Automatic Design Optimisation of Pharmaceutical Tablets using

PDEs

Norhayati Ahmat

1,2

,

Gabriela González Castro

1

and

Hassan Ugail

1

1

Centre for Visual Computing, University of Bradford, BD7 1DP, U.K.

2

Faculty of Science and Mathematics, Universiti Pendidikan Sultan Idris, 35900 Tg. Malim, Perak, Malaysia

Keywords: PDE Method, Parametric Surfaces, Pharmaceutical Tablets, Automatic Optimisation.

Abstract: Pharmaceutical tablets and capsules are the dominant forms for drug delivery. Both types of dosage forms

need to be strong enough to handle different types of stress due to packaging and loading conditions before

use. Hence, it is important to produce these pharmaceutical forms with maximum mechanical strength while

conserving the properties of their active ingredients during the design process. The present work describes a

methodology for parametric design and optimisation of a solid cylindrical tablet and a soft spherical cap-

sule, which is based on the use of Partial Differential Equations (PDEs). The PDE-based formulation is ca-

pable of parameterising complex shapes using the information at some boundary curves that describe the

shape. It is shown that the optimal designs of both tablet and capsule can be obtained using an automatic de-

sign optimisation which is performed by combining the PDE method and a standard method for numerical

optimisation.

1 INTRODUCTION

In the past few decades, tablets and capsules have

become the important dosage form for drug delivery

in pharmaceutical industry. Tablets and capsules

have many advantages over other dosage forms.

They are convenient to use by patients and have long

storage stability. Additionally, they can hide the

unpleasant taste of their contents.

These types of dosage forms have been made in

many shapes, sizes and consistencies. This helps to

distinguish different medicines and is also useful for

product branding. The most common shapes for

tablets are round, oval and caplet whereas capsules

are divided into two types: hard-shelled capsules and

soft-shelled ones. The size of these dosage forms

varies from a few millimetres to about a centimetre.

The quality of both tablets and capsules are de-

scribed by several parameters such as hardness,

content uniformity, and accurate mass and height

(Elkhider et al., 2007).

Tablets are produced through three distinct stag-

es. These are die filling, compaction process and

ejection. It has been reported in Coube et al. (2005)

that the mechanical strength or disintegration of a

tablet depends on the behaviour of powder during all

stages of the tabletting process. The most important

stage of tablet production is the powder compaction

stage that involves compression and decompression

of the powder bed. During this stage, the compaction

properties (compressibility and compactibility) of

the pharmaceutical powder bed can be determined.

Compressibility, which is usually analysed using the

Heckel, Kawakita and Walker models (Ilić et al.,

2009), explains the mechanical properties of the bed

in terms of elasticity and plasticity (Ilić et al., 2009).

Meanwhile, compactibility refers to the ability of

powders as small particles to change into the coher-

ent solid dosage form (Sonnergaard, 2006). Com-

pactibility can be estimated by measuring the me-

chanical strength of the powder compact which is

generally characterised by the measurement of ten-

sile strength (Han et al., 2008).

The tensile strength of a solid dosage form

measures the ability of the object to resist forces

before it breaks. This can generally be determined

using the diametrical or axial compression tests (Han

et al., 2008). The measured force (F) obtained from

the test together with the diameter (D) and thickness

(h) of the dosage form are used to calculate the ten-

sile strength

=

2

ℎ

,

(1)

125

Ahmat N., González Castro G. and Ugail H..

Automatic Design Optimisation of Pharmaceutical Tablets using PDEs.

DOI: 10.5220/0004059601250130

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 125-130

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

and

=

4

,

(2)

where F

max

is the maximum crushing force and F

y

is

the force at the yield point. Equations (1) and (2)

represent the tensile strength of a dosage form ob-

tained from the diametrical and axial compression

test respectively. It has been reported in Elkhider et

al. (2007) that the properties of dosage forms such as

density and surface area can influence the tensile

strength of the form.

Given that the shape and size of dosage forms

play an important role in determining their mechani-

cal properties, this work proposes a method to model

solid shapes of cylindrical tablet and spherical cap-

sule interactively based on the use of parametric

surface representations. Additionally, a methodology

for automatic design optimisation within an interac-

tive environment for both dosage forms is also de-

scribed in this work. The objective is to obtain an

optimal shape for a tablet and also predicting the

optimal thickness of a spherical capsule’s shell.

Many authors have reported that the choice of the

design variables is important in shape optimisation.

Moreover, the number of design variables also needs

to be considered because too many variables may

increase the computational time (Ugail, 2003).

PDE method has been widely used as a surface-

modelling technique in many areas (González Castro

et al., 2010). This method can generate a smooth

surface of complex geometries from a few design

parameters. Furthermore, the PDE surface can be

manipulated intuitively by changing the boundary

curves or design parameters (Ugail, 2003). This

method also has been proven to be useful to address

optimisation problems including in biological (Ugail

and Wilson, 2003) and industrial applications

(Ugail, 2003). The PDE-based optimisation is per-

formed within a reasonable computational time by

combining engineering design criteria as constraints

into the geometric design of PDE surfaces (Ugail,

2003). Therefore, the PDE method is used in this

work to perform the automatic design optimisation

of pharmaceutical tablets and capsules.

2 THE PDE METHOD

The PDE method produces a parametric surface,

X

,

)

that is generated by solving the fourth order

elliptic PDE

+2

+

,

)

=0,

(3)

where u and v are the independent variables in do-

main [0, 1] and [0, 2π] respectively. Equation (3) is

known as the Biharmonic equation. The analytic

solution to Equation (3) is found using separation of

variables subject to four periodic boundary condi-

tions.

For the sake of brevity, the present work em-

ployed the approximated solution of Equation (3)

which has been truncated to N Fourier modes

,

)

=

+

)

cos

)

+

)

sin

)

+

,

)

,

(4)

where

=

+

+

+

,

(5

)

=

+

)

+

+

)

,

(6

)

=

+

)

+

+

)

,

(7

)

=

+

)

+

+

)

.

(8)

Given that

,

,⋯,

,

,⋯,

,⋯,

are

vector valued constants. Their value is determined

by the boundary conditions at u = 0 and u = 1. The

term

represents the spine of the patch which

brings out the symmetry of the patch while the re-

maining terms in Equation (4) define the position of

a point on the surface relative to the spine. The vec-

tor

is known as a remainder function which is

responsible for fully satisfying the original boundary

conditions. Thus, the vectors

,⋯,

and are

obtained from the difference between the original

boundary conditions and the one satisfied by the first

two terms in Equation (4).

As mentioned earlier in this section, four bound-

ary conditions are needed to solve the Biharmonic

PDE. Hence in this work, four periodic curves are

chosen as the boundary conditions to create a PDE

surface. These curves are shown in Figure 1(a)

where the positional boundary curves, P

1

and P

2

correspond to the boundary conditions on the edges

of the surface at u = 0 and u = 1 respectively while

d

1

and d

2

define the derivative boundary conditions.

Figure 1(b) illustrates the resulting shape of a fourth-

order PDE surface. Figure 1(d) shows the effect of

changing the derivatives boundary conditions (d

1

and d

2

) originally shown in Figure 1(a). These

boundary conditions have been resized and vertical-

ly translated from the corresponding positional

boundary curves. From this example, it is shown that

the shape of the surface can simply be controlled by

the shape of the boundary conditions.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

126

Figure 1: The boundary curves (a) and the corresponding

surface shape (b). The effect on the shape of the surface by

resizing and translating the derivative curves: the bounda-

ry curves (c) and the resulting manipulated surface shape

(d).

2.1 Geometry of Tablets and Capsules

This section discusses on how the geometry of a

cylindrical tablet and a spherical capsule can be

generated based on the analytic solution of the Ellip-

tic PDE. The geometric models representing both

objects have been obtained using a number of closed

curves. The number of boundary curves depends on

how many PDEs are required to produce the tablet

shape.

As a simple geometry, a flat-faced cylindrical

tablet is fully represented by the solution of one PDE

subject to four boundary curves. However, more

than one PDE is needed to generate the surface of

spherical capsule since the shape of this object is

considered as a complex geometry. The graphic

representation of such PDE is referred as patch and

therefore, complex geometries are represented by

several surface patches. Each of the patches is com-

posed of four boundary curves,

where c indicates

the type of curve, with the letter P denoting the posi-

tional curves and d denoting the derivative curves.

The index j (j = 1, ..., n) represents the patch; j = 1

for the first patch, j = 2 for the second patch and so

forth. The subscript k (k = 1, 2) corresponds to the

boundary edges of the surface.

Adjacent patches need to be blended together by

sharing one boundary curve with either one or two

different PDEs to guarantee the position continuity

along the generated surface. In this work, a spherical

capsule is generated from a surface composed of two

patches representing the outer surface of its hemi-

spheres (upper and lower). As it can be seen in Fig-

ure 2(d), the second positional boundary curve of the

lower hemisphere corresponds to u = 1 (marked as

P

12

) is used as the first positional curve of the upper

hemisphere (P

21

). Hence, only seven curves are

required to generate the outer surface of the capsule.

In order to create a hollow spherical capsule, another

two patches are needed to represent its inner surface.

Figure 2(a) shows the conditions in terms of the

curves to generate a flat-faced cylindrical tablet with

radius 4.91 mm and thickness 6 mm. In particular,

the four conditions are such that

0,

)

=

,

1

3

,=

,

2

3

,=

,

1,

)

=

.

It can be seen in Figure 2(b) that all curves lie on the

resulting surface. In case of generating the axisym-

metric spherical capsule, we only consider the upper

hemisphere since this object is symmetric. The size

(r

i

) and position in z-direction (z

i

)

for each boundary

curve representing the upper hemisphere are deter-

mined by

=cos

)

and

=sin

)

for=4,5,6,7

(9)

where i represents the number of curves, =0,

and R is the radius of the sphere (a and b denote the

outer and inner radius of the capsule respectively).

Generally, the coordinate of these boundary curves

can be written as

cos,

sin,

)

.

(10)

Therefore, the coordinate for all boundary curves

used to generate the outer surface of an upper hemi-

sphere with a centre (x

0

, y

0

, z

0

) and radius (a) 2.5

mm is such that

:

+2.5cos,

+2.5sin,

)

,

:

+2.17cos,

+2.17sin,

+1.25

)

,

:

+1.25cos,

+1.25sin,

+2.17

)

,

:

,

,

+2.5

)

.

(11)

The conditions in Equation (11) can be reflected to

obtain the conditions corresponding to the lower

hemisphere. The inner surface of the capsule with

radius (b) 2.0 mm is also created from boundary

curves generated using Equations (9) and (10).

Figure 2(d) illustrates the geometry of the upper

hemisphere of a spherical capsule generated using

the analytic solution of the Biharmonic PDE.

AutomaticDesignOptimisationofPharmaceuticalTabletsusingPDEs

127

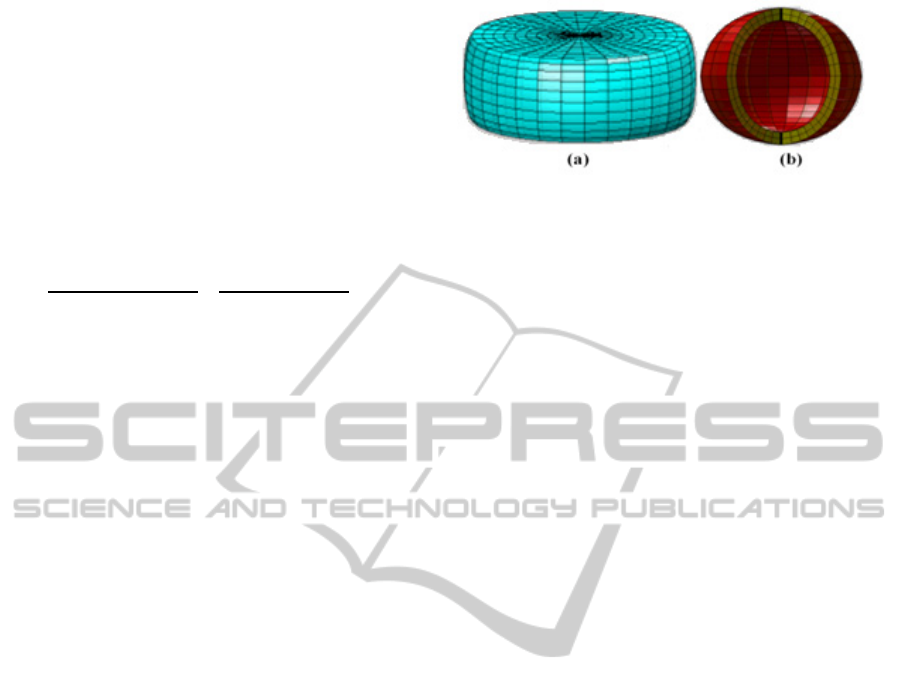

Given that the analytic solution of the Elliptic

PDE only generates the surface of any given object,

a new parameter (w) has been introduced into Equa-

tion (4) in order to generate a solid representation of

the particular object

,,

)

=

+

,

)

+

)

cos

)

+

)

sin

)

(12)

where 0≤≤1. This parameter describes the

volume inside the generated object. The solid cylin-

drical tablet and spherical capsule are shown in

Figures 3(a) and 3(b) respectively. The parametric

region of parameter v is set to be from

to 2 in

order to show the interior part of the PDE-based

representation of a spherical capsule.

3 DESIGN OPTIMISATION

This section shows how automatic design optimisa-

tion of a solid tablet and capsule can be carried out

using the parametric model discussed in Section 2. It

is assumed that both dosage forms are finite, homo-

geneous and isotropic. The design optimisation of

these objects is performed by solving a constrained

optimisation problem formulated based on the objec-

Figure 2: Generating curves in three-dimensional space for

tablet (a) and capsule (c). The resulting surface shape of

both objects in (b) and (d) respectively.

Figure 3: Solid PDE-based representation of cylindrical

tablet (a) and spherical capsule (b).

tive function together with the boundary conditions

(positional and derivatives curves) associated with

the geometry of the dosage form and the required

constraints.

The most important aspect of design optimisation

is the definition of a suitable objective function,

which has to be minimised or maximised. The gen-

eral mathematical formulation of an optimisation

problem to minimise a given objective function

under nonlinear equality and inequality constraints

can be written as

minimise

)

subject to

)

≤0,=1,…,

ℎ

)

=0,

=1,…,

≤≤

;∈

ℝ

(13)

where f(x) is the nonlinear objective function, is a

vector of n design variables with sets of lower (

)

and upper (

) bounds, while

)

and ℎ

)

repre-

sent inequality and equality constraints respectively.

There is a wide variety of methods for numerical

optimisation such as Interior-point and Active set

methods (Eitrich and Lang, 2006). It has been re-

ported in Leyffer (2005) that the Active set method

is more robust than the Interior-point method. The

Active set method solves constrained nonlinear

optimisation problems by minimising the objective

function in each iteration over the active set until the

optimal solution is obtained. In this method, the

optimisation problem is split into one active and one

inactive parts where the active part refers to a subset

of the constraints that are locally active (Eitrich and

Lang, 2006).

This work carries out the optimisation using the

Active set method, which is run in Matlab. A MEX

file has been created as an interface between Matlab

and Visual C++. A subroutine has been developed in

C++ to read the boundary curves that define the

shape of the tablet and produce the solution for each

set of curves. When the Matlab file is compiled, the

MEX file is dynamically loaded and allows calling

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

128

the pertaining C++ subroutine within Matlab as if it

was a built-in function. Moreover, Matlab was used

to display the resulting shapes after the optimisation

process is finished.

3.1 Optimisation Process for

Cylindrical Tablet

The automatic optimisation of the cylindrical tablet

shown in Figure 3(a) is considered. The tablet dis-

cussed in this work is composed of 300 mg of α-

lactose monohydrate with the value of E = 2460

N/mm

2

, γ = 0.21 and true density (

) 1.3

mg/mm

3

. The initial diameter and thickness of this

tablet are 9.82 mm and 6 mm respectively. Assum-

ing that the tablet is located in the bottom of a bottle

filled with tablets, such the tablet experiences a

stress. This is due to the weight of the rest of the

tablets in the bottle and hence, this tablet becomes

either slightly deformed or damage. Therefore, the

required strength of the tablet needs to be measured

by calculating the maximum tensile strength within

the tablet. This is done by means of axisymmetric

boundary value analysis where the force is applied

on the top plane of the tablet caused by the weight of

the other tablets in the bottle. It is also assumed that

the bottom plane of the tablet is fixed at z = 0.

The objective here is to determine the optimal

shape of a cylindrical tablet with a maximum tensile

strength subject to a given volume. Therefore, Equa-

tion (2) is employed to measure the strength of the

cylindrical tablet occurring in the whole structure.

The yield force (F

y

) in Equation (2) is replaced by

the yield pressure (P

y

), which can be obtained from

the Heckel model

ln

1

1−

=+,

(14)

where

is a relative density, P is a pressure, and

K and A are constants. The constant K gives the

value of the plasticity of a compressed powder bed

while A is associated with the particle rearrangement

before deformation (Ilić et al., 2009). The yield

pressure is measured from the reciprocal of K (Ilić et

al., 2009) and hence, Equation (2) is transformed to

=

ln

ℎ

ℎ

−

−

,

(15)

where h, c and m represent the thickness, radius and

mass of the tablet respectively.

The design space is further restricted by choos-

ing a constraint to represent the volume of the tablet.

In this case, the volume is fixed to 235 mm

3

, which

can be calculated using the expression given by

1

3

∙

)

=235,

(16)

where n

i

and

are the unit vector normal and area

of the i

th

defining surface. Here, M represents the

number of rectangular surfaces since the PDE-based

representation of the tablet in question is generated

from cuboid mesh. It is worth mentioning that Equa-

tion (16) represents a means for the numerical com-

putation of the volume enclosed within a closed

surface. With the above formulation, the boundary

curves and their initial size and position for the op-

timisation process of this tablet are shown in Table

1. Emphasis is made on the fact that we only consid-

ered the translation in z direction and dilations in the

xy plane for all boundary curves within the defined

limits. The radius of each curve is set from 4.5 mm

to 5.15 mm while the position in the z-direction for

every curve is chosen between 0 to 3.5 mm.

The Active set method finds the design with the

lowest possible value of the chosen merit function

from the design space. The optimisation took less

than an hour to obtain the maximum strength after

four iterations starting from a randomly chosen solu-

tion point. The optimal shape which had a relative

reduction in height of 50 % is found with maximum

tensile strength as shown in Figure 4(a). The values

of the design curves obtained for the optimal design

are given in Table 1.

Table 1: Parameter values for the cylindrical tablet.

Boundary

curve

Initial Optimal

P

osition z Radius

(mm) (mm)

P

osition z Radius

(mm) (mm)

P

1

0.0 4.91 0.0 4.83

d

1

1.88 4.91 0.9 5.15

d

2

4.12 4.91 2.0 5.15

P

2

6.0 4.91 2.93 4.83

103.333 N/mm

2

3.2 Shape Optimisation of a Spherical

Capsule

The aim for this example is to identify the optimal

thickness of the capsule shell whilst possessing a

predefined level of strength. Again, the translation in

z direction and dilations in the xy plane of all bound-

ary curves are considered.

AutomaticDesignOptimisationofPharmaceuticalTabletsusingPDEs

129

Here, the elastic gelatin spherical capsule is sub-

jected to an external pressure (P

ext

) at its outer sur-

face r = a and an internal pressure (P

int

) at its inter-

nal surface r = b. Equation (1) is used in the optimi-

sation routine as the objective function. The thick-

ness of the capsule shell is measured by considering

the radial displacement of the pressurised sphere.

The displacement is determined by making use of

the Love’s stress function subjected to particular

boundary conditions (González and Fitt, 2002)

=−

−

)

3+2

)

−

)

−

−

)

4

−

)

,

(17)

where λ and µ are the Lame modulus and shear

modulus respectively.

A pressure of 153 µN/mm

2

is applied on the out-

er surface of the capsule while the pressure on its

inner surface is 39 µN/mm

2

. As far as the material

properties are concerned, the Young modulus and

Poisson’s ratio of the gelatin are 0.11 N/mm

2

and 0.4

respectively (Markidou et al., 2005). For this partic-

ular example, the volume of the spherical capsule is

fixed to 14.14 mm

3

.

With the above formulation, the automatic opti-

misation was performed about 72 minutes on a

Matlab R2008a with 2.20 GHz Intel Core 2 Duo

T7500 processor. The resulting optimal thickness of

capsule’s shell is shown in Figure 4(b). This shape

has a relative reduction in thickness and size of 46 %

and 40 % respectively. The maximum tensile

strength for the capsule was found to be 10.89

N/mm

2

.

4 CONCLUSIONS

This work outlines a methodology for shape optimi-

sation of pharmaceutical dosage forms based on the

PDE method enabling efficient shape definition and

parameterisation of complex geometries. The shape

of a tablet and capsule is generated from a small set

of design parameters and can be controlled by the

chosen boundary curves. Thus, the optimised shape

is obtained after carrying out an optimisation analy-

sis and relating the pertaining results to the solution

of the corresponding PDE as given in Equation (4).

It is worth mentioning that the concise parameterisa-

tion characteristics of the PDE method can be used

to carry out automatic design optimisation in a prac-

tical setting where the time taken for tablet testing

can be significantly reduced and encourages future

development of pharmaceutical technologies.

Figure 4: Optimal shape of a tablet (a) and optimal

thickness of capsule shell with maximum tensile strength

(b).

REFERENCES

Coube, O., Cocks, A. C. F., Wu, C. Y., 2005. Experi-

mental and numerical study of die filling, powder

transfer and die compaction. Powder Metallurgy 48,

68-76.

Eitrich, T., Lang, B., 2006. Efficient optimization of sup-

port vector machine learning parameters for unbal-

anced datasets. Journal of Computational and Applied

Mathematics 196, 425-436.

Elkhider, N., Chan, K. L. A., Kazarian, S. G., 2007. Effect

of moisture and pressure on tablet compaction studied

with FTIR spectroscopic imaging. Journal of

Pharmaceutical Sciences, 96, 351-360.

González Castro, G., Athanasopoulos, M., Ugail, H.,

2010. Cyclic animation using partial differential equa-

tions. The Visual Computer 26, 325-338.

González Castro, G., Fitt, A. D., 2002. A mathematical

model for tonometry. Springer-Verlag.

Han, L. H., Elliot, J. A., Bentham, A. C., Mills, A., Ami-

don, G. E., Hancock, B. C., 2008. A modified Drucker-

Prager Cap model for die compaction simulation of

pharmaceutical powders. International Journal of Sol-

ids and Structures 45, 3088-3106.

Ilić, I., Kása, P., Dreu, R., Pintye-Hódi, K., Srčič, S., 2009.

The compressibility and compactibility of different

types of lactose. Drug Development and Industrial

Pharmacy 35, 1271-1280.

Leyffer, S., 2005. The return of the active set method.

Oberwolfach Reports 2(1), 107-109.

Markidou, A., Shih, W. Y., Shih, W.-H., 2005. Soft-

materials elastic and shear moduli measurement using

piezoelectric cantilevers. Review of Scientific Instru-

ments 76.

Sonnergaard, J. M., 2006. Quantification of the compacti-

bility of pharmaceutical powders. European Journal of

Pharmaceutics and Biopharmaceutics 63, 270-277.

Ugail, H., 2003. Parametric Design and Optimisation of

Thin-Walled Structures for Food Packaging. Optimi-

zation and Engineering 4, 291-307.

Ugail, H., Wilson, M. J., 2003. Efficient shape parametri-

sation for automatic design optimisation using a par-

tial differential equation formulation. Computers &

Structures 81, 2601-2609.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

130