Eulerian-Lagrangian Modeling of Forestry Residues Gasification

in a Fluidized Bed

Jun Xie

1

, Wenqi Zhong

1

, Baosheng Jin

1

, Ming Song

1

, Yingjuan Shao

1,2

and Hao Liu

2

1

Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education,

School of Energy and Environment, Southeast University, Nanjing 210096, China

2

Institute of Sustainable Energy Technology, The University of Nottingham, Nottingham, U.K.

Keywords: Forestry Residues, Fluidized Bed Gasifier, Numerical Simulation, Eulerian-Lagrangian Approach.

Abstract: A comprehensive three-dimensional model is developed to simulate forestry residues gasification in a

fluidized bed gasifier using Eulerian-Lagrangian method. Both complex gas-solid flow and chemical

reactions are considered. The model is based on the multiphase particle-in-cell (MP-PIC) method, which

uses an Eulerian method for fluid phase and a discrete particle method for particle phase. Homogenous and

heterogeneous chemistry are described by reduced-chemistry and the reaction rates are solved on the

Eulerian grid. Simulations were carried out in a laboratory scale pine gasifier at different operating

conditions. The predicted product gas contents and carbon conversion efficiency compare well with the

experimental data. The formation of flow patterns, profiles of temperature and distributions of gas

compositions were also obtained.

1 INTRODUCTION

within the fluid mixture were considered. Granular

flow patterns, gas composition distributions and

Biomass is important in energy conversion processes

due to its favourable status with respect to

greenhouse gas emissions (Nemtsov, 2008). Biomass

materials known as potential sources of energy are

agricultural residues such as straw, bagasse, and

husk and residues from forest-related industries such

as wood chips, sawdust, and bark (Nikoo, 2008).

Fluidized bed gasifiers are advantageous for

transforming biomass, particularly agricultural and

forestry residues, into energy. Advantages of

fluidization include high heat transfer, uniform and

controllable temperatures, perfect gas–solid

contacting and the ability to handle a wide variation

in particulate properties (Nemtsov, 2008; Nikoo,

2008).

Over the last decade computational fluid

dynamic (CFD) models have been applied to

biomass gasifier. There are two approaches:

Eulerian-Eulerian models (EEM) and

Eulerian-Lagrangian models (ELM). The ELM

tracks each individual fuel particle, making it

possible to include the changes in physico-chemical

characteristics of the fuel particle during

devolatilization and subsequent char conversion.

There are some models for biomass conversion

employing ELM in entrained-flow gasifiers. Little

work has been found using ELM to simulate biomass

gasification in a fluidized bed because of the

computational complexity of calculating dense

particle-particle interactions. If coupled with

chemical reactions, this application is

computationally more expensive (Barea, 2010).

The objective of this study is to develop a

comprehensive three-dimensional numerical model

for fluidized bed coal gasification. The methodology

describes the dense gas-solid flow on a basis of

multiphase particle-in-cell (MP-PIC). The method is

a form of Eulerian-Lagrangian approach, where each

particle has three-dimensional forces from fluid drag,

gravity, static-dynamic friction, particle collision and

possibly other forces (Snider, 2007). Homogenous

and heterogeneous chemistry are described by

reduced-chemistry and the reaction rates are solved

numerically on the Eulerian grid. Complex particle

and gas flow, mass and heat transfer, chemical

reactions between phases and other important

characteristics were obtained at different operating

conditions. The calculated product gas compositions

and carbon conversion efficiency compare with the

experimental data to confirm the validity of the

297

Xie J., Zhong W., Jin B., Song M., Shao Y. and Liu H..

Eulerian-Lagrangian Modeling of Forestry Residues Gasification in a Fluidized Bed.

DOI: 10.5220/0004013802970302

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 297-302

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

model.

2 NUMERICAL MODELS

2.1 Governing Equations for Gas Phase

The gas dynamics is described by averaged

Navier-Stokes equations with strong coupling with

the particle phase. The large eddy simulation (LES)

turbulence model is adopted. Mass, momentum and

energy of the two-phase mixture are conserved by

exchange terms which can be included in the mass,

momentum and energy conservation equations,

respectively (Snider, 2011&2001).

pggg

gg

mu

t

)(

)(

(1)

)(

)(

)(

gggg

ggggg

ggg

g

Fpuu

t

u

(2)

where

gg

u

,

and ρ

g

represent the gas velocity vector,

volume fraction and density, respectively.

p

m

is the

gas mass production rate per volume from

particle-gas chemistry. The terms p,

g

and g are the

mean flow gas thermodynamic pressure, stress

tensor and gravitational acceleration. F is the rate of

momentum exchange per volume between the gas

and particle phases.

As a form of energy equation, the enthalpy

equation is

Dhg

ggggggggg

qSQq

pu

t

p

uhh

t

)(

)()(

(3)

Where

g

h

is the gas enthalpy;

is the viscous

dissipation; and

Q

is an energy source per volume.

In this work, the viscous dissipation is ignored, and

there is no energy source. q is the fluid heat flux and

D

q

is the enthalpy diffusion term. The term

h

S

represents the conservative energy exchange from

the particle phase to the gas phase.

The gas phase is a multicomponent mixture.

Through recombining chemical bonds of molecules

and atoms, mass is transferred between gas species,

which is represented as chemical source term

chemi

m

,

. The transport equation for individual gas

species is

chemi

iggggiggg

iggg

m

YDuY

t

Y

,

,,

,

(4)

where D is the turbulent mass diffusivity which is

related to the viscosity by the Schmidt number

correlation μ/ρ

g

D=Sc. Sc is set as 0.9.

2.2 Governing Equations for Solid

Phase

The methodology is a form of Eulerian-Lagrangian

method, in which the dynamics of the particle phase

is calculated by solving a transport equation for the

particle distribution function (PDF) f. The transport

equation for the PDF is derived from

Boltzmann-BGK model of gas dynamics. And some

improvements were made for collision damping time

which includes the effects of the particle material

coefficient of restitution and non-equilibrium

particle velocity distributions. For simplicity, it is

assumed that f is a function of particle spatial

location x

s

, particle velocity u

s

, particle mass m

s

,

particle temperature T

s

and time t. Thus f(x

s

, u

s

, m

s

,

T

s

, t) du

s

dm

s

dT

s

is the average number of particles

per unit volume with velocities in the interval (u

s

,

u

s

+du

s

), mass in the in the interval (m

s

, m

s

+dm

s

), and

temperature in the interval (T

s

, T

s

+dT

s

) (Snider,

2011).

The transport equation for f is

D

D

ff

v

fA

x

fv

t

f

(5)

where A is the particle acceleration; f

D

is the PDF for

the local mass-averaged particle velocity; and τ

D

is

the collision damping time.

FsgpuuDA

s

sss

sgs

11

)(

(6)

where D

s

is the drag function which depends on the

particle size, velocity, position and time. θ

s

, ρ

s

and τ

s

are the solids volume fraction, mass density and

contact normal stress, respectively. The particle

friction per mass, Fs is opposite and limited to the

relative particle motion.

Particle-to-Particle collisions are modeled by the

particle normal stress which is an approximation of

collective effects of neighbor particles on a particle.

The MP-PIC method makes use of spatial gradients

because they are readily calculated on the Eulerian

grid and then apply the gradient to discrete particles.

The particle stress is derived from the particle

volume fraction which is in turn calculated from

particle volume mapped to the grid. The particle

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

298

normal stress model used here is

)1(),(max

sscs

ss

P

(7)

where the constant P

s

has units of pressure, and θ

cs

is

the particle volume fraction at close packing.

is the

constant, 2≤

≤5. The ε is a small number on the

order of 10

-7

to remove the singularity.

The particles volume fraction is defined by f

sss

s

s

s

dTdudm

m

f

(8)

and the gas volume fraction is θ

g

=1-θ

s

.

The conservative mass, momentum and energy

exchange between gas and solid phases are presented

as follows

sss

s

s

dTdudm

dt

dm

fm

(9)

sss

s

s

s

sgss

dTdudm

dt

dm

u

p

uuDmfF

)(

(10)

sssgss

s

s

Vgsssh

dTdudmuuh

dt

dm

dt

dT

CuuDmfS

2

2

)(

2

1

)(

(11)

In which, h

s

is the particle enthalpy. The energy from

the solid is the sensible heat and the heat of

formation.

2.3 Chemical Reaction Models

In the MP-PIC method, we use a cell-average

chemistry calculation. By interpolating discrete

computational particle properties to the grid, average

properties of the particle phase are got for the

chemical rate equations. The reaction rates are

calculated in each grid cell. The total consumption

rate of solids is defined by the reaction rates. The

time rate of change of mass of individual particles

dm

s

/dt is related to the total rate of change of molar

concentration of solid carbon d[C(s)]/dt by the

volume of the particles (Snider, 2011).

dt

sCd

m

Mw

dt

dm

s

ss

cg

s

)(

(12)

where Mw

c

is the molecular weight of carbon.

In our present work, we assumed that forestry

residues devolatilization takes place instantaneously

and volatile products consist of CO, CO

2

, H

2

O, H

2

,

CH

4

, and C

2

H

4

. The quantities of these compositions

are determined based on some experimental support,

as well as the proximate and elemental analysis

Table 1: Chemical equations and reaction rates (Snider,

2011; de Souza-Santos, 2004).

Stoichiometric

equation

Reaction rate expression / mol m

-3

s

-1

C+H

2

O→CO+H

2

r

1

=1.272m

s

Texp(-22645/T) [H

2

O]

CO+H

2

→C+H

2

O

r

2

=1.044×10

-4

m

s

T

2

exp(-6319/T-17.29)[CO]

[H

2

]

C+CO

2

→2CO

r

3

=1.272m

s

Texp(-22645/T) [CO

2

]

2CO→C+CO

2

r

3

=1.044×10

-4

m

s

T

2

exp(-2363/T-20.92)[CO]

2

0.5C+H

2

→0.5CH

4

r

4

=1.368×10

-3

m

s

Texp(-8078/T-7.087)[H

2

]

0.5CH

4

→0.5C+H

2

r

5

=0.151m

s

T

0.5

exp(-13578/T-

0.372)[CH

4

]

0.5

C+O

2

→2CO

r

6

=4.34×10

7

θ

p

Texp(-13590/T)[O

2

]

CO+H

2

O→CO

2

+H

2

r

7

=7.68×10

10

Texp(-36640/T) [CO]

0.5

[H

2

O]

CO

2

+H

2

→CO+H

2

O

r

8

=6.4×10

9

Texp(-39260/T) [H

2

]

0.5

[CO

2

]

CO+0.5O

2

→CO

2

r

9

=5.62×10

12

exp(-16000/T) [CO][O

2

]

0.5

CH

4

+2O

2

→CO

2

+2H

2

r

10

=3.552×10

11

exp/T(-15700/T)[CH

4

][O

2

]

C

2

H

4

+3O

2

→2CO

2

+2H

2

r

11

=3.552×10

11

exp/T(-15700/T)[C

2

H

4

][O

2

]

H

2

+0.5O

2

→H

2

O

r

12

=1.63×10

11

expT

-1.5

(-3430/T)[H

2

]

1.5

[O

2

]

CH

4

+H

2

O→CO+3H

2

r

13

=3×10

5

exp(-12500/T)[CH

4

][H

2

O]

(Thunman, 2001). For the sake of simplification,

reactions with sulfur are ignored for their little

amount. Char only contains carbon.

There are thousands of chemical reactions in a

gasifier. A set of fourteen reactions describe the

major conversion rates in the reactor. The solids are

consumed and the particles shrink by heterogeneous

chemistry reactions of combustion, gasification and

methanation. The homogeneous reactions include

carbon monoxide, hydrogen and methane

combustion, water-gas shift and methane steam

reforming reactions. The fourteen chemical reactions,

together with the reaction rate expressions, are listed

in Table 1.

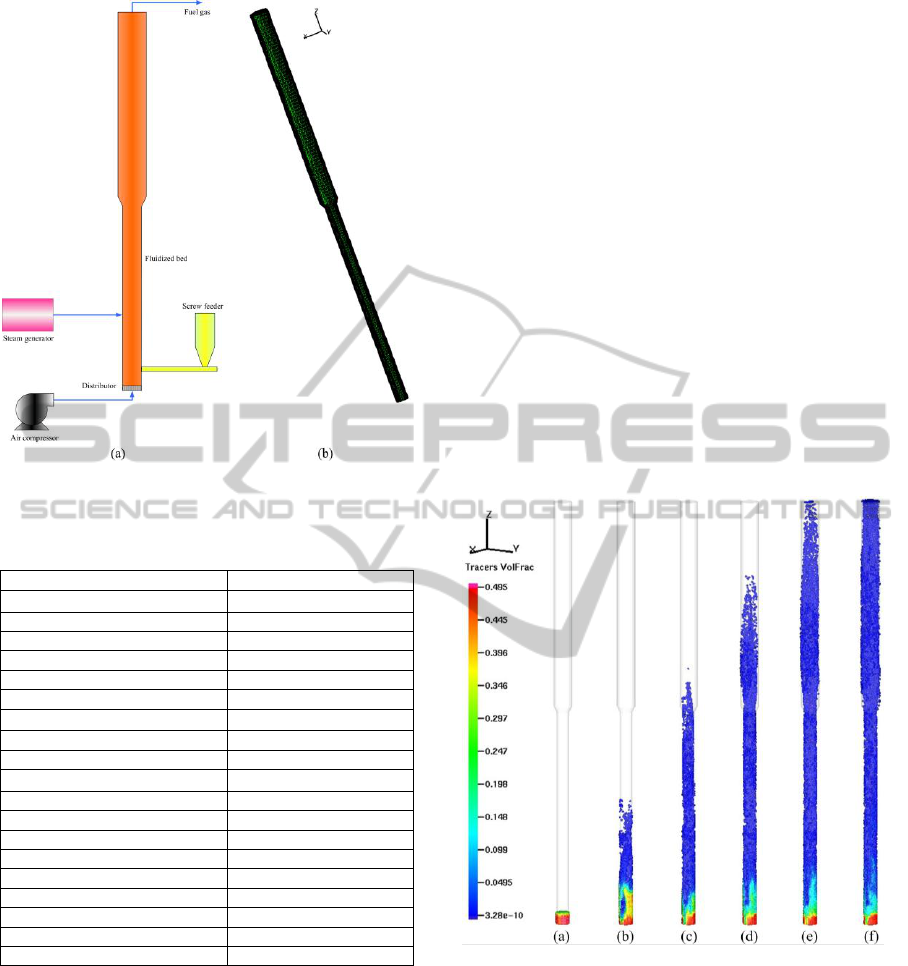

2.4 Computational Setup

This simulated object is a lab-scale fluidized bed

gasifier whose details can be found elsewhere (Lv,

2004). A schematic diagram of the reactor and the

simulation grid are shown in Fig. 1. The

experimental setup parameters and the operating

conditions appear in Table 2. At the outlet, gas phase

adopts out-flow boundary condition and no particle

exit. The reactor is initially filled with N

2

and the

silica sand is in the vessel with the volume fraction

grids of 0.48 (Wang, 2009). To prevent excessive

compression of particles, we set the solid close pack

volume fraction as 0.5. The particle normal-to-wall

momentum retention coefficient is 0.2 and the

tangent–to-wall retention coefficient is 0.99. The

time step of 2.0×10

-4

s is used.

Eulerian-Lagrangian Modeling of Forestry Residues Gasification in a Fluidized Bed

299

Figure 1: Schematic of the gasifier and simulation grid.

Table 2: Experimental setup parameters and operating

conditions.

Fluidized bed reactor

Temperature (℃)

750,800,850

Pressure (Pa)

101325

Bed diameter (mm)

40

Freeboard diameter (mm)

60

Height (mm)

1400

Air

Temperature (℃)

65

Flow rate (Nm

3

/h)

0.5

Steam

Temperature (℃)

154

Flow rate (kg/h)

1.2

Feed material: Pine sawdust

Particle diameter (mm)

0.3-0.45

Absolute density (kg/m3)

556

Char density (kg/m3)

1300

Flow rate (kg/h)

0.445

Bed material : Silica sand

Particle diameter (mm)

0.2-0.3

Weight (g)

30g

3 RESULTS AND DISCUSSION

3.1 Flow Patterns

In the fluidized bed, air was used as the fluidizing

agent and introduced into the reactor below the

distributor. The particles include three species: silica

sand, carbon and ash. The formation and

development of granular flow regimes are illustrated

with particle volume fraction in Fig. 2. As shown in

Fig. 2(a)-(f), the particles tend to rise with time

driven by gas-particle interactions. The particle

concentration decreases along the reactor height.

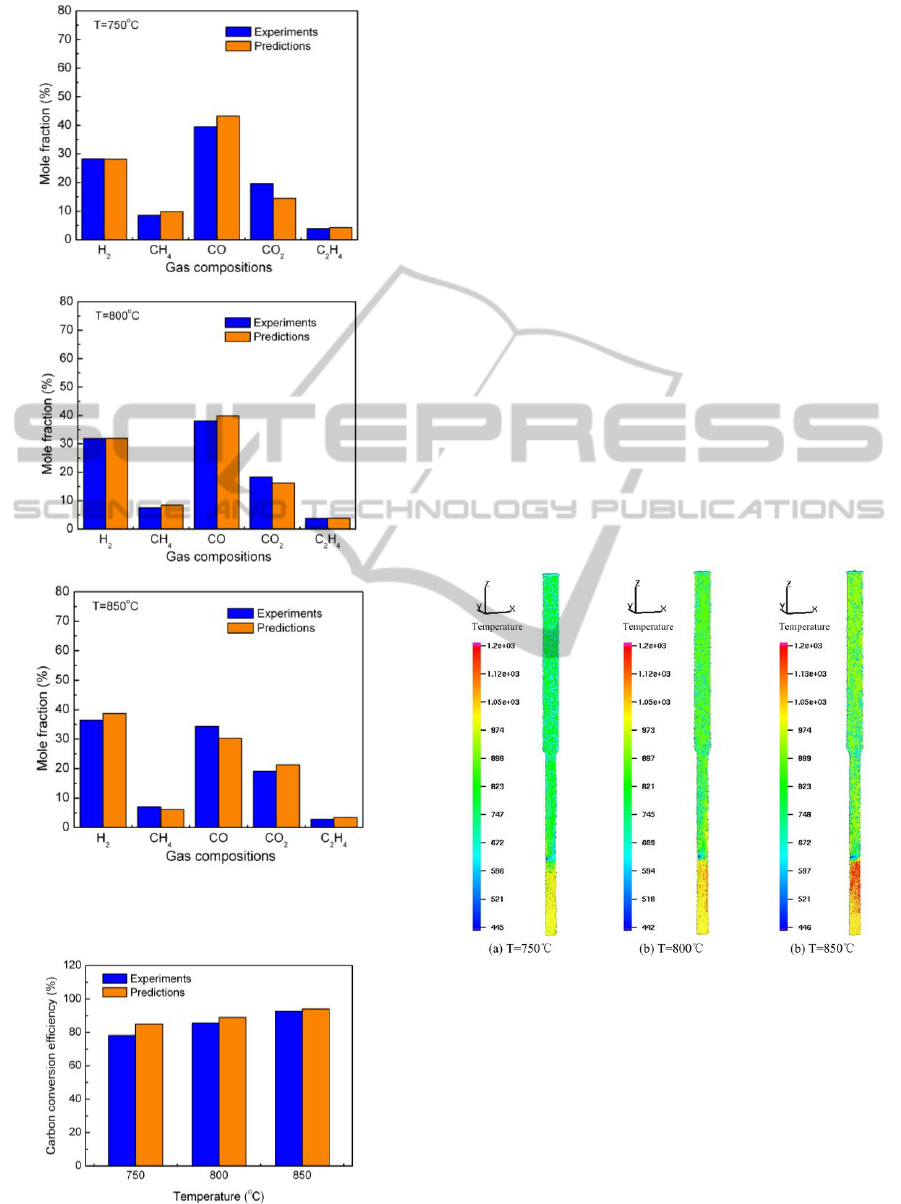

3.2 Comparisons with Experiments

The present developed model was applied to three

cases with different operating temperatures. Fig. 3

portrays the product gas composition of calculations

and experiment data. All species are dry-gas molar

contents.

Fig. 3(a)-(c) shows the predicted results compare

well with the experimental data. The minimum

relative error is less than 1%, and the maximum

relative error is about 20%. The average relative

error is less than 12%.Very little difference is found

between predicted and measured H

2

, CH

4

and C

2

H

4

contents. The H

2

concentrations increase with

increasing temperature and the contents of CH

4

show

an opposite trend. Higher temperature favors the

endothermic reaction of methane steam reforming.

Figure 2: Flow patterns transition with time: (a) t=0s, (b)

t=0.25s, (c) t=0.5s, (d) t=0.75s, (e) t=1.0s, (f) t =1.25s.

One or two calculation error of CO and CO

2

molar

contents are more than 15%. The reason for these

deviations is likely to be the simplified distribution

coefficient of reactions: C +

O

2

→ (2-

) CO

2

+

(2-2

) CO

and C + αH

2

O → (2-α) CO + (α-1) CO

2

+

αH

2

, the coefficients, α and

, change with

temperature which are set as constants in our model.

Part of the deviation comes from the neglect of tar

production.

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

300

(a)

(b)

(c)

Figure 3: Comparisons between species mole contents

predicted by model and experimental data.

Figure 4: Comparisons between carbon conversion

efficiency predicted by model and experimental data.

Fig. 4 compares the predicted carbon conversion

efficiency with the measured data. Higher

temperature improves the gasification process and

increases the carbon conversion. There is good

agreement between the simulation and experimental

results. The average relative difference is only about

5%. Biomass produces tar and other light

hydrocarbon (C

x

H

y

) in pyrolysis and gasification

process. The present model did not consider the tar

and light hydrocarbon, which is the main reason for

over-estimation of carbon conversion efficiency.

3.3 Distributions of Gas Compositions

Fig. 5 displays the distributions of particle and gas

temperatures in the reactor (a half slice at y=0). In

general, the temperature in the bed region is higher

than in the freeboard for the more contact of

gasifying agent and fuel. The steam injection affects

the temperature profile and lowers the temperature

above the injection level. The peak temperatures are

observed in the lower part of the bed, where the

highest intensities of combustion and gasification

reactions are located.

Figure 5: Distributions of particle and gas temperatures.

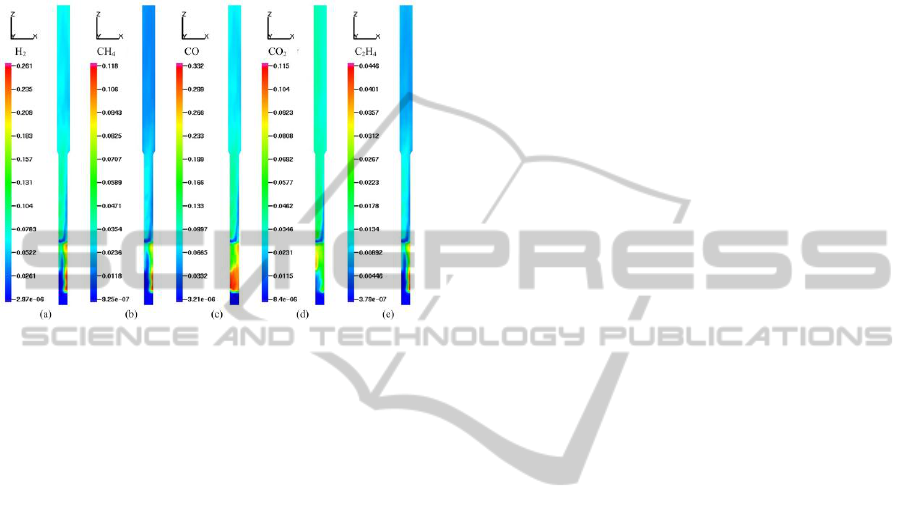

Fig. 6 illustrates the molar fraction distribution of

the five most important gas species in the reactor (a

half slice at y=0). It can be seen from the figure: the

positions of the sawdust feeder and steam injector

influence the gas profile. Near the particle inlet level,

the molar concentrations of CO are highest due to

the existence of a large number of carbon particle

and devolatilization. The CO

2

concentrations remain

almost constant along the whole height of the reactor

for the homogeneous combustion reaction and

Eulerian-Lagrangian Modeling of Forestry Residues Gasification in a Fluidized Bed

301

water-gas shift reaction. The overall trend of H

2

,

CH

4

and C

2

H

4

contents is consistent. As a result of

devolatilization, the peak concentrations of them are

presented close to the feeder. Nevertheless, H

2

molar

contents are higher than those of CH

4

and C

2

H

4

in

the freeboard region due to water-gas shift reaction

and methane steam reforming reaction.

Figure 6: Molar fraction distributions of gas compositions

(T=800℃).

4 CONCLUSIONS

A three-dimensional Eulerian-Lagrangian numerical

model was developed to study the forestry residues

gasification in a laboratory scale fluidized bed

gasifier. By the simulations at different operating

temperaures, gasifier’s behavior was effectively

predicted, including the complex particle flow

patterns, profile of temperature and distributions of

gas composition. The predicted product gas contents

and carbon conversion efficiency compared well

with experimental data. The present mathematical

model can be a tool to explore the complex gas-solid

flow and chemical reaction characteristics of

fluidized bed gasification.

ACKNOWLEDGEMENTS

Financial supports from the Major State Basic

Research Development Program of China (NO.

2011CB201505), China MOST for Inter-government

S&T Optional Cooperation between China and

Europe (2010DFA61960), NSFC (No. 51076029),

and UK EPSRC for Collaboration Project of China

and British (EP/G063176/1) were sincerely

acknowledged.

REFERENCES

Nemtsov, D. A., Zabaniotou, A., 2008. Mathematical

modelling and simulation approaches of agricultural

residues air gasification in a bubbling fluidized bed

reactor. Chemical Engineering Journal 143, 10–31.

Nikoo, M. B., Mahinpey, N., 2008. Simulation of biomass

gasification in fluidized bed reactor using ASPEN

PLUS. Biomass and Bioenergy 32, 1245–1254.

Gómez-Barea, A., Leckner, B., 2010. Modeling of biomass

gasification in fluidized bed. Progress in Energy and

Combustion Science 36, 444-509.

Snider, D. M., 2001. An incompressible three dimensional

multiphase particle-in-cell model for dense particle

flows. Journal of Computational Physics 170,

523-549.

Snider, D. M., 2007. Three fundamental granular flow

experiments and CPFD predictions. Powder

Technology 176, 36-46.

Snider, D. M., Clark, S. M., O’Rourke, P. J., 2011.

Eulerian-Lagrangian method for three-dimensional

thermal reacting flow with application to coal

gasifiers. Chemical Engineering Science 66,

1285-1295.

Thunman, H., Thunman, H., Niklasson, F., Johnsson, F.,

Leckner, B., 2001. Composition of Volatile Gases and

Thermochemical Properties of Wood for Modeling of

Fixed or Fluidized Beds. Energy Fuels 15, 1488-1497

de Souza-Santos, M. L.,. Modeling, Simulation, and

Equipment Operations. 2004. Marcel Dekker, Inc.

Lv, P. M., Xiong, Z. H., Chan, g J., Wu, C. Z., Chen, Y.,

Zhu, J. X., 2004. An experimental study on biomass

air–steam gasification in a fluidized bed. Bioresource

Technology 95, 95-101.

Wang, X. F., Jin, B. S., Zhong, W. Q., 2009.

Three-dimensional simulation of fluidized bed coal

gasification. Chemical Engineering and Processing 48,

695-705.

SIMULTECH 2012 - 2nd International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

302