Visual Anomaly Detection in Production Plants

Alexander Maier

1

, Tim Tack

1

and Oliver Niggemann

1,2

1

Institute Industrial IT, OWL University of Applied Sciences, Lemgo, Germany

2

Fraunhofer IOSB-INA, Application Center Industrial Automation, Lemgo, Germany

Keywords:

Anomaly Detection, Production Plant, Automation System, Visualization Technique, Visual Analytics.

Abstract:

This paper presents a novel method for visual anomaly detection in production plants. Since the complexity of

the plants and the number of signals that have to be monitored by the operator grows, there is a need of tools

to overcome the information overflow. The human is highly able to recognize irregularities in figures. More

than 80% of the perceived information is captured visually. The approach proposed in this paper exploits this

fact and subjects data to make the operator able to find anomalies in the displayed figures. In three steps the

operator is lead from the visualization of the normal behavior over the anomaly detection and the localization

of the faulty module to the anomalous signal.

1 INTRODUCTION

Modern production plants nowadays grow more and

more complex. Thus, the number of sensors and ac-

tuators grows also. Programmable Logic Controllers

(PLCs) are used to manage the signals and to operate

the plant. Supervisory Control and Data Acquisition

(SCADA) systems get the data from the PLC to man-

age the process automatically. Due to the increasing

number of signals the analyzing task gets more dif-

ficult. More and more the activity of the operator

changes to a passive role; from operating to analyz-

ing the production plants. Figure 1 illustrates a typical

production plant monitored with the help of a SCADA

system.

Figure 1: A typical complex interface of a SCADA system.

Different visualization techniques can help the op-

erator to analyze the plant behavior. The goal is a

graphical representation of the data which provides

the operator with an overview of the current plant

state. Additionally, the operator should be supported

in detecting unusual behavior, i.e. anomalies. Exam-

ples for anomalies are unusual power consumptions

or wears of conveyor belts. This paper adapts visual

analytic approaches from different scientific areas to

the field of automation.

In this paper, a novel visual anomaly detection ap-

proach is presented which guides the operator in a

top-down manner starting from a general overview to

a detailed description of identified anomalies. A main

new idea here is to place a visualization of the learned

normal behavior side-by-side to a visualization of

the current behavior. This side-by-side visualization

starts with an abstract graph computed by means of

data dimensionality reduction techniques which give

a coarse, time-independent system overview. The

user is then guided to a more detailed visualization

of the system’s timing behavior. So three main ideas

are combined here: (i) the usage of machine learn-

ing techniques to give the operator initially an ab-

stract view onto these complex data, (ii) the usage

of machine learning techniques to visualize the nor-

mal behavior (in comparison to the current behavior)

and (iii) a guided interface which leads the user step-

by-step to more detailed views onto anomalous data

items.

The paper is organized as follows: In section 2

67

Maier A., Tack T. and Niggemann O..

Visual Anomaly Detection in Production Plants.

DOI: 10.5220/0004039600670075

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 67-75

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

an overview to the state of the art is given and the

research gap which should be closed is pointed out.

Section 3 defines some requirements for the visual-

ization of technical processes and introduces a new

method for the visualization of high-dimensional dis-

crete data. In section 4, based on the defined re-

quirements the visualization techniques are evalu-

ated. For this, real data from a production plant

are used. Advantages and disadvantages regarding

process overview and anomaly detection are evalu-

ated. To exploit the advantages found in the analyzed

techniques, section 5 introduces a new approach. It

combines the techniques in one new visualization ap-

proach to provide a more informative overview and

to increase the anomaly detection performance. The

results are discussed in the conclusion.

2 STATE OF THE ART

This section gives an overview to the state of the art

and related work. First, in subsection 2.1 some basics

of visual analytics process are presented.

The subsections 2.2 and 2.3 give an overview of

some techniques which can be used to visualize dis-

crete, continuous or hybrid data which are a combi-

nation of both. The visualization techniques should

support the operator in two ways. At first, the high-

dimensional data should be visualized in a neat way

that allows humans to deal with the overwhelming

information input. The second is to make process

anomalies visible in the visualization.

2.1 Visual Analytics

According to (Keim et al., 2010) the visual analytics

process is organized as follows (see also figure 2):

First, the data have to be acquired from the ob-

served system. In many cases the data have to be pre-

processed (e.g. normalization or feature generation).

From this, a (mathematical) model is created using

data mining approaches. The model can be extended

by parameter refinement. In parallel the data are vi-

sualized for the further usage. This visualization is

enhanced by user interactions. Very important in this

context is the tight coupling of automated and visual

analysis through interaction. Both steps lead to the re-

quested knowledge, i.e. the needed information about

the systems behavior. Based on this knowledge the

operator is able to detect anomalies.

There exist many approaches to create a system’s

model using observations. E.g. in (Niggemann et al.,

2012) a method to learn a behavior model by means

Data

Models

Visualization

Knowledge

Data Mining

Mapping

User interaction

Parameter

refinement

Model

building

Model

visuali-

zation

Transformation

Feedback Loop

Visual Data Exploration

Automated Data Analysis

Figure 2: Principle of visual analytics according to (Keim

et al., 2010).

of timed automata is presented. In many cases, es-

pecially in the case of high amounts of data, these

models are created to be used by computers and are

therefore not easily accessible for humans. For this,

special visualization methods have to be developed.

Visual analytic approaches have been applied for

many years. One early example is the Londoner

physician Dr. John Snow in the year 1854. To find

the reason for a cholera pandemic he used a visualiza-

tion method. He marked each place of occurrence in a

map and was therefore able to find the reason, which

was a contaminated water fountain (Tufte, 1997).

Approaches in visual analytics are applied to dif-

ferent research areas. For example it is used in the fi-

nancial sector to visualize and analyze the fall and rise

of stocks and to detect frauds, e.g. in (Huang et al.,

2009). The study of environment and climate change

also often uses visualization approaches. The temper-

ature and other relevant parameters are recorded over

a long period of time. These data are visualized to rec-

ognize dependencies and to show up the changes over

time. Another area of application is the prevention of

terrorist attacks (Thomas and Cook, 2006).

However, there are only few examples where vi-

sual analytics have been applied to the manufacturing

industry. Frey uses self-organizing maps to generate

a two dimensional map which visualizes the observed

process (Frey, 2008).

2.2 Visualization of Multidimensional

Data

Figure 3 shows an excerpt taken from a process data

set. The dataset comprises a timestamp and the cor-

responding process variables f

1

... f

11

. The example

is rather small. Yet following the process or detect-

ing an anomaly by viewing this figure is not easy. It

can be seen that monitoring and anomaly detection in

high dimensional process datasets is a tough task for

computers and humans. Operators need to react on

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

68

time

f

1

f

2

f

3

f

4

f

5

f

6

f

7

f

8

f

9

f

10

f

11

25

0

0

1

1

1

0

1

0,60

993,3

235

1,5

60

0

0

1

0

0

0

1

0,50

983,4

235

1,8

124

0

1

1

1

1

0

0

0,38

983,7

236

2,2

149

0

1

1

0

1

1

0

0,44

982,4

233

2,5

248

0

0

1

1

0

1

1

0,46

980,1

234

2,9

324

1

0

1

1

0

1

1

0,52

978,5

231

3,2

419

1

1

1

1

0

0

0

0,48

980,5

231

3,6

455

1

1

1

0

1

0

0

0,44

990,2

232

3,9

513

1

0

1

1

1

0

0

0,42

993,4

232

4,3

Figure 3: An example dataset.

changes of large amount of different variables in dif-

ferent value ranges quite fast.

A trivial method to visualize data is to use signal

curves in dependency of time. This simple yet espe-

cially for continuous data effective method helps to

get an overview of the trends of a signal e.g. tempera-

ture over time. Further, the crossing of thresholds can

be seen very well. However, this method is only us-

able for a small number of signals. The visualization

of many signals in one diagram leads to an informa-

tion overflow, such that the single curves cannot be

detected separately. Figure 4 shows the visualization

of 30 signals with 300 data points for each. Even for

this small number the single curves cannot be sepa-

rated well and it is very difficult to find an anomaly in

this figure. This disadvantage is even worse for dis-

crete data, because here the constant parts of the sig-

nals overlap and only the signal changes can be seen.

Figure 4: Visualization with data curves.

In (Alfred, 1985) the method of parallel coordi-

nates is introduced. This technique allows the visu-

alization of multiple dimensions (as coordinates) in

parallel. This makes the dependencies between sig-

nals visible. As disadvantage, it has to be mentioned

that the quality of the datapoints within the visualiza-

tion is highly dependent on the order.

To get along with overlapping signals in high di-

mensions several figures can be depicted in a plot ma-

trix (Cleveland, 1993). Here, the dependency of each

pair of signals is displayed in one figure. All these

figures are then arranged in a matrix. However, very

high dimensions cannot be displayed clearly as well.

E.g. an input dimension of 20 leads to a matrix with

400 single plots.

A detailed description of these methods can be

found in (Keim, 2002).

The Multidimensional Scaling (MDS, e.g. in

(Bronstein et al., 2006)) is a set of techniques from the

mathematical statistics. The goal is the arrangement

of objects and their relation to each other. The far-

ther the objects are from each other, the more dissim-

ilar they are and the closer they are, the more similar

they are. There are thus collected information about

pairs of objects to identify them to metric information

about objects.

2.3 Principal Component Analysis

As outlined in the previous section, it is difficult to vi-

sualize high-dimensional data. Therefore, dimension-

ality reduction methods have to be used. The Prin-

cipal Component Analysis (PCA) was introduced by

Pearson and Hotelling and is here described based on

(Jolliffe, 2002).

The PCA finds new uncorrelated features, the

principal components. The dimensionality of the

dataset is then reduced by using just two principal

components to describe the dataset. This is possible,

because most of the variance of the original dataset,

i.e. the information, is represented by the first few

principal components. (Jolliffe, 2002). In this contri-

bution a two dimensional approach is used for the vi-

sualization (choosing two principal components), be-

cause it is difficult to extract information from a figure

with three dimensions and for more than three dimen-

sions it is impossible to create a visualization.

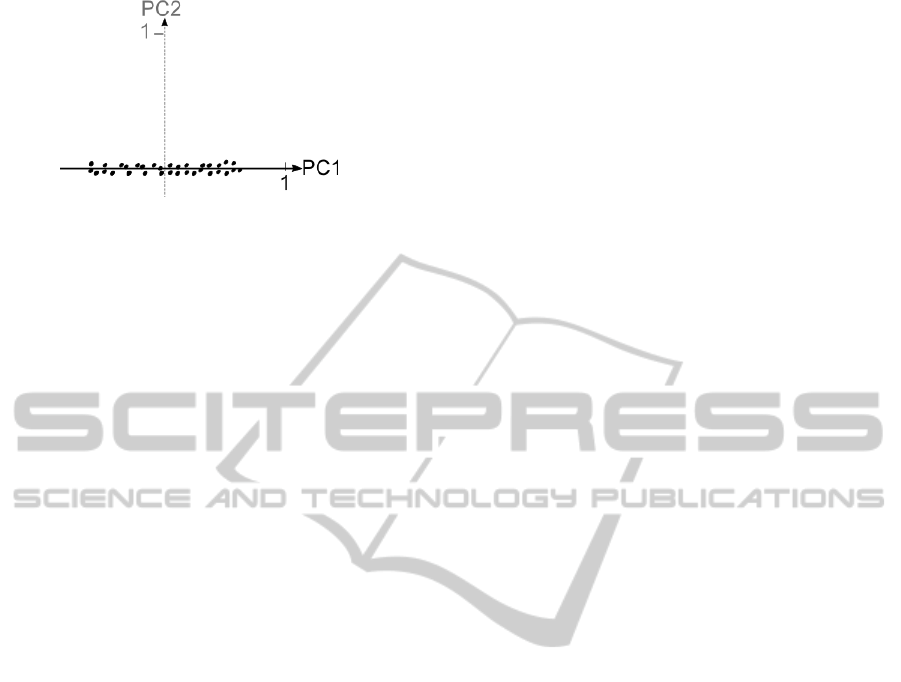

Figure 5 shows an example dataset visualized

based on its two features X and Y.

Figure 5: Example dataset with original features.

In figure 6 the same dataset is depicted based on

its first two principal components. We can see that

the most variance is represented by the first princi-

pal component (PC1). The variance represented by

the second principal component (PC2) is rather small.

In the notion of feature reduction only PC1 would be

used for data representation of the example dataset.

VisualAnomalyDetectioninProductionPlants

69

Figure 6: Example dataset with principal components.

The most information of the original dataset is pre-

served.

Although the most variance is kept it must be taken

into account how many information is lost due to the

reduction. For example reducing a dataset from 20

signals to 2 principal components (reduction of 90%)

while keeping 80% of the information (loss of 20%)

is a quite effective way of dimensionality reduction.

Nevertheless the informational loss is highly depen-

dent on the dataset and maybe worse than in the given

example. Therefore this should be considered. Be-

sides the potential of dimensionality reduction it has

to be considered that the process is not visualized ex-

plicitly with respect to its time line.

3 VISUAL DATA EXPLORATION

This section gives some requirements for the visual-

ization of technical processes. These requirements

will be used for the evaluation in the next section.

Based on the requirements section 3.2 introduces a

new approach, the Discrete State Encoding (DSE),

which is especially developed for the visualization of

high-dimensional discrete input data.

3.1 Requirements for the Automation

Domain

Every domain uses different methods to visualize the

data. While the climate study uses maps which are

colored to show the temperature, the financial indus-

try uses curves to show the trends of stocks. To place a

visualization method in the area of automation, tech-

nical requirements have to be considered:

High Dimensionality. Data of production plants is

typically high-dimensional. This is caused by a large

amount of sensors and actuators which are used to re-

alize processes. Most of them are controlled by PLCs

and need to be monitored by operation personnel in

SCADA systems.

Different Data Types. The variety of sensors and ac-

tuators that are used to realize a process may result

in different types of data. For instance a temperature

sensor provides a continuous value, the temperature.

Whereas a switch that activates a conveyor belt pro-

vides a discrete value, the state of the conveyor belt.

Each data type puts different requirements on the vi-

sualization.

Importance of Data. Due to the high amount of data

visualizing all values would lead to an information

overload. Occurring anomalies may remain unde-

tected. Therefore, only the most important data have

to be visualized. This results in the need of methods

which distinguish between important and less impor-

tant data.

Time Dependency. Processes in the automation do-

main are dependent on the factor time. The system’s

states are usually observed in relation to the process

time. Therefore, the visualization approach should

consider and preserve time information. This enriches

the process analysis and enables the operator to access

the plant state in a natural way.

Cyclic Processes. In typical production plants prod-

ucts are produced in large amounts. This leads to re-

occurring process phases. Therefore, system states

that recur should be depicted in the visualization, so

that the operator is able to recognize them as such. As

a consequence new occurring states (maybe anoma-

lies) can be visualized in a more exposed way. This is

an ease for the operator.

3.2 Discrete State Encoding

Since no appropriate method for the visualization of

discrete data exists, this section introduces the Dis-

crete State Encoding (DSE). It can be utilized for the

visualization of datasets which consist of discrete fea-

tures only. Like the PCA this technique also com-

presses high dimensional information. Here, the plant

behavior is represented by one feature only. This fea-

ture is then utilized in process visualizations to give

operators a neat view on the process progress.

Datasets are represented as tables with N features

f

i

in the columns and the measured process data, i.e.

the observations per row (see also figure 3). Each row

from the dataset is encoded to a representative num-

ber, the stateID. It needs to be mentioned that the

encoding uses only discrete values while continuous

features are ignored. Slightly changing continuous

values would result in a new state for each observa-

tion although the information has not changed signif-

icantly. The stateID computation is based on the fol-

lowing equation.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

70

stateID =

N−1

∑

i=0

f

N−1−i

· 2

i

(1)

In the following step the stateID values are

renumbered. The first occurring stateID is renum-

bered to 1. To each newly occurring state a new num-

ber is assigned, whereas already known stateIDs al-

ways get the same number.

Renumbering stateIDs is necessary to avoid bias

in the visualization. E.g. a bit change in a highly

weighted feature would affect the visualization with

a higher impact than a bit change in a rather low

weighted feature. This misguiding perception should

be avoided, following the notion of the Lie Factor in-

troduced in (Tufte, 2001) in a figure. In the dataset the

state change itself is the important information, not

the artificial weight that is introduced for computation

purpose. The renumbering preserves the state change

information, but removes the bias resulting from the

weights. Figure 7 shows a visualized discrete state

encoding. It can be seen that two cycles are detected

which describe the same process or at least two simi-

lar ones.

Figure 7: Discrete state encoding of an example dataset.

4 EVALUATION OF

VISUALIZATION METHODS

In this section the visualization techniques described

in sections 2 and 3 are evaluated. As basis, the re-

quirements from section 3.1 are used. In the con-

text of visualization of technical processes, the most

important requirement is the visualization of high di-

mensions. Since most visualization techniques (men-

tioned in subsection 2.2) are not able to handle high

dimensions properly or to reduce to the main infor-

mation, only two methods are considered for detailed

evaluation: The discrete state encoding (subsection

4.1) and the principal component analysis (subsection

4.2).

For the evaluation, a dataset of a part of a Model

Factory (shown in figure 8) is used. The first objec-

tive is to provide an abstract process overview. The

second is to detect anomalies. This is done by com-

paring the visualizations of a reference process with

the observed process, which comprises anomalies.

The observed process produces popcorn out of the

resource maize. In total 19 continuous and discrete

features need to be analyzed online while the process

is active. The production process is separated into two

modules. Module one creates the product. The maize

is heated until it pops. Via exhaustion the popcorn is

transferred to a weight cell. In module two the pop-

corn is filled into cups or a larger pot, depending on

what is available at time. The whole process works

sequentially. First the popcorn is produced, next it is

filled into the cups.

Figure 8: A model factory as exemplary plant.

4.1 Discrete State Encoding of a

Production Process

Figure 9 shows the discrete encoded stateIDs for one

process visualized over its time line. Out of the for-

mer 19 features, one new feature, the stateID, is cre-

ated. As mentioned before, continuous values are not

taken into account in the discrete state encoding.

Figure 9: Discrete state encoded process.

VisualAnomalyDetectioninProductionPlants

71

As depicted in figure 9, the operator is provided

with an abstract process overview by following the

process visualization. Without any expert knowledge,

it can be seen that the process has three main opera-

tion phases, and some short transfer phases between

time units 285 - 295. Expert knowledge allows us to

say, that the process states have been identified cor-

rectly. The stateID 1 represents the standby state of

the process. In stateID 2 the production phase is dis-

played. Once enough popcorn is produced, it is filled

into a cup. StateIDs 3-5 represent the cup filling. In

stateID 6 the heating is turned off while the ventila-

tion is still active to cool down the production module.

Afterwards the process returns to standby (stateID 1).

Utilizing the visualization from figure 9 the op-

erator is able to keep track of the process in a very

convenient way. The operator is able to see the pro-

cess over its actual time line. Furthermore, repeating

process phases are represented correctly.

In the next step, the technique is tested regard-

ing anomaly detection in the process. For that pur-

pose, an anomaly is induced into the same dataset

that was used before. A discrete sensor (e.g. a cup

filling level sensor) changes its value in an unusual

moment. Figure 10 shows the stateID representation

of that dataset. As shown, the anomaly can be rec-

ognized by comparing figures 9 and 10. The operator

is also able to determine the point in time where the

anomaly occurred. However, the operator is not able

to interpret the shown anomaly in a semantic way.

Figure 10: Discrete state encoded process containing an

anomaly.

Concluding, the discrete state encoding provides

the operator with a neat view on the process. Besides,

discrete anomalies can be detected by comparing the

visualizations. Even repeating process phases can be

perceived easily while monitoring the stateIDs. Nev-

ertheless the operator needs some expert knowledge

about the process, to benefit of all information pre-

sented by the visualization. A disadvantage of this

visualization technique is the missing ability of visu-

alizing continuous data.

4.2 Visualization of the Principal

Components

In contrast to the discrete state encoding the prin-

cipal component analysis considers both continuous

and discrete features for computation. In this sub-

section the principal component analysis is utilized

to reduce the 19 features of the dataset to two repre-

sentative features which are used in the visualization.

The timestamp is used as an additional feature for the

principal component computation. In figure 11 the

process is visualized with the help of two new fea-

tures, the two principal components. The reduction to

two new features preserves about 83% of the variance

former represented by 20 features; the informational

loss is about 20%.

At first, the operator is able to see a neat pro-

cess visualization. The process is grouped into three

clusters. Considering the knowledge gained in sec-

tion 4.1, it can be said that this is the number of the

main process phases. However, the operator is not

able to semantically interpret the three clusters. It is

not possible to determine whether the process phases

are clustered correctly, nor to see the process phases

with respect to the process time line.

Figure 11: Principal component based process visualiza-

tion.

To evaluate the performance in anomaly detection,

an anomaly has been induced into a continuous signal.

The power consumption rises without any bit change,

i.e. without actively switching on a consumer. Figure

12 shows the visualization of the anomaly-induced

process. Comparing figures 11 and 12, an anomaly is

perceptible. The operator is able to recognize a fourth

cluster in the visualization. In addition anomalies in

discrete and hybrid features were tested. Both were

visualized by this technique.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

72

In summary, the visualization based on the princi-

pal components is able to show anomalies in contin-

uous, discrete or hybrid datasets. Yet it must be ad-

mitted that not all anomalies are depicted by the prin-

cipal component based visualization. Depending on

the influence the original feature had on the principal

component, the anomaly can be visualized in a less

exposed way than shown in figure 12. In the worst

case, anomalies in features that have no significant in-

fluence on the used principal components will not be

visualized as failures.

The PCA works well for continuous and hybrid

data. Here, the data points form a cluster in which

a certain spread is given such that a tolerance in the

test data set is allowed. In the case of only discrete

data the clusters consist of overlapping data points.

Due to the informational loss caused by choosing the

principal components, not all signal changes would

result in a new cluster and therefore not all anomalies

could be displayed.

Figure 12: Principal component based process visualization

containing an anomaly.

5 ANOMALY DETECTION IN

PRODUCTION PLANTS

The main goal of the proposed visualization ap-

proaches is to detect anomalies in the production pro-

cess. In subsection 5.1 a new anomaly detection ap-

proach based on visual analytics is presented. In sub-

section 5.2 it is evaluated and some experimental re-

sults are given.

5.1 Hybrid Visualization and Anomaly

Detection Approach

As mentioned in section 4, both visualization tech-

niques are able to provide the operator with a neat pro-

cess overview, but still have issues in visualizing dif-

ferent types or special anomalies. The discrete state

encoding focuses on anomalies in discrete signals and

gives a process overview with respect to the time line.

The principal component analysis based visualization

provides the operator with a more abstract process

overview and allows the viewer to detect anomalies

in continuous and hybrid data. Hower, the process of

dimensionality reduction considers the time informa-

tion, but the operator is not able to see the process

with respect to its timeline.

Table 1: Comparison of DSE and PCA.

DSE PCA

high dimensionality + +

time + -

continuous data - +

discrete data + -

hybrid data - +

loss of information + -

cyclic processes + +

Table 1 shows the advantages and disadvantages

for both methods. It can be seen that a combination of

both methods would enrich the possibilities of visual

anomaly detection.

To combine the advantages of both methods, the

hybrid visualization and anomaly detection approach

is introduced. The method is organized in three steps.

These three steps are illustrated in figure 13:

Step (1) Observation of the process and detection of

anomalies by comparing the reference process with

the currently running process:

The visualization of the principal components is used

to get an abstract view on the process based on its con-

tinuous and discrete values. The discrete state encod-

ing is used to extend the process visualization with a

reference to the point in process time. Now the opera-

tor is able to compare the reference with the ovserved

behavior in a convinient way.

Anomalies in discrete signals can be seen in the

discrete state encoding, anomalies in continuous sig-

nals are displayed in the principal component visu-

alization. To demonstrate the anomaly detection, in

figure 13, an anomalous process is observed. The

anomaly can be seen in both representations. In the

PCA based visualization the anomalous data items

form a new cluster. The discrete state encoding ad-

ditionally gives the timing information: the anomaly

occurred around the time stamp 20 seconds.

Step (2) Determination of anomalous module:

Additionally the process is separated based on its

modules, to get a more detailed view insight. Dis-

crete state encoding is utilized again to visualize each

module separately. In this example, it can be seen that

the anomaly occurred in the second module.

Step (3) Determination of anomalous signal(s):

VisualAnomalyDetectioninProductionPlants

73

Current process Reference process

PCA

DSE

StateID

StateID

Time Time

PC1 PC1

PC2

PC2

DSE

StateID

StateID

StateID

StateID

Time Time Time Time

Module 1

Module 2 Module 1

Module 2

Sensor PL1

Time

1

2

3

Figure 13: Hybrid visualization and anomaly detection approach.

The last element of the hybrid visualization approach

refers to the continuous process values. The dif-

ference between values in a reference process and

such in an anomaly induced process is calculated and

shown. It allows the viewer to see which continuous

sensor value differs by which amount to the process

time line. Following the example in the top down

manner, it can be said that the anomaly is based on

an unusual energy consumption; in the signal P

L1

.

All mentioned visualization methods are inter-

nally linked with the help of the timestamp. Based

on Shneidermann’s information seeking mantra

Overview first, zoom and filter, then details-on-

demand (Shneiderman, 1996), the operator gets a pro-

cess overview and is able to interactively explore the

process. Interesting data points can be marked in one

figure and corresponding data points will be high-

lighted in each other figures. The operator is able to

see the process behavior in different levels of abstrac-

tion with respect to the time line.

In the given case, the visualization enables the op-

erator to determine the point in time the anomaly oc-

curred precisely. Additionally, the user is able to lo-

calize the module in which the anomaly occured with

the help of the module separated visualization.

The combination of linkage and different visual-

ization techniques allows the operator to find anoma-

lies and learn about the dataset. Because of this, the

PCA based visualization could be enriched with la-

bels to provide semantic information.

5.2 Discussion

As can be seen in table 2 the advantages of the pro-

posed methods could be combined. The hybrid visu-

alization approach allows an enhanced visualization

since the abstract view of the principal components is

combined with the temporal process visualization of

the system’s states. Additionally, the hybrid approach

is able to handle all relevant data types for technical

processes. It was confirmed by experts that the data

abstraction using the PCA reduces the information to

the most important needed to mirror the normal be-

havior of the system. Despite these results, it is pos-

sible that not all anomalies will be displayed by the

PCA based visualization. Especially in the case of

high dimensional input data, important information

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

74

Table 2: Evaluation of the hybrid visualization and anomaly

detection approach.

hybrid approach

high dimensionality +

time +

continuous data +

discrete data +

hybrid data +

loss of information +

cyclic processes +

may be unconsidered by choosing the first two princi-

pal components only.

The approach was also evaluated in order to de-

tect anomalies. In most cases the anomalous behavior

could be detected and the anomalous module and sig-

nal could be determined correctly.

A minor disadvantage of the proposed approach

is that still some expert knowledge is needed to ana-

lyze the plant’s behavior in detail. Nonetheless it is

possible to detect anomalies and the anomalous pro-

duction module(s) and signal(s) without any expert

knowledge.

Another disadvantage is that the proposed ap-

proach works well for the cyclic process, but not for

extended production plants which deal with different

variants of products. This will be improved in future

work.

6 CONCLUSIONS

In this paper a visual analytics approach to the vi-

sualization of technical processes is presented. The

discrete state encoding gives a neat overview of the

observed process and shows the main process states

over the time line. The principal component analy-

sis gives a more abstract overview of the process and

additionally includes continuous data. Both methods

were connected to combine their advantages.

Further it was shown how the visualization and

anomaly detection approach can be used to analyze

a technical process. In three steps the operator is

guided through the observation of the current behav-

ior and the corresponding reference behavior. This

side-by-side visualization enables to detect an occur-

ring anomaly. In the further steps (by zooming into

the process) the operator is guided to the anomalous

module and finally to the anomalous signal.

In further work some other visualization ap-

proaches will be explored. These shall show the most

relevant data in a more intuitive way to give the pos-

sibility to analyze the process behavior without (or at

least with less) expert knowledge. To face the dis-

advantage of the DSE, continuous values can be dis-

cretized using an n-bit-discretization. This will also

be considered in future work.

Furthermore, the visualized reference process will

consider more than only one reference process. This

will provide a more generalized view on the plant’s

behavior.

REFERENCES

Alfred, I. (1985). The plane with parallel coordinates. The

Visual Computer, 1:69–91.

Bronstein, M. M., Bronstein, A. M., Kimmel, R., and

Yavneh, I. (2006). Multigrid multidimensional scal-

ing. Numerical Linear Algebra with Applications,

13(2-3):149–171.

Cleveland, W. (1993). Visualizing Data. AT&T Bell Labo-

ratories.

Frey, C. W. (2008). Diagnosis and monitoring of complex

industrial processes based on self-organizing maps

and watershed transformations. In IEEE International

Conference on Computational Intelligence for Mea-

surement Systems and Applications.

Huang, M. L., Liang, J., and Nguyen, Q. V. (2009). A vi-

sualization approach for frauds detection in financial

market. In Proceedings of the 2009 13th International

Conference Information Visualisation, IV ’09, pages

197–202, Washington, DC, USA. IEEE Computer So-

ciety.

Jolliffe, I. T. (2002). Principal Component Analysis.

Springer.

Keim, D. A. (2002). Information visualization and visual

data mining. IEEE Transactions on Visualization and

Computer Graphics, 8(1):1–8.

Keim, D. A., Kohlhammer, J., Ellis, G., and Mansmann, F.,

editors (2010). Mastering The Information Age - Solv-

ing Problems with Visual Analytics. Eurographics.

Niggemann, O., Stein, B., Voden

ˇ

carevi

´

c, A., Maier, A., and

Kleine B

¨

uning, H. (2012). Learning behavior models

for hybrid timed systems. In Twenty-Sixth Conference

on Artificial Intelligence (AAAI-12), Toronto, Ontario,

Canada.

Shneiderman, B. (1996). The eyes have it: A task by data

type taxonomy for information visualizations. IEEE

Symposium on Visual Languages, page 336.

Thomas, J. J. and Cook, K. A. (2006). A visual analytics

agenda. IEEE Computer Graphics and Applications,

26:10–13.

Tufte, E. (2001). The visual display of quantitative infor-

mation. Graphics Press.

Tufte, E. R. (1997). Visual Explanations: Images and

Quantities, Evidence and Narrative. Graphics Press

LLC.

VisualAnomalyDetectioninProductionPlants

75