Planning and Control Model for a Forest Supply Chain

C. Alayet

1, 3

, N. Lehoux

1, 3

, L. Lebel

2, 3

and M. Bouchard

4

1

Department of Mechanical Engineering, Laval University, Quebec, Canada

2

Department of Wood Science and Forest, Laval University, Quebec, Canada

3

Interuniversity Research Centre on Enterprise Networks, Logistics and Transportation, Quebec, Canada

4

NSERC VCO Network, University Laval, Quebec, Canada

Keywords: Decision Making Process, Forest Industry, Mixed-Integer Linear Model, Logistics Planning.

Abstract: This paper presents a mixed-integer linear program (MILP) for a planning problem of multiple activities in

the forest industry. The model developed aims at maximizing the total profit of the value chain by

optimizing operations in harvesting, transportation, storage, and production. The main motivations for the

model is a need to better account for important factors in planning and control, such as quality, freshness,

and species of wood products. These factors have a direct influence on costs and supply decisions. In

particular, the model developed will improve forest product companies’ industrial processes by a better

control over the wood fibre freshness. Furthermore, our model is designed for a context where multiple

independent companies supply their raw material from the same sources. It can therefore be used as a

support tool for collaboration between actors in a forest supply chain.

1 INTRODUCTION

The forest industry is an important economic sector

for Canada. In 2011, it provided a value of $ 26.0

billion of Canada’s total export with a gross

domestic product of $ 23.2 billion. Therefore it

ensures about 600,500 direct and indirect

employments (

FPAC, 2011).

However, the forest industry network is complex,

being composed of a set of nodes (i.e., forest,

sawmills, paper mills, wholesalers, retailers …)

interconnected by flows of materials (i.e., logs,

chips, lumber, paper …), information (orders,

demand, forecasts …), and financial transactions.

The network also includes a large set of constraints,

for example those related to product quality (for

lumber, paper, and other forest products), raw

material availability, and capacity requirements (at

the different business unit sites). Among these

constraints, product quality has reached standards

that require a very precise control over the supply

and production processes. For forest products,

freshness of raw material such as the logs and wood

chips is considered essential to optimise value while

satisfying customer needs. Furthermore, as a general

rule, the lower the quality of the fibre, the higher the

production cost for manufacturing forest products

(Beaudoin et al., 2006); (Maness and Norton, 2002).

In order to improve its efficiency, the forest

supply chain needs a continuous supply of raw

materials to ensure quality and achieve expected

standards. On the other hand, the procurement of

timber is a real challenge because of the fibre quality

variation, especially in the presence of various forest

stands and many tree species. The problem becomes

even more complex when many independent firms

in the same region use wood from the same stands to

produce their forest products. If each firm plans its

own activities without considering the needs of the

others (e.g., small or large trees, fir or spruce ...), the

wood fibre will not necessarily be matched to mill

demands efficiently. Moreover, the residue of one

company (i.e., chips from sawmill) becomes the raw

material for another one (i.e., the paper mill).

Therefore when there is no coordination between

the stakeholders, it leads to a set of problems such as

higher stock levels in the forest or at the different

business unit sites, delivery times not respected,

unsatisfied demands, poor value of the final product,

and so on. From operational and tactical planning

perspectives, timber supply is challenging on several

levels. it involves several activities such as forest

road building and maintenance, selection and

scheduling of harvesting areas, transport operations

(truck routing and scheduling), and the coordination

of interactions between these activities based on

203

Alayet C., Lehoux N., Lebel L. and Bouchard M..

Planning and Control Model for a Forest Supply Chain.

DOI: 10.5220/0004202200050013

In Proceedings of the 2nd International Conference on Operations Research and Enterprise Systems (ICORES-2013), pages 5-13

ISBN: 978-989-8565-40-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

information sharing. Resolving these issues may be

achieved through planning and effective monitoring

of resource flows and improved business processes

in a network of value creation (Suzanne et al., 2004).

The present work aims at helping forest companies

in better planning and controlling their forest supply

activities through a mathematical model that could

be used as a decision support tool for value creation.

The main motivation of the model is to deal with

elements of competition namely cost, quality, and

agility. More specifically, the model developed aims

at optimizing all activities related to the satisfaction

of customer demand, that is the quantity of wood to

harvest and to transport to the sawmills, the quantity

of lumber and chips to produce, the paper needed to

satisfy the demand, and the different products to

keep in stock to ensure a certain level of service. To

achieve these results, we assume that there is no

competition between the different business units.

Diverse scenarios are also tested to evaluate the

impact of wood freshness variations, price changes,

and demand variations on the value network. These

scenarios were explored to reflect the reality of the

forest industry.

The paper is structured as follows: the next

section presents a literature review, followed by the

description of the case study. Section 4 describes the

modelling of the problem and the assumptions made.

The experiment is then explained in detail in Section

5. Finally, Section 6 concludes the paper.

2 LITERATURE REVIEW

Managing the forest supply chain is an important

activity due to its impact on value creation and the

generation of profits for all business units. It

involves different planning decisions that should

cover different levels: strategic, tactical, and

operational (Martel, 2003). It begins with the

harvesting of wood in the forest, followed by species

sorting, wood transportation to different mills, log

sawing, and processing factories such as pulp, paper,

and energy. It ends with the delivery of final forest

products to end users (Carlsson et al., 2006).

However, planning decisions and their optimization

are complex tasks since they have to include many

factors such as wood species, wood freshness,

lumber price, final product quality, processing time,

and so on, as well as multiple independent decision-

makers.

Therefore, different planning approaches have

been proposed over the time to better use the wood

fibre and ensure the synchronization of network

activities. Beaudoin et al., (2010) presented supply

planning models for multiple forest companies in

which supply areas are shared. These planning

models were based on coordination and

collaboration approaches coupled with distributed

and centralized structures. Horne et al., (2006)

explained the importance of value creation based on

innovation and the development of products and

processes from a center of expertise in the forest

industry. The objective of their research was to

develop a model based on value creation of

innovative knowledge to improve decision making

and facilitate understanding of complex

mechanisms.

It is difficult to think about planning forest

operations without considering the control of the

different logistic activities. In the literature, there are

many definitions of logistic control systems. Among

them, we evoke the definition of Meinadier (1998)

cited in Trentesaux and Tahon (2010). The authors

introduced three activities that defined the driving

process: capture, edit, and order.

Several control structures were used to solve

complex problems of the forest supply chain. We

first distinguish the centralized or integrated

structure. This is the classic approach in which all

resources are controlled by a single decision center.

This center oversees the supply chain, synchronizes

and coordinates the various resources, and manages

real-time contingencies that occur (Mirdamadi et al.,

2009). Among the works that rely on a centralized

control structure, we find the work of Walker and

Preiss (1988). They developed a model for planning

logging (harvesting, quantity of timber harvested per

block, etc.) and transportation activities.

A second approach is characterized by a

coordinated structure. This structure aims at

ensuring coordination between the subsystems and

improving resource utilization while promoting a

better flow of information (Martel, 2003). This

structure usually improves the ability of decision in

each sub-control system to effectively solve

problems (Mirdamadi et al., 2009). It is within this

context that the study of D'Amours et al., (2004)

mentioned the importance of coordination in

establishing a value forest product network. The

authors identified four dimensions for this structure:

(1) competitiveness and customer service, (2)

integration, (3) coordination, and (4) operational

excellence.

Several other driving approaches were treated in

the literature depending on the area of study as well

as the planning horizon aimed, such as the

distributed approach (Gaudreault et al., 2009), the

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

204

hierarchical approach (Chang et al., 2009), etc.

However, the lack of collaboration between network

members is a major obstacle for planning and

controlling logistic activities efficiently (Lehoux et

al., 2008). In the forestry context, few authors

treated the topic of collaboration. Beaudoin et al.,

(2010) used a MILP approach and protocols of

negotiation / collaboration to plan the wood supply

for multiple forest companies. Lehoux et al., (2011)

evaluated various collaborative strategies between a

pulp and paper producer and its customer. They

presented different MILP models as well as a

methodology to solve the various modes of

collaboration and measure their impact on partners’

benefits.

The different articles show that forest supply

chain optimization has an increasing interest, the

planning of the different activities and the

integration of many factors such as quality

representing real challenges. This context will

therefore be explored in the following section.

3 CASE STUDY

3.1 Problem Description

The effective management of the forest supply chain

certainly requires a better planning and control of

logistic activities. Nevertheless, the management of

material flows and information is considered

complex, because of the interdependence of the

stakeholders involved, the quantity and the quality

of the information needed, and success factors such

as demand satisfaction and product quality.

Moreover the freshness of the wood fibre is a

particular problem that characterizes the forest

product market. It influences the harvesting

decisions like labor allocation, harvesting schedules,

site selection, etc. Similarly, the wood freshness

often causes problems during processing operations

such as the choice of the technology and the way to

use this technology (sawing processes, parameters

setting and cutting setup times for sawmills, etc.).

Thus, the freshness of the raw material has a

direct effect on the manufacturing process, the plant

performance, and the quality of finished products. In

the pulp and paper industry, the chips freshness has

a direct impact on the quantity of chemical products

(whiteness) to be added during the production.

Solving the above enumerated problems represents

long, medium, and short term decisions that have a

direct influence on production costs.

In this context, we study the case of a forest

supply chain located in Côte-Nord, a Quebec region

in Canada. The network includes several harvesting

areas, covering 103,146 km2 while 84,382 km2 are

accessible and productive forest lands (MRNFP,

2004). Several sawmills with variable processing

capacities procure their raw material/logs/timber

from these harvesting areas. The wood is used to

manufacture lumber for construction market as well

as chips delivered to a pulp and paper mill located in

the same region. In recent years, the network has

faced many difficulties such as an overcapacity of

sawing, a decrease in wood fibre quality, and higher

operational costs. Combined with a lower demand

for forest products on traditional markets, these

factors lead to a loss of 6,300 jobs in the last five

years. Different studies suggested that procurement

cost could be reduced and final product quality

increased if raw material quality could be better

matched to mill demands. To make this possible, a

global strategy involving a better planning and

control over the network activities is required.

To address this challenge, we have first

developed an integrated or centralized planning

model adapted to this context. The model includes

five forest areas and the four sawmills of the region.

A fictional bioenergy plant has been added because

the region is considering using wood residues for

energy. The forest is made up of two different

species, fir and spruce, and four intermediate

products are delivered to the sawmills (small and

large spruce logs + small and large fir logs).

Sawmills can also be supplied from external sources

to cover the lack in case of high demand. Sawmills

consume raw material to produce chips for paper

making as well as lumber for the construction

market. The model also takes into account a paper

mill supplies by the four sawmills. The paper mill

gets all its chips from the sawmills. It produces

newsprint and magazine paper.

The main objective of this study is to determine

an effective supply plan for this network that could

maximize the profit of all the stakeholders. An

illustration of the network is given in Fig 1.

Figure 1: Logistics network of the case study.

PlanningandControlModelforaForestSupplyChain

205

3.2 Assumptions

The model developed is based on a one-year

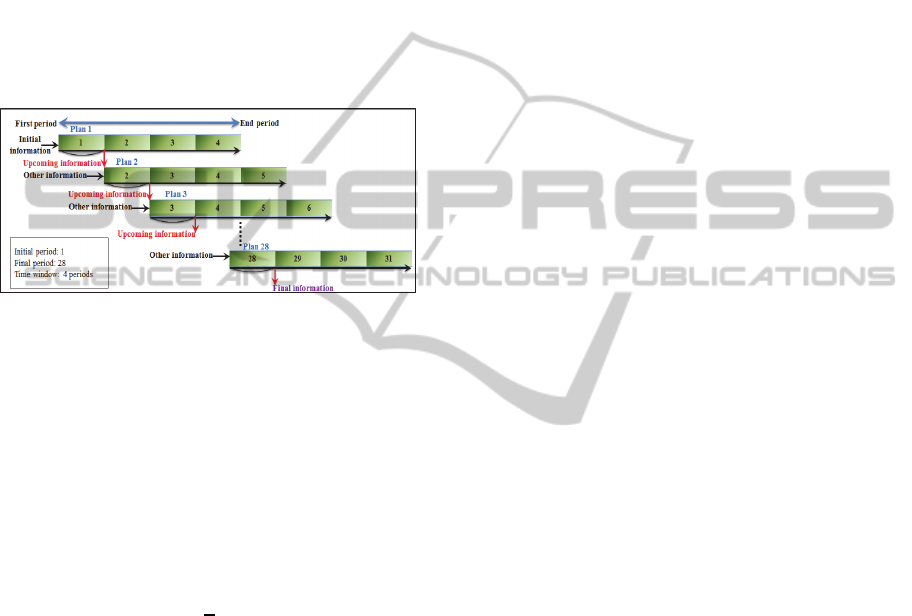

planning period divided into fifty-two weeks. Our

experiment is performed on a rolling horizon of four

weeks (Fig. 2). For each scenario, we solve the

model for the first four weeks, for example weeks 1

to 4. Then, we consider the results of the first week

to solve the next four weeks, weeks 2 to 5, and so

onBy using a rolling horizon, we can develop a 4

week schedule for forest operations while

considering updates, revisions, and adjustments

when necessary. This assumption has been made to

reflect companies’ reality.

Figure 2: An example of the rolling horizon approach

used.

We also assume that the level of freshness of the

wood fibre is divided into three categories: green

(young or fresh), yellow (medium or less fresh), and

red (old or not fresh).

In particular, we use "θ" to reflect the percentage

of aging during the period "t", and these parameters

are set according to product types and seasons.

Furthermore, φ is the percentage of aging per time

unit. So if the percentage of aging per week, θ, is

seven days, the percentage of aging per day is:

φ =

√

7

(1)

4 MATHEMATICAL

MODELLING

In this section, the mathematical model for Côte-

Nord network is presented. The model, based on a

centralized driving approach, reflects the network

shown in Figure 1.

Through this model, we try to maximize profits

for forest companies by determining harvested

volumes, the quantities to keep in stock and to

transport at each node, as well as the quantities

produced by the processing units. The decision

variables, parameters, and the complete

mathematical model are described in Appendix A.

The objective function is summarized by equation

(2).

(2)

Where R is the revenue of the value network, C

, the

cost for harvesting operations, C

,the cost for

buying wood from an external supply, C

, the total

transportation cost (transport between network

nodes: forest, plants, and customers), C

, the

inventory cost for the whole network, and C

,the

cost for processing the wood at the different

business units.

The network revenues are generated from the

sale of lumber, paper and the delivery of wood

residues to the bioenergy plant. Costs are divided

into several categories. Specifically, the harvesting

cost includes the cost for forest road construction

and maintenance, as well as the administrative cost.

The cost of external supply includes all costs

induced by moving logs from an outside supplier to

the sawmill (purchasing cost, ordering cost …). The

transportation cost includes product delivery costs as

well as loading and unloading costs. There is also an

inventory cost that includes, among other things,

material handling and equipment costs. The

processing cost then covers the costs and expenses

for producing lumber, wood chips, and paper.

As presented in detail in Appendix A, constraints

have been defined to represent the Côte-Nord

context. Two constraints were used to ensure

customer demand satisfaction. Two other constraints

have been added to ensure a product flow balance

between the sawmills and the paper mill. In order to

reflect aging at the different storage areas (i.e.,

forest, sawmills and paper mills sites), different

constraints were used. Constrains for processing

capacity of each business unit, capacity of the

different storage areas, and transportation capacity

were also considered. Finally, a constraint has also

been used to specify the maximum capacity of

supply from external sources.

5 EXPERIMENTATION AND

DISCUSSION

5.1 Scenarios and Results

The mathematical model was solved using the

CPLEX solver under ILOG OPL environment.

Several scenarios were tested to solve the problem.

First, different levels of freshness were considered in

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

206

order to evaluate its effect on network profits.

Demand variability was also taken into account to

reflect the reality of the forest industry. A

disturbance of market prices for lumber was then

analyzed because the price for forest products is

usually far from linear so it becomes necessary to

understand the impact of this change on the system.

If we look at the first scenario, five levels of wood

freshness have been explored. The percentage of

aging assumed for each level is presented in Table 1.

Table 1: Levels of wood freshness considered in the

experimentation.

Levels 1 2 3 4 5

(%)

0 10 30 50 60

Results summarized in Table 2 show that a

decrease in fibre quality (freshness) has a direct

impact on the total network profit.

Table 2: Results for variations of wood freshness.

Costs (M $) \

Instances

1 2 3 4 5

Harvest Cost 861.3 861.5 852 801.1 751.9

Cost of

External

Supply

268.7 265.8 272.4 317 392.4

Storage Cost 31.5 32 33.1 36.1 40.9

Total Cost 1953.6 1950.3 1945.2 1931.4 1972.6

Revenue 2055.6 2052.2 2050 2039.3 2051.7

Network

profit

102 101.9 104.8 107.9 79.1

We also note an improvement in profit when

some of the forest products become older from one

period to another. This improvement is justified by

the demand for products of lower quality that

necessarily cost less to the customer and that cannot

be satisfied when all the wood fibre is considered

fresh. However, it is clear that when the percentage

of aging is very high (i.e., 60%), the network profit

decreases abruptly. Indeed, the rapid aging forces

sawmills to buy wood from external supply sources

which significantly increases the cost of external

supplies. We can also point out the storage cost that

becomes more and more significant. This increase is

justified by the accumulation of low quality wood

fibre that remains in stock from one period to

another. This inventory cost will therefore decrease

the total profit. Similarly, the cost for harvesting and

logging significantly decreases when the percentage

of aging increases. In fact, when there is a rapid

aging, the network optimization requires a decrease

of harvesting because the harvested logs quickly get

old and remain in storage due to low demand for low

quality.

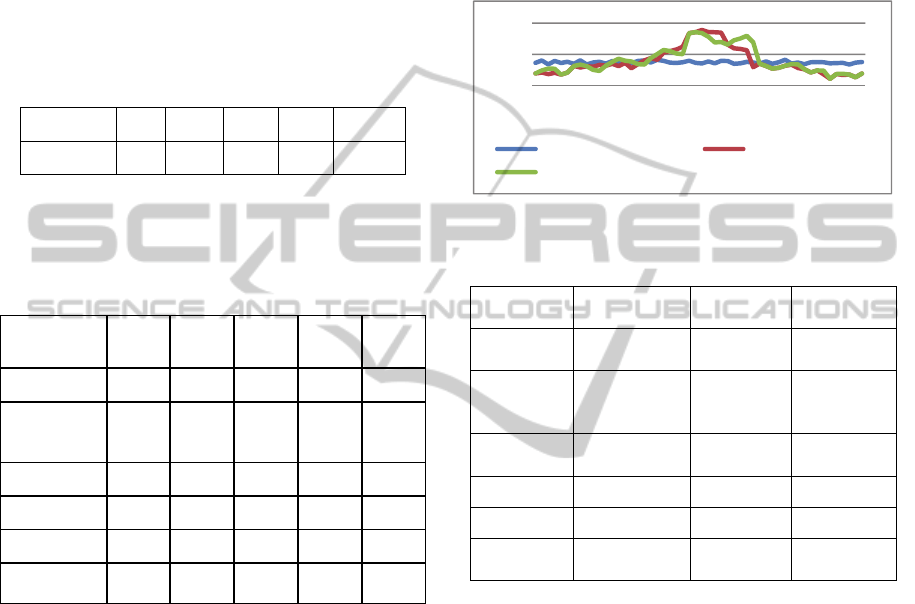

The second scenario considered different

variations of the lumber demand, that is, few

perturbations, seasonality, and cyclical seasonality

(Fig 3).

Figure 3: Variations of the lumber demand (m

3

/Week).

Table 3: Results for variations of the lumber demand.

Costs (M $)

\ Instances

Few

perturbations

Seasonality

Cyclical

seasonality

Harvest

Cost

873.0 867.9 875.2

Cost of

External

Supply

250.3 252.1 254.3

Storage

Cost

31.8 30.6 30.4

Total Cost 1945.6 1934.7 1947.1

Revenue 2080.5 2035.4 2050.5

Network

profit

134.9 100.7 103.4

The benefits of having a stable timber demand

are highlighted by Table 3. In fact, stability is

difficult to achieve since demand for lumber, at least

in Canada, is characterized by a seasonal structure

related to the construction market. To ensure a more

constant demand, forest product companies are

therefore trying to develop new external markets by

producing more value-added products.

Results in table 3 show that the harvesting cost is

lower when the demand is seasonal. This is due to

the fact that it is cheaper to harvest during the

summer (favorable climatic condition). The cost

related to external supplies is also not negligible,

since it represents almost a quarter of the total cost.

This value is justified by a harvesting capacity that is

limited and even null during the thawing season.

The sale price is an important and a classic factor

to consider in the analysis of a value creation

network. For our case study, results show that the

network profit may be doubled if the lumber price

750

950

1150

1 142740

Few perturbations Seasonality

Cyclical seasonality

PlanningandControlModelforaForestSupplyChain

207

increases by 7%. These results are justified by the

importance of lumber demand that represents almost

80% of the total network demand. Thus, it becomes

essential to plan the supply chain efficiently in order

to deliver the right product to the right customer

with the right quality. By managing quality

standards (freshness) it becomes also possible to

offer a more advantageous and stable price.

6 CONCLUSIONS

This article proposes an integrated model to plan

supply chain operations for the forest industry while

considering key constraints related to the freshness

of the wood fibre. In particular, we analyze a case

study, which includes four sawmills and one paper

mill located in eastern Canada. To ensure a better

use of the wood fibre and a greater synchronization

of the network activities, the model provides

harvesting, transportation, production, and storage

plans for the forest companies of this region. The

model aims at improving the management of the

wood fibre quality while reducing the operating

costs such as storage, transportation, and processing.

The proposed model has been tested using three

different scenarios: variations of the wood freshness,

different patterns of lumber demand, and variations

of the lumber price. Results show that the wood

fibre freshness is a key criterion to consider for

increasing the benefit of the value network. On the

other hand, scenario analysis based on lumber price

and demand confirm the necessity for Canadian

forest product companies to expand their market to

avoid the effects of the relative instability of the

Canadian lumber market.

The next step will be to develop multiple models

based on a coordinated driving strategy for

addressing the fact that each company is

“independent” or autonomous. It will also be

necessary to develop some mechanisms to ensure a

fair benefit sharing generated of a better

synchronization of network members’ operations.

REFERENCES

Beaudoin, D., Frayret, J. M., LeBel, L., 2010. Negotiation-

based distributed wood procurement planning within a

multi-firm environment. Forest Policy and Economics,

vol. 12, no. 2, pp. 79–93.

Beaudoin, D., LeBel, L., Frayret, J. M., 2006. Tactical

Supply Chain Planning and Robustness Analysis in the

Forest Products Industry. Canadian Journal of Forest

Research, vol. 37, no. 1, pp. 128-140(13).

Carlsson, D., D'Amours, S., Martel, A., Rönnqvist, M.,

2006. Supply Chain Management in the Pulp and

Paper Industry. CENTOR, Working Paper, DT-AM-3.

Chang, Y. H., Weyb, W. M., Tseng. H. Y., 2009. Using

ANP priorities with goal programming for

revitalization strategies in historic transport: A case

study of the Alishan Forest Railway. Expert Systems

with Applications, vol. 36, no. 4, pp. 8682–8690.

D’Amours, S., Frayret, J. M., Rousseau, A., 2004. De la

forêt au client – Pourquoi viser une gestion intégrée

du réseau de création de valeur ? Université Laval,

FORAC, CENTOR, Document de travail.

Forest Products Association of Canada (FPAC)., 2011.

Industry by the number. Key economics facts.

Gaudreault, J., Frayret, J. M., Pesant, G., 2009. Distributed

search for supply chain coordination. Computers in

Industry, vol. 60, no. 6, pp. 441–451.

Horne, C. V., Frayret, J. M., Poulin, D., 2006. Creating

value with innovation: From centre of expertise to the

forest products industry. Forest Policy and

Economics,vol. 8, no. 7, pp. 751–761.

Lehoux, N., D’Amours, S., Langevin, A., 2008.

Collaboration et coordination dans les réseaux, une

revue des travaux clés. CIRRELT-2008-51.

Lehoux, N., D’Amours, S., Frein, Y., Langevin, A., Penz,

B., 2011. Collaboration for a two-echelon supply

chain in the pulp and paper industry: the use of

incentives to increase profit. Journal of the

Operational Research Society, vol. 62, pp. 581-592.

Maness, T. C., Norton, S. E., 2002. Multiple Period

Combined Optimization Approach to Forest

Production Planning. Scandinavian Journal of Forest

Research, vol. 17, no. 5, pp. 460-471.

Martel, A., 2003. Le pilotage des flux : concepts de base et

approches contemporaines. DF-3.1.1. La conception

de réseaux logistiques. CENTOR, Université Laval.

Ministère des ressources naturelles, de la faune et des

parcs, direction régionale de la Côte-Nord (MRNFP).,

2004. Région de la Côte-Nord. Document

d’information sur la gestion de la forêt publique.

Mirdamadi, S., Dupont, L., Fontanili, F., 2009.

Modélisation du processus de pilotage d’un atelier en

temps réel à l’aide de la simulation en ligne couplée à

l’exécution. Thèse de doctorat. Institut National

Polytechnique de Toulouse.

Suzanne, T., Roy, D. S., Ari-Pekka, H., 2004. From supply

chain to demand chain: the role of lead time reduction

in improving demand chain performance. Journal of

Operations Management, vol. 21, no. 6, pp. 613–627.

Trentesaux, D., Tahon, T., 2010. Pilotage hétérarchique

des systèmes de production. Habilitation à diriger des

recherches. L’Université de Valenciennes et du

Hainaut-Cambresis. LAMIIH. UMR CNRS 8530.

Walker, H. D., Preiss, S. W., 1988. Operational planning

using mixed integer programming. The Forestry

Chronicle, vol. 64, no. 6, pp. 485-488.

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

208

APPENDIX

The data required to formulate the problem are:

r: Set of products

w: set of supply sources

e: Set of external supply sources

u: Set of sawmills

u’: Other Plants (bioenergy plant ...)

u’’: Set of paper mills

c: End clients of paper mills

b: Timber clients

a: Level of freshness (age group: 1: green (young),

2: yellow (medium), 3: Red (old))

t: Number of periods

The decision variables, parameters and coefficients

used for mathematical modeling are:

Parameters

C

: Unit harvesting cost of product r belongs to

the supply source w during period t

C

: Unit supply cost of product r from external

supply source e to the plant u’ during period t

C

: Unit storage cost of product r in the supply

source w during period t

C

: Unit transporting cost of product r from the

source w to the sawmill u during period t

C

: Unit transporting cost of product r from the

source w to the plant u’ during period t

C

: Unit transporting cost of product r from the

sawmill u to the paper mill u’’ during period t

C

: Unit transporting cost of product r from the

sawmill u to the timber client b during period t

C

: Unit storage cost of raw materials r in the

sawmill u during period t

C

: Unit storage cost of raw materials r in the

paper mill u’’ during period t

C

: Unit storage cost of finished product r in the

sawmill u during period t

C

: Unit storage cost of finished product r in the

paper mill u’’ during period t

C

: Unit production cost of product r, aged a, in

the sawmill u during period t

C

: Unit production cost of product r, aged a, in

the paper mill u during period t

p

: Selling price of product r, aged a and directly

transported to the plant u’ during period t

p

: Price of finished product r, aged a and

manufactured by the sawmill u during period t

p

: Price of finished product r, aged a and

produced by the paper mill u during period t

α

: Coefficient of adjustment of units: raw material;

finished product r for the sawmill u

β

: Coefficient of adjustment of units: raw

material; finished product for the paper mill u’’

θ

: Proportion of aging product r, aged a for the

source w

θ

: Proportion of aging product r, aged a for the

initial stock of the sawmill u

θ

: Proportion of aging product r, aged a for the

final stock of the sawmill u

θ

: Proportion of aging product r, aged a for the

initial stock of the paper mill u’’

θ

: Proportion of aging product r, aged a for the

final stock of the paper mill u’’

b

: Maximum harvesting capacity product r of the

source w during period t

b

: Minimum harvesting capacity product r of the

source w during period t

b

: Maximum available storage capacity of the

supply source w

b

: Maximum storage capacity for raw materials

from the sawmill u

b

: Maximum storage capacity for raw materials of

the paper mill u’’

b

: Maximum storage capacity of finished products

from the sawmill u

b

: Maximum storage capacity of finished products

of the paper mill u’’

b

: Maximum transport capacity from the source w

during period t

b

: Minimum transport capacity from the source

w during period t

b

: Maximum supply capacity from the external

source e during period t

b

: Maximum transport capacity from the sawmill u

during period t

b

: Maximum processing capacity of the sawmill u

during period t

b

: Maximum processing capacity of the paper

mill u’’ during period t

D

: Demand of product r, aged a, from the

sawmill u customers during period t

D

: Demand of product r, aged a, from the paper

mill u’’customers during period t

M: Big number

Decision Variables

: Harvested volume of product r from the source

w during period t

: Stored volume of product r, aged a, in the

supply source w during period t

: Transported volume of product r, aged a,

from the source w to the sawmill u during period t

PlanningandControlModelforaForestSupplyChain

209

: Transported volume of product r, aged a,

from the source w to the plant u’ during period t

: Transported volume of product r, aged a,

from the external source e to the plant u’ during

period t

: Transported volume of product r, aged a,

from the sawmill u to the paper mill u’’ during

period t

: Transported volume of product r, aged a,

from the sawmill u to the timber client b during

period t

: Transported volume of product r, aged a,

from the paper mill u’’ to the final client c during

period t

: Inventory of stored raw materials r, aged a,

in the sawmill u during period t

: Stored volume of final product r, aged a, in

the sawmill u during period t

: Inventory of stored raw materials r, aged a,

in the paper mill u’’ during period t

: Stored volume of final product r, aged a, in

the paper mill u’’ during period t

: Inventory volume of transformed product r,

aged a, in the sawmill u during period t

: Quantity of available finished products r,

aged a, in the sawmill u during period t

′′

: Quantity of available finished products r,

aged a, in the paper mill u during period t

′′

: Inventory volume of transformed product r,

aged a, in the paper mill u’’ during period t

: 1, if the source w is transported to the mill u

during period t

0, otherwise

′

: 1, if there is a transport from the source w to

the mill u’ during the period t

0, otherwise

Mathematical Model

Objective Function

∑

,,,

∗

∑

,,,

,

∗

∑

,,

,

∗

∑

,,

∗

∑

,,

,

∗

∑

∗

,,,

∑

∗

,,,,

∑

∗

,,,

,

∑

∗

,,,

,

∑

∗

,,,,

∑

∗

,,,

∑

∗

,,

,

∑

∗

,,,

∑

∗

,,

,

∑

∗

,,,

∑

∗

,,

,

(1)

Constraints

Demand constraints

∀,,

(2)

∀,,′′′′

(3)

Production constraints

∗

∀,,

(4)

∗

∀,,

(5)

∗

∈

∈

1

∗

∀ ,,, 1

(6)

Conservation flows and aging constraints

∗

1

∗

∈

∈

∀ ,, , 1

(7)

∈

1

∗

∀ ,,, 1

(8)

∈

∈

1

∗

∀ ,,, 1

(9)

∗

1

∗

∈

∀ ,,, 1

(10)

∗

1

∗

∈

∈

∀ ,,, 1

(11)

∗

1

∗

∀ ,,,

1

(12)

∗

∈

1

∗

∀ ,,,′′′′ 1

(13)

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

210

∗

1

∗

∀,,,′′′′ 1

(14)

∗

1

∗

∈

∀,,,′′′′ 1

(15)

Capacity constraints

∀

(16)

∀′′′′

(17)

∀;

(18)

∀;

(19)

∀;

(20)

∀;

(21)

∀;

(22)

∀;

(23)

∈

∀;

(24)

∈

∗

∀;

(25)

∈

∗

∀;

(26)

∗

∈

∀;

(27)

∗

∈

∀;

(28)

∈

∈

∀;

(29)

Non-negativity constraints

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

0

∀

,,,,

,′′

(30)

, ′

∈ 0,1

∀

(31)

PlanningandControlModelforaForestSupplyChain

211