Smart Household

Selected Problem Solutions using Intelligent Controllable Electric Appliances

Miroslav Pr

´

ymek and Ale

ˇ

s Hor

´

ak

Faculty of Informatics, Masaryk University, Botanicka 68a, 602 00 Brno, Czech Republic

Keywords:

Smart Home, Home Automation, Power Consumption Planning, Multi-agent Systems.

Abstract:

In the current perspectives, renewable power sources bring new challenges for the power distribution. Substan-

tial advances in the reliability and flexibility in the overall power consumption can be achieved via a network

of intelligent and controllable appliances, especially on the micro level, i.e. on the level of individual electric

appliances within the scope of one household or one institution. In the paper, we identify the typical problems

of the smart household approach and present a communication and control model which offers a solution to

these problems based on the multi-agent system approach.

1 INTRODUCTION

Within the search for new alternative energy sources

the percentage of electricity produced by renewable

power sources grows rapidly in the worldwide mea-

sures. The irregular nature of these sources brings

new demands on the control of the power distribution

network (Ibrahim et al., 2008). A possible solution

lies in the design of smart power grids on all levels

of the energy flow ranging from the wide distribution

networks to housing estates, institutions or individual

households. A combination of a set of small decen-

tralized sources of electric power, photovoltaic sys-

tems being a typical example, and a smaller or larger

set of intelligent or intelligently controlled electric ap-

pliances offers new operation scenarios of power con-

sumption profiles (Roncero, 2008).

In order to analyze the design details of new in-

telligent elements of a power network in the smart

household concept, we have identified typical imple-

mentation problems connected with combined power

distribution from heterogeneous sources. The solu-

tions to these problems have been incorporated in the

development process of a new Smart Home Simula-

tion (SHS) system that is implemented at our institu-

tion and is used as a research testbed for this topic.

1.1 Common Power Distribution

Problems Connected with

Heterogeneous Sources

In this section, we identify the major problems caused

by the inflexibility of the traditional power grids in

the environment with increasing number of unstable

sources.

The biggest problem of new renewable sources of

electrical power is that their production is driven by

natural conditions and their production profile can-

not be changed to suit the consumption profile of

the users. This limits the usability of renewable

sources not even on the national level but even more

as sources in the off-grid arrangement.

One of the possible approaches lies in the effort to

improve the means of energy storage. This approach

surely attracts attention (Carrasco et al., 2006). The

parameters of the energy storage facilities are improv-

ing but the usability is still very limited.

Another approach works with adjusting the power

consumption profile to better suit the profile of the

source – in contrary to the conventional control of

the particular sources. This brings new problems

of communication between the sources and the con-

sumers (or consumer appliances), consumption plan-

ning and appliance control itself. These problems are

complicated but the effect is obvious and the limita-

tions are often not as strict (physical) as in the above-

mentioned problem of energy storage.

Next issue of the renewable sources is their un-

avoidable instability. To increase the grid control ef-

fectiveness, the supply changes must be either pre-

dictable or the appliance must be capable of very fast

reactions to the situation and it must adjust its param-

eters accordingly. This puts strong requirements on

the flexibility and speed of the control system.

204

Prýmek M. and Horák A..

Smart Household - Selected Problem Solutions using Intelligent Controllable Electric Appliances.

DOI: 10.5220/0004236502040210

In Proceedings of the 5th International Conference on Agents and Artificial Intelligence (ICAART-2013), pages 204-210

ISBN: 978-989-8565-38-9

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Nevertheless, the grid control system can solve

not only the problems connected with new power

sources. The ability to quickly, flexibly and specif-

ically control particular power consumers (up to the

appliance level) brings also new possibilities from the

whole power network perspectives. One of them is

the ability to appropriately react on negative external

influences like blackouts, brownouts and other non-

standard situations.

In the next section we will present a model of an

intelligent power grid and in Section 3 we will show

how an implementation of this model can diminish

the described problems.

2 PRIORITY-BASED POWER

GRID CONTROL MODEL

The problem of power grid control is in general a

problem of coupling between the providers (power

sources) and consumers. A general solution to this

problem is to employ standard market mechanisms

to establish deals between providers and consumers,

mainly in the form of an energy auction. Block et

al. (Block et al., 2008) present a good review and

comparison of many proposed auction styles and their

implementations presented in the literature. They

conclude that the main disadvantage of the market

approach is the lack of sufficient flexibility (immedi-

acy requirement) of the underlying algorithms. The

grid control model construction obviously is a mat-

ter of trade-off between the complexity and feature-

completeness on the one hand and interactivity and

ease of implementation on the other.

In our work, we focus on the micro-grids on the

household level and therefore we stress the later crite-

rion in the presented model to make the model more

straightforward and implementable even in low-cost

embedded controllers dedicated to particular house-

hold appliances. The whole model is built using

the multi-agent system approach, where the required

global operation model is obtained purely by means

of inter-agent communication (the details are pre-

sented further).

The central notion of the model is a priority. In-

stead of providing a complicated way to reach a con-

sensus between a producer and a consumer by the

means of an auction, the model assumes that the price

along with other criteria constitutes the summary

value determining the coupling between a producer

and a consumer. The coupling is based on the fun-

damental rule that high-priority consumers must, in

every moment, be satisfied before the lower-priority

ones.

The system priorities are also assigned to pro-

ducers, the second system rule is: consumers with

priority p can only be satisfied by producers with

the priority ≤ p. The resulting behavior of the sys-

tem approximates the auction result in the way where

non-necessary (low-cost) appliance effects are not ac-

quired for the price of inappropriate costs. E.g. long-

term heat accumulation is not performed when the

system is in an outage and running on an expen-

sive power source such as a diesel power generator.

And vice versa: the lowest priority is assigned to the

”no-cost” power sources like photovoltaic panels such

that, in an ideal case, all power from them is con-

sumed instead of more expensive power from the grid.

In the Smart Home Simulation (SHS) model im-

plementation (Pr

´

ymek and Hor

´

ak, 2012), the follow-

ing navigation labels are used as a hint for user to de-

cide which priority to assign to particular appliances

and their states:

1. unnecessary, time unlimited

2. small outcome

3. significant outcome

4. user inconvenience avoidance

5. financial loss avoidance

6. significant user inconvenience avoidance

7. significant financial loss avoidance

8. health risk avoidance

2.1 Appliance Categories

The grid appliances are classified into several types

according to their control mechanism, user expectan-

cies and power consumption profiles.

2.1.1 Interactive Appliance

An interactive appliance (IA) is directly controlled by

the user and the IA’s reaction cannot be deferred. Also

the power consumption is mostly constant and cannot

be controlled.

A typical examples of such an appliance is electric

light, electric kettle or television.

2.1.2 Intelligent Interactive Appliance

Intelligent Interactive Appliance (IIA) is a special

case of the previous type. The main difference lies in

the IIA’s power control. The appliance can have more

power consumption profiles which can be chosen ac-

cording to the current situation or it can be driven by

special extra communication/control treatment (e.g. a

server computer power cannot be cut off immediately,

instead a control signal must be emitted and the com-

puter will undergo the internal shut down process as

soon as possible).

SmartHousehold-SelectedProblemSolutionsusingIntelligentControllableElectricAppliances

205

Table 1: Summary of system messages used between agents in the Smart Home Simulation system.

power available(from,amount,priority) The power source agent advertises the

amount of power it can supply to the network

starting at the time from

power request(from,amount,priority) An appliance agent requests amount power

starting at time from

power granted(from) The scheduler agent authorizes the given

consumption request

power denied(until) A consumption request is denied

power release(from) The agent’s consumption will end in time

from and the power will be freed

power grant proposal(from) An appliance agent advertises that the appli-

ance can defer the consumption to time from

accepted() A given proposal is accepted

refused() A given proposal is refused

not implemented() A response that the previous message is not

understood or the requested functionality is

not implemented (e.g. the appliance can not

defer its consumption)

A typical example of IIA is a computer.

2.1.3 Deferrable-operation Appliance

This appliance is also controlled by the user but an

immediate operation is not necessary. When the user

commands the appliance to operate, he/she only ex-

pects it to begin the work in a reasonable (configured)

amount of time. The user does not depend on the pre-

cise time of the operation start and end, only the op-

eration result must be delivered appropriately.

Typical examples of deferrable-operation appli-

ances are washing machine, dryer, dishwasher, slow

cooker, car battery charger and generally all appli-

ances which require some user intervention before

the operation and whose products are expected to be

available in a longer time.

2.1.4 Feedback-controlled Appliance

A feedback-controlled appliance (FCA) is usually de-

signed to keep a predefined and (repeatedly) mea-

sured value within specified limits. The value is spon-

taneously tending in one direction and the power sup-

ply is needed to push it in the opposite direction. A

conventional operation cycle is as follows: whenever

a feedback value reaches the lower bound, the appli-

ance engine is powered up to push it to the oppo-

site bound and powered off as soon as this value is

reached. This way the power profile of the appliance

consists of alternating periods of maximal and none

power consumption of a more or less constant dura-

tion.

A generalization of the feedback-controlled appli-

ance model in SHS is based on the assumption that

the boundaries of the appliance operation should not

be defined as hard limits that cannot be exceeded

but rather as gradually increasing measures of the

power demand priority. From this point of view, a

FCA appliance can be seen as a highly flexible device

whose power consumption can be efficiently planned

to fit together with a power consumption profile of

other less-controllable devices. From the most gen-

eral point of view it can be seen as a power storage

device. Of course, FCA cannot store arbitrary amount

of power – low amounts of stored power would have

unintended consequences such as e.g. food going to

rotten in an under-cooled refrigerator.

2.2 The System Communication

In contrast with the auction-style planning, the pre-

sented model is designed to achieve good planning

results without the need of a complicated communi-

cation schema and slow decision-making algorithms.

Hence it is well suited for implementation even in

small embedded devices without a substantial com-

puting power.

The final power consumption plan of the whole

system is driven by a scheduler agent with its deci-

sions based on the communication of consumption re-

quests between the scheduler and the appliances. The

architecture of the system is centralized and directive

from the decision-making point of view. However, the

planning and primary reasoning is decentralized. The

field agents (particular appliance controllers) make up

suitable individual plans and present them as sugges-

tions to the scheduler agent. The scheduler then pre-

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

206

pares the final authoritative decision. With this ap-

proach the whole system is user-controllable and pre-

dictable.

Of course, the centralized architecture is not suit-

able for control of an arbitrarily large number of de-

vices. Instead of a flat horizontal scaling, the hier-

archical scalability must be used. This corresponds

to the energy distribution model where every distri-

bution point has a limited number of sub-branches

which are to be controlled as a solid blocks. There-

fore, we focus on the control of a relatively small

unit (household) with the aim to make it a more pre-

dictable unit on the higher level of the power distribu-

tion topology.

A list of the main system messages is presented

in Table 1. All communicated values are considered

valid until changed. That is why the system uses only

the ”from” property with no ”to”. Examples of par-

ticular communication scenarios are presented in the

next section.

3 SMART GRID PROBLEM

SOLUTIONS

In this section, we refer to the power grid problems

identified above and we offer their solutions justified

by the solution implementation within the presented

Smart Home Simulation system.

3.1 Surplus Power

The conventional not-controllable appliances can usu-

ally be only in on or off mode. Electronics usually add

some sort of power-saving mode which does not limit

the user experience as much as the off mode while

consuming substantially less power than the full-on

mode.

This principle can be generalized as “provide

maximal effect to the user for the minimal amount of

power.” Such general principle is applied in many ar-

eas and is undoubtedly the right one as an effort to

minimize the cost/effect ratio.

But in the environment with uncontrollable and

hardly predictable sources of energy, the mere savings

do not necessarily present the best result. With many

renewable source types the price of the energy mostly

consists of the share of the fixed purchase-price of the

facility. Therefore to minimize the cost/effect ratio,

there is a need to increase the effect, not to lower the

cost.

Without intelligent appliance control, the surplus

power can only be stored for future use or sold. The

first solution surely is the best one, but the efficiency

of power storage is still insufficient and the costs are

high. Selling the surplus power can have complicated

administrative or technical preconditions and so can-

not be easily applied to small amounts of energy. Also

it is unusable for the off-grid operation.

In the smart grid environment with controllable

appliances, the problem of surplus power can be

solved in a flexible way. The precondition is that

intelligent appliances in the network support sev-

eral consumption level modes (ideally arbitrarily

selectable consumption level with fixed consump-

tion/effect ratio) and the control system can quickly

negotiate the right consumption level according to the

amount of power currently available in the system.

3.2 Intelligent Sources Allocation

The next identified problem consists in searching

the correspondence between the consumption and the

power supply such that:

• the cheapest sources are used to the maximal ex-

tent

• peaks are minimized

• the user experience is not substantially affected

These goals can be met with intelligent consumption

planning according to the predicted power supply. In

the SHS priority-driven model, this is solved by rear-

ranging particular appliances operation in such a way

that the priority constraints are met.

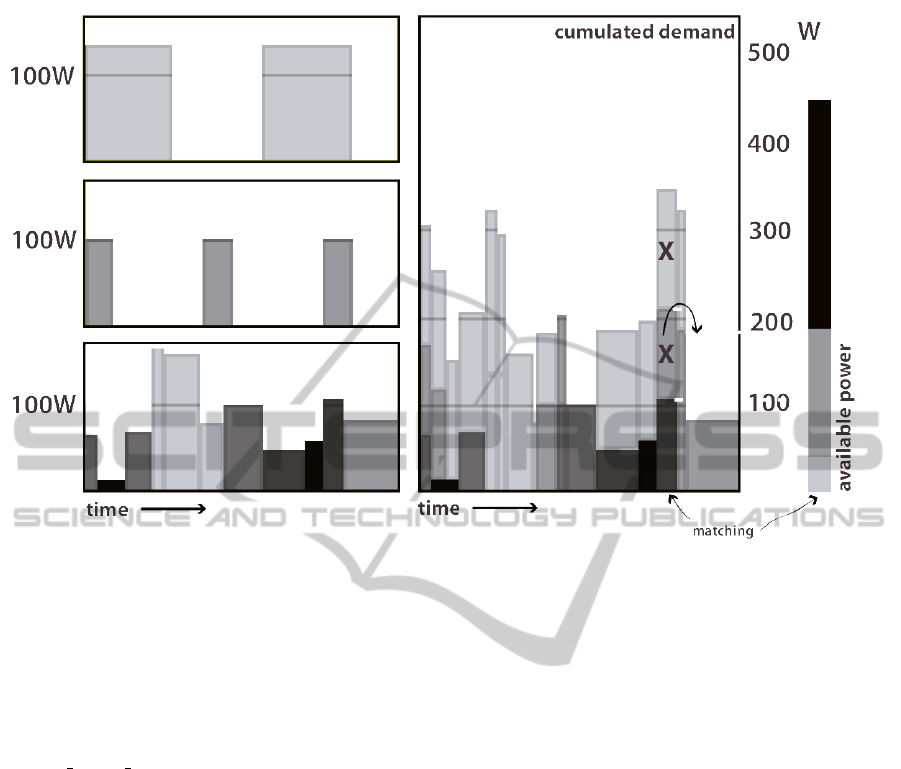

The problem is illustrated in Figure 1. Three small

charts on the left side depict the consumption plan

of the three appliances (the first two are feedback-

controlled and the third is an IIA). The cumulated

demand chart on the right side shows the overall re-

quested power consumption of these three appliances.

Darker color of a bar means higher priority. The cu-

mulated demand must be matched with the supply

prediction. The algorithm is as follows:

1. the demand and supply plans are approximated by

discrete values (bars on the chart),

2. both plans are partitioned to have equal time-

spans with constant values,

3. each timespan of the demand plan is compared to

the corresponding timespan of the supply plan.

The third step is illustrated by the “matching” label in

the chart. In this graphical representation, the priority

rule can be described as: the darkest bars of the de-

mand are preferably matched with the lightest bars of

the supply and each bar of the demand must not end

higher than the corresponding supply bar of the same

or lighter color. We can see that the rule is not satis-

fied with the bars marked with the “X” sign – i.e. the

corresponding consumption requests do not fulfill the

constraints and will be denied by the scheduler.

SmartHousehold-SelectedProblemSolutionsusingIntelligentControllableElectricAppliances

207

Figure 1: Visualization of the supply/demand matching algorithm.

In addition to the binary decision whether to

approve or reject a particular consumption request,

the scheduler also proposes a solution to the situ-

ation: in this example to shift the consumption to

the timespan where it would satisfy the priority con-

straints (marked with an arrow and a dotted bar in

the cumulated demand chart). The scheduler sends

the power grant proposal message to the appliance

agent and the appliance agent decides whether the

postponement of this particular consumption request

is acceptable or not. It will communicate its decision

to the scheduler with the accepted() or refused()

message.

This way the peaks in the consumption plan will

be eliminated if possible without a negative impact on

the appliances operation (they autonomously decide

whether the proposal is acceptable or not).

3.3 Unexpected Events

In a similar way, the scheduler can react to the unex-

pected drop of the power supply. We can again illus-

trate the situation in Figure 1. If the lightest bar of the

supply will not be in place, even the above-described

time-shift of the consumption would not solve the sit-

uation. This consumption request will be denied be-

cause it has lower priority than any available power

source of the appropriate capacity. Nevertheless, this

one-source outage will not affect the appliances with

higher priority. This way the network will automat-

ically adapt its operation to the changed conditions

caused by external influences.

4 PROTOTYPE

The research of SHS is directed to testing in real-

world situations. In the following sections, we de-

scribe the hardware and software parts of the SHS

testbed.

4.1 Hardware

The efforts to develop standards for home automa-

tion communication infrastructure have a long history

(e.g. see (Murata et al., 1983)). But none of the pro-

posals gained dominance in the field and up today

there are many incompatible standards of the hard-

ware infrastructure (lines level), communication pro-

tocols and software solutions. Many of them are pro-

prietary and patented so they are not well suited for

open, vendor-independent solution development.

One of the oldest solutions is an X10 standard us-

ing the house electrical wiring as the physical layer

for communication. There were attempts to improve

the standard and overcome some of its limitations,

namely CEBus and LonWorks (for their comparison

see (Strassberg, 1995)). These standards are often

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

208

limited in purpose – the type of information to be

communicated is limited to the specific home automa-

tion commands like “dim lights to x%” or “switch the

device on.”

Another approach is to utilize the standards used

in the industrial communication – e.g. RS485, Mod-

bus, or the standards used in the computers or con-

sumer electronics: I2C, 1-Wire, SMBus, Ethernet,

USB. The disadvantage of the consumer electronics

standards (except Ethernet) is that they were not de-

signed for large-scale communication.

The Ethernet standard seems as a best solution due

to its widespread use. Moreover, Ethernet networks

are used as convergence networks for once separated

networks like phone lines (VOIP), TV wiring (IPTV)

etc. Nevertheless, the Ethernet standard is not us-

able for our scenario mainly because its complexity

– its implementation in low-power microcontrollers

is inconvenient, hard or even impossible. The best

approach is to use chips specialized for the Ether-

net communication, however, this makes the solution

more expensive and complicated.

For our prototype implementation, we have de-

cided to choose the RS485 standard (Electronic In-

dustries Association, 1983). Its main advantages can

be summarized as:

• it is widespread and highly tested, mainly in the

industrial environment

• it is designed to be very interference-resistant –

RS485 uses differential signaling (two symmetric

signal wires)

• it does not place high demands on the wire quality

– the common twisted pair cable is used, so stan-

dard existing house wiring (e.g. Ethernet Cat5 or

phone cables) can be used

• it can achieve high transmission speed or long dis-

tances (about tens of megabits over tens of meters

or up to hundred kilobits over one kilometer long

cable)

• its electronic implementation is simple and cheap

• unlike its predecessors (mostly RS232, also

known as the computer ”serial port”), the RS485

is a multi-drop bus, so multiple clients can be con-

nected to the same wire

The main disadvantage of the RS485 standard is that

it defines only the physical layer of the communi-

cation. The communication protocol must be cho-

sen/developed independently. It is common to use a

custom-developed protocol over the RS485 line. This

is also the case of our prototype. To keep the proto-

type flexible for future extensions, we have decided

to use a ”meta-protocol” encapsulating the commu-

nication data itself. The communication protocol is

based on the master/slave principle, so we have used

the same approach for the data exchange on the line

level. The cooperative master/slave communication

can also be implemented in simple microcontrollers

because it does not need complicated collision detec-

tion like in other shared-media protocols such as the

CSMA/CD used in a coaxial-cable Ethernet standard.

The details of the communication protocol implemen-

tation are outside of the scope of this paper.

4.2 Software

The overall controlling system consists of a central

agent implementing the main scheduling and plan-

ning logic (scheduler) and many autonomous agents

controlling particular household appliances (nodes).

The nodes are autonomous because the scheduler

does not instruct them with precise orders. Instead the

nodes just inform the scheduler about their knowledge

of the situation and future predictions. The sched-

uler then summarizes the knowledge and instructs the

nodes about which actions are viable and which are

not.

In this arrangement, the assumptions about the ca-

pabilities necessary in each network node are kept

as low as possible. In combination with the chosen

physical layer (RS485), a device controller can be

implemented with the cheapest low-power microcon-

trollers. For instance the above-described interactive

appliance needs just the following capabilities:

• one sensor for user interaction

• one actuator for device control

• implementation of a few communication acts (see

Table 1)

• one cheap-chip RS485 line driver

This functionality can be implemented e.g. with At-

mel ATtiny microcontroller (priced about USD 3)

with one RS485 driver chip. Due to the chosen co-

operative master/slave protocol, the line driver can be

only half-duplex, so again very cheap (under USD 1).

In our prototype we have used software implemen-

tation for Arduino prototype boards (Banzi, 2008).

The Arduino board is based on the Atmel microcon-

troller so the developed software can be uploaded to

the above-mentioned Atmel ATtiny with only minor

or no modification.

As we have argued earlier in the paper, the SHS

protocol is very scalable. It is possible to implement

the basic functionality with a small microcontroller,

but at the same time sophisticated behaviour can be

implemented with more-computing-power chips or

computers.

The scheduler is a standard-computer software

implemented in the Erlang programming language,

SmartHousehold-SelectedProblemSolutionsusingIntelligentControllableElectricAppliances

209

which is well suited for this purpose due to its capa-

bilities:

• highly-concurrent programming

• distributed computing and multi-agent systems

with highly autonomous nodes

• it is well tested in the industrial environment

• it is designed for high-availability and fault-

tolerance

• it provides good performance

• it is portable

The scheduler software is used not only to manage

the information in the network and to control the de-

vices operation but also to provide an overview of the

network functionality and immediate state of the re-

sources planning.

The SHS software also implements agents for vir-

tual appliances. This way, we can use the software for

the simulation of the household appliances planning,

or to control real appliances through the physical net-

work and microcontroller-controlled devices. Proba-

bly the most interesting feature is the ability to freely

mix these types of agents to form a semi-virtual, semi-

real network and simulate its behavior with different

scheduling scenarios.

5 CONCLUSIONS

We have identified the main problems that are com-

mon to most of the smart grid consumption control

systems, such as the treatment of the surplus power

from renewable power sources, intelligent allocation

of multiple power sources to consumer appliances or

the reactions to unexpected events in the power net-

work.

Besides the references to standard solutions to

these problems with the description of the respective

drawbacks such as high costs of the requested facili-

ties or high demands on the computing algorithms, we

have presented a new Smart Home Simulation (SHS)

system that is based on priority matching algorithms

and flexible communication infrastructure which can

incorporate large variety of nodes from the simplest

microcontroller-driven appliances up to sophisticated

and intelligent computer-driven systems. We have

shown how the SHS system can be advantageously

used to solve the identified smart grid problems.

Nowadays, SHS has been used for simulation and

post-hoc analysis of real-world systems and basic real

devices control. The future research of SHS is di-

rected to the evaluation of the system in connection

with networks with live intelligent appliances.

ACKNOWLEDGEMENTS

This work has been partly supported by the Czech

Science Foundation under the project 102/09/1842.

REFERENCES

Banzi, M. (2008). Getting Started with Arduino. O’Reilly

Media.

Block, C., Neumann, D., and Weinhardt, C. (2008). A mar-

ket mechanism for energy allocation in micro-chp

grids. In Hawaii International Conference on System

Sciences, pages 172–180, Los Alamitos, CA, USA.

IEEE Computer Society.

Carrasco, J., Franquelo, L., Bialasiewicz, J., Galv

´

an, E.,

Guisado, R., Prats, M., Le

´

on, J., and Moreno-Alfonso,

N. (2006). Power-electronic systems for the grid inte-

gration of renewable energy sources: A survey. Indus-

trial Electronics, IEEE Transactions on, 53(4):1002–

1016.

Electronic Industries Association (1983). Electrical Charac-

teristics of Generators and Receivers for Use in Bal-

anced Multipoint Systems – EIA Standard RS-485.

Ibrahim, H., Ilinca, A., and Perron, J. (2008). En-

ergy storage systems – characteristics and compar-

isons. Renewable and Sustainable Energy Reviews,

12(5):1221–1250.

Murata, M., Namekawa, T., and Hamabe, R. (1983).

A proposal for standardization of home bus system

for home automation. Consumer Electronics, IEEE

Transactions on, CE-29(4):524 –530.

Pr

´

ymek, M. and Hor

´

ak, A. (2012). Priority-based smart

household power control model. In Electrical Power

and Energy Conference 2012, pages 405–411, Lon-

don, Ontario, Canada. IEEE Computer Society.

Roncero, J. (2008). Integration is key to smart grid man-

agement. In SmartGrids for Distribution, 2008. IET-

CIRED. CIRED Seminar, pages 1 –4.

Strassberg, D. (1995). Home-automation buses: Protocols

really hit home. EDN Magazine, 40(8):69–79.

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

210