Hardware in the Loop Module to Calculate Production Indicators

M

ildred J. Puerto

1

, Josu Larra˜naga

1

, Ulrich Doll

2

and Damien Sall´e

1

1

TECNALIA, Paseo Mikeletegi 7, Parque Tecnol´ogico, E-20009 Donostia, San Sebasti´an, Spain

2

HOMAG AG, 72296 Schopfloch, Germany

Keywords:

HIL, KPI, Remote Module, Manufacturing, Matlab, Hybrid Simulation.

Abstract:

Currently Hardware in the Loop (HIL) is a powerful tool in manufacturing planning. A HIL module for

manufacturing must include the dynamics of a critical machine, the logical control signals and the production

sequence information. By this way Hardware in the Loop can provide a complete set of possible cycletimes,

due the module capability to change delays times, sizes of the workpieces and problems in the parts or in

the logic states. All this information could be re-used for manufacturers to improve factory designs or by

other management modules to improve production indicators under the Virtual Factory Framework European

project framework. Due to the level of detailed dynamics required in Hardware in the Loop simulations, it is

suggested to integrate information from the multibody dynamic simulations programmed at the design level.

1 INTRODUCTION

In current days the industry has to adapt to the com-

petitive pressures of global economy (Manufuture,

2011). In order to improve process manufacturing,

several strategies need to be applied to current indus-

tries, and at the same time need to be included in the

design for future factories. The ability to achieve cost

efficiency, high quality and enhanced robustness with

product variability and changing production require-

ments calls for the application of advanced engineer-

ing tools. One way to give advanced design tools to

designers and industrial machine providers is to sup-

ply them with detailed models of the machines and

information about its performance.

HIL shows to the manufacturing providers and

end-users the way in which a machine will operate

without the necessity to performs real testing and even

without having the real machine.

This paper analyzes from the manufacturing point

of view the different benefits of HIL used as a func-

tional module, in the framework of the Virtual Factory

Framework European project (VFF, 2011).

The structure of this paper is presented as follow:

first is described an overview of HIL, next are pre-

sented the specifications of the HIL module, where is

included the machine model, the control system and

the database for the communication. In section three

are presented the bases to program the HIL module,

followed by specifications of the module. In section 5

is showed the implementation of the module. Prelim-

inary results suggest that random rotations in work-

pieces could affect the cycle time of a production line.

Finally the conclusions are presented.

2 HIL FROM EMERGING

TECHNOLOGY TO DESIGN

TOOL

This section is not a survey about HIL applications;

it is a summary about how HIL has evolved from be-

ing an innovative emerging technology in the 50s into

a tool used by other innovative solutions to current

challenges.

HIL is used since 1950s in Defence and Aerospace

Industry where the high cost of equipment and the

risk index in trials had required of a new manner to

perform testing. However HIL was also an expensive

technique due the limited computational performance

available at the time. In the 90s with the advances in

computer technology and the confirmed functionality

of HIL, it was assimilated by the automotive industry.

Nowadays, HIL is getting in better implementations

and more affordable solutions, which has allowed its

expansion to different sectors. It is well known that

HIL accelerates product development, increases prod-

uct quality and minimizes cost in prototypes and tests.

All this is making this technique more used every day.

Today, HIL is itself a tool for other emerging tech-

nologies like renewable energy, robotics and manu-

464

Puerto M., Larrañaga J., Doll U. and Sallé D..

Hardware in the Loop Module to Calculate Production Indicators.

DOI: 10.5220/0004040604640467

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 464-467

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

facturing. In energy, PHIL (Power HIL) is used to test

the response of smart grids and power components.

In this manner, PHIL performs optimization of power

supply and prevents dangerous failures see (Lentijo

et al., 2010). In robotics, the robot interaction with

other robots and/or humans is a growing application,

it is generating new challenges in terms of response

time, stability and security.

In manufacturing, HIL is providing a tool to an-

alyze production and maintenance capabilities. The

information about factory performance is showed by

the KPIs (Key Performance Indicators), so HIL must

focus in providing the signals needed to calculate

determined KPI. (Gu et al., 2007) has studied how

HIL could provide reduction in unscheduled down-

time and in the KPI MTTR (Mean Time to Repair).

Meanwhile (Harrison et al., 2012) has used it in a de-

tailed level for manufacturing systems where real and

virtual world could be used simultaneously.

A description of how HIL could be used in pro-

duction management is described in the next sections.

3 HIL MODULE BASES

In modern factories the continuity of the link design-

real machine is broken due the provider-customer re-

lations. Machines that are used in manufacturing pro-

cesses are designed mostly by Computer Aided Engi-

neering (CAE). The design information is lost when

the machine is commissioned in a plant under real

conditions, as well as the real performance and be-

haviour of the real machine is not feedback to design-

ers.

One of the big differences between engineering

models and real machines is that in a factory, the be-

haviour of a machine depends of the industrial control

system (PLC), it is a fundamental part of a machine

performance and operation.

Therefore, real manufacturing systems need hy-

brid simulations to represent the combination of dy-

namics and logical states. A detailed model with

logic states, mechatronic and environmentsystems in-

dicators is fundamental to calculate properly the main

production KPIs, like are production and cycle time,

reaching even the level of work pieces.

The cycle time is defined as the total time from the

beginning to the end of the process. To calculate cy-

cle time, process time and delay time are needed. The

performance of HIL module is the combination of the

level of detail in the representation of the process and

in the real-time hardware (Cai et al., 2008).

Summarizing, HIL module for manufacturing

needs three basic elements: a dynamic model of the

machine, the PLC control program and the character-

istics of the production sequence.

Several ways could be used to obtain the dynam-

ics of a machine, one of them is the mechatronic mod-

elling of final prototypes in multibody dynamics CAE

tools, such as ADAMS or ProEngineer. Based on

ADAMS (Multibody Dynamics and Motion Analysis

Software) model, a set of linear state space matrices is

exported to MATLAB as the linear representation of

the machine. Other way to find the machine dynamics

is using the Lagrange-Euler laws of the mechanism,

this approach is implemented in mechanic machines

and robots (Siciliano et al., 2011).

With the machine model in MATLAB/Simulink it

is possible to use StateFlow to model the control pro-

gram of the machine and perform a hybrid simula-

tion between logic programming and the continuous

states.

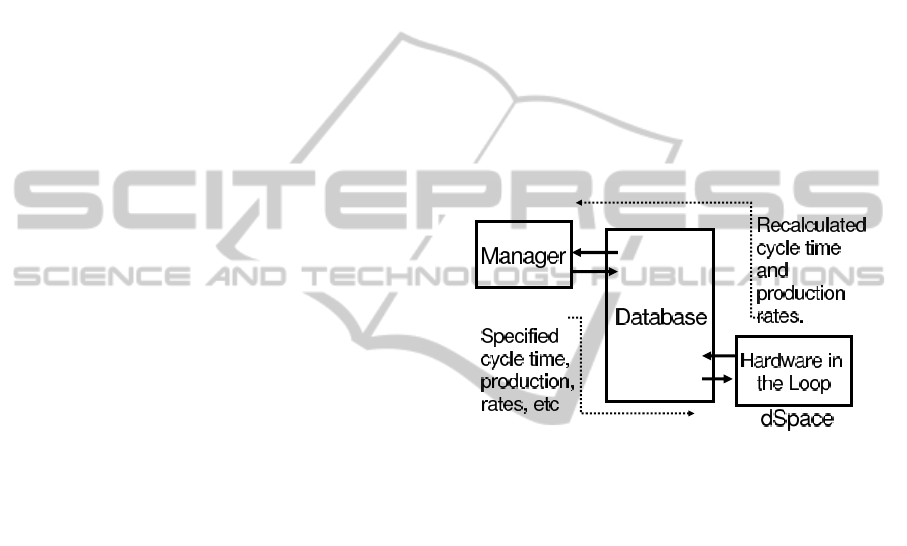

Figure 1: Communication process to read production se-

quence and write generated KPIs.

The application needs to be loaded to a real-time

environment; in this case it has been implemented

with dSpace. The processor dSpace rti1006 runs to

1KHz and the results can be transmitted during the

simulation thanks the Control Desk application and

the connection libraries in C ++/Java. The imple-

mented HIL runs in a PC with Matlab/Simulink (ver-

sion 2007 or later) and the Control Desk application

must be a 2008 version at least.

Finally the production sequence information

could be directly introduced by the designer or loaded

from a database. Then, HIL calculations could be

stored.

The key issue is the HIL configuration as a mod-

ule that is used by the management actions to improve

the factory performance (Sauer et al., 2009). With the

modelling of a critical machine in Matlab/Simulink,

this module needs to be communicated with other

modules (Fig.1). This is the view of VFF, that all

modules could exchange information; in other words,

that the knowledge produced in one place could be

accessible for other modules interested in having it.

HardwareintheLoopModuletoCalculateProductionIndicators

465

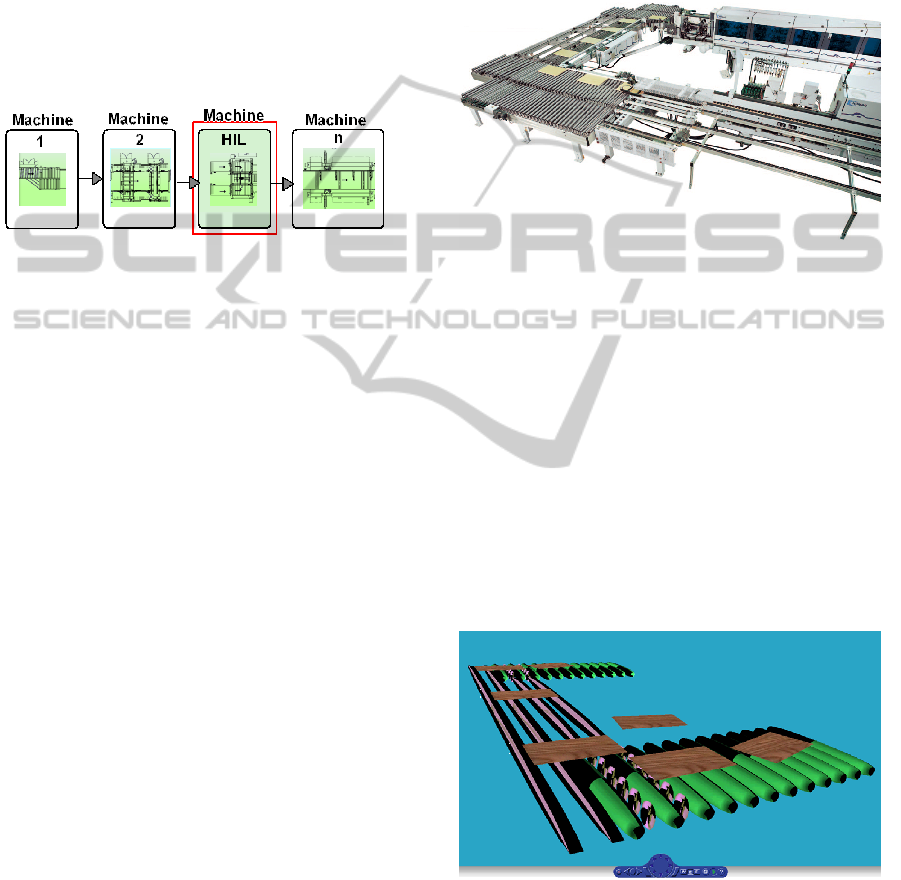

4 SPECIALIZED MODULE FOR

RECALCULATE KPI

Normally, testing of industrial machines is very ex-

pensive and some times it is not possible due the

consuming time or because the complete fabrication

line is not available. Then becomes imperative to

test some parts on a simulation of the actual system.

This is the stage where HIL is highly recommended

(Fig.2). Besides, this module based in dynamics of a

process is better modelled by continuous simulation

than discrete event simulations.

Figure 2: HIL simulation inside the production line.

Since HIL requires a strong modelling effort,

a primary approach could be to choose a com-

plex/problematic machine that affects a complete pro-

duction line and based on its calculate function the

main problems in the line and how it is affecting the

complete production planning.

The module could calculate the variables needed

for some performance indicators that are affected by

the critical machine performance.

The module reads the process plan and the pro-

duction rate information from a database. Then it

simulates the given operation in the station/machine

in closed loop and calculates the station performance

parameters with more precision. The results are more

realistic values for the performance indicators.

A designer or provider of production lines could

use a machine model to calculate the behaviour of

a solution with low development cost, improving the

response of the factory design (VFF, 2011); (Bathelt

et al., 2010).

The novelty in this approach is to use HIL as a

module with the possibility of interacts with other

modules. For a multi-component system it is neces-

sary to parameterize the properties that will be ex-

changed through a remote database or a manager

module.

When the machine is working in a real factory,

the information about its performance is feedback to

the designers to improve the control program or even

change the mechanical design.

5 IMPLEMENTATION OF THE

HIL MODULE

HIL module contain the information about a specific

machine (Fig.3), together with the information about

work pieces and cycle times provided by HOMAG

(HOMAG, 2011).

Figure 3: Angular Transfer Machine, provided by HOMAG

(HOMAG, 2011).

This critical machine connects two stages into the

production line, carrying pieces of wood at the max-

imum speed from one machine to the next one. Due

its shape, this machine saves space in the factory, but

also tends to rotate the parts producing unwanted col-

lisions. With this information, the programming of

the PLC and the stateflow was carried out. The spe-

cific dynamics about the friction and random rotation

of the piece of wood are used in HIL to calculate the

cycle times. Leading the module prepare to recalcu-

late KPIs under a large range of conditions. The re-

calculated cycle times are communicated to a central

modules manager through a server application.

Figure 4: Virtual reality animation of the HIL module.

The parameters that can be changed in the HIL

simulation are: the velocity of the line, the wood

mass and size, the rolling resistance coefficient and

the range of rotation in the wood pieces.

The simulation runs (Fig.4) in a VRML environ-

ment. The preliminary results about the cycle time

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

466

shows that the rotation in the piece of wood affects

the necessary gap to avoid collisions in the machine

(Figs.5 and 6).

With all pieces of: 2810 mm x 1010 mm, 25 mm

height and 65 kg of weight, without rotation, one

minute is requeried to transport 24 pieces. With the

Poisson distribution applied to the random rotation,

simulation shows that 2 or 3 pieces collide. To avoid

that it is necessary to increase the gap between pieces

from 1.23 s to 1.29 s. The meaning of this time in-

crement is reflected in the new number of parts trans-

ported: only 22. The differenceof 2 pieces per minute

affects the complete production line.

Module validation is required and future improve-

ments in the model are needed, such us the automa-

tion in the collisions detection and the simulation of

failures in the PLC inputs.

Figure 5: VRLM frame showing a random rotation in the

pieces of wood. The calculated necessary space to avoid

collision is B, meanwhile A is a shorter space produced by

a random rotation.

Figure 6: VRLM example of wood pieces collision due the

rotation in one of them.

6 CONCLUSIONS

The goal of the HIL module is to investigate the ef-

fect of faults, both in sensors and actuators, and the

machine itself.

This paper presents how a detailed model of a real

critical machine can calculate the production cycle

time, this under real conditions for factory produc-

tion.

The communication of the defined KPI to other

modules allows the exchange of knowledge for the

factory design or for production improvement. The

design of a production line could be optimized even

before the line is assembled, increasing productivity

even in future factories. The validation of this tool in

the VFF framework is still under development.

ACKNOWLEDGEMENTS

This research obtained the financial support of the EU

commission for the VFF project: Holistic, extensi-

ble, scalable and standard Virtual Factory Framework

(FP7-NMP-2008-3.4-1).

REFERENCES

Bathelt, J., Politze, D., Jufer, N., Joensson, A., and Kunz,

A. (2010). Factory of the future enabled by the virtual

factory framework (vff). In 7th International DAAAM

Baltic Conference, pages 203–208.

Cai, G., Chen, B. M., Lee, T. H., and Dong, M. (2008).

Design and implementation of a hardware-in-the-loop

simulation system for small-scale uav helicopters.

Proceedings of the IEEE, pages 29–34.

Gu, F., Harrison, W. S., Tilbury, D. M., and Yuan, C.

(2007). Hardware-in-the-loop for manufacturing au-

tomation control: Current status and identified needs.

In Automation Science and Engineering, 2007. CASE

2007. IEEE International Conference, pages 1105–

1110. IEEE.

Harrison, W., Tilbury, D., and Yuan;, C. (2012). From

hardware-in-the-loop to hybrid process simulation:

An ontology for the implementation phase of a manu-

facturing system. Automation Science and Engineer-

ing, IEEE Transactions on, 9:96–109. ISSN: 1545-

5955.

HOMAG (2011). Woodworking machinery from homag.

www.homag.com.

Lentijo, S., Arco, S. D., Monti, A., and Member, S.

(2010). Comparing the dynamic performances of

power hardware-in-the-loop interfaces. IEEE Trans-

actions on Industrial Electronics, 57(4):1195–1207.

Manufuture (2011). Manufuture strategic research agenda.

www.manufuture.org/manufacturing/.

Sauer, M., Zeiger, F., and Schilling, K. (2009). A simulation

setup for communication hardware in the loop exper-

iments. In Proceedings of the 6th International Con-

ference on Informatics in Control, Automation and

Robotics, pages 312–317.

Siciliano, B., Sciavicco, L., Villani, L., and Oriolo, G.

(2011). Robotics: Modelling, Planning and Control

(Advanced Textbooks in Control and Signal Process-

ing). Springer, ISBN-10: 1846286417.

VFF (2011). Holistic, extensible, scalable and standard vir-

tual factory framework. www.vff-project.eu/.

HardwareintheLoopModuletoCalculateProductionIndicators

467