Contactless Electrical Bioimpedance System for Monitoring Ventilation

A Biodevice for Vehicle Environment

Ra

´

ul Mac

´

ıas Mac

´

ıas, Miguel

´

Angel Garc

´

ıa Gonz

´

alez, Juan Ramos Castro, Ramon Brag

´

os Bardia

and Mireya Fern

´

andez Chimeno

Department of Electronic Engineering, Universitat Polit

`

ecnica de Catalunya, Campus Nord,

Edifici C-4 08034, Barcelona, Spain

Keywords:

Bioimpedance, Ventilation, Contactless Electrodes, Textrodes, Automotive.

Abstract:

Nowadays, automotive companies are focused in improving road traffic safety. For that, not only the vehicle

performance is improved but also the driver behavior is monitored. This could be done in many ways. One of

them is to monitor a specific physiological parameter using a biodevice. That device should be reliable enough

to use in a very noisy environment like a vehicle is. Furthermore, because long-term monitoring is required,

any invasive and annoying method should be avoided. Therefore, an electrical bioimpedance device capable

of monitoring driver ventilation using several textiles electrodes has been designed and implemented.

1 INTRODUCTION

In recent years one of the main goals of the automo-

tive industry is to improve the road safety. Because of

most of traffic crashes occur during the appearance of

non-appropriate states for driving, e.g. drowsy driv-

ing or drunk driving (Anund et al., 2008), apart from

improving the vehicle performance, monitoring the

driver behavior is also required. To achieve that, sev-

eral systems are being tested. These systems can be

mainly classified on three types. First type is based

on driving performances i.e. unintended lane depar-

tures, steerings and brakes. The second one is based

on camera systems that detect the percentage of eye

closure (PERCLOS), head movements and blinkings.

Finally, the third type is based on recording biomed-

ical signals. In (Michail et al., 2008), signals from

electroencephalography (EEG), electrocardiography

(ECG) and heart rate variability (HRV) are used. On

the other hand, electroocculography (EOG) and venti-

lation are used in (Lal and Craig, 2001) and in (Folke

et al., 2003), respectively.

Focusing on the third type, regardless of the phys-

iological parameter to be measured, any biodevice

should fulfill three requirements at least. Firstly, the

biodevice must be capable of recording signals in a

very noisy environment. In a vehicle, there are not

only artifacts produced by the car engine but also arti-

facts caused by other reasons like body motion or the

state of the roads. As for the second feature, a long-

term monitoring system is required because the ap-

pearance of non-appropiate states while driving is a

slow process. Moreover, the device should also be

non-invasive and non-annoying to allow the driving

as comfortable as possible. Therefore, the use of hos-

pital devices is not recommended and the design of

new biodevices is required.

Thus, this paper shows a new biodevice suitable

for automotive applications. This device consists of

an electrical bioimpedance (EBI) system capable of

monitoring the ventilation, and also the heart rhythm,

using textile electrodes. These electrodes are placed

on the steering wheel and also in the car seat. In addi-

tion, this paper also shows some results according to

some parameters such as the electrode configuration,

the frequency of the injected signal and the clothing

thickness.

2 SYSTEM

As mentioned above, the biodevice is based on an in-

strumentation system of EBI. This allows to monitor

signals from the driver by textiles electrodes. The de-

vice is designed following the guidelines shown in

(Riu et al., 2009). In addition, in order to avoid the

impedance of the electrodes, the EBI system is based

on the four-wire method proposed by (Schwan and

Ferris, 1968).

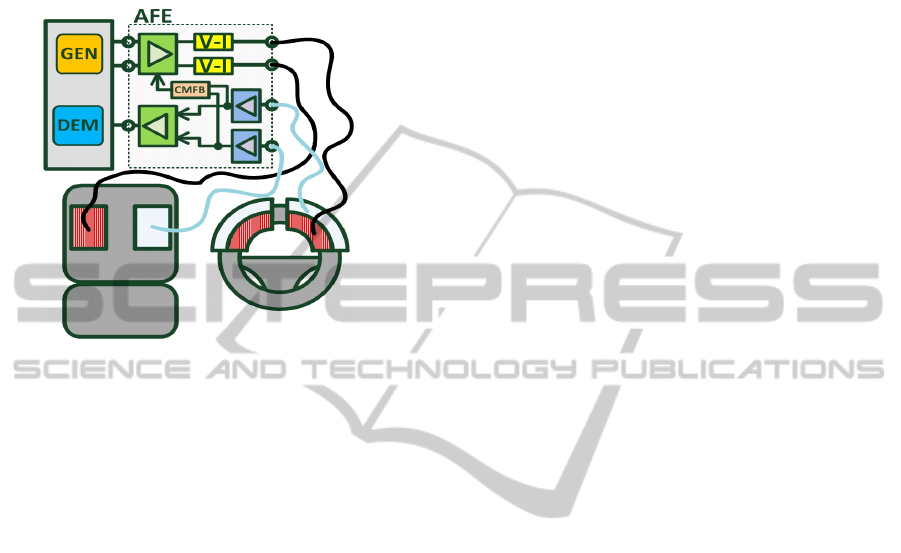

Thus, as shown in figure 1, the biodevice can be

14

Macías Macías R., Ángel García González M., Ramos Castro J., Bragós Bardia R. and Fernández Chimeno M..

Contactless Electrical Bioimpedance System for Monitoring Ventilation - A Biodevice for Vehicle Environment.

DOI: 10.5220/0004195800140020

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 14-20

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

divided into three main blocks:

• Signal Generator (GEN).

• Analog Front-End (AFE).

• Demodulator and Acquisition (DEM).

Figure 1: A block diagram of the EBI device. The striped

areas are the possible placements of the driving electrodes.

In light color, the possible placements of the sensing elec-

trodes.

2.1 Signal Generator

Signal generation can take several forms, e.g. from

a simple linear oscillator or digital clock to a Direct

Digital Synthesizer (DDS) able to produce sinusoidal

waveforms or arbitrary waveforms in a wide range

of frequencies and amplitudes. In this case, and be-

cause of hardware limitations, the selected option is

to generate by a microcontroller, PIC18F1320, an ad-

justable amplitude single tone waveform of 62.5 kHz.

Later, this signal is used also as the reference sig-

nal in the demodulator block.

2.2 Analog Front-end

Once the signal is generated, this is sent to an AFE.

Basically, the AFE consists of two main stages. In

the first stage, the AFE injects an excitation signal

through a pair of driving electrodes. In the second

one, a pair of sensing electrodes are used to measure

the voltage difference which is related to the proper-

ties of the tissue.

2.2.1 Current Injection Stage

The excitation signal is sent to a differential-

differential amplifier, AD8138. However, instead of

applied directly the voltage of these two outputs to

the driving electrodes, each one is used as an input of

a voltage-current (V-I) converter based on a second-

generation current conveyor (CCII). Thus, the V-I

converter acts as a voltage-controlled current source

(VCCS), (Bragos et al., 1994). In this way, using

current driving instead of voltage driving achieves a

current limiting mechanism and reduces the possible

nonlinearities. So the guidelines of safety risks pro-

vided by the IEC-60601-1 standard can be fulfilled.

In this case where a 62.5-kHz frequency current is in-

jected, the current limit is established in 6.250 mA.

In addition, as there are filter capacitors to avoid

the flow of the Direct-Current (DC) current to the

body, in this stage a DC feedback of the CCII is also

required to avoid saturation problem.

2.2.2 Voltage Sensing Stage

In the voltage sensing stage, a differential to single

ended voltage conversion is done by a wideband dif-

ferential amplifier. However, before this conversion,

the voltage difference between the pair of sensing

electrodes is measured by a pair of high-impedance

buffers. These buffers are used because of their input

impedances are higher than the input impedance of

the differential amplifier. Furthermore, these buffers

also allow to measure the common-mode voltage

without disturbing the signal quality.

In addition, as in the current injection stage, filter

capacitors are also required. Thus, to avoid the satu-

ration of the amplifiers the polarization currents of the

amplifiers should be as low as possible.

2.2.3 Common-mode Feedback Block (CMFB

Block)

Usually there is not a perfect isolation between the

current injection stage and the voltage sensing stage.

Thus, due to these unbalanced conditions a common-

mode voltage can exist. To reduce this voltage a feed-

back circuit with the appropiate negative open loop

gain is required. Furthermore, this feedback circuit

should also maintain the stability of the system.

2.2.4 Active Shielding

In order to reduce interferences from external elec-

tromagnetic fields and crosstalk between the driving

electrodes and the sensing ones, shielded cables are

used. The shield of these cables is connected to a cir-

cuitry. This circuitry drives the shield to a voltage

that is equal to the voltage in the internal wire. Due

to oscillation problems could appear at high frequen-

cies, a filter capable of reducing the gain below one at

high frequencies is also used at the input of the active

shielding circuitry.

ContactlessElectricalBioimpedanceSystemforMonitoringVentilation-ABiodeviceforVehicleEnvironment

15

2.3 Electrodes

As mentioned above, the electrodes should be as no-

invasive and no-annoying as possible for the driver.

Therefore, using standard metal electrodes seems to

be not the better option. In addition, as cited in

(Wheelwright, 1962),during long-term monitoring,

the hidrogel used with this kind of electrodes can

cause irritation and allergy problems.

So, in this system instead of using standard metal

electrodes, electrodes made of textiles, also called

textrodes, are chosen. In this way, not only irrita-

tion and allergy problems are solved but also a higher

comfort for the driver is achieved. However, the

main drawback of the textrodes is that the electrode

impedance, Z

ep

, shows a strong capacitive behavior,

(Beckmann et al., 2010). In addition, as the textrode is

not directly in contact the skin, this capacitive behav-

ior depends on the exerted pressure and factors related

to the clothing of the driver like material, thickness or

number of layers.

2.4 Demodulator & Acquisition

Although there are several demodulation techniques,

a switching demodulator is used. Switching demod-

ulators are based on a switch controlled by a square

signal. The frequency of this square signal is the same

that the signal generated by the microcontroller in the

signal generator block. After the switching demodu-

lator, the signal is driven to a third-order Sallen-Key

low-pass filter (LPF). Then using this output signal

from the LPF, the measured voltage is acquired. In

addition, by a high-pass filter (HPF) and a basic cir-

cuitry, the relative variations of the measured voltage

are also amplified and acquired. These voltage vari-

ations should be amplified before recording because

of their low amplitude and also the poor accuracy

that the 10-bit Analog-to-Digital Converter (DAC) of

the microcontroller can provide. Finally, the acquired

data are sent from the microcontroller to a computer

by a mini USB-Serial UART development module.

Thus, any software such as Matlab or LabVIEW can

be used later to process and to estimate the impedance

value.

3 MEASUREMENTS

To check that the biodevice works properly, several

measurements are carried out. These measurements

can be classified into three groups according to:

• Comparison to a reference signal.

• Configuration of electrodes, i.e, the placement of

the driving and sensing electrodes in the car seat

and steering wheel.

• Influence of the thickness of clothing.

Note the measurements were done in a simulation

environment where there are no interferences caused

by the state of the road or the car engine vibrations.

3.1 Comparison to a Reference Signal

In this group, several subjects are monitored by the

designed device and also by a commercial one made

by BIOPAC Systems. The commercial device ac-

quires at a sampling frequency of 1 kHz the ventila-

tion signal using a piezoresistive thoracic band. Then,

this signal is used as reference signal to verify the cor-

rect operation of the designed device.

It is worth mentioning that in this case, only the

proper behavior of the AFE is checked in fact. In-

stead of using the signal generator block and the de-

modulator block mentioned above, a National Instru-

ments Data Acquisition (DAC) module is utilized. By

this module, a single frequency sine wave of 300 kHz

is generated and In-phase Quadrature (IQ) demodu-

lation is done to obtain the real and imaginary part

of the signal at a sampling frequency of 25 Hz. Fi-

nally, using a Labview application, the magnitude and

the phase of the estimated impedance are saved. Note

that instead of generating a signal of 62.5 kHz, a sig-

nal of 300 kHz is applied. There are two reasons to

apply a higher frequency. First, using this DAC mod-

ule, the hardware limitation is less strong as the one

imposed by the generator and the demodulator blocks

described above. Second, the higher the frequency a

better response of the system is achieved because of

the capacitive behavior of the textile electrodes.

3.2 Configuration of Electrodes

In the second group of measurements, the biodevice is

checked according the placement of electrodes. Thus,

whereas the frequency of the injection signal is fixed

to 62.5 kHz, the place of driving and sensing elec-

trodes is changed, giving three configurations:

• Steering Wheel-steering Wheel Configuration.

• Steering Wheel-back Seat Configuration.

• Back Seat-back Seat Configuration.

In the steering wheel-steering wheel configura-

tion, a driving electrode and a sensing electrode are in

contact with the right hand of the driver. In the same

way, the other pair of driving-sensing electrodes and

the left hand are also in contact.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

16

On the other hand, in the second configuration,

whereas a driving and a sensing electrode remain in

the steering wheel, the other driving and sensing elec-

trode are moved to the upper half of the back seat.

Finally, in the back seat-back seat configuration,

instead of using the 4-wire technique, the 2-wire tech-

nique is carried out because of both textile electrodes

on the back seat act as driving and sensing.

3.3 Influence of the Thickness of

Clothing

In the last group of measurements, the relationship be-

tween the clothing and the measured signals is tested.

Therefore, using the steering wheel-back seat config-

uration, the ventilation of a subject is monitored under

the following states according to the clothes:

• Thin t-shirt.

• Thin jacket over thin t-shirt.

• Thick sweater over thin t-shirt.

4 RESULTS

As in previous section, the results are discussed based

on the three kinds of measurements.

4.1 Comparison to a Reference Signal

As mentioned above, the signal acquired by the tho-

racic band acts as a reference to check the signal

from the designed biodevice. Thus, the biodevice

works properly if the measured signal fits to the refer-

ence, i.e. for the same period of time, the exhalation-

inhalation ratio is the same in both signals.

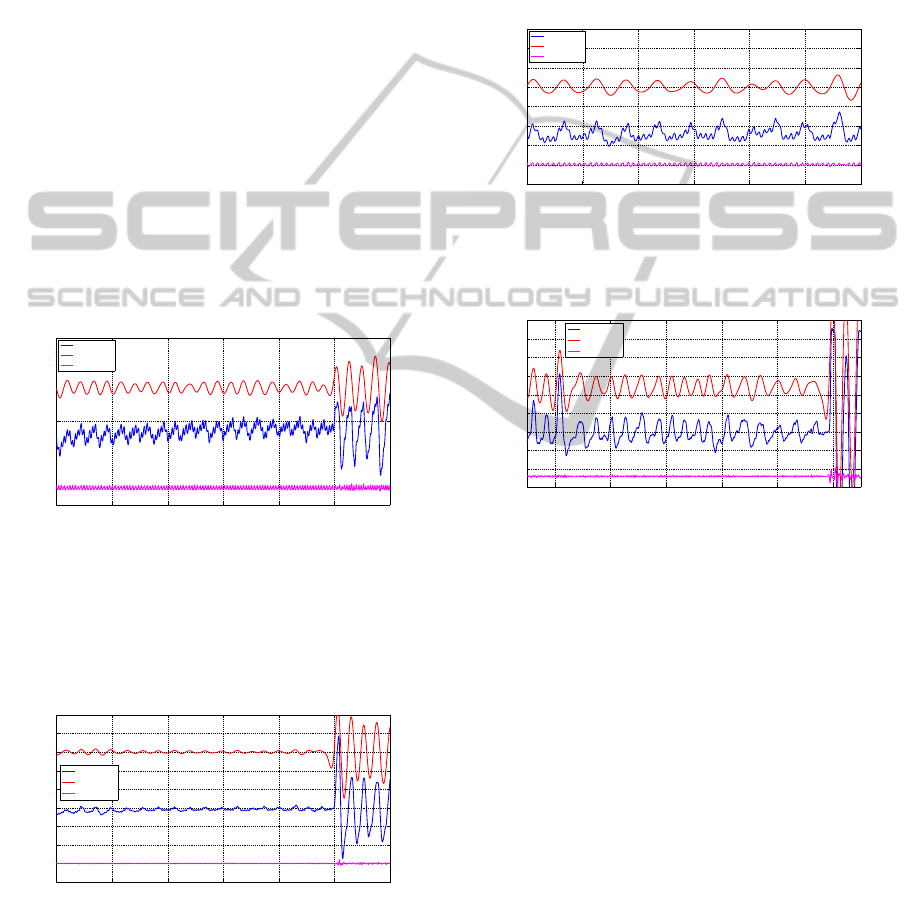

For each volunteer, two different configurations

are tested. In the upper graphs of the figures 2, 3 and

4, as a driving electrode and a sensing electrode are

in contact to the left hand, the second driving and the

second sensing electrode are placed in the right and

left side of the back seat, respectively. On the other

hand, in the bottom graphs whereas the electrodes on

the back seat remain at the same point, both electrodes

on the steering wheel are moved to the right side.

Note that for all cases except one (bottom graph in

figure 4), both signals, from the bioimpedance device

and from the thoracic band, match up. The special

case can be due to the lack of contact between any

textrode and the volunteer.

Furthermore, whereas the figures 2 and 4 show

a normal respiration rate, i.e. between 12 and 20

breaths per minute in adults and in normal conditions,

in the figure 3 a slower respiration rate, around 6-7

breaths per minute, can be observed.

50 60 70 80 90 100 110 120

−5

0

5

10

Time (s)

Magnitude(Ω)

Thoracic Band vs. Impedance Ventilation:

Right Hand − Back Seat Configuration

50 60 70 80 90 100 110 120

−5

0

5

10

Time (s)

Magnitude(Ω)

Left Hand − Back Seat Configuration

Thoracic Band

Impedance

Figure 2: Comparison between the Thoracic Band and the

Bioimpedance Device for the first volunteer. (Top) Configu-

ration where both driving electrodes, back seat and steering

wheel, are in the right side of the body. (Bottom) Config-

uration where the driving electrode of the steering wheel is

in the left hand and the other driving electrode is in the right

side of the back. In both plots, the upper line is related to

the bioimpedance device and the bottom one comes from

the thoracic band.

20 40 60 80 100 120 140

−20

0

20

Time (s)

Magnitude(Ω)

Thoracic Band vs. Impedance Ventilation:

Right Hand − Back Seat Configuration

20 40 60 80 100 120 140

−20

0

20

Time (s)

Magnitude(Ω)

Left Hand − Back Seat Configuration

Thoracic Band

Impedance

Figure 3: Comparison between the Thoracic Band and the

Bioimpedance Device for the second volunteer. (Top) Both

driving electrodes are in the right side of the body. (Bottom)

The driving electrode of the steering wheel is in the left the

other driving electrode is in the right side of the back.

20 40 60 80 100 120 140

−5

0

5

Time (s)

Magnitude(Ω)

Thoracic Band vs. Impedance Ventilation:

Right Hand − Back Seat Configuration

20 40 60 80 100 120 140

−5

0

5

Time (s)

Magnitude(Ω)

Left Hand − Back Seat Configuration

Thoracic Band

Impedance

Figure 4: Comparison between the Thoracic Band and the

Bioimpedance Device for the third volunteer. (Top) Both

driving electrodes are in the right side of the body. (Bottom)

The driving electrode of the steering wheel is in the left the

other driving electrode is in the right side of the back.

4.2 Configuration of Electrodes

In this group of measurements, the influence of the

placement of the electrodes in the measured signal is

ContactlessElectricalBioimpedanceSystemforMonitoringVentilation-ABiodeviceforVehicleEnvironment

17

checked. Then, as mentioned above, three configura-

tions are tested. In any configuration, the same test

is done. The test consists of a two-minute monitor-

ing and, around the last 30 seconds, five deep breath-

ing are taken. It is worth mentioning that instead of

using the National Instruments DAC module, in this

group of measurements, and in the group below, the

signal generation block and the demodulation block

are based on a microcontroller which gives an injec-

tion signal of 62.5 kHz.

As shown in figures 5, 6, 7 and 8, three signals

are plotted. The middle one is the raw signal mea-

sured by the bioimpedance device and without pro-

cessing. Note that this signal is based on two compo-

nents: a low-frequency component, between 0.1 Hz

and 0.3 Hz, and a high-frequency component, over 1

Hz. Then, in the figures the upper signal is related to

the low frequency component of the raw data and the

bottom one is related to the high frequency compo-

nent. Furthermore, the low frequency signal and the

higher one are also related to the ventilation and the

cardiac rhythm, respectively.

20 40 60 80 100 120 140

−5

0

5

time(s)

Variations of Z(Ω)

Steering Wheel − Steering Wheel Configuration

Raw Data

Ventilation

Heartbeat

Figure 5: Steering Wheel - Steering Wheel Configuration.

(Middle) The raw data obtained from the bioimpedance de-

vice. (Top) The processed data after applying a simple soft-

ware band-pass filter, between 0.1 Hz and 0.3 Hz, to obtain

the ventilation signal. (Bottom) The processed data after

applying a simple software high-pass filter, over 1 Hz, to

obtain the signal related to the cardiac rhythm.

20 40 60 80 100 120 140

−20

−15

−10

−5

0

5

10

15

20

25

time(s)

Variations of Z(Ω)

Steering Wheel (Left Hand) − Back Seat Configuration

Raw Data

Ventilation

Heartbeat

Figure 6: Steering Wheel - Back Seat Configuration with a

driving electrode in the left hand and the other in the right

side of the back. (Middle) The raw data. (Top) The ven-

tilation signal. (Bottom) The signal related to the cardiac

rhythm.

Checking the figures 5, 6, 7 and 8, a first issue can

be observed. As in figures 5 and 7, the high frequency

component is noticed easily, in figure 8 this compo-

nent is insignificant. Therefore, either it is not possi-

ble to measure the signal related to the cardiac rhythm

using a 2-wire technique or using the designed biode-

vice, to be in contact directly to a hand is required to

obtain the high frequency component.

50 60 70 80 90 100 110

−3

−2

−1

0

1

2

3

4

5

time(s)

variations of Z(Ω)

Steering Wheel (Left Hand) − Back Seat Configuration

Zoom in 1−minute Period

Raw Data

Ventilation

Heartbeat

Figure 7: Zoom in to the figure 6 in a one-minute period.

(Middle) The raw data. (Top) The ventilation signal. (Bot-

tom) The signal related to the cardiac rhythm.

20 40 60 80 100 120

−15

−10

−5

0

5

10

15

20

25

30

time(s)

Variations of Z(Ω)

Back Seat − Back Seat Configuration

Raw Data

Ventilation

Heartbeat

Figure 8: Back Seat - Back Seat Configuration using a 2-

wire measurement technique. (Middle) The raw data. (Top)

The ventilation signal. (Bottom) The signal related to the

cardiac rhythm.

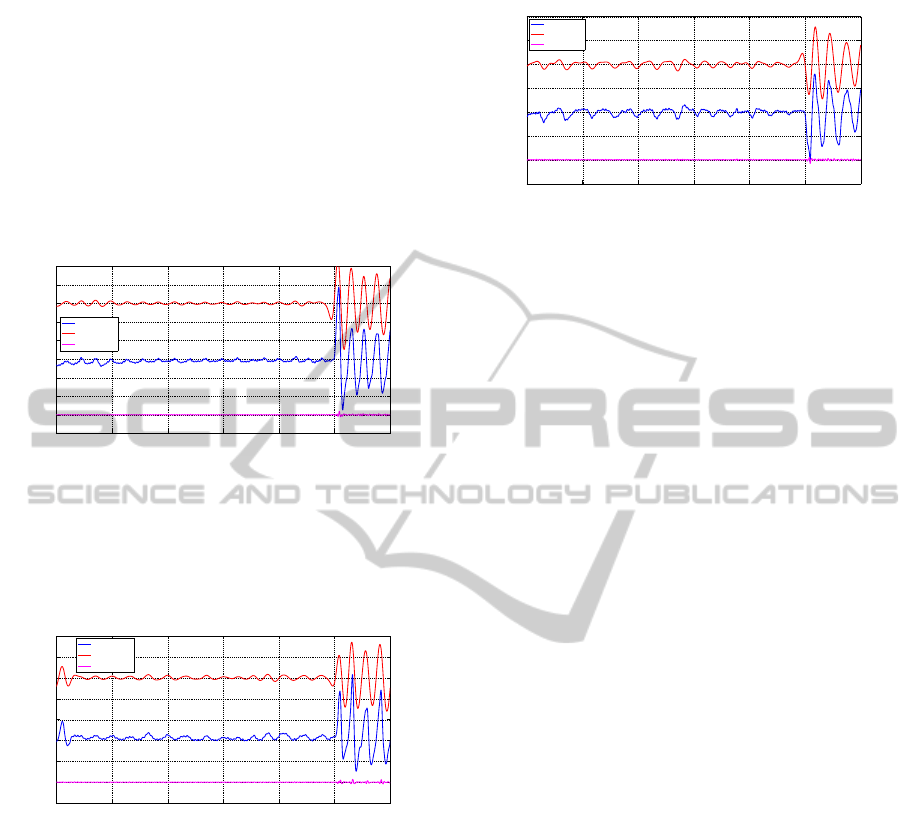

4.3 Influence of the Thickness of

Clothing

In the last group of measurements, dependencies on

clothing are checked. Applying the same test ex-

plained above and the steering wheel - back seat con-

figuration of electrodes, a subject is monitored wear-

ing three different clothing. In figure 9, the signal

is measured wearing a thin 100% cotton T-shirt. On

the other hand, over this T-shirt a thin 100% polyester

jacket and a thick sweater are worn in figures 10 and

11, respectively.

Note that the respiration rate is different in the

three figures. In figures 10 and 11, the respiration rate

is around 8 breaths per minute, lower than the mini-

mum respiration rate for normal condition in adults.

On the other hand, in figure 9 a normal rate of 11

breaths per minute can be observed. Furthermore, as

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

18

thicker the clothing, the measured signal is less sim-

ilar to the reference ventilation signal, refered to the

thoracic band.

Therefore, there seems to be a correlation between

clothing and the measured signal. Depending on the

clothings, the biodevice could not work properly be-

cause of some inhalations or exhalations cannot be

monitored. In fact, due to the capacitive behavior of

the textrodes, this problem could be solved using an

injection signal with a higher frequency.

20 40 60 80 100 120 140

−20

−15

−10

−5

0

5

10

15

20

25

time(s)

Variations of Z(Ω)

Steering Wheel (Left Hand) − Back Seat Configuration

Raw Data

Ventilation

Heartbeat

Figure 9: Steering Wheel - Back Seat Configuration with

the driving electrodes in the left hand and in the right side

of the back, respectively. The subject is wearing a thin T-

shirt made of cotton (100%). (Middle) The raw data. (Top)

The ventilation signal. (Bottom) The signal related to the

cardiac rhythm.

20 40 60 80 100 120 140

−15

−10

−5

0

5

10

15

20

25

time(s)

Variations of Z(Ω)

Steering Wheel − Back Seat Configuration wearing a Thin Jacket

Raw Data

Ventilation

Heartbeat

Figure 10: Steering Wheel - Back Seat Configuration with

the driving electrodes in the left hand and in the right side of

the back, respectively. The subject is wearing a thin jacket

made of polyester (100%) over a thin T-shirt made of cot-

ton (100%). (Middle) The raw data. (Top) The ventilation

signal. (Bottom) The signal related to the cardiac rhythm.

5 CONCLUSIONS

As shown in this paper, using a bioimpedance de-

vice, signals related to physiological parameters can

be monitored. In this particular case, not only sig-

nals related to the ventilation are measured but also

signals related to the cardiac rhythm. However, due

to the fact that the use of standard metal electrodes

are not recommended, new challenges related to the

textile electrodes arise. Thus, to analyze the behavior

20 40 60 80 100 120 140

−15

−10

−5

0

5

10

15

20

time(s)

Variations of Z(Ω)

Steering Wheel − Back Seat Configuration wearing a Thick Sweater

Raw Data

Ventilation

Heartbeat

Figure 11: Steering Wheel - Back Seat Configuration with

the driving electrodes in the left hand and in the right side

of the back, respectively. The subject is wearing a thick

sweater made of woolen (33%), polyester (27%), acrylic

(27%) and polyurethane (13%) over a thin T-shirt made of

cotton (100%). (Middle) The raw data. (Top) The ven-

tilation signal. (Bottom) The signal related to the cardiac

rhythm.

of the clothing-textrode interface in depth is required.

Furthermore, to test the bioimpedance device in a real

environment is also required.

But, in any case, the tests in a simulation environ-

ment show a proper operation of the biodevice. This

system is capable of monitoring the ventilation signal

just like a thoracic band. Furthermore, the biodevice

is also able to acquire the signal related to the car-

diac rhythm. Therefore, this biodevice seems to be

a further step to obtain a non-annoying non-invasive

biodevice capable of monitoring some physiological

parameters in a vehicle environment.

ACKNOWLEDGEMENTS

This work has been partially funded by the Span-

ish MINISTERIO DE CIENCIA E INNOVACI

´

ON.

Proyecto IPT-2011-0833-900000. Healthy Life style

and Drowsiness Prevention-HEALING DROP.

REFERENCES

Anund, A., Kecklund, G., Peters, B., and

˚

A kerstedt, T.

(2008). Driver sleepiness and individual differences

in preferences for countermeasures. Journal of Sleep

Research, 17(1):16–22.

Beckmann, L., Neuhaus, C., Medrano, G., Jungbecker, N.,

Walter, M., Gries, T., and Leonhardt, S. (2010). Char-

acterization of textile electrodes and conductors us-

ing standardized measurement setups. Physiological

Measurement, 31(2):233–247.

Bragos, R., Rosell, J., and Riu, P. (1994). A wide-band AC-

coupled current source for electrical impedance to-

mography. Physiological Measurement, 15(2A):A91–

A99.

ContactlessElectricalBioimpedanceSystemforMonitoringVentilation-ABiodeviceforVehicleEnvironment

19

Folke, M., Cernerud, L., Ekstr

¨

om, M., and H

¨

ok, B. (2003).

Critical review of non-invasive respiratory monitoring

in medical care. Medical & Biological Engineering &

Computing, 41(4):377–383.

Lal, S. K. L. and Craig, A. (2001). A critical review of the

psychophysiology of driver fatigue. Biological Psy-

chology, 55(3):173–194.

Michail, E., Kokonozi, A., Chouvarda, I., and Maglaveras,

N. (2008). EEG and HRV markers of sleepiness and

loss of control during car driving. In Conference pro-

ceedings : 30th Annual International Conference of

the IEEE. Engineering in Medicine and Biology Soci-

ety (EMBS)., volume 2008, pages 2566–9.

Riu, P., Bragos, R., and Rosell, J. (2009). In-

strumentation for Bio-impedance Measurements.

http://www.mn.uio.no/fysikk/english/people/aca/ogm

/index.html.

Schwan, H. P. and Ferris, C. D. (1968). Four-Electrode

Null Techniques for Impedance Measurement with

High Resolution. Review of Scientific Instruments,

39(4):481–485.

Wheelwright, C. D. (1962). Physiological sensors for use

in Project Mercury. NASA technical note ;NASA

TN D-1082. National Aeronautics and Space Ad-

ministration, Washington, D.C. [Online] Available

from: http://catalog.hathitrust.org/Record/011447015

[Accessed 12th April 2012].

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

20