Non-rigid Surface Tracking for Virtual Fitting System

Naoki Shimizu, Takumi Yoshida, Tomoki Hayashi, Francois de Sorbier and Hideo Saito

Graduate School of Science and Technology, Keio University, 3-14-1 Hiyoshi, Kohoku-ku, Yokohama, Japan

Keywords:

Deformable 3D Registration, Principal Component Analysis, RGB-D Camera, Augmented Reality, Local

Feature Point.

Abstract:

In this paper, we describe a method for overlaying a texture onto a T-shirt, for improving current virtual fitting

system. In such systems, users can try on clothes virtually. In order to realize such a system, a depth camera

has been used. These depth cameras can capture 3D data in real time and have been used by some industrial

virtual cloth fitting systems. However, these systems roughly, or just do not, consider the shape of the clothes

that user is wearing. So the appearance of these virtual fitting systems looks unnaturally. For a better fitting,

we need to estimate 3D shape of cloth surface, and overlay a texture of the cloth that the user wants to see

onto the surface. There are some methods that register a 3D deformable mesh onto captured depth data of a

target surface. Although those registration methods are very accurate, most of them require large amount of

processing time or either manually-set markers or special rectangles. The main contribution of our method is

to overlay a texture onto a texture of T-shirt in real-time without modifying the surface.

1 INTRODUCTION

Recent progress in computer vision significantly ex-

tended the possibilities of augmented reality, a field

that is quickly gaining popularity. Consequently, aug-

mented reality has been applied to many domains like

entertainment and navigation.

For clothes retail industry, examples of virtual

clothes fitting system, which enables the users to try

the clothes on virtually, have been presented. It can

be applied to tele-shopping systems over the inter-

net, garment designing, and etc. Recently, commodity

RGB-D camera with reasonable price became popu-

lar, and practical virtual fitting systems have been re-

leased. However, these systems roughly, or just do

not, consider the shape of the clothes that user is wear-

ing. So the displayed result of these virtual fitting sys-

tems looks unnatural. For a better result, estimation of

the shape of cloth surface is required.

We are developing a real-time method for over-

laying a texture on a cloth. In our system, a RGB-D

camera captures a moving person in front of a display

that shows the mirrored input image. Camera and dis-

play are mounted such that the user has the impres-

sion of looking into a mirror showing the upper part

of user’s body. A part of the cloth is replaced with a

virtual texture, resulting in the user shown to be wear-

ing the virtual cloth in the mirror. For that purpose we

developed a dynamic texturing method for non-rigid

surface like a T-shirt that registers deformed mesh fit

to a surface from RGB and Depth images captured by

the camera and renders in real-time a virtual texture

onto the moving surface with correct deformation.

Non-rigid surface tracking from a RGB-D camera

encounters the problem of surface region detection.

In previous methods related to virtual fitting system,

special colored shirt or markers were used. For pre-

vailing virtual fitting system, we need to detect sur-

face region from common T-shirt that the user is wear-

ing. For this, we use the texture on the T-shirt to de-

fine the target region. However, in most cases, this

texture have less feature points, and obviously, are

deformed. Most algorithms for feature correspond-

ing points and removing outliers like SIFT (Lowe,

1999) or RANSAC (Chum et al., 2003) are only avail-

able for planar surfaces. Therefore, in such situation,

the non-rigid surface region should be detected and

tracked by using relatively few feature points, and

these feature points should be correctly detected from

deformed texture. We propose a method based on fea-

ture corresponding points on the shirt that can handle

these problems.

We improve the method proposed by Hayashi et

al. (Hayashi et al., 2012), which can handle non-rigid

surface tracking from a few corresponding points.

They used manually attached color makers on T-shirt

12

Shimizu N., Yoshida T., Hayashi T., Sorbier F. and Saito H..

Non-rigid Surface Tracking for Virtual Fitting System.

DOI: 10.5220/0004303000120018

In Proceedings of the International Conference on Computer Vision Theory and Applications (VISAPP-2013), pages 12-18

ISBN: 978-989-8565-48-8

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

to detect the target tracking region. We present a

method that can find correct corresponding points

even if the target texture is not on planar surface. By

using this method, we can remove color makers from

the T-shirt. Furthermore, we improvedpoint sampling

method, which allowed us to obtain more accurate

point cloud from captured 3D data.

One important characteristic of our method is that

we achieve accurate non-rigid surface deformation in

real-time with simple hardware and equipment. This

was achieved by only using inexpensive devices: reg-

ular PC, commodity RGB-D camera, and a display. In

addition, the users are not required to wear specially

prepared T-shirt, such as the ones that are specially

colored or have markers attached.

Generally, depth components captured by com-

modity RGB-D camera contain noises. Therefore,

we couldn’t get accurate deformed mesh by using 3D

reconstruction from these noisy data. Our method

is based on learning representative deformation of

meshes, deformed mesh is registered to the target sur-

face. The shape of registered mesh is accurate and

noise-free.

The rest of this paper is structured as follows. Sec-

tion 2 briefly describes the related works in non-rigid

surface tracking, and states the contribution of this

paper. Section 3 describes our system. Section 4

explains the detection of the region on non-rigid ob-

ject. Section 5 describes the tracking and overlaying

texture approach for non-rigid surface in RGB-D se-

quence. Finally, Section 6 presents experimental re-

sults.

2 RELATED WORKS AND

CONTRIBUTION

Non-rigid surface tracking and texturing have re-

cently been addressed by a number of researchers.

Most of them are applying a two or three dimensional

deformable model reconstructed from RGB camera.

There are some researches approaching practical

virtual fitting system. For example, Hilsmann and

Eisert proposed a real-time system that tracks clothes

and overlays a texture on them by estimating the elas-

tic deformations of the clothes from a single camera

in the 2D image plane (Hilsmann and Eisert, 2009).

The problem of self-occlusion is addressed by using a

2D motion model regularizing an optical flow field. It

works correctly in real-time, but under an assumption

that the motion is small enough, and that the T-shirt is

specially colored and textured.

In order to handle larger and sharp deformation,

many researches about 3D deformable model recon-

struction have been done. Pilet et al. have pre-

sented a feature-based fast method which detects and

tracks deformable objects in monocular image se-

quences (Pilet et al., 2007). They applied a wide base-

line matching algorithm for finding correspondences.

Shen et al. recovered the 3D shape of an inextensi-

ble deformable surface from a monocular image se-

quence (Shen et al., 2010). Their iterative L

2

-norm

approximation process computes the non-convex ob-

jective function in the optimization. The noise is re-

duced by applying a L

2

-norm on re-projection errors.

All these 3D reconstruction methods yield impres-

sive results. However, they need sophisticated acqui-

sitions setups or have a high computational cost. We

strive for a different goal, i.e. to estimate non-rigid

surface of common T-shirt in real-time with normal

hardware. For that purpose we are interested in gen-

eration of a deformation mode space from the PCA

(Principal Component Analysis) of sample triangular

meshes (Salzmann et al., 2007). Reducing DOF (De-

gree of Freedom) by PCA achieved real-time 3D de-

formable model reconstruction. The non-rigid shape

is then expressed by the combination of each defor-

mation mode. This step does not need an estimation

of an initial shape or a tracking. Later, they proposed

a linear local model for a monocular reconstruction

of a deformable surface (Salzmann and Fua, 2011).

This method reconstructs an arbitrary deformed shape

as long as the homogeneous surface has been learned

previously. However, these approaches require a lot

of corresponding points between a template image

and an input image. Therefore, users have to wear

texture-rich T-shirt.

Hayashi et al. improved the method proposed

by Salzmann (Hayashi et al., 2012). By using 3D

data captured by a RGB-D camera, even though input

depth data is noisy, this learning-based method can

generate a natural and smooth mesh. And, because

the 3D data is directly captured, texture-rich surface

is not required. Furthermore, this method achieves a

real-time process by taking the advantage of PCA, a

simple method of reducing the dimensionality of the

data, which in this case is the meshes. Unfortunately,

in this method, users are required to set color markers

on their T-shirt for detecting target region.

In our research, we improved non-rigid surface

tracking method based on Hayashi’s method. The

main contribution of this paper lies in a real-time

tracking and texture overlaying method for non-rigid

surfaces on common T-shirt. Common T-shirt means

a T-shirt without rich texture or markers. The dif-

ficulty is to detect sufficiently accurate correspond-

ing points from texture on the shirt. We present

a method which can detect accurate corresponding

Non-rigidSurfaceTrackingforVirtualFittingSystem

13

(a) template image (b) input RGB image

Figure 1: Example of template and input image.

points even if the T-shirt is largely deformed. Along

with Hayashi’s method, our method can generate a

mesh that fits to target surface from at least 7 corre-

sponding points. Additionally, we also used a sophis-

ticated point sampling method. By using this sapling

method, even if the positional relationships of de-

tected corresponding points are not uniform, we can

get applicable point cloud from input image. As a re-

sult, the virtual texture is deformed in real-time and

overlaid onto the user’s T-shirt.

3 OVERVIEW

Our method can work in real-time with a regular PC,

and a RGB-D camera (Microsoft Kinect). The user

does not need to wear a T-shirt with specific color or

markers. However, a certain level of texture on the

T-shirt is required.

Before using virtual fitting system, we capture a

texture on user’s T-shirt without deformation. We call

it the ”template image”. After that, input RGB and

Depth images are captured in every frame. Example

of template and input image is shown in Figure 1.

In every frame, we need to detect accurate corre-

sponding points between input and template image.

However, as shown in Figure 1(b), texture on worn

T-shirt is deformed. So if we use matching algo-

rithm based on local features like SIFT (Lowe, 1999),

SURF (Bay et al., 2006), many miss-correspondences

will occur. For obtaining stable corresponding points,

we present local feature detection algorithm suited

for deformed texture. Details of this method are de-

scribed in Section 4.

After detecting corresponding points, we could

recognize target non-rigid surface on T-shirt. By us-

ing positional relationships of corresponding points,

3D point cloud is sampled from target region. Sam-

pled point cloud are used by non-rigid surface track-

ing method shown in Section 5. After that, we can get

3D mesh that fits to estimated surface shape. Lastly,

by overlaying texture onto this mesh, a virtual texture

on the T-shirt is displayed.

4 KEY POINT DETECTION

FROM DEFORMED TEXTURE

In this section, we describe a method which can de-

tect corresponding points between input and template

image, even if input texture is deformed. Conven-

tional local features such as SIFT, SURF, etc., have

scale and rotation invariance but often fail to match

points when the camera pose significantly changes.

In other words, even if camera is stationary, defor-

mation of the texture is assumed to be changes of

comparative camera position. Because it also leads to

miss-corresponding points. To remove such outliers,

RANSAC based algorithms are widely used (Chum

et al., 2003). However, the transformation between

template and input image is nonlinear, so RANSAC

based algorithms do not work well. So we present an

accurate corresponding points detection method from

deformed input image.

Some local features have scale and rotation in-

variance resulting from their feature descriptors. Our

approach is to collect these invariant features on the

generated patterns as seen from different viewpoints.

Viewpoint generative learning enables us to train with

various data without actually collecting them. As

long as we use a local feature to detect or recog-

nize a target, only one template image is needed to

learn. Therefore, for offline learning, we generate

various patterns, extract stable key points from them

and create a database of collected features. After

learning, the template image and an input image can

be matched by comparing them using the database.

The basic idea and detail of this key point detection

method is shown in (Yoshida et al., 2013). It is focus-

ing on planar pattern tracking for generic AR applica-

tion.

Figure 2: Viewpoint generation model.

4.1 Generation of Various Patterns

First, we generate variouspatterns as seen from differ-

ent viewpoints that are computed from one template

image of the target. We apply perspective transfor-

mation. The viewpoint model is shown below in Fig-

ure 2. The rotation ranges are set as follows camera

longitude φ ∈ [−75

◦

, 75

◦

], latitude θ ∈ [−75

◦

, 75

◦

].

VISAPP2013-InternationalConferenceonComputerVisionTheoryandApplications

14

In our method we use rotation invariant features, so

that the camera spin ψ becomes constant. To calcu-

late perspective transformation matrix P, we obtain

an intrinsic camera parameter matrix A and an extrin-

sic parameter, the distance d to a target plane. More-

over, due to scale invariant features, the distance is

fixed. Therefore, we have A, R and translation matrix

t = (0, 0, d)

T

for P = A(R|t).

template image deformed image

Figure 3: Template & deformed input images.

4.2 Key Point Detection and Matching

On each generated pattern, we detect key points by

using SIFT (Lowe, 1999). To increase repeatability,

we select the stable key points that have high de-

tectability, defined as how often the same key point

is detected in different pose patterns, at stable loca-

tions. By using these key points generated from var-

ious viewpoint, we can get accurate corresponding

points between template image and deformed texture

in input image.

To confirm effectivity of our approach, we de-

tect corresponding points between 4 deformed tex-

tures and template images shown in Figure 3. Table 1

shows our method can detect accurate corresponding

points even if the target texture is deformed.

Table 1: Accuracy of corresponding points.

Template Method Correct Incorrect Accuracy

Upper SIFT 74 20 79%

Upper Proposed 22 4 85%

Lower SIFT 145 20 89%

Lower Proposed 29 2 94%

5 TEXTURE OVERLAY ONTO

NON-RIGID SURFACE

In this section, we describe our method to overlay

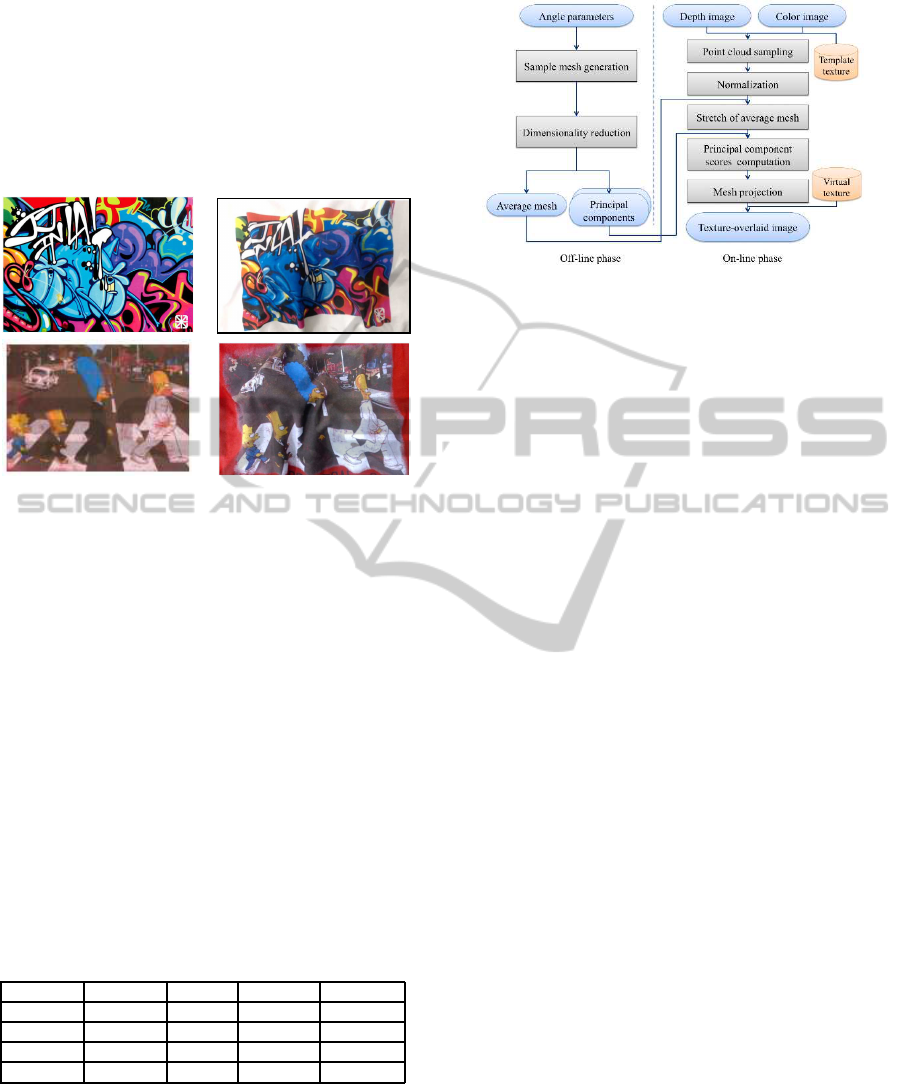

a texture onto a non-rigid surface. Figure 4 illus-

Figure 4: Flow of our method.

trates the flow of our method. Our method is based

on Hayashi’s method (Hayashi et al., 2012). First, in

the off-line phase, we generate deformation models

by learning many representative meshes. Because the

dimensionality of the mesh in the model is low, we

can quickly generate an arbitrarily deformable mesh

to fit the target surface in the on-line phase. In addi-

tion, this is learning-based approach, so even though

the input data is noisy, we can generate a natural mesh

that has a smooth shape.

Hayashi’s method used color markers to detect tar-

get surface region. On the other hand, our method

makes it possible to remove such markers because

the accurate correspondences from deformed texture

are detected by using the method described in Sec-

tion 4. We also proposed sophisticated point sam-

pling method in Section 5.2.1. By using this sam-

pling method, even if the positional relationships of

detected corresponding points are not uniform, we

can get suitable point cloud from input sequence.

5.1 Surface Deformation Models

Generation

In the off-line phase, we generate the deforma-

tion models by learning several representative sam-

ple meshes. This part is based on Salzmann’s

method (Salzmann et al., 2007).

In our approach, the target surface and the tem-

plate texture are rectangular. We introduce a rectan-

gular surface sample mesh made of m = M × N ver-

tices V = {v

1

, ..., v

m

} ⊂ R

3

.

By using PCA based dimensionality reduction de-

scribed in (Salzmann et al., 2007), we can get the

average mesh

¯

V = {y

1

, ..., y

m

} ⊂ R

3

and N

c

princi-

pal component vector P

k

= {p

k1

, ..., p

km

} ⊂ R

3

which

represents some deformation modes. Then an arbi-

trary mesh can be expressed as follows:

V =

¯

V+

N

c

∑

k=1

ω

k

P

k

(1)

Non-rigidSurfaceTrackingforVirtualFittingSystem

15

where V is the vertices of the target surface mesh that

we want to generate, ω

k

denotes k

th

principal compo-

nent score or weights, and P

k

denotes the correspond-

ing principal components or deformation modes. N

c

is the number of the principal components, which is

determined by looking at the contribution rate of the

PCA. Once principal component score vector Θ =

{ω

1

, ..., ω

N

c

} is known, the surface mesh can be easily

reconstructed using Eq. 1.

5.2 Mesh Registration

For overlaying virtual texture onto target surface T ,

we need to estimate the optimal principal component

score vector Θ. The principal component score ω

k

is

described as:

ω

k

= (V−

¯

V) · P

k

(2)

¯

V, P

k

and V were defined in Eq. 1.

5.2.1 Point Cloud Sampling

V in Eq. 2 is unknown. Thus, the input point cloud of

the target surface T is used as a candidate to replace

V. By sampling the input point cloud from T , we can

get V

T

, which is approximation of V.

Therefore, we sample the point cloud of T to

match its dimensionality to the dimensionality of V.

The sampling is done on the input depth image by

using corresponding points detected with the method

described in Section 4.

Hayashi et al. used linear interpolation for sam-

pling point cloud. It works well only if the corre-

sponding points are located close from the target re-

gion’s edges. However, in our method, position of

detected corresponding points are not ordered in such

ways. Because we present a point sampling method

based on non-linear transformation.

At first, non-linear transformation matrix is calcu-

lated as presented in Eq. 3 and 4.

x

2

y

2

1

= H

x

3

1

y

3

1

x

1

y

1

1

(3)

H =

H

11

H

12

H

13

H

14

H

15

H

21

H

22

H

23

H

24

H

25

H

31

H

32

H

33

H

34

H

35

(4)

x

1

, y

1

denote coordinates of key points in template

image, x

2

, y

2

denote coordinates of corresponding

points in input image. If there are at least 7 corre-

sponding points, we can calculate H. For accurate

calculation of H, these corresponding points should

Figure 5: Corresponding points and sampled points. Green

points on the surface denote corresponding points. Yellow

points are the sampled points.

be spread throughout the target region. By using cal-

culated H, each vertices on

¯

V can be transformed to

T . These transformed points are used as target sam-

pling point mesh V

T

. Figure 5 shows corresponding

points and sampled points. Even if the corresponding

points are situated discretely, our method can obtain

sampled points on the target surface point cloud T .

5.2.2 Normalization and Stretching Mesh

Once we get mesh V

T

from the sampled point cloud

obtained in Section 5.2.1, we need to transform it to

the same coordinate system of

¯

V and P

k

. We used the

same rigid transformation matrix M as described in

Hayashi’s paper (Hayashi et al., 2012). M transforms

data in world coordinate system V

T

to normalized co-

ordinate system which is the same as

¯

V and P

k

.

By using M transformation, V

T

is transformed to

normalized mesh V

′

. We can use V

′

as approximation

of V.

At last,

¯

V is stretched so that coordinates of

¯

V

and V

′

become similar to each other. In other word,

each vertices of

¯

V are transformed based on coordi-

nate points. After that, by using these two meshes,

we can calculate each principal component score ω

k

from Eq. 1.

5.2.3 Principal Component Scores Computation

Thus, we can adapt Eq. 1 and Eq. 2 to:

ω

k

= (V

′

−

¯

V

′

) · P

k

. (5)

V =

¯

V

′

+

N

c

∑

k=1

ω

k

P

k

. (6)

This means that each ω

k

that is calculated in the Eq. 5

is compatible to

¯

V

′

. Then we get the mesh V corre-

sponding to T .

VISAPP2013-InternationalConferenceonComputerVisionTheoryandApplications

16

generated mesh comparison with input depth data

Figure 6: Generated mesh and its comparison with depth data from RGB-D camera. The yellow line of left images denotes

the vertices which we used for comparison.

5.2.4 Mesh Projection

The last stage is to transform it to the world coordinate

system. Because we already know transformation M

from the world coordinate system to the normalized

coordinate system, we can transform V by using M

−1

.

For the rendering, we define the texture coordi-

nates for each vertex of a surface mesh. Therefore,

the virtual texture is overlaid on the target surface ob-

tained by M

−1

V.

6 EXPERIMENTAL RESULTS

In this section, we make experiments to confirm the

effectiveness of our method. All the experiments have

been done on a system equipped with a Intel Core

i7-3930K 3.20GHz CPU, NVIDIA GeForece GTX

580 GPU, and 16.0 GB RAM. We use the RGB-D

camera Microsoft Kinect with an image resolution of

640 × 480 pixels and a frame rate of 30 fps. This

RGB-D camera can capture depth component directly

by using infrared in real-time. The target surface is a

region of a T-shirt with texture. For the resolution of

the rectangular mesh, we set both M and N to 21 ver-

tices.

We evaluated generated meshes by comparing

depth (z) value between generated mesh and captured

from RGB-D camera. The results are shown in Fig-

ure 6.Yellow lines on generated mesh denote 20 ver-

tices which we sampled for this evaluation. As Fig-

ure 6 shows, the registered mesh is deformed follow-

ing input depth data. In spite of noisy depth data, our

method can generate similar and smooth mesh.

We calculated the processing time because our

method is supposed to be used for a real-time vir-

tual fitting application. The result of the average pro-

cessing time for 100 frames is shown in Table 2. As

a whole, the average processing speed was over 20

frames per second.

Table 2: Processing time.

Task Time(msec)

Capturing 11

Key Point Detection 22

Mesh Registration 7

Image Rendering 4

Finally, Figure 7 shows visualization results of the

texture overlay onto the non-rigid target surface of 2

kinds of T-shirt. Users can move freely in front of

the camera and perform elastic deformations with the

cloth, including stretching and bending it. Rotation is

possible as long as the texture on the shirt stays visi-

ble. Left two columns of Figure 7 demonstrate results

using T-shirt with rich texture. Right two columns

show results with relatively sparse texture. Even if

the T-shirt does not have special color or markers, our

method can deform mesh to fit the surface according

to the data obtained by RGB-D camera.

7 CONCLUSIONS AND FUTURE

WORKS

In this paper, we presented a non-rigid surface track-

ing methodthat registers 3D deformable mesh for tex-

ture overlay. Our method has several advantages

over the aforementioned previous works. Firstly, our

method does not require makers or special color on

the target surface. Additionally, registering a de-

formed mesh is possible with as few as 7 correspon-

dences. This means that our method is available for

Non-rigidSurfaceTrackingforVirtualFittingSystem

17

Figure 7: Texture overlaying result. Upper images are input RGB images. Lower images are output images.

relatively poor texture. Secondly, by using low di-

mension deformable model from PCA, our method

obtains a real-time processing.

As a future work, we will improve the method

to detect key points from template and input image.

The accuracy of registered mesh depends on the po-

sitions of key points. If most of the key points are

concentrated to a particular region, then the accuracy

of the generated mesh becomes lower when it is far

from those regions. Therefore we need to improve

the key point detection methodto make detecting the

key points from wider region possible.

In addition, we will take the light source informa-

tion into consideration in texturing part for more nat-

ural visualization.

REFERENCES

Bay, H., Tuytelaars, T., and Van Gool, L. (2006). Surf:

Speeded up robust features. Computer Vision–ECCV

2006, pages 404–417.

Chum, O., Matas, J., and Kittler, J. (2003). Locally opti-

mized ransac. Pattern Recognition, pages 236–243.

Hayashi, T., de Sorbier, F., and Saito, H. (2012). Texture

overlay onto non-rigid surface using commodity depth

camera. In VISAPP.

Hilsmann, A. and Eisert, P. (2009). Tracking and retex-

turing cloth for real-time virtual clothing applications.

In Proceedings of the 4th International Conference

on Computer Vision/Computer Graphics Collabora-

tionTechniques, pages 94–105. Springer-Verlag.

Lowe, D. (1999). Object recognition from local scale-

invariant features. In Computer Vision, 1999. The Pro-

ceedings of the Seventh IEEE International Confer-

ence on, volume 2, pages 1150–1157. Ieee.

Pilet, J., Lepetit, V., and Fua, P. (2007). Fast Non-Rigid Sur-

face Detection, Registration and Realistic Augmenta-

tion. IJCV, 76(2):109–122.

Salzmann, M. and Fua, P. (2011). Linear local models

for monocular reconstruction of deformable surfaces.

PAMI, 33(5):931–44.

Salzmann, M., Pilet, J., Ilic, S., and Fua, P. (2007). Surface

deformation models for nonrigid 3D shape recovery.

PAMI, 29(8):1481–7.

Shen, S., Shi, W., and Liu, Y. (2010). Monocular 3-D track-

ing of inextensible deformable surfaces under L(2) -

norm. image processing, 19(2):512–21.

Yoshida, T., Saito, H., Shimizu, M., and Taguchi, A. (2013).

Stable keypoint recognition using viewpoint genera-

tive learning. In VISAPP.

VISAPP2013-InternationalConferenceonComputerVisionTheoryandApplications

18