Knowledge Discovery in the Smart Grid

A Machine Learning Approach

Aldo Dagnino

ABB Corporate Research, ABB Inc., 940 Main Campus Drive, Raleigh, NC, U.S.A.

Keywords: Machine Learning, Smart Grid, Knowledge Discovery, Fault Prognostics.

Abstract: The increased availability of cheaper sensing technologies, the implementation of fibre-optic networks, the

availability of cheaper data storage repositories, and development of powerful machine learning models are

fundamental components that provide a new facet to the concept of the Smart Power Grid. An important

element in the Smart Grid concept is predicting potential fault events in the Smart Power Grid, or better

known as fault prognostics. This paper discusses an approach that uses machine learning methods to

discover fault event-related knowledge from historical data and helps in the prognostics of fault events in

power grids and critical and expensive components such as power transformers circuit breakers, and others.

1 INTRODUCTION

Recent technological advances in sensor

technologies, fibre-optic networks, cheaper data

storage capabilities, powerful data mining

techniques, and faster computing power coupled

with the need of improving the efficiency of

electrical power utilization have contributed to the

development of smarter power grids in the

transmission and distribution industries. Utilities are

increasingly interested in incorporating sensor

technologies to expensive assets such as power

transformers, circuit breakers, and back-up batteries,

in overhead and underground transmission lines and

connecting equipment. Many utilities are developing

fibre-optic networks that allow the transmission of

data from sensors to central data repositories.

2 THE SMART GRID

The existing power grids consist of multiple power

networks that coordinate their operations using

various levels of communication and control

mechanisms, which are primarily manually

controlled. The primary elements of the Smart Grid

include: (a) data; (b) information; (c) intelligence;

(d) communications (Mousavi, 2009). Data elements

are supplied by sensors embedded in different

components of the grid. The information element is

delivered by processors that perform certain

operations on data. The intelligence element is

generated by processing data and information via

analytics models. The communications element is

required to deliver data, information, and

intelligence to the right decision making agent in the

right format at the right time. The IEEE – Power and

Energy Society (IEEE-PES) and the National

Institute of Standards (NIST) have developed a

conceptual model for the Smart Grid that defines

seven important domains: Bulk Generation,

Transmission, Distribution, Customers, Operations,

Markets, and Service Providers.

3 FAULTS IN THE SMART GRID

Machine learning approaches have been utilized to

forecast fault events in the power distribution grid

and in critical equipment. This section discusses

how machine learning models were utilized

determine; (a) fault vulnerability profiles in power

distribution grids; (b) equipment fault forecasting.

3.1 Power Grid Fault Prognostics

Power distribution is typically managed by power

substations that receive power from the transmission

lines and distribute electrical power through feeders

to consumers. In addition of the equipment within

the substation, the typical distribution grid is

composed of equipment such as distribution

366

Dagnino A..

Knowledge Discovery in the Smart Grid - A Machine Learning Approach.

DOI: 10.5220/0004144303660369

In Proceedings of the International Conference on Knowledge Discovery and Information Retrieval (KDIR-2012), pages 366-369

ISBN: 978-989-8565-29-7

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

transformers, switches, fuses, power lines

(underground or overhead), and relays. Utilities are

very interested in fault prognostics in the power

distribution grid to minimize power disruptions to

customers. Faults in the distribution grid are

typically related with power line fatigue, burned

fuses, lightning falling on equipment (such as

distribution transformers, etc.), short circuits, animal

contacts, trees and tree branches falling on assets,

weather related faults to overhead or underground

equipment, faults in splicing, power lines touching

each other, and many more. Currently, the vast

majority of utilities are reactive to faults and they

manually deal with a contingency. There are many

factors identified in the literature that can cause fault

events in a power distribution grid (Lu, 2010). These

factors can be broadly classified into (a) physical

properties of the distribution grid; (b) electrical

values of grid; (c) weather conditions; (d) assets or

components degradation in the grid; and (e) type of

grid infrastructure (see Figure 1). The work

described in this paper has been focused on the

prognostics of faults in two primary areas: (a) the

forecast of fault events in a distribution grid; (b)

forecasting potential faults to expensive assets such

as power transformers in either the transmission or

distribution network. Forecasting fault events in the

distribution grid has been conducted by utilizing

historical data on weather conditions, grid electric

value readings at the time of a fault event, and the

type of grid infrastructure. Forecasting faults on

expensive assets has been conducted by analyzing

the condition of power transformers utilizing

historical data collected while performing dissolved

gas analyses and other tests. This investigation was

conducted with an Investor Own Utility (IOU)

partner in the US. Several types of historical datasets

associated with the IOU were collected and utilized

during this investigation. The historical dataset types

utilized include: (a) fault data and electrical values

from the IOU; (b) weather data; (c) infrastructure

type of the IOU. The fault data from the IOU was

collected utilizing an automated system of intelligent

electronic devices (IED’s) with sensing and analytic

capabilities located at power feeders. These IED’s

monitor electrical values from the distribution lines

and are able to detect a fault event in the grid after it

occurred. The fault data includes these electrical

values, and was also corroborated with data entries

documented by IOU engineers after restoring

service. The weather data was collected from the US

National Weather Service (NWS) and from the

WeatherBug (WBUG) weather services. The NWS

data was collected by their weather station every

five minutes in METAR format. The WeatherBug

data was collected from small weather stations

located in various locations close to the different

substations of the IOU.

Figure 1: Fault factors in Smart Grid.

3.2 Machine Learning for Forecasting

Power Distribution Grid Fault

Events

Supervised classification machine learning

techniques were utilized to forecast the occurrence

of faults in the distribution power grid of the IOU.

Four supervised classification machine learning

algorithms were utilized to conduct the analyses:

Neural Networks (NN), kernel support vector

machines (KSVM), decision-tree based

classification (recursive partitioning; RPART), and

Naïve Bayes (NB). Five analyses were conducted

utilizing these four algorithms: (a) fault event

prediction; (b) grid zone prediction; (c) substation

prediction; (d) type of grid infrastructure; (e) feeder

number prediction.

3.2.1 Fault Prediction Models

Four models were created to identify weather

patterns that are most likely to result in a fault event

using the NN, KSVM, RPART, and NM algorithms.

The models were constructed by taking weather data

points joined to fault events, as well as random

weather data samples when no fault events were

recorded in the selected IOU substations. The

dataset contained a total of 3471 records (1725 with

faults and 1746 without faults), of which 2430 were

used for training each of the four models and 1041

for testing the models. The output of these models

shows a prediction of the weather conditions for

which a fault event may or may not occur. The best-

Weather

Component

Degradation

Physical

Properties of

Distribution

Grid

Volume

precipitation

Snow precipitation

Storms

Temperature

(outdoor, indoor)

Humidity

Ice formation

Insulator integrity

levels

Zinc coating

degradation

Cable (OH)

sagging

Cable (OH)

strand fatigue

Rate of cable

(OH) breaks

Infrastructure

Type

Overhead

(OH)

Underground

(UG)

Type of UG cable

connectors

Temperature at (UG)

cable joints

Material of cables

Transmission

temperature profiles

Maximum conductor

tension limits

Cable operation

temperature (OH)

Type of cables (OH)

Materials of poles

Pole foundation

characteristics

Voltage profiles of

network

Temperatures of circuit

breakers

Temperatures of line

connectors

Temperatures of

transformers

Age of grid assets

Wind (speed,

direction)

Urban or

rural grid

Asset degradation

Grid Electrical

Values

Pre-Fault

Power

Values

Pre-Fault

Current

Values

Pre-Fault

Voltage

Values

Lightning

parameters

Pressure

Factors that can

cause fault events in

distribution grids

Temperatures of

disconnectors

KnowledgeDiscoveryintheSmartGrid-AMachineLearningApproach

367

performing model was the one created with the feed-

forward trained by a multi-layer perceptron back-

propagation Neural Network algorithm with an f-

measure of 75%.

3.2.2 Zone Prediction Models

The four zone prediction models were trained by

considering fault historical data from the IOU grid

and weather data. Of the 1725 records with faults

and weather data, 70% were used for training and

30% for testing the trained models. The output of

these models predict in what zone (AMZ, UMZ,

PMZ) on the IOU grid the fault occurred. The best-

performing model was the one created training a

Neural Network algorithm. The model contains one

hidden layer with 20 nodes, and produces an

accuracy of 66%, an average precision of 69%, an

average recall of 68%, and an f-measure of 68%.

3.2.3 Substation Prediction Models

The four substation prediction models were trained

by considering fault historical data from the IOU

grid and weather data. Of the 1725 records with

faults and weather data, 70% were used for training

and 30% for testing the trained models. The output

of these models predicts the IOU substation ID

where the fault occurred. The best performing model

was the one created with the recursive partitioning

algorithm and produces an accuracy of 59%, an

average precision of 66%, an average recall of 54%,

and an f-measure of 59%.

3.2.4 Infrastructure Prediction Models

The four infrastructure prediction models were

trained by considering fault historical data from the

IOU grid and weather data. Of the 1725 records with

faults and weather data, 70% were used for training

and 30% for testing the trained models. The output

of these models predicts the type of infrastructure

(overhead or underground) on the section of the IOU

grid where the fault occurred. The best-performing

model was the one created training a Neural

Network algorithm with an f-measure of 57%.

3.2.5 Feeder Prediction Models

The four feeder prediction models were trained by

considering fault historical data from the IOU grid

and weather data. Of the 1725 records with faults

and weather data, 70% were used for training and

30% for testing the trained models. The output of

these models predicts the IOU Feeder where the

fault occurred. The best-performing model is the one

created with the recursive partitioning algorithm

with an f-measure of 74%.

3.3 Machine Learning for Forecasting

Fault Events in Assets

Many utilities have deployed diverse types of

sensors in their mission critical and expensive assets

such as power transformers. When monitoring

power transformers two types of on-line

measurements can be collected: (a) operational

information such as voltage, load, current, oil

temperature, winding temperatures, pump status, fan

status, cooling system status, etc; (b) condition

information, such as oil quality, gassing, dielectric

properties, aging, etc. Utilities use a variety of

sensors in their transformers and such sensors have

different monitoring capabilities, especially in terms

of the types and concentrations of gasses in the oil of

the transformers. Some time utilities supplement the

monitored concentration of gasses by conducting a

dissolved gas analysis (DGA) test periodically. A

study has been completed with the objective of

developing analytical models based on data mining

to identify patterns in gas concentrations, to identify

trends of gas concentrations that may lead to

catastrophic failures of equipment, and in general to

identify correlations between observations that

would result in new knowledge or confirm existing

heuristic knowledge about power transformers. The

example presented below does not identify the name

of the utility with which this study was conducted.

Hence, we refer our customer as Utility A. In our

example, Utility A had a fleet of over 300 power

transformers and had historical data collected for a

period of ten years. The historical data collected

included DGA analysis tests for all transformers

(concentration of H2, CH4, C2H6, C2H4, C2H2,

CO, CO2, O2, N2, and moisture), ID transformer

data (transformer name, type, age, pump type,

construction type, and conservator type), oil

temperature, winding temperature, and fluid quality

(metal particles present in oil). Utility A installed

sensors in its transformers fleet and recently

installed a fibre-optic network that helped to

transmit the monitored data into a central repository.

The objective was to develop a profile of

potential “hot spots” in power transformers where

the concentration of CO, CO2, and O2 are high (CO

> 571 parts per million, CO2 > 4001 ppm, and O2 >

10,000 ppm) and oil temperatures need to be

monitored so they do not exceed values > 150 C.

These conditions can show deterioration of the

KDIR2012-InternationalConferenceonKnowledgeDiscoveryandInformationRetrieval

368

insulation of the windings. The following data sets

were employed to conduct the data mining analyses:

(a) Transformer Description Database: that includes

the following data attributes: SERIAL_NUMBER,

AGE, CONSTRUCTION_TYPE; (b) Gasses

Concentration Database: concentrations in parts per

million (ppm) of the following gasses: H2, CH4,

C2H6, C2H4, C2H2, CO, CO2, O2, N2, and

MOISTURE. The data availability studied for this

case includes 335 power transformers for which

gasses data concentrations have been collected

during 10 years. The total number of gasses

concentration observations is 3100. The working

dataset analyzed includes the fusion of both the

transformer description and combustible gasses

concentration databases. Entries with missing data

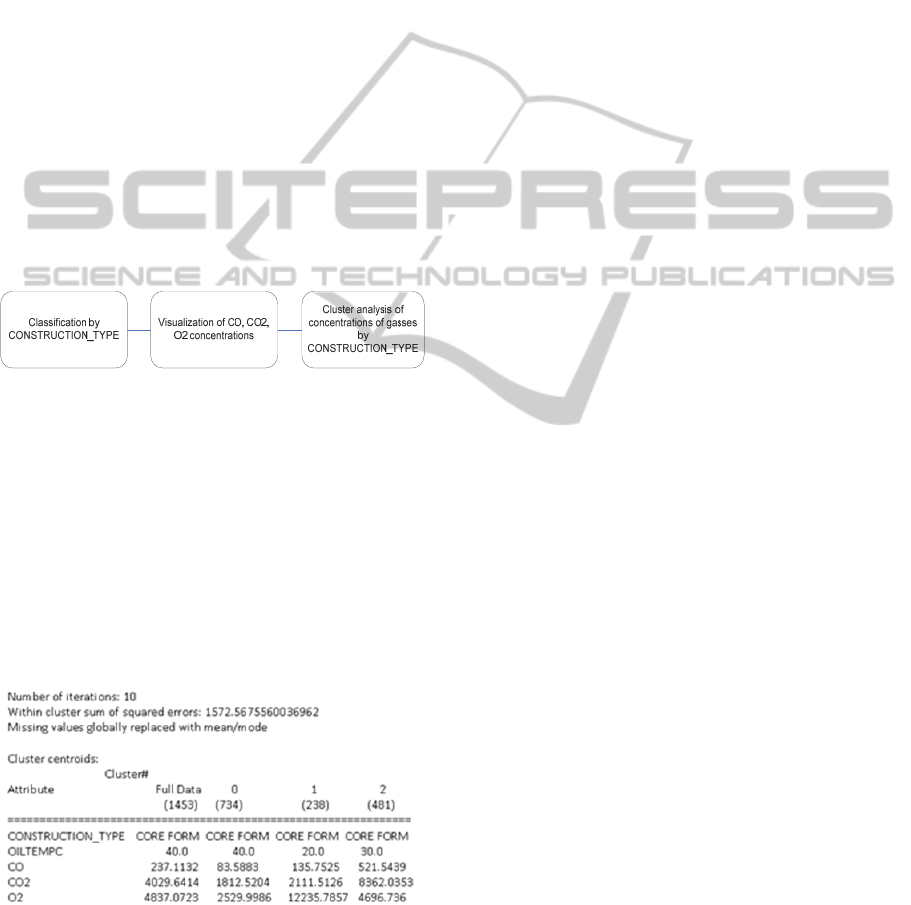

points were removed from the analysis. Figure 2

shows the sequence of machine learning approaches

utilized for this analysis. First, the data was

classified based on the CONSTRUCTION _ TYPE

of the transformers (where transformers can be

Core_Form and Shell_Form).

Figure 2: CO, CO2, and O2 Concentration Analysis.

With this classification completed, CO, CO2, and

O2 gasses concentrations were identified for each of

the construction types. Also, a cluster analysis was

conducted with all data using the SimpleKMeans

algorithm and the clusters shown in Table 1 were

obtained. Sixty percent of the data was utilized to

train the algorithm and forty percent of the data was

utilized to test the algorithm. The data mining open

source tool utilized for this analysis was Weka.

Table 1: Cluster Analysis of CO, CO2, and O2

Results from these analyses suggest that the number

of CORE_FORM transformers that has high

concentrations of O2 is larger than SELL_FORM or

TPN-V CORE_FORM. Similarly, Fig. 8 shows that

CORE_FORM transformers have the largest number

of CO2 gas concentration. Results also suggest that

CORE_FORM transformers have the highest

concentration of CO gas. The results of the analyses

above show that a utility with a fleet of transformers

that have CORE_FORM construction type should

pay to the temperature of these transformers if the

concentrations of CO, CO2, and O2 are in dangerous

concentration neighbourhoods (CO > 571 parts per

million, CO2 > 4001 ppm, and O2 > 10,000 ppm).

After running the cluster algorithm, Table 1 shows

that a cluster of 481 transformers (cluster 2) have

high concentrations of CO and CO2 with moderate

concentration of O2. For this cluster of transformers,

it is important to monitor temperatures and also

concentration of O2.

4 CONCLUSIONS

The development of smart sensors, fibre-optic

networks, large data storage repositories, powerful

hardware, and robust machine learning algorithms

are becoming important elements that bring the

concept of the Smart Grid to the forefront. The

objective of the work presented in this paper is to

demonstrate that machine learning models can be a

powerful element of the Smart Grid concept.

Machine learning can be utilized for diagnostics and

forecasting of faults in a power transmission and

distribution grid. This is an important element of the

concept of the Smart Grid.

REFERENCES

Heine, P., Turunen, J., Lehtonen, M., Oikarinen, A., 2005,

Measured Faults During Lightning Storms , Proc.

IEEE Power Tech 2005, Russia, pp.1- 5.

Lu, N., Taylor, T., Jiang, W., Jin, C., Correia, J., Leung,

L., and Wong, P. C., 2010, Climate Change Impacts

on Residential and Commercial Loads in the Western

U.S. Grid, IEEE Transactions on Power Systems, Vol.

25, No. 1, pp. 480 – 488.

Mousavi, M., Donde, V., Stoupis, J., McGowan, J., Tang,

L., 2009, Information, not Data: Real-time automated

distribution event detection and notification for grid

control, ABB Review Journal, The Corporate

Technical Journal of the ABB Group, no. 3, pp. 38-44.

Wei, C., 2010, A Conceptual Framework for Smart Grid,

IEEE, 978-1-4244-4813-5.

KnowledgeDiscoveryintheSmartGrid-AMachineLearningApproach

369