Development of Intelligent Assistance System to Support

Eco-efficient Planning

Sarfraz Ul Haque Minhas and Ulrich Berger

Chair of Automation Technology, Brandenburg University of Technology Cottbus, Cottbus, Germany

Keywords: Production Scheme, Knowledge Management, Knowledge Repository, Environmental Impact.

Abstract: The automotive industry is facing challenges due to high mass customization and consequent

decentralization of manufacturing systems. Currently, the evaluation and optimization of eco-efficiency of

production processes is complicated due to time consuming LCA simulations and inexperience of

production planners to make respective decisions. This paper addresses this issue by developing ontology

based intelligent assistance system to support planner in environmental assessment of manufacturing of

customized production in decentralized manufacturing networks as well as decision making in production

planning.

1 INTRODUCTION

The manufacturing industry particularly the

automotive industry is facing challenges to remain

competitive. The increasing product customization

and continuously reducing time to market on the

automotive landscape has compelled manufacturers

to speed up their innovation process as well as

frequent restructuring of value chains. Additionally,

the shifting of manufacturing facilities from high

wage locations to low wage locations, high

outsourcing and frequent collaboration with external

partners has resulted in distribution of

manufacturing facilities. It can be realised by that

fact that currently 75% of the vehicle production and

50% of automotive research and development is

carried out by suppliers (Christensen, 2009).

Furthermore, the lack of skilled people to manage

change and enable customized production in

manufacturing facilities has put the complete

innovation process at risk. The decision concerning

selection of optimal production schemes for

customized products is quite complicated as it

requires optimization of manufacturing processes

not only based on conventional key performance

indicators such as cost, time, quality, flexibility but

also on potential environmental impact. Unlike the

conventional key performance indicators, the

knowledge concerning environmental impact as well

as assessment is not well versed and intrepretable for

machines and users to be taken as decision support

system. In addition to this fact, reducing number of

skilled workers, inexperienced planners to take

decisions based on eco-efficiency and the time

consuming environmental simulations demand

leveraging of exploiting concepts and innovative

methods related to knowledge management.

Focussing on the scope of this paper, it must be

added that the increasing number of activities in a

decentralized production environment results in

increasing environmental impact in terms of several

emissions and ecological wastes. The new

environmental directives and regulations needs new

metrics, advanced assessment methods and efficient

environmental assessment tools have limited the

potential environment assessment in conducting

holistic, reliable, quick and precise assessment.

Furthermore, the addition or removal of certain

environmental terms according to the new directives

and changing assessment methods and unfamiliarity

with the potential impact of combinations of

materials, process and resources on the

environmental impact of the production processes

has made manufacturers to ignore this factor in

production planning and optimization.

Consequently, the production planning in distributed

environment is not cost efficient any more. A strong

need has been felt for an efficient environmental

information system to support decisions on

environmental impact of the potential production

schemes. In the absence of such system, the planner

must be experienced enough to conduct precise and

331

Ul Haque Minhas S. and Berger U..

Development of Intelligent Assistance System to Support Eco-efficient Planning.

DOI: 10.5220/0004110903310334

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2012), pages 331-334

ISBN: 978-989-8565-30-3

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

efficient assessment. The probability of availability

of such experts is very low as the knowledge about

environmental terms, regulations, assessment

methods as well as the simulation tools is expanding

along with the expansion of manufacturing domain

with new materials, processes and resources such as

machines. Therefore, the planner cannot conduct

assessment without the knowledge assistance system

or tool and therefore be be facilitated with

information or knowledge assistance system to get

the desired information from the knowledge

assistance system upon request. This approach will

enhance productivity in planning.

2 KNOWLEDGE MANAGEMENT

IN DECENTRALIZED

PRODUCTION NETWORK

Production planning and scheduling refers to

activities that deal with selection and sequence of

production processes as well as the optimal

assignment of tasks to manufacturing resources over

a specific time. Several methodologies have been

introduced in the literature to enable computer aided

process planning namely feature based planning

(Cai, 2007; Mokhtar et al., 2007; Berger et al.,

2008), artificial intelligence i. e. neural networks and

genetic algorithms) based planning (Joo, 2005;

Monostori et al., 2000; Venkatesan et al., 2009;

Zhang et al. 1997) and knowledge based approaches

(Wu et al., 2010; Tsai et al., 2010). In a highly

individualized customer demand scenario i. e. one-

of-a-kind production, incremental process planning

has been proposed for extension or modification of

primitive plan incrementally according to the new

product features (Tu et al., 2000). Likewise, agent

based approach is used to enable manufacturing

organizations dynamically and cost effectively

integrate, optimize, configure, simulate and

restructure their manufacturing system as well as

supply networks (Zhang et al., 2006). It must be

added that the scope of optimization in planning is

mainly limited to the traditional key performance

indicators such as cost, time and quality. Mass

customization production scenario has however

made manufacturers focus on flexibility in

optimizing processes. The sebsequent

decentralization of manufacturing systems demand

planning decisions based on environmental impact

of the intended activity or process besides decisions

made on conventional key performance indicators.

From the literature, several approches and

methodolgies have been proposed convering several

distinct areas of planning but no significant

contribution has been made sofar that help accessing

and supporting decision making based on key

performance indicators. The knowledge

management framework for supporting

manufacturing system design is proposed by

Efthymiou et al., 2011a. The proposed framework

encompasses four constituent components of the

knowledge management system. The extended work

to this framework is described in work presented by

Efthymiou et al., 2011b, in which the ontology for

the manufacturing system is defined. The extended

work emphasizes structuring of knowledge to

support evaluation of manufacturing facilities and

activities based on cost, time, quality and flexibility.

There is no contribution made sofar in the scientific

literature that addresses the issues related to eco-

efficient evaluation as well as decisions support

system for optimal selection of production processes

for customized products. Moreover, commercially

available PLM tools as well as lifecycle assessment

tools are incapable of facilitating planners with the

environmental knowledge that support them in

decision making. Therefore, an intelligent assistance

system must be devised as an add-on to existing

planning tools that facilitate planners in make

decisions on eco-efficiency of manufacturing.

3 DEVELOPMENT OF

INTELLIGENT ASSISTANCE

SYSTEM

In this regard, the concept for intelligent assistance

system is described by Minhas et al., 2012. The

production scheme for manufacturing customized

products is retrieved from the commerical planning

tools in XML format. It contains information about

the whole production scheme for manufacturing any

customized product. The scheme consists of several

nodes each specifying the product information, the

process technological information and the resource

information corresponding to the process

technology. The ontology based knowledge

repository is enriched with the already existing

simulated environmental impact results of the

potential production schemes. The information

concerning the input (process node specifications)

and output information (simulated environmental

impact results) for the simulated case are stored

either manually in the knowledge repository by

experts or exchange through the xml file from the

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

332

conventional LCA tool such as SimaPro.

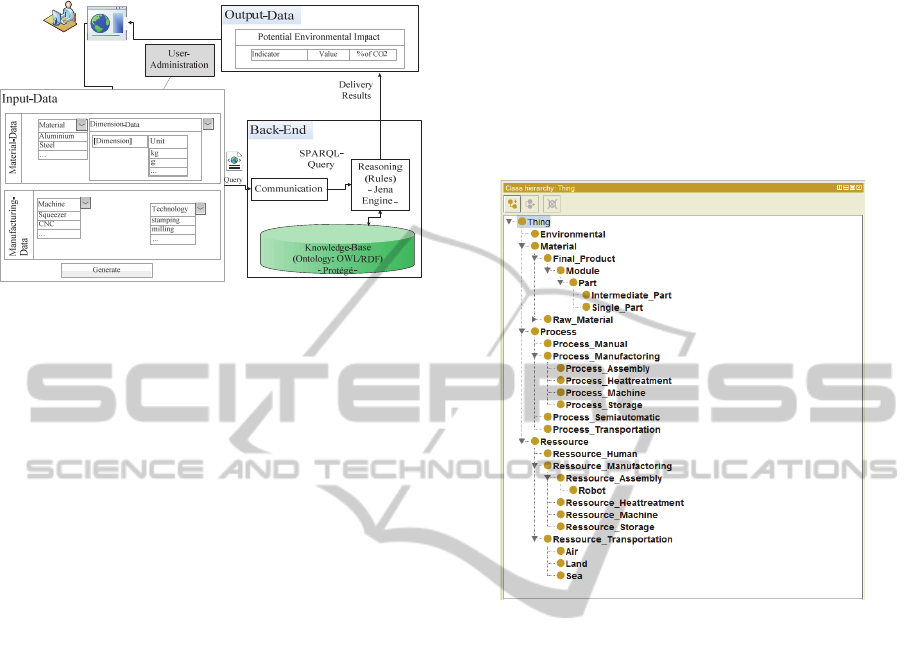

Figure 1: Architecture for web-based reasoner.

There are two possibilities for the user to query

the knowledge repository of the intelligent

assistance system. One way is to query in complete

natural language format. It triggers huge complexity

in processing the natural language sentence and

extracting the context of the query. The second way

is (see Figure 1) to restrict the degree of freedom of

user’s in specifying search. This is done with the

web-based configurator developed in PHP. The

SPARQL query is generated as a result of the

configurator input. It is communicated to the server

through web-service which then navigates the

required information concerning the potential

environmental impact of any desired process node.

The knowledge repository is regarded as multiple

instances of domain ontological concepts. This

ontology is represented in specific platform

independent open source language to maintain

consistency while navigating information as well as

the information exchange. This knowledge

repository is made capable of making conclusions

against the queries due to its inherent reasoning

capabilities. The reasoning part of the knowledge

repository is enriched with production and inference

rules associated with the material and process

environment of decentralized manufacturing.

The outcome of the navigation is the

environmental impact results by matching the same

case stored in the knowledge repository or inferred

from similar cases. The application is capable of

running on the web-based system and a web service

has been created to query the knowledge repository.

The planner before making environmental

assessment sends request to the server; the server

generates the required output in reponse to the

SPARQL query which navigates the information

into the ontology based knowledge repository.

The concepts for manufacturing domain relevant

to the environmental impact are modelled in an open

source ontology editor named as Protégé. At the

process level, material specifications, operation and

relevant resource information formulate the basic

concepts for manufacturing domain (see Figure 2) in

RDF format. Furthermore, semantic web rules are

defined to incorporate reasoning capabilities in the

intelligent assistance system. These rules are

programmed using JENA Engine.

Figure 2: Fundamental Ontology Concepts.

The user can send the request for the search of

environmental impact or emissions of certain

combination of materials. The web service based on

JAVA will generate a query which will navigate

inside ontology for retrieval of the information using

JENA inference engine.

4 SUMMARY

The knowledge management concepts can be

exploited in each of the planning area in the

automotive production networks to achieve quick

and reliable multi-objective decision making. The

artificial intelligent approaches and knowledge bases

implemented using ontologies with reasoning

capabilities, will be helpful in reusing, inferring

from as well as for making quick optimization. In

this paper, these concepts are being exploited

considering optimization of production processes

based on environmental impact assessments. The

addition of environmental impact factor as one of

the key performance indicator needs to be evaluated

first using commercially available software tools.

DevelopmentofIntelligentAssistanceSystemtoSupportEco-efficientPlanning

333

The representation of knowledge about material,

process and resource and its consequent impact of

environment using ontologies together with

reasoning capabilities will help the inexperienced

planners as well the experienced ones to get

knowhow concerning emissions that is anticipated to

be assessed as well as the environmental impact of

combination of potential product, process and

resource. The intelligent assistance tool runs on web

based system to facilitate geographically distributed

planners in building, updating, sharing knowledge.

Moreover, this knowledge helps in conducting

assessements regarding eco-efficiency in

manufacturing of customized products.

ACKNOWLEDGEMENTS

The work reported in this paper is supported by EC

FP7 Factories of the FUTURE Research Project e-

Custom "A Web-based Collaboration System for

Mass Customization" (NMP2-SL-2010-260067), to

configure production systems through web based

collaboration in a decentralized production

environment.

REFERENCES

Berger, U., Kretzschmann, R., Arnold, K. P., Minhas, S.,

2008, Approach for the Development of a Heuristic

Process Planning Tool for Sequencing NC Machining

Operations, Applied Computer Science, 4/2:17-41

Cai, J., 2007, Development of a Reference Feature-Based

Machining Process Planning Data Model for Web-

Enabled Exchange in Extended Enterprise, PhD

Dissertation, Shaker Verlag, Aachen.

Christensen, T. B., 2009, Integration of Environmental

Technology in Modularized Production Systems in the

Automotive Industry, in: Proceedings of Joint Action

on Climate Changes Conference, Denmark.

Efthymiou, K., Alexopoulos, K., Sipsas, P., Mourtzis, D.,

Chryssolouris, G., 2011,(a), Knowledge Management

Framework, Supporting Manufacturing System

Design, Proceedings of 7

th

International Conference

on Digital Enterprise Technology (DET2011), Athens,

28-30 Sep. 2011.

Efthymiou, K., Sipsas, K., Melekos, D., Georgoulias, K.,

Chryssolouris, G., 2011, (b), A Manufacturing

Ontology Following Performance Indicators

Approach, Proceedings of 7

th

International

Conference on Digital Enterprise Technology

(DET2011), Athens, 28-30 Sep. 2011.

Fjällström, S., Säfsten, K., Harlin, U., Stahre, J., 2009,

Information Enabling Production Ramp-Up, Journal

of Manufacturing Technology Management. 20/2:178-

196.

Joo, J., 2005, Neural Network-based Dynamic Planning

Model for Process Parameter Determination,

Proceedings of International Conference on

Computational Intelligence for Modelling, Control

and Automation and International Conference on

Intelligent Agents, Web Technologies and Internet

Commerce, Vienna, 28.-30. Nov., 117-122.

Minhas, S., Juzek, C., Berger, U., 2012, Ontology based

Intelligent Assistance System to Support

Manufacturing Activities in a Distributed

Manufacturing Environment, Proceedings of 45

th

CIRP Conference on Manufacturing Systems, Athens,

16.-18. May, 2012.

Mokhtar, A., Tavakoli-Bina, A, Houshmand, M., 2007,

Approaches and Challenges in Machining Feature

Based Process Planning, Proceedings of 4th

International Conference on Digital Enterprise

Technology.

Monostori, L., Viharos, Z. J., Markos, S., 2000, Satisfying

Various Requirements in Different Levels and Stages

of Machining using One General ANN Based Process

Model, Journal of Materials Processing Technology,

107/1-3:228-235.

Tsai, Y. L., You, C. F., Lin, J. Y., Liu, K. Y., 2010,

Knowledge-based Engineering for Process Planning

and Die Design for Automotive Panels, Computer-

Aided Design & Applications, 7/1:75-87.

Tu, Y., Chu, X., Yang, W., 2000, Computer-Aided

Process Planning in Virtual One-of-a-Kind

Production, Journal Computers in Industry, 41:99-

110.

Venkatesan, D., Kannan, K., Saravanan, R., 2009, A

Genetic Algorithm-Based Artificial Neural Network

Model for the Optimization of Machining Processes,

Neural Computing and Applications, 18/2:135-140.

Wu, M., Li, D., Ji, W., 2010, Knowledge-Based

Reasoning Assembly Process Planning Approach to

Laser Range-Finder, International Conference on

Computer Application and System Modeling

(ICCASM), Taiyuan, 22.-24. Oct., V2-686-V2-690.

Zhang, D. Z., Anosike, A. I., Lim, M. K., Akanle, O. M.,

2006, An Agent-Based Approach for e-Manufacturing

and Supply Chain Integration, Journal of Computers

and Industrial Engineering, 51/2:343-360.

Zhang, F., Zhang, Y. F., Nee, A. Y. C., 1997, Using

Genetic Algorithms in Process Planning for Job Shop

Machining, IEEE Transactions on Evolutionary

Computation, 1/4:278-289.

KEOD2012-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

334