Three Dimensional Packing Algorithm

with Consideration of Loading and Unloading Order

Naoki Kobatake, Hidenori Ohta and Mario Nakamori

Department of Information and Computer Sciences,

Faculty of Engineering, Tokyo University of Agriculture and Technology, Koganei, Tokyo, Japan

Keywords: 3-Dimensional Packing, Re-Packing, The Order of Loading and Unloading.

Abstract: A novel packing problem for truck or containership transportation is considered. A truck or a ship visits

several accumulation places in a delivery tour, and items are loaded or unloaded at each accumulation place.

In order to carry items as many as possible at one delivery tour, we often have to unpack and repack some

items even at nondestination places if they blockade loading other items. Such packing and repacking,

however, will make the transportation cost increase. Thus, a packing that requirs smaller number of

unpacking and repacking is desired. In this paper, we extend the slicing-tree which is a method of a

representation of packing and propose an algorithm to pack items into the container with minimum the

number of unpacking and re-packing.

1 INTRODUCTION

From the viewpoint of reducing the cost of

transportation by truck or containership, it is desired

to carry as many items as possible at one delivery.

Developing a plan of loading items into a container

is often considered as “the rectangular solid packing

problem,” i.e., to allocate small rectangular solids

without overlapping in a big rectangular empty box,

and there have been published many papers on the

rectangular solid packing problem (S. D. Allen et al.,

2011), (G. Fuellerer et al., 2010), (H. Kawashima et

al., 2010), (F. K. Miyazawa, and Y. Wakabayashi,

2009), and (H. Ohta et al., 2008) .

In practice, we often have to take care about the

order of items loading and unloading when we

develop a loading plan. For example, suppose that a

ship or a truck visits several accumulation places in

a delivery tour, and items are loaded or unloaded at

each accumulation place. In such a case, the loading

and unloading order of items is subject to the order

of visiting the accumulation places, which is

difficult to be changed without changing the delivery

routing. There are, however, few preceding studies

about the packing problem where the order of both

loading and unloading is given.

Moreover, even if we consider only about either

loading or unloading, the packing problem is still

difficult. That is because, if we put each item in the

rear side of the container in the order of loading (or

the inverse order of unloading), all items may not be

put in the container.

Therefore, we should permit to unload

temporarily an item if it blockades other items

loading (unloading), and after the loading

(unloading), to reload the blockading item again into

the container. Hereafter we call such unloading of

blocking items unpacking and such reloading

repacking. Since repacking causes

increase of cost,

we should pack the items in the container so that

fewer items are to be repacked.

In this paper, we discuss the above packing

problem where the order of both loading and

unloading is given. An effective algorithm to put the

items with the minimum number of repacking is

proposed and its performance will be shown by

computational experiments.

2 DEFINITION OF THE

PROBLEM

In this paper, we assume that items are rectangular

solids and the container is also rectangular placed

along x-axis, y-axis and z-axis in three-dimensional

Euclidean space. The direction from left [resp. front,

top] to right [back, bottom] is viewed as the x[y, z]-

116

Kobatake N., Ohta H. and Nakamori M..

Three Dimensional Packing Algorithm with Consideration of Loading and Unloading Order.

DOI: 10.5220/0004277502640269

In Proceedings of the 2nd International Conference on Operations Research and Enterprise Systems (ICORES-2013), pages 264-269

ISBN: 978-989-8565-40-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

direction. The door of the container is located at the

right side. Figure 1 shows an aspect of the container

and directions of loading and unloading of items.

Centers of gravity of the items are out of

consideration in this paper, i.e., any allocations of

the items are permitted unless items overlap with

other items or walls of the container.

Figure 1: Container and direction of loading and unloading.

The loading and the unloading clock time are

already given for each item. In accordance with the

clock times, we obtain a partial order of loading and

unloading. In the process of an item loading

(unloading), other items which have been already

located in the container may blockade the loading

(unloading). In this case, we unload the items, which

we call “blocking items,” from the container. After

loading (unloading) of the item, we re-pack the

blocking items into the original position.

Now, we discuss the locations of the blocking

items when an item is loaded to or unloaded from

the container. When the item a is loaded into the

container, the locations of the blocking items are on

the left of or the upper of the place where the

loading item a is to be located. In this paper, if the

item b satisfies both of the following two conditions,

then b is defined as the blocking item against the

item a loading:

(i) After loading of the item a, the front face of the

item a is located in the front side of the rear face of

the item b, and the rear face of the item a is located

in the rear side of the front face of the item b;

(ii) After loading of the item a, both of the following

two conditions are satisfied:

(ii-1) The right face of the item a locates in left side

of the left face of the item b, and the bottom face of

the item a is lower than upper face of the item b:

(ii-2) The upper face of the item a is lower than the

bottom face of the item b, and the left face of the

item a locates in left side of the right face of the item

b.

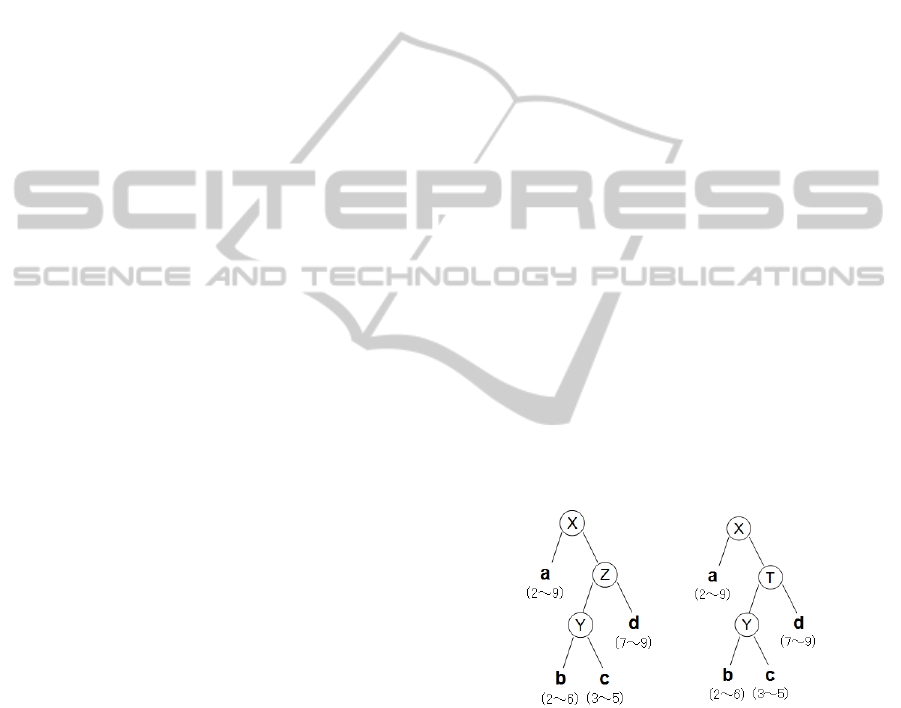

Figure 2 (a) shows that the item d blocks when

the item b is loaded, where the space in which the

item b is to be located is represented by broken lines.

Item d has to be unloaded first and then be repacked

after the loading of the item b. Thus, the number of

repacking is one.

(a)

(b)

Figure 2: Blocking items against loading and unloading.

The blocking item against the item unloading is

also defined similarly. Figure 2 (b) shows that the

item c blocks when the item a is unloaded. Item c

has to be unloaded, but the item d blocks unloading

of the item c. Therefore the item c has to be also

unloaded and then to be repacked after the unloading

of the item a. Thus, the number of repacking is two.

The purpose of this paper is to propose an

algorithm of packing items into a container so that

the number of re-packing is the minimum.

3 THREE-DIMENSIONAL

SLICING-TREE

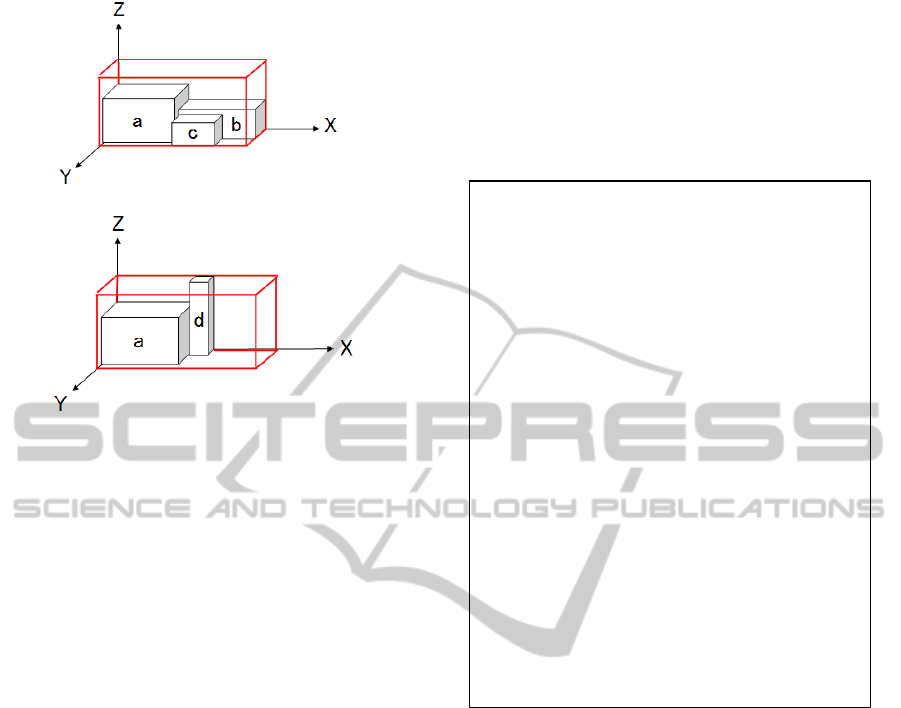

A rectangular solid dissection, which is a dissection

of a rectangular solid region into smaller rectangular

solids (rooms) by places

is often used to represent a

packing. That is,

items are assigned to the distinct

rooms (any two items do not share a single room). In

particular, a structure of a rectangular solid

dissection which is obtained by recursively cutting

by planes

perpendicular to x, y or z-axis is called

three-dimensional slicing-structure. Figure 3(a)

shows a three-dimensional slicing-structure.

(a) (b)

Figure 3: Three-dimensional slicing structure and the

corresponding slicing-tree.

ThreeDimensionalPackingAlgorithmwithConsiderationofLoadingandUnloadingOrder

117

A three-dimensional slicing-structure can be

represented by a binary tree, where internal nodes

and external nodes correspond to planes and rooms

respectively. In particular, the internal nodes are

classified into “X-nodes”, “Y-nodes” and “Z-nodes”.

X-nodes [resp. Y-nodes, Z-nodes] correspond to the

planes

perpendicular to x-axis [y-axis, z-axis] in the

rectangular solid dissection. The left subtree of the

X-node [resp. Y-node, Z-node] corresponds to the

leftward [frontward, upward] region of the

corresponding plane, and the right subtree of the X-

node [resp. Y-node, Z-node] corresponds to the

rightward [backward, downward] region of the

corresponding plane. The slicing tree does not allow

the representation of all packings, However the near

optimal packing can be modeled. Figure 3(b) shows

the slicing-tree which is the representation of the

slicing-structure shown in figure 3(a).

It is obvious that a region which corresponds to

an external node must be larger than the item. In

addition, the shape of each region which

corresponds to a subtree is a rectangular solid. Now

we express the size of rectangular solid A as

(

A

X

A

Y

A

Z

), where

A

X

[resp.

A

Y

,

A

Z

] is the

x[y, z]-length of the rectangular solid A. Assume the

size of the rectangular solid which corresponds to

the left subtree of a X-node P is (

L

X

L

Y

L

Z

),

the size of the rectangular solid which corresponds

to the right subtree of P is (

R

X

R

Y

R

Z ) and

the size of the rectangular solid which corresponds

to the subtree which is merged the trees and whose

root is P is (

P

X

P

Y

P

Z ) respectively. Then we

have the following inequalities.

RLP

XXX

,

),max(

RLP

YYY ,

),max(

RLP

ZZZ

In the case where P is Y-node or Z-node, similar

inequalities are also satisfied. The properties mean

that we can decode the slicing-tree into the

corresponding packing by the post order traverse of

the tree in O(n) time, where n is the number of items

(L. Cheng et al., 2004).

If the size of the rectangular solid which

corresponds to the entire slicing-tree is smaller than

the size of the container, every item can be located

into the container and the packing is feasible.

4 PROPOSED ALGORITHM

We extend the three-dimensional slicing-tree to

represent placement, loading and unloading of the

items. Using the extended representation, we search

for a packing that minimizes the number of re-

packing with simulated annealing. The search of

item placement consists of two phases. In Phase 1,

every item are put into the container. In Phase 2, the

number of re-packing is minimized.

4.1 Extension of Slicing-Tree

For any two items, if one is unloaded earlier than the

loading of the other, they never overlap with each

other. So these two items can be located into the

same place in the container. To represent the above

placement of two items, we introduce "T nodes" as

internal nodes of the slicing-tree. The meaning is

that any two items, which correspond to the external

nodes on the left and right subtree of the T-node

respectively, do not exist in a container at the same

time. Figure 4(a) shows an original three-

dimensional slicing-tree, and Figure 4(b) shows a

proposed slicing-tree which is obtained by

introducing T node into the slicing-tree shown in

Figure 4(a). Note that the clock time of loading and

unloading are set and each external node stores the

times. Figure 5 (a) and (b) show the placement of

items which is represented by the slice tree shown in

Figure 4(b).

(a) (b)

Figure 4: Introduction of T node to slicing-tree.

We can check whether any X(Y, Z) node in the

original slicing-tree can be changed to T-node by

comparing "clock times of loading of items in the

right subtree" and "clock times of unloading of items

in the left subtree". Therefore, we obtain the

extended slicing-tree by the original slicing-tree in

O(n) time.

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

118

(a) Placement of items when time clock is 4

(b) Placement of items when time clock is 8

Figure 5: Placement of items corresponding to slicing-tree

shown in Figure 4 (b).

If the size of the rectangular solid which

corresponds to the left subtree of a T-node P is

(

L

X

L

Y

L

Z

), the size of the rectangular solid

which corresponds to the right subtree of P is

(

R

X

R

Y

R

Z

), and the size of rectangular solid

which corresponds to the subtree whose root is P is

(

P

X

P

Y

P

Z

) respectively, then the following

inequalities are satisfied.

),max(

RLP

XXX ,

),max(

RLP

YYY

,

),max(

RLP

ZZZ .

4.1.1 Counting the Number of Re-Packings

Using an extended slicing-tree, we can count the

number of re-packing of the placement of items. For

any pair of items a and b, the following necessary

conditio

ns are satisfied if b will block to a loading:

(i) The type of a least common ancestor of a and b is

X-node or Z-node;

(ii) a is contained in the left subtree of the least

common ancestor ;

(iii) When a is loaded into the container, b is located

in the container.

We can count the number of re-packing by using

above conditions in O(n

2

) time. However, since the

conditions are not a sufficient condition, we may

overestimate, if we count only by using the

conditions. Such overestimate can be detected by

considering the positional relation between a and b.

Thus, we present an algorithm to count the number

of re-packing by the proposed slicing-tree. The

running time of the algorithm is O(n

2

t), where t is

the number of clocking time when items are loaded

or unloaded.

4.2 Phase 1

In Phase 1, we don’t evaluate the number of re-

packings but evaluate the size of a rectangular solid

corresponding to the entire extended slice-tree to see

whether all items can be located into the container or

not.

An objective function of simulated annealing

search is the x-length of a rectangular solid

corresponding to the extended slice-tree. In addition,

if the y-length or z-length is larger than that of the

container, a penalty proportional to the surplus is

added to the cost function.

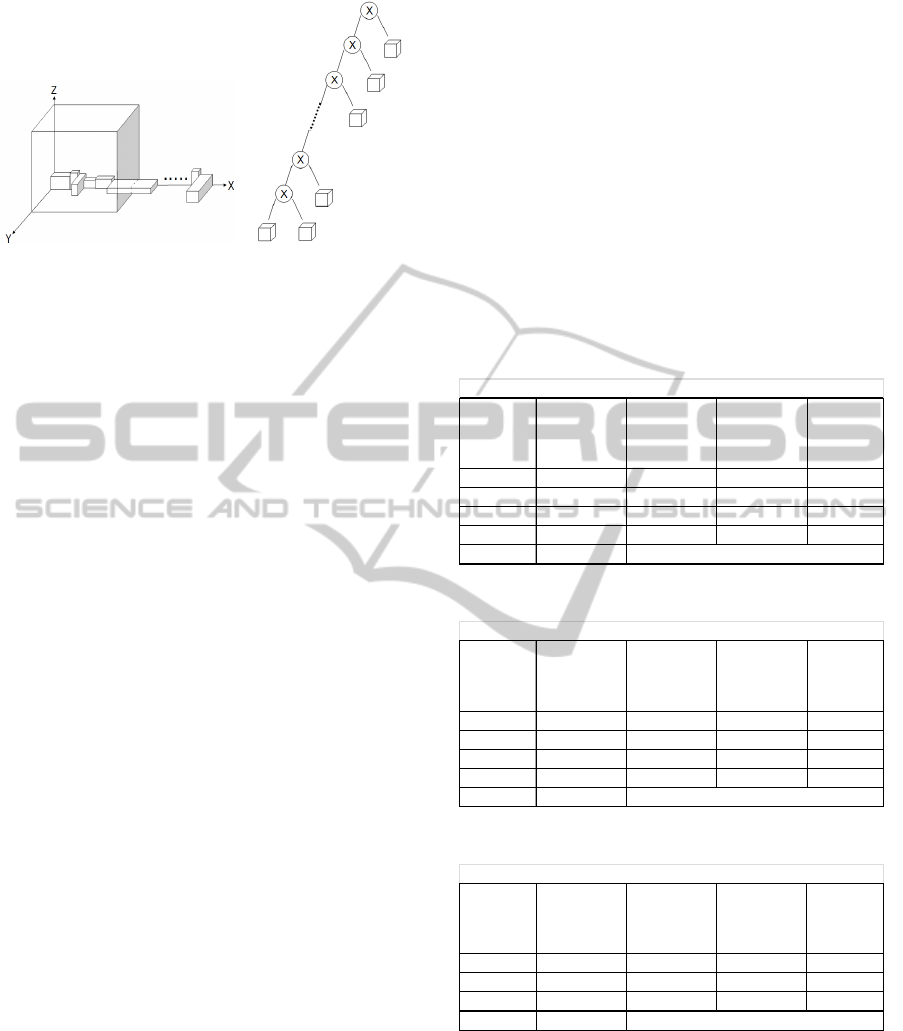

We search by using the original slicing-tree (The

tree does not include the T-node), and obtain the

extended slicing-tree for the evaluation. The initial

solution is that the items are laid out on the line.

Figure 6 (a) shows the placement of items in the

initial solution, Figure 6 (b) shows the

corresponding slicing-tree.

I

nput: extended slicing-tree

Output: N_r (the number of re-packing

for items loading)

Count_repacking (extended slicing-tree)

{

N_r = 0;

for(each clock time

t

){

for(each node n in post-order traverse of the

extended slicing-tree){

calculate num_of_blocked(

n,t

);

}

N_r = N_r + num_of_blocked(root of the extended

slicing-tree

,t

);

}

return N_r;

}

num_of_blocked(node

n,

clock time

t

)

{

if (node n is an external node){

check the positional relation between n and each item

if (when the clock time is

t

, there exists at least

one item whose loading is blocked by

n

) return 1;

else return 0;

}

else

return( num_of_blocked(left child of

n

,

t

)

+ num_of_blocked(right child of

n

,

t

)) ;

}

ThreeDimensionalPackingAlgorithmwithConsiderationofLoadingandUnloadingOrder

119

(a) (b)

Figure 6: Initial placement of items and corresponding

slicing-tree.

The neighbourhood solution is obtained by one

of the following four operations:

(a)Rotation of the item: One item is chosen at

random, and the direction of the item is changed;

(b)Exchange of subtrees: Two subtrees are chosen at

random, and exchanged with each other, if the sub-

trees do not contain each other;

(c)Exchange of items: Two external nodes are

chosen at random and are exchanged with each

other;

(d)Transposition of placement: an internal node is

chosen at random and its type (X-node, Y-node or

Z-node) is changed.

4.3 Phase 2

In Phase 2, we evaluate the number of re-packings

and minimize it. During the search, if a

neighbourhood solution is infeasible, the solution is

rejected and new neighbourhood solution is created.

The initial solution of the search is the result of

searching in Phase 1. The neighbourhood solution is

obtained by using the above four operations.

5 COMPUTER EXPERIMENTS

We carried out an experiment on a computer to

evaluate the performance of the proposed method.

The computer environment is an Intel Core i7-200

3.40 GHz CPU with 2 GB of memory. The

programming language used is C.

The instances for the experiment were made at

random. The number of items is 20, 30 or 50. The

length of each side of the items is 10 through 30.

The loading clock time and unloading clock time of

each item are 1 through 10. Several sets of

containers of different size are made. The ratio of

length along x, y, and z axis of a container is 5:2:3,

which reflects the side ratio of real trucks.

The results of the experiments are shown in table

1, 2 and 3. These results show that we obtain small

number of re-packings except in one instance.

Time_Phase1 is the average of the time until all

items be located into the container. We almost

obtained feasible solutions in a practical time. But

the increase of the packing ratio or the number of

items makes it difficult to gain the feasible solutions,

and we failed loading in some instances. To solve

them, we need more flexible re-packing.

Time_Phase2 is the average of the time until the

convergence of the search.

Table 1: Experiment results (20 items).

total

packing

ratio(%)

maximum

packing

ratio(%)

time_Phase1

(sec.)

time_Phase2

(sec.)

number of

re-

packings

64.80 34.15 0 2310 0

87.50 46.10 1 1167 2

122.16 64.37 1 1167 2

146.52 77.21 1546 113 21

177.82 93.70

20 items

loading failure

Table 2: Experiment results (30 items).

total

packing

ratio(%)

maximum

packing

ratio(%)

time_Phase1

(sec.)

time_Phase2

(sec.)

number of

re-

packings

79.46 43.31 2 23542 0

91.99 50.13 2 24161 3

107.29 58.47 3 23877 4

126.18 68.77 134 48683 10

149.79 81.63

30 items

loading failure

Table 3: Experiment results (50 items).

total

packing

ratio(%)

maximum

packing

ratio(%)

time_Phase1

(sec.)

time_Phase2

(sec.)

number of

re-

packings

86.89 44.26 53 11318 4

100.91 51.40 48 58699 4

118.17 60.19 491 550445 4

150.14 76.48

50 items

loading failure

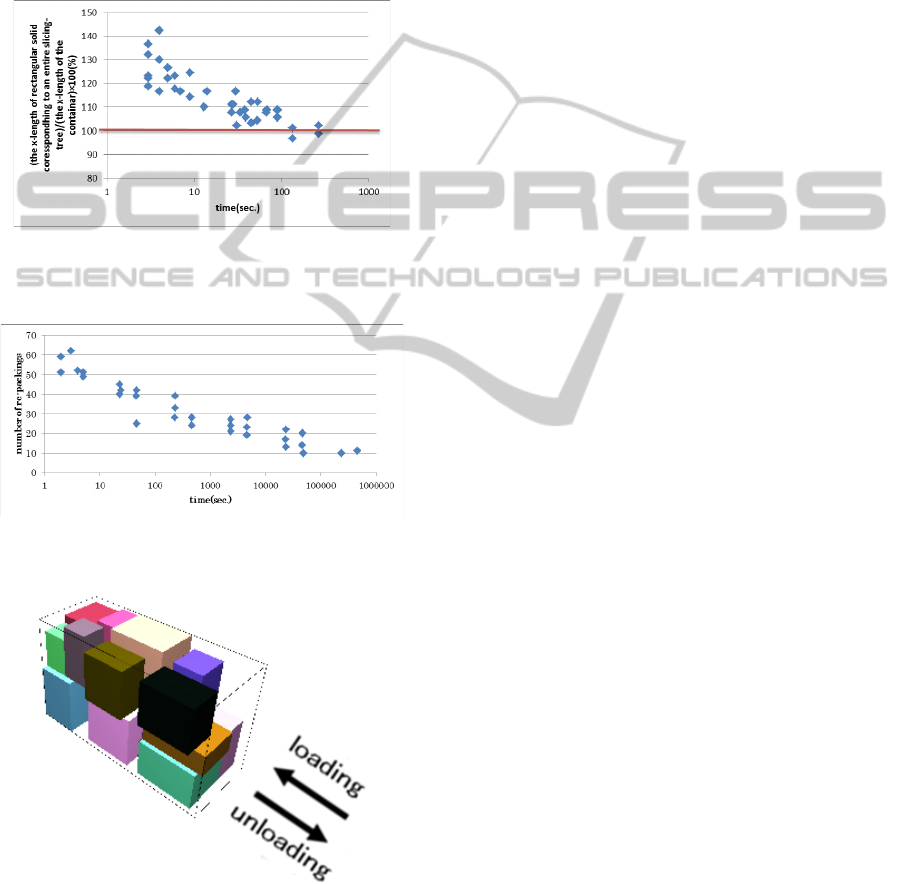

In particular, we will show the detail of the result

of one of our instances. The instance has 30 items

whose length of each side is 10 through 30. The size

of the container is (90

36

54). The maximum

packing ratio is 68.77%, and the ratio of the sum of

volume of all items to the volume of the container

(total packing ratio) is 126.18%.

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

120

Figure 7 shows the result in the Phase 1, that is

the relation between the length of the rectangular

solid corresponding to the extended slicing-tree and

the searching time.

Figure 8 shows the relation between the number

of re-packings and the searching time.

Figure 9 shows the result of placement of items

when the packing ration is the maximum (68.77%).

The number of repacking of the placement is 10.

Figure 7: Relation between the length of the rectangular

solid corresponding to the extended slicing-tree and the

searching time.

Figure 8: Relation between the number of re-packing and

the searching time.

Figure 9: Placement of items when the packing ratio is the

maximum.

6 CONCLUSIONS

In this paper, we described a novel packing problem

which is the order of loading and unloading of items

is given and proposed an algorithm that minimizes

the number of repacking. Further works are as

follows:

(i) More flexible re-packing: when an item is

repacked, we would like to allow that the item is put

on arbitrary position in the container, i.e., the

position different from the position which the item

was unloaded from;

(ii) Application to a more practical case: we should

consider about a center of gravity of the items and

packaging materials.

REFERENCES

S. D. Allen et al., 2011. A hybrid placement strategy for

the three-dimensional strip packing problem, European

Journal of Operational Research, Vol. 209, pp.219-227.

L. Cheng et al., 2004, Floorplan Design for 3-D ICs, Proc.

SASIMI, pp.395-401.

G. Fuellerer et al., 2010. Metaheuristics for vehicle routing

problems with three-dimensional loading constraints,

European Journal of Operational Research, Vol. 201,

pp.751-759.

H. Kawashima et al., 2010, An efficient implementation of

a constructive algorithm for the three-dimensional

packing problem, Forum of Information Technology

2010 (FIT2010) Vol. 1,pp.31-38.

F. K. Miyazawa, and Y. Wakabayashi, 2009, "Three-

dimensional packings with rotations," Computers &

Operations Research, Vol. 36, pp.2801-2815.

H. Ohta et al., 2008. The O-Sequence: Representation of

3D-Dissection, IEICE Transactions on Fundamentals

of Electronics, Communications and Computer

Sciences, Vol. E91-A, pp.2111-2119.

ThreeDimensionalPackingAlgorithmwithConsiderationofLoadingandUnloadingOrder

121