100 200 300 400 500

1

2

3

4

5

6

Torque[Nm]

4

4.5

5

5.5

6

Samples(T=0.01s)

0 100 200 300 400 500

Velocity[rad/s]

0 50 100 150 200 250 300 350 400

Samples(T=0.01s)

Torque[Nm]

Figure 5: Register of position and torque in the Barret WAM

when rotating joint 1 by 0.5 rads.

3.3 The Friction Model

Friction phenomena in robot manipulators may affects

the accuracy of the system in position control and when

moving the manipulator at very low velocities. Most

of the friction models employed when modelling posi-

tion controlled mechanisms, include several components

as the sliding friction (or Coulomb friction), the break-

down friction (or stiction) and the viscous friction (Bona

and Indri, 2005). In most cases if the manipulator is ex-

pected to displace at medium or medium-high velocities,

the friction can be expressed mathematically as a func-

tion of the joint velocity considering the effects of the

viscous friction and the Coulomb friction only (Guran

et al., 2001; Lewis et al., 2004; Kelly et al., 2005; Si-

ciliano et al., 2009). This simplified friction model is

known as classic friction model:

F = F

c

sign(v) + σ

2

v (6)

where F

c

in the parameter for Coulomb friction, σ

2

is

the viscous damping coefficient and v is the velocity of

the system. The value of the parameters for the classic

friction model can be estimated from experimental data

DynamicModelofa7-DOFWholeArmManipulatorandValidationfromExperimentalData

219

Friction[Nm]

Velocity[rad/s]

Friction-VelocityMapofJoint1

Friction-VelocityMapofJoint5

-0.4

-0.3

-0.2

-0.1

0

0.1 0.2 0.3

0.4

-0.4

-0.3

-0.2

-0.1

0

0.1 0.2 0.3

0.4

Velocity[rad/s]

Friction[Nm]

Friction[Nm]

Friction[Nm]

-4

-2

0

2

4

6

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.4

Velocity[rad/s]

0.8

0.4

Friction-VelocityMapofJoint2

Friction-VelocityMapofJoint6

Velocity[rad/s]

-0.4

-0.3

-0.2

-0.1

0

0.1 0.2 0.3

0.4

-0.4

-0.3

-0.2

-0.1

0

0.1 0.2 0.3

0.4

F

riction[Nm]

Friction[Nm]

-3

-2

-1

0

1

2

3

4

5

0

Velocity[rad/s]

Friction-VelocityMapofJoint3 Friction-VelocityMapofJoint4

Friction-VelocityMapofJoint7

-0.4

-0.3

-0.2

-0.1

0

0.1 0.2 0.3

0.4

-0.4

-0.3

-0.2

-0.1

0

0.1 0.2 0.3

0.4

-0.4

-0.3

-0.2

-0.1

0

0.1 0.2 0.3

0.4

Velocity[rad/s]

Velocity[rad/s]

Friction[Nm]

2

1

0

-1

-2

-3

2

1

0

-1

-0.4

-0.2

0

0.2

0.4

Measureddata

Estimation

Figure 6: Friction velocity maps corresponding to each joint of the 7 DOF manipulator. The measured data is obtained after

rotating each joint of the manipulator at different constant velocities whilst the estimated value is computed using a fitted

classic friction model.

through the execution of joint rotations at constant veloc-

ity, this process in not straight forward and is explained

in detail in section 3.3.1.

3.3.1 Friction Identification

The procedure for the identification of the friction model

parameters for each joint of the 7-DOF whole arm ma-

nipulator follows several steps. First a closed loop PD

control with gravity compensation is used to move the

link following a trapezoidal velocity profile at different

positive and negative velocities, the measurements of po-

sition in addition with the corresponding sampling time

are employed to compute the velocity of the link in each

experiment. Afterwards, the values of torque and veloc-

ity during the constant velocity stage of the trajectory are

averaged and used to construct the friction-velocity map,

which is basically a torque versus velocity plot. Finally,

the parameters for the friction model are estimated to

fit the friction-velocity map by applying a least-squares

minimization method (Canudas de Wit and Lischinsky,

1997; Canudas de Wit et al., 1995; Olsson et al., 1998;

Johnson and Lorenz, 1992) using

n

∑

i=1

[F(v

i

) −

ˆ

F(v

i

)]

2

(7)

where F(v

i

) is the measured torque at certain velocity

v

i

(i.e the friction force), and

ˆ

F(v

i

) is the value com-

puted by the friction model represented in Equation (6).

Figure 5 shows an example of the measured position and

torque in the manipulator when rotating joint 1. The data

segment in the inset of the figure corresponds to the lin-

ear change in the position which is used to compute the

joint velocity. The averages of the computed velocity v

i

and measured torque F(v

i

), respectively, yield to ordered

pairs [F(v

i

),v

i

] that shape the friction velocity map.

The obtained friction model parameters for each

Table 1: Friction model parameters for the seven joints of

the robot manipulator. V +/V− stands for positive and neg-

ative velocities respectively.

Joint Coulomb friction Viscous friction

F

c

σ

2

(V + /V−) (V + /V−)

1 4.4748/ 4.3609 1.3348/ 0.8266

2 2.6385/ 3.5643 3.5572/-2.3951

3 1.7399/ 2.3529 0.3944/ 1.2075

4 1.5414/ 0.7342 -2.7045/-1.0969

5 0.2798/ 0.1172 -0.1972/ 1.4670

6 0.4834/ 0.4417 0.8291/ 0.1836

7 0.0538/ 0.1370 1.0689/ 0.7954

joint of the 7-DOF whole arm manipulator are listed in

Table 1. There can be noted that the first joint is the

most affected by the Coulomb friction F

c

whilst the 3

DOF that shape the wrist of the manipulator are the least

influenced. These parameters were used to estimate the

joint friction velocity maps plotted in Figure 6, where the

velocity maps obtained using real data are also shown.

The measured friction suited perfectly the shape of

the classic friction model, which reinforces the initial

choice of the friction model for the development of this

project. In general, the estimation of friction is very ac-

curate for all the joints, and it is suitable enough to be

considered when compensating the friction phenomena

manifested in the real manipulator.

4 SIMULATIONS

Several joint rotational motion experiments were per-

formed with the aim of evaluate the accuracy of model

with respect to the real manipulator. First, a LSPB joint

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

220

Manipulator

Model

ix10

-3

0

2

4

6

5

3

1

Joint1

P

ositionError[rads]

Time[sec]

10

12

18

16

Joint2

PositionError[rads]

2

4

6

PositionError[rads]

Joint3

PositionError[rads]

Joint4

0

2

4

6

8

PositionError[rads]

Joint5

P

ositionError[rads]

Joint6

0

10

20

30

40

PositionError[rads]

Joint7

Time[sec] Time[sec] Time[sec]

Time[sec] Time[sec]

Time[sec]

7

14

8

6

2

4

1

3

5

4

3

2

1

1

3

5

7

2

4

6

8

10

12

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

ix10

-3

ix10

-3

ix10

-3

ix10

-3

ix10

-3

ix10

-4

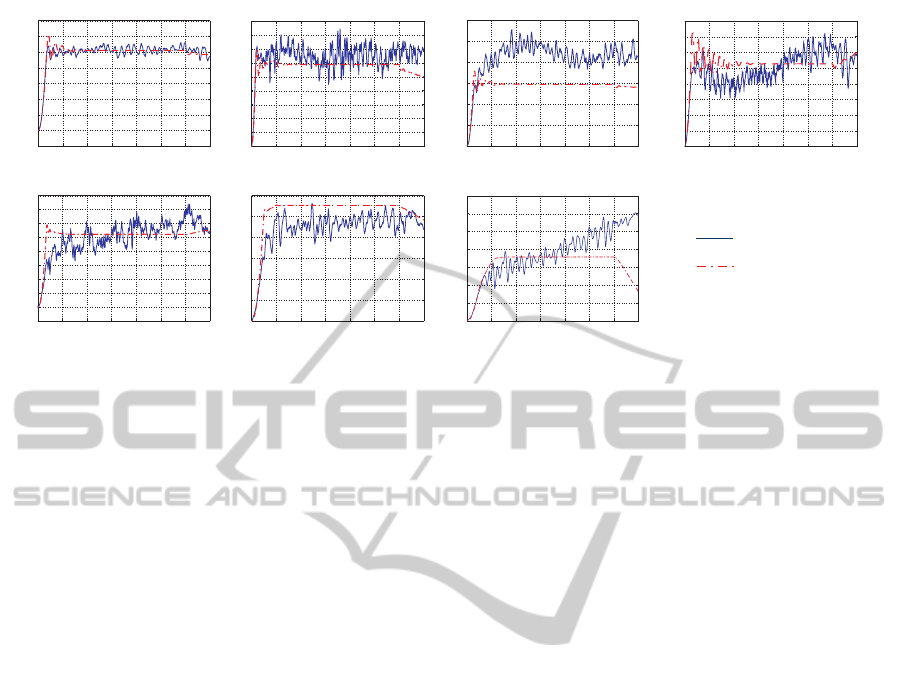

Figure 7: Real and simulated joint error of the 7 DOF manipulator when executing a specific trajectory. Every link is rotated

one at a time and the error is calculated using the reference position minus the actual position.

trajectory with a rotation of 0.5 rad at a velocity of 0.083

rads/sec was used as a reference in the real system, and

the joint position was measured while the manipulator

was in motion. Subsequently, the joint position error

was calculated to be used as a performance measure-

ment. Later, in simulation, the same joint trajectory was

generated using experimental data as described in Sec-

tion 3.1. The response of the model was recorded and

the model joint position error was calculated.

The position error was chosen as a performance mea-

surement in order to have a closer comparison of the re-

sponse of both the real manipulator and the model when

executing the exact same trajectory. As mentioned ear-

lier, the real system uses a PD control with gravity com-

pensation, and therefore, throughout the simulations a

PD control was used and zero gravity was assumed.

During the first set of simulations every link was ro-

tated one at a time. The second set consisted in one simu-

lation only, where all the joints were rotated at the same

time. This gave a total of eight simulations performed

by the model, to be compared to the behaviour of the

real system when executing the exact same trajectory.

The graphs in Figure 7 show a comparison of the posi-

tion error obtained in the first set of simulations. This

practice helped to prove the veracity of the model with

friction joint per joint and showed that, regardless of the

real manipulator is exposed to transducer noise and sen-

sor errors, the response of the model is accurate.

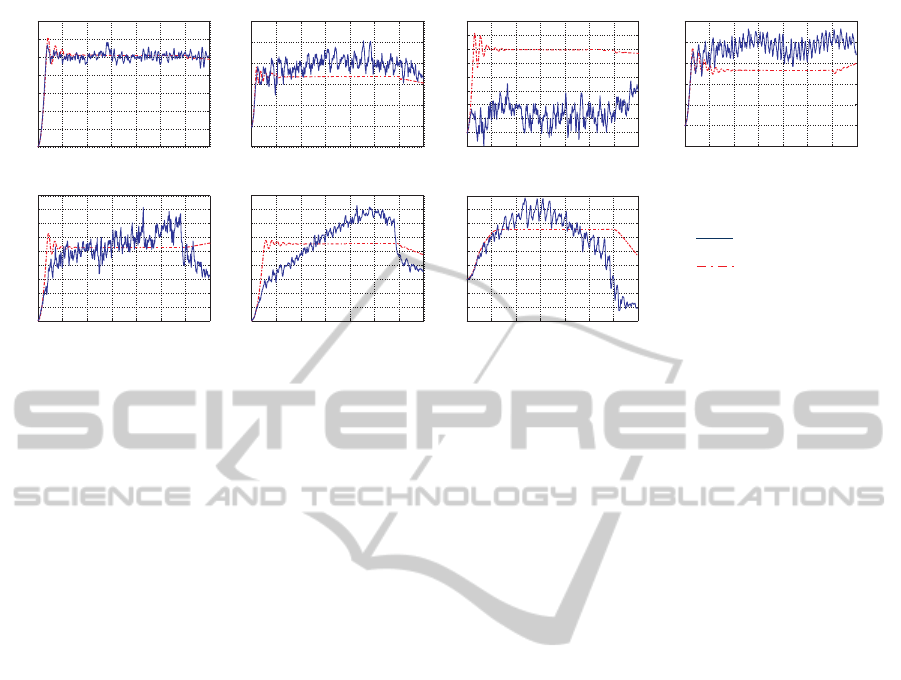

The second set of simulations was more an evalua-

tion of reliability, due to in real exercise the manipulator

might operate in Cartesian space and all the joints would

rotate at the same time. The response of the model dur-

ing this simulation was good as expected despite of the

clear difference between the simulated and the real po-

sition error of the third joint. Figure 8 shows the results

of the second set of simulations. The difference in errors

between model and real system are expected due to the

disturbances at which the real system is exposed, such as

nonlinearities caused by the joint motors and the inertia

of the system. Other sources of disturbance to be con-

sidered are the joint actuators and the scheme used for

gravity compensation.

5 CONCLUSIONS

The identification of friction phenomena in the manip-

ulator is helpful to observe the effects that friction has

in the overall performance of the system, so a compen-

sation technique, if necessary according to the applica-

tion task of the manipulator, may be implemented on the

current joint PD/PID control. On the other hand, the in-

clusion of a friction model in the dynamic model of the

mechanical system establish a good platform for simu-

lations in order to observe and analyse the response of

the manipulator to different control strategies in a more

realistic scenario.

The presented dynamic model with friction is prompt

to be used as a reference in the design of joint control

strategies implemented in Simulink. By taking advan-

tage of the fact that real joint trajectory is completely

emulated in our simulations by setting up the desired ro-

tation angle and execution time, a close comparison of

the simulation results with respect to experimental data

is also possible.

The development of a dynamic model with friction

is extremely useful for observing and improving the per-

formance of the manipulator by analysing the effective-

ness of the on system control. In certain cases, some

types of stimuli utilised in controller tuning techniques

are not feasible to be implemented in experiments whilst

the model can be easily manipulated in simulations.

DynamicModelofa7-DOFWholeArmManipulatorandValidationfromExperimentalData

221

2

4

6

5

3

1

2

4

2

4

6

8

-10

10

20

30

7

1

3

4

3

2

1

1

3

5

7

2

4

6

8

10

18

25

20

15

10

5

0

0

5

0

9

12

14

16

0

25

15

5

-5

Manipulator

Model

ix10

-3

Joint1

P

ositionError[rads]

Time[sec]

Joint2

PositionError[rads]

PositionError[rads]

Joint3

PositionError[rads]

Joint4

PositionError[rads]

Joint5

P

ositionError[rads]

Joint6

PositionError[rads]

Joint7

Time[sec] Time[sec] Time[sec]

Time[sec] Time[sec]

Time[sec]

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

ix10

-3

ix10

-3

ix10

-3

ix10

-3

ix10

-3

ix10

-4

Figure 8: Real and simulated joint error of the 7 DOF manipulator when executing a specific trajectory. All the joints are

rotating at the same time and the error is calculated using the reference position minus the actual position.

REFERENCES

Barrett Technology Inc (2008). WAM Arm User's Manual.

Bompos, N., Artemiadis, P., Oikonomopoulos, A., and Kyr-

iakopoulos, K. (2007). Modeling, full identification

and control of the mitsubishi pa-10 robot arm. In

IEEE/ASME International Conference on Advanced

Intelligent Mechatronics,.

Bona, B. and Indri, M. (2005). Friction compensation in

robotics: an overview. In 44th IEEE Conference on

Decision and Control.

Canudas de Wit, C. and Lischinsky, P. (1997). Adaptive

friction compensation with partially known dynamic

friction model. In International Journal of Adaptive

Control and Signal Processing.

Canudas de Wit, C., Olsson, H., Astrom, K., and Lishinsky,

P. (1995). A new model for control of systems with

friction. In IEEE Transactions On Automatic Control.

Corke, P. (1996). A robotics toolbox for matlab. In IEEE

Robotics and Automation Magazine.

Guran, A., Pfeiffer, F., and Popp, K. (2001). Dynamics with

friction. In Series on Stability, Vibration and Control

of systems.

Indri, M. (2006). Control of manipulators subject to un-

known friction. In 45th IEEE Conference on Decision

and Control.

Johnson, C. and Lorenz, R. (1992). Experimental identifi-

cation of friction and its compensation in precise, po-

sition controlled mechanisms. In IEEE Transactions

on Industry and Applications.

Kelly, R., Santibanez, V., and Loria, A. (2005). Control of

Robot Manipulators in Joint Space. Springer.

Kostic, D., de Jager, B., Steinbuch, M., and Hensen, R.

(2004). Modeling and identification for high perfor-

mance robot control: An rrr-robotic arm case study.

In IEEE Transactions on Control System Technology.

Lau, H. and Wai, L. (2002). A jacobian-based redun-

dant control strategy for the 7-DOF WAM. In Sev-

enth International Conference on Control, Automa-

tion, Robotics and Vision.

Lewis, F., Dawson, D., and Abdallah, C. (2004). Robot

Manipulator Control: Theory and Practice. Marcel

Dekker, second edition.

MathWorks (2011). MATLAB/SimMechanics.

Olsson, H., Astrom, K., Canudas de Wit, C., Gafvert, M.,

and Lischinsky, P. (1998). Friction models and friction

compensation. In European Journal of Control.

Siciliano, B., Sciavicco, L., Villani, L., and Oriolo, G.

(2009). Robotics: Modelling, Planning and Control.

Springer, London.

Sousa, C., Cortesao, R., and Queiros, P. (2009). Compli-

ant co-manipulation control for medical robotics. In

Proceedings of the 2nd Conference on Human System

Interactions.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

222