Semi-quantitative Monitoring of VOCs Emission Decay

based on Gas Sensor Array and Graphical Display

Andrzej Szczurek and Monika Maciejewska

Faculty of Environmental Engineering, Wroclaw University of Technology,

Wybrzeże Wyspiańskiego 27, 50-370, Wrocław, Poland

Keywords: Gas Sensor Array, Visualization, Monitoring, Semi-quantitative Assessment.

Abstract: We propose a method of evaluating volatile organic compounds (VOCs) emission decay semi-

quantitatively. The method utilizes continuous measurements performed with gas sensor array and the

simultaneous visualization of measurement data. Individual VOCs are evaluated against the graphically

displayed quantitative criteria, which describe the stages of the emission process. Based on the displayed

information, human operator evaluates the gas mixture composed of the emitted VOCs. In order to visualize

the data together with the quantitative criteria the two-dimensional feature space was proposed. A number

of issues were discussed in this work regarding the selection of the adequate feature spaces and suitable

methods of their partitioning in order to reflect the stages of the VOCs emission process in the structure of

the feature space.

1 INTRODUCTION

Over the last decades it has become evident that

many products can be major contributors to the

pollution of the indoor environment with volatile

organic compounds. These substances are found in

wide variety of everyday products such as floor

coverings, solvent-based paints/coatings, adhesives,

sealants, printing inks, many consumer products,

organic solvents and petroleum products. VOCs

contained in products tend to diffuse to the surface

of the products and then they are emitted to the air

over time. When these emissions occur indoors,

building occupants are exposed via inhalation.

Unfortunately, some of the emitted VOCs may

affect the perception of the indoor air quality, e.g. in

the form of odor nuisance, eye and airway irritation.

Thus, there is an increasing awareness and emphasis

on receiving the information, whether concentrations

exceed levels that may affect human health or

comfort. Therefore manufacturers are increasingly

asked or required to demonstrate that vapor-phase

emissions of chemicals of concern from their

products under normal use conditions comply with

various voluntary or regulatory acceptance criteria.

In practice, it is difficult to accomplish this

requirement. In general, the mechanism of VOCs

release from products and the factors influencing the

emission process are complex and can involve the

diffusion of VOCs within the product and their

evaporation from the surface to the ambient air.

Additionally, the emission rate of VOCs may be

affected by the concentration of these species in the

air, decomposition related to the hydrolysis or heat,

oxidation, chain breakdown resulting in the smaller

and more volatile molecules as well as the sorption

on the material surface. All these phenomena cause

that the process of VOC emission is time dependent.

For these reasons, there is the absence of a uniform

procedure for modelling and calculating the

emission rate of VOCs.

Other approach requires manufacturers to have

their products periodically tested for VOC emissions

by independent laboratories using designated

reference test methods (for example, Test Method

D6007, ISO 16000-9, and ISO 16000-10). This

strategy very often uses chromatography and

spectroscopy which are accurate and precise.

However, reference methods for testing chemical

emissions from products are typically expensive, too

time-consuming and impractical for routine emission

monitoring in a production environment. So, there is

a great need for rapid, easy-to-use, inexpensive,

portable instruments for real-time, continuous or

periodic measurements performed in situ or on-line,

162

Szczurek A. and Maciejewska M..

Semi-quantitative Monitoring of VOCs Emission Decay based on Gas Sensor Array and Graphical Display.

DOI: 10.5220/0004310401620170

In Proceedings of the 2nd International Conference on Sensor Networks (SENSORNETS-2013), pages 162-170

ISBN: 978-989-8565-45-7

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

that do not require specialist technicians. This

demand can be fulfilled by the devices equipped

with the solid-state chemical sensors. Among solid-

state chemical sensors, tin oxide semiconductor

sensors developed by Taguchi are highly sensitive to

volatile organic compounds (VOC) and other

reducing gases. Unfortunately, they cannot be used

as individual devices for qualitative and quantitative

analyses, because of very low selectivity. This

problem may be solved by the use of the

measurement system consisting of a suitable

sampling system, an array of gas sensors with partial

or overlapping sensitivities and a pattern recognition

component capable of discriminating between

simple as well as complex gas mixtures (Jurs et al.,

2000).

In practice, there is frequently a need for rapid

characterization of volatile compounds emission.

Such measurements are performed in an analysis

mode termed “semi-quantitative”. They are not

designed to offer the ultimate accuracy but to

provide the results with the sufficient accuracy in

both an analysis time and labour efficient manner

(Lemke et al., 2005, Dias et al., 2011). The aim of

this work was to propose a method of semi-

quantitative analysis of VOCs multi-component gas

mixtures which are emitted from different products.

Several assumptions were made in our studies.

The first one was related to the instrumental aspects

of semi-quantitative analysis. The elaborated system

should be based on: (1) semiconductor gas sensor

array, (2) dynamic mode of operation and (3) pattern

recognition module. Sensor array usually generates

highly dimensional response to the target gas.

Therefore it is difficult to extract the information

useful for solving the problem under investigation

from the obtained data. Graphical methods offer a

simple way of analyzing data in an exploratory

manner (Scott et al., 2007). For that reason, it was

assumed that the graphical method of data analysis

could be used in the system for semi-quantitative

measurements. Additionally, we assumed that from

the start, the emission of VOCs decreases over time

and the decay process is relatively fast. In our work,

semi-quantitative analysis was designed to provide

the information which allows for comparing the

concentration of the selected species with the

standards using minimum effort and in close to real

time. It is assumed that the investigated substances

belong to the brad category of VOCs are they are

known in advance. By definition, the accuracy of the

method should be in the range of ± 30 to 50 %.

2 MATERIALS AND METHODS

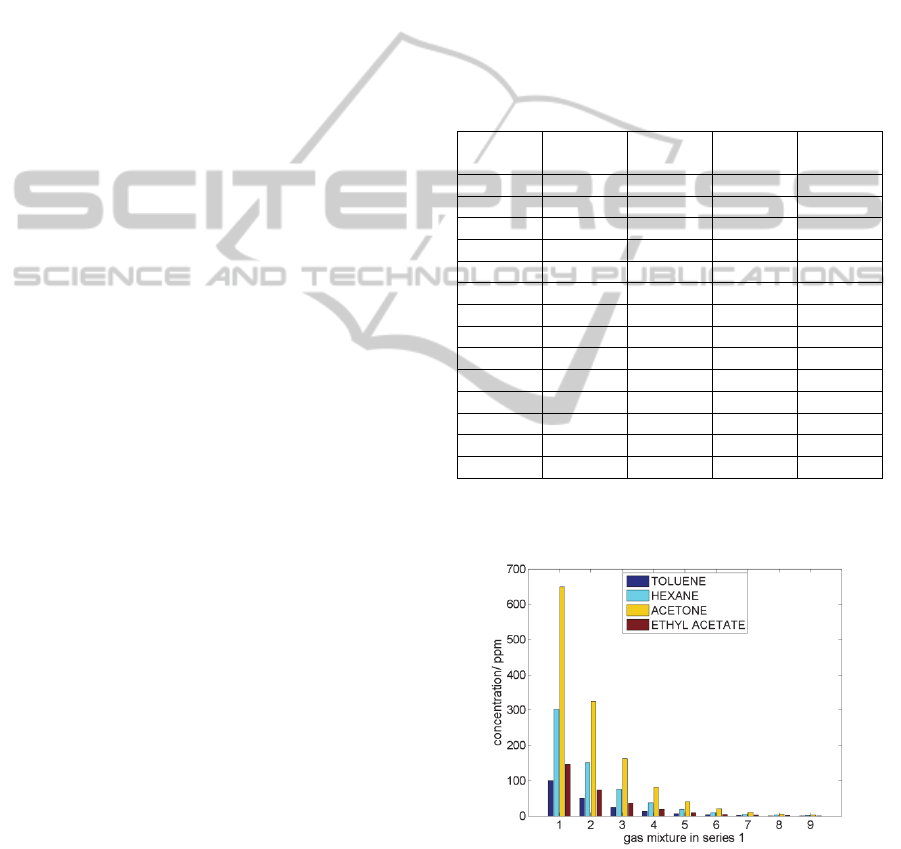

2.1 VOCs Gas Mixture

In order to test the approach we focused our

attention on the four-component gas mixture. It was

composed of toluene, hexane, acetone and ethyl

acetate, see Fig. 1 and Table 1. These VOCs are

widely used in many commercial products and by

means of evaporation from the surface they find

their way to the surrounding air. Fourteen series of

gas mixture samples were experimentally examined.

Table 1: Initial concentrations of four VOCs in each of

fourteen measurement series [ppm].

Series Toluene Hexane Acetone

Ethyl

acetate

1 101.0 302.0 650.2 146.8

2 110.4 299.6 640.3 149.7

3 122.0 296.6 628.1 153.2

4 136.7 292.9 612.7 157.7

5 155.9 288.0 592.5 163.5

6 182.0 281.4 565.2 171.4

7 219.5 271.9 525.9 182.8

8 277.9 257.0 464.5 200.5

9 381.8 230.6 355.5 232.1

10 618.0 170.7 107.6 303.7

11 874.2 0.0 0.0 325.8

12 959.1 0.0 0.0 240.9

13 1064.9 0.0 0.0 135.1

14 1090.9 0.0 0.0 0.0

Each series of gas mixture samples started from

different initial concentrations of VOCs (Table 1).

Figure 1: Single measurement series of gas mixtures.

There were chosen decreasing concentrations

within series, in order to simulate the decay of

VOCs emission process in a manner which is shown

in Fig. 1. The measurements were repeated three

times.

Semi-quantitativeMonitoringofVOCsEmissionDecaybasedonGasSensorArrayandGraphicalDisplay

163

2.2 Gas Sensor Array

The experimental setup consisted of several

functional blocks. Pure and dry air was produced

using zero air generator manufactured by Horiba.

The installation for standard gas preparation

included vaporizer in the form of the heated glass

coil with an injection port, Tedlar bag (12 l) and the

chromatography syringe (Hamilton). The module for

delivering and control of the gas flow was equipped

with the diaphragm pump, mass flow controllers,

valves and Teflon gas line. Sensing array was

equipped with the set of six commercially available

Taguchi Gas Sensors made by Figaro Engineering

Japan. There were applied: TGS2620, TGS821,

TGS825, TGS826, TGS2104, TGS2602. Each

sensor was mounted inside its own, specially

designed, airtight, flow-type test chamber. Chambers

were made of aluminum. The chambers were

provided with gas inlet and outlet and they were

connected parallel using Teflon-tubing. Such

configuration allowed for the simultaneous exposure

of the sensors to the same gas. The sensor array was

attached to the module for delivering and control of

the gas flow. The chambers were also equipped with

electrical connections. Each sensor was connected to

the voltage supplier and electronic circuit. The

output signals were measured in the form of voltage

variations on the load resistance with the time

resolution of 1 s. The ADC (Maxim 1231) was used

for analog to digital signal conversion. Signals were

recorded by the application developed in LabView.

Personal computer with the suitable software was

used for data storage, processing and analysis. The

system was operated in the dynamic mode. The

sensor signal was collected for a predefined period

of time. The responses of sensor array at each time

point of exposure to the test gas were considered as

distinct sources of information about the state of the

gas mixture. They were the candidates to become the

basis of semi-quantitative gas mixture assessment.

3 MEASUREMENT DATA

VISUALISATION FOR GAS

MIXTURE MONITORING

Semiconductor gas sensor array was chosen as the

source of measurement data to be applied for VOCs

emission decay monitoring. Due to their operation

principle sensors provide the data which contains

wide range of information about the tested gases.

Very accurate information may be acquired from

sensor array data provided that the adequate pattern

recognition methods are applied (Bermak et al.,

2006). This requirement comes from the fact that the

data has multivariate character and it is usually

featured by a considerable redundancy. In this work,

we proposed a simple manner of analyzing gas

sensor array measurement data. It was designed to

satisfy the objective of performing the semi-

quantitative assessment of emitted VOCs gas

mixture. The principal element of the concept was

the visualization of the data.

There are many thinkable ways of sensor array

data visualization, radar plots being most popular

among them. However, the graphical representation

of measurement data, which is to serve semi-

quantitative assessment of gas mixture, imposes

certain requirements on the method. The chosen

domain of graphical representation shall allow for:

1) simultaneous visualization of the data and the

criteria of its division, 2) establishing the semi-

quantitative relationship between the data and the

criteria, based on the visual inspection.

In this work there was exploited the concept of

employing feature space as the visualization domain.

In principle, the feature space encompasses the

representations of all possible states of gas mixture.

There was performed a division of the feature space.

The division resulted from solving the gas mixture

classification problem in that space. The division

criteria had the quantitative character i.e. they

referred to the quantitative parameter(s) of gas

mixture. As a result, there were separated the sub-

spaces containing representations of gas mixture

compositions, which complied with distinct criteria.

The criteria were displayed in the feature space as

the decision boundaries.

We chose two-dimensional feature spaces for

displaying the criteria and the measurement data.

More dimensions were not allowed to assure

comprehensive visualization. The current state of

gas mixture was represented as a wandering point in

the feature space. The coordinates of the point were

defined by the result of measurement obtained upon

dynamic exposure of sensor array to the investigated

gas.

It was proposed to monitor gas mixture evolution

by simultaneously analyzing the change of its main

components. Separate display panel was dedicated to

demonstrate the fate of each component of gas

mixture. The evolution of single component was

carried out against quantitative criteria. Depending

on the application they could refer to concentrations

of substances or other quantities describing

environmental impact of the test gas e.g. odor

SENSORNETS2013-2ndInternationalConferenceonSensorNetworks

164

intensity. The background of the display was to

provide visually the information on parts of the

feature space which represent particular stages of the

emission process decay. The partitioning of the

feature was guided by the mentioned criteria. The

gas mixture component evolution would be

evaluated by looking at the location of the data point

representing current measurement results against the

background information. The combined assessment

of gas mixture would be based on the human

judgment. It shall utilize the information about all or

just selected components of the gas mixture,

presented in the display panels.

A number of issues had to be considered while

designing a visualization of measurement data in the

proposed manner. The main ones were: 1) the

selection of features to form feature spaces, 2) the

selection of method to organize the feature space in

a way that its different regions correspond to the

subsequent stages of evolution of gas mixture

composed of the emitted VOCs. In both cases the

selection criteria had to be articulated and applied.

We proposed to anchor the feature space in a

defined time point of exposure to the test gas in the

dynamic mode of operation.

There were proposed two kinds of feature spaces

for consideration. The first kind was formed by

single time point signals of two different sensors.

The main advantage of using the time point sensor

signal as the feature is the direct transfer of the

sensor measurement result to the display, as the data

pre-processing is not required. In such case, there

are a number of available feature spaces to choose.

They may be associated with different time points of

exposure and also different pairs of sensors may be

considered. The main drawback of this solution is

that features of this kind are not orthogonal. The

second kind of feature was the principal component

(PC) resulting from the transformation of the data

associated with a single time point of sensor array

exposure to the test gas with principal component

analysis. This kind of feature represents the

combined information provided by all sensors in the

array. The features are orthogonal, but the

measurement data preprocessing step is required for

obtaining them. It was allowed that the feature

spaces selected for different components of gas

mixture are associated with different time points of

exposure to the test gas.

In this work, we applied an exhaustive search

across the pool of all two-dimensional feature spaces

in order to find the best ones.

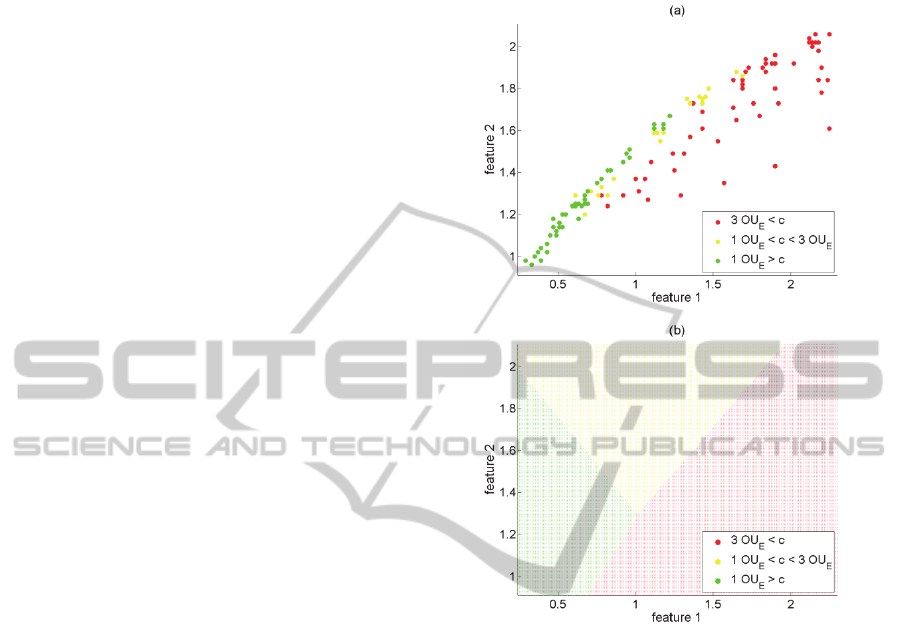

The simplest way to display measurement results

which allows for tracing the gas mixture evolution in

feature space is to use the data on the reference gas

mixtures as the ‘background’, as shown in Fig. 2a.

Figure 2: Two options of the background information

visualization on the gas mixture evolution in feature space:

a) with the use of reference gas measurement data, b) by

applying feature space division.

The data may be shown using different colours

or shapes which indicate separate categories of

reference gases, associated with different stages of

VOCs emission decay process. The way to evaluate

the current state of gas mixture is by comparing the

location of the measurement data point with the

location of reference data points on the display. This

simple solution has one major drawback. The test

gas mixture may be evaluated if the result of the

current measurement shows up in the part of the

display which is populated by data points associated

with the reference gas mixtures. While moving out

of this range the assessment becomes dubious due to

lack of reference. In practical applications, such

situation is very likely.

This major shortcoming may be overcome by

applying a classification engine for feature space

structuring. It is a way of dividing entire feature

space in an objective manner, see Fig. 2b. Two

Semi-quantitativeMonitoringofVOCsEmissionDecaybasedonGasSensorArrayandGraphicalDisplay

165

issues shall be addressed in relation to that

operation. These are: the method of dividing feature

space and the formulation of the classification

problem.

There are basically utilized the distance principle

and the decision boundary concepts while

developing classifiers (Snopok and Kruglenko,

2002). In the first approach the class assignment is

performed by calculating the data point distance to

different classes and by choosing the least distant

class. The second strategy involves the division of

the feature space into subspaces by imposing

decision boundaries which are in general

multidimensional surfaces (in 2D space these are

lines). They divide the space into disjoint regions

associated with distinct classes. The advantage of

the second approach consists in proposing the

division of entire feature space directly. Although

far from the regions populated by the calibration

data points the division shall be treated with caution

the feature space is reasonably well structured close

to them. Moreover, the class assignment of the new

data is related to its location with respect to the

displayed decision boundaries. In the particular

application considered in this work, the methods

based on decision boundaries would be favored also

for another reason. We found that the set of points

representing the gas mixture evolution has a

characteristic layout in the feature space, see Fig. 2a.

They are not arranged into a number of disjoint

clusters but they rather form one stretched grouping.

Due to the continuous transition between the stages

of gas mixture evolution the data points representing

subsequent stages are neighbours. In such

circumstances, the methods designed to cope well

with compact and disjoint clusters are inappropriate.

In this work, Discriminant Analysis was applied for

feature space partitioning. It is the most simple and

least time consuming classification method based on

decision boundary concept. We tested whether the

liner technique (LDA) or Quadratic Discriminant

Analysis (QDA) is more suitable for our application.

The way of formulating the classification

problem gains importance while applying multi-

criteria division of the feature space. It is a necessity

upon monitoring the evolution of gas mixture.

Willing to discriminate k stages of gas mixture

emission decay one may decide to apply one

division of feature space into k classes or k-1 two-

part divisions. While the first approach is quite

inflexible, the other leaves space for some

adjustment of the feature space structure to the

relative importance of the individual criteria. In this

work there were applied the criteria allowing to

assess VOCs emission process regarding their odor

impact (CIWEM's, 2011). We were willing to

discriminate between the following three stages of

gas mixture evolution: odor intensity below 1

OU

E

/m

3

, odor intensity between 1 OU

E

/m

3

and 3

OU

E

/m

3

and odor intensity higher than 3 OU

E

/m

3

. In

principle, the examination was performed for each

component of gas mixture separately.

Finally, one shall articulate the criteria of

selecting the best feature space. In this work we

considered two criteria. The first criterion was the

misclassification rate of reference gas mixtures. This

objective criterion indicated how successful was the

particular feature space together with the way of its

partitioning in assigning training patterns,

representing different stages of VOCs emission

process to the appropriate classes. There was also

applied other, subjective criterion. It referred to the

correspondence between the logics of feature space

fragmentation and the logics of gas mixture

evolution. Namely, there were examined the

arrangement, in particular the neighbourhood, of

distinct fragments of feature space, representing the

sequence of VOCs emission decay stages.

4 RESULTS AND DISCUSSION

The accuracy of reference gas mixtures

classification was the first criterion employed for the

assessment of data visualization method dedicated to

semi-quantitative gas assessment using sensor array.

The criterion was aimed to represent the accuracy of

feature space division with respect to the stages of

VOCs emission process. The following aspects of

visualization were examined with this criterion: 1)

selection of feature space coordinates (single sensor

related or sensor array related), 2) method of feature

space partitioning (linear or nonlinear), 3)

formulation of feature space division problem (k-1

divisions into two-part, or one division into k parts).

The misclassification rates of reference gas

mixture patterns are presented in Table 2, Table 3

and Table 4. The values shown in the tables are

medians. They provide a statistical indication of

misclassification rates obtained in feature spaces,

which were built separately for each time point of

sensor signal obtained upon dynamic exposure. Due

to the fact that misclassification rates were low for

most of the time points, the error rates shown in

Table 2, Table 3 and Table 4 well represent

minimum misclassification rates achievable with the

particular approach. The pairs of best sensor are

quoted in Table 5.

SENSORNETS2013-2ndInternationalConferenceonSensorNetworks

166

Table 2: Error rates while applying k-1 two-part divisions

in best feature spaces, by means of LDA. Criterion I: 1

OU

E

/m

3

, Criterion II: 3 OU

E

/m

3

.

VOC

Best sensor pair PC1 - PC2

I II I II

Toluene 13.49 7.14 9.52 18.25

Hexane 2.38 4.76 7.94 14.29

Acetone 7.94 8.73 15.87 11.11

Ethyl acetate 11.90 7.94 14.29 8.73

Table 3: Error rates while applying k-1 two-part divisions

in best feature spaces, by means of QDA. Criterion I: 1

OU

E

/m

3

, Criterion II: 3 OU

E

/m

3

.

VOC

best sensor pair PC1 - PC2

I II I II

Toluene 7.14 4.76 7.94 9.52

Hexane 3.17 0.00 3.17 0.00

Acetone 3.97 1.59 7.94 3.17

Ethyl acetate 12.7 5.56 12.70 7.94

Table 4: Error rates while applying one division of feature

space into k parts.

VOC

LDA QDA

best sensor

pair

PC1-PC2

best sensor

pair

PC1-

PC2

Toluene 23.20 26.98 13.49 19.50

Hexane 3.97 11.11 3.17 5.56

Acetone 13.49 23.02 8.73 14.29

Ethyl

acetate

15.08 16.67 11.11 12.70

Table 5: Best sensor pairs.

VOC

k-1 two-part divisions one division into k parts

LDA QDA LDA QDA

Toluene

TGS825,

TGS2104

TGS825,

TGS2104

TGS825,

TGS2104

TGS826,

TGS2104

Hexane

TGS825,

TGS2602

TGS826,

TGS2104

TGS825,

TGS2602

TGS2620,

TGS2104

Acetone

TGS826,

TGS2104

TGS826,

TGS2104

TGS826,

TGS2104

TGS825,

TGS2104

Ethyl

acetate

TGS825,

TGS826

TGS2620,

TGS826

TGS825,

TGS2602

TGS825,

TGS2104

Based on the joint analysis of Table 2, Table 3

and Table 4, the application of k-1 two-class

divisions of feature space resulted in lower

misclassification rates as compared to one division

into k fragments. The differences were considerable

and in single cases they exceeded 10 %. In general,

nonlinear classification offered better results than

linear. Regarding kind of features applied for

constructing the feature space it was shown that

responses of best pairs of sensors outperformed

principal components. The gain was less obvious

while applying k-1 two-class partitioning (Table 2

and Table 3) than in case of one division into k

classes (Table 4). It is noticeable in Table 5 that

different sensor pairs were found best for tracing the

evolution of the individual components gas mixture.

Except for one case (Table 4, toluene) all considered

methods allowed for the assessment of gas mixture

evolution stages with an error not exceeding 20 %.

In most cases the error was lower than 10 %. The

obtained result is satisfactory in view of ±30 to 50 %

accuracy expected from the gas sensor system which

performs semi-quantitative analysis.

While choosing the criterion of best separation of

classes as decisive, the obtained results indicate that,

the best choice for visualization of gas mixture

evolution is: 1) selecting responses of single sensors

as coordinates, 2) applying nonlinear division of

feature space and 3) using k-1 two-part divisions of

feature space. However, while designing the

visualization system the consideration of other

aspects is also worthwhile.

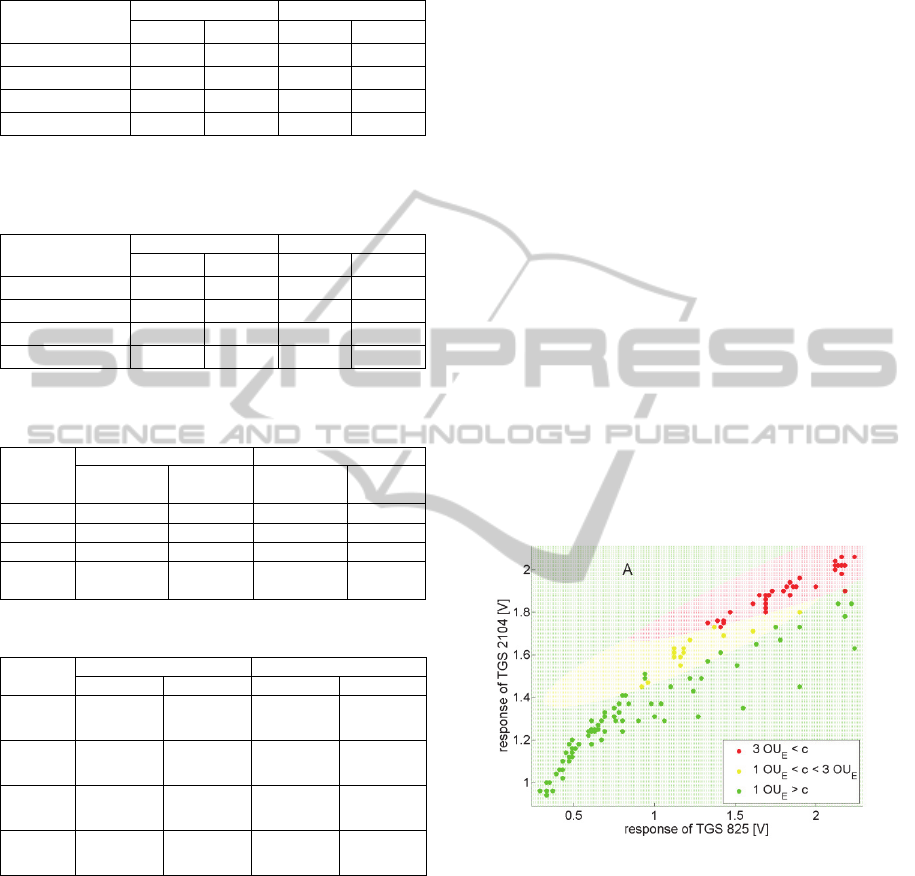

The first of other aspects considered in this work

is the reflection of the logics of gas mixture decay in

the structure of feature space. It is shown in Fig. 3

that illogical divisions are likely to occur while

applying nonlinear method of feature space division/

data classification.

Figure 3: Illogical division of feature space realized by

QDA.

From the logic of the arrangement of reference

gases data points, it is unlikely to encounter low

odor intensity gas mixtures in the region of feature

space marked A (Fig. 3). The structure of feature

space proposed by the classifier is questionable. The

problem indicated by the presented example may be

encountered both, when applying multiple two-class

partitioning as well as one division into k parts. It

comes from the fact that nonlinear classifier tends to

tighten nonlinear boundaries around groups of points

which belong to the same class. It result in lower

Semi-quantitativeMonitoringofVOCsEmissionDecaybasedonGasSensorArrayandGraphicalDisplay

167

misclassification rates (Table 2 to Table 4) but at

some distance from the centers of the classes, the

organization of the feature space may fail to agree

with the logics of the variability of real object

represented by the data. The linear solution,

although less advantageous in terms of the

classification performance is less likely to generate

such misinterpretations.

The second of other visualization aspects

considered in this work is associated with the

multiple two-class approach to the feature space

division. While choosing this strategy instead of one

multiclass division, the designer of data visualization

for the sensor system may decide about the priority

of one or the other criteria of gas mixture state

assessment. This problem is illustrated in Fig. 4. An

example of linear division was chosen for showing,

although the same possibility is available while

using nonlinear classifier.

The region marked A, between the dashed lines

(red and green), may host data points considered as

representing highly odorous gas mixture or low odor

Figure 4: Prioritization of the criteria for gas mixture

evolution stages detection.

intensity gas mixture depending on whether the

priority was given to the decision boundary set at c =

3 OU

E

/m

3

or to c = 1 OU

E

/m

3

. In the second case the

field denoted with A shall be marked green.

The division shown in Fig. 4 would be favoured

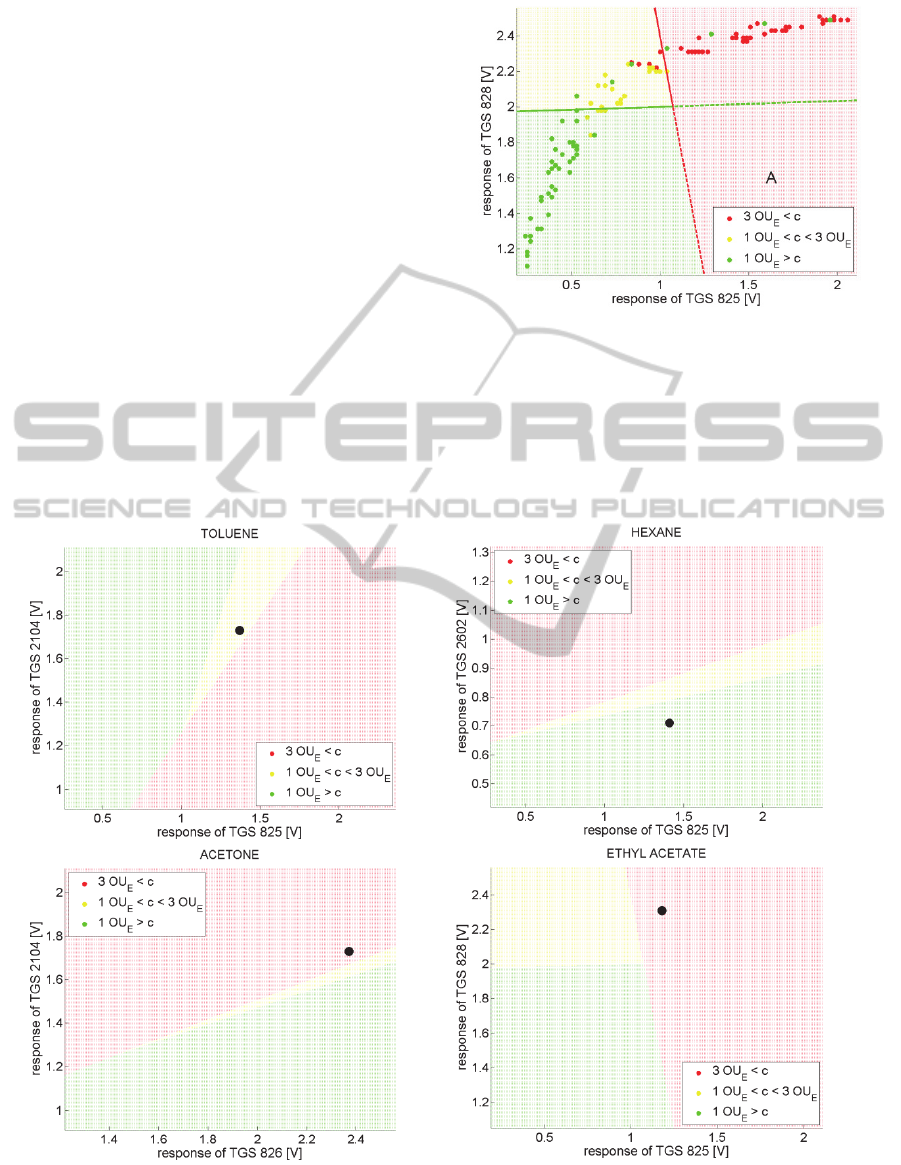

Figure 5: Sensor array measurement data visualization for semi-quantitative monitoring of VOCs emission decay process.

There is shown a exmple of a display designed for four-component gas mixture. We were willing to discriminate between

the following three stages of gas mixture evolution: odor intensity below 1 OU

E

/m

3

, odor intensity between 1 OU

E

/m

3

and 3

OU

E

/m

3

and odor intensity higher than 3 OU

E

/m

3

. Black dot indicates the current state of gas mixture.

SENSORNETS2013-2ndInternationalConferenceonSensorNetworks

168

if the underestimation of the gas mixture odor

intensity was not desired, e.g. in environmental

applications. However, one would rather choose the

other way of dividing the feature space if avoiding

too strict judgment of gas mixture odor intensity was

most important. In case of a single multiclass

partitioning the possibility of gas mixture

assessment criteria tuning is not available. We

additionally showed that in this case the

classification errors are higher (Table 2 to Table 4).

Based on the above findings, we proposed the

concept of gas sensor system for the semi-

quantitative monitoring of multi-component VOCs

mixture emission decay. The system consists of the

semiconductor gas sensor array and the graphical

display. Commercial TGS sensors are used. They are

operated in the dynamic mode. The display of the

sensor system is divided into panels, as shown in

Fig. 5. Each panel hosts the graph of two-

dimensional feature space. Separate graphs are used

to address distinct components of gas mixture with

the quantitative criteria. The responses of selected

sensors are used as features (dimensions of feature

spaces). Best pair of sensor is chosen for each

substance individually. Linear division of feature

space is performed using Linear Discriminant

Analysis. Mulitple two two-class divisions are

applied with the priority assigned to detecting gas

mixtures with higher polluting potential. The

integral elements of the feature space are the

decision boundaries. They represent the quantitative

criteria which separate different stages of gas

mixture evolution. The tested gas mixture is

represented as the wandering point in the feature

space on each display. The diagnosis of gas mixture

state results from the combined assessment which

utilizes the displayed information about all, or

selected components of gas mixture, and it is based

on human judgment.

5 CONCLUSIONS

In this work there was proposed the concept of gas

sensor system for the semi-quantitative monitoring

of the emission process decay of multi-component

VOCs mixture. The principal idea for realizing the

assessment was to visualize the evolution of gas

mixture components against the objective,

quantitative criteria. It allows for fast human

judgment on the condition of the mixture as a whole,

based on the visual inspection of the graphical

display.

For visualization we proposed to use the two-

dimensional feature spaces. They were defined for

each component of gas mixture individually.

Classifiers were applied in order to partition feature

spaces according to the criteria which discriminate

between different stages of VOCs emission process.

The measurement data resulting from an ongoing

measurement was displayed in the feature spaces. Its

location with respect to the distinguished fragments

of feature spaces was indicative for the current state

of gas mixture.

Based on our investigation, the most difficult

problem of sensor system design was the lack of

objective criteria to decide whether the proposed

division of feature space is adequate. It was shown

that the criterion of lowest misclassification rate of

reference gas mixture patterns was insufficient for

assuring that the obtained partitioning of feature

space follows the logic of gas mixture evolution.

The objective criteria regarding neighborhood and

sequence of regions corresponding to particular

classes would be needed to evaluate the candidate

feature spaces in that respect. In this work we dealt

with these problems in a heuristic manner.

We think that the proposed solution may be

interesting for the constructors of sensor systems

addressed to environmental monitoring applications.

ACKNOWLEDGEMENTS

This work was supported by the project "Detectors

and sensors for measuring factors hazardous to

environment - modeling and monitoring of threats",

POIG.01.03.01-02-002/08-00.

REFERENCES

Bermak A., Belhouari S. B., Shi M., Martinez D. (2006).

Pettern recognition techniques for odor discrimination

in gas sensor array, Encyclopedia of Sensors, 10, 1-17.

CIWEM's Position on Odours, Feb. 2011,

http://www.ciwem.org/knowledge-

networks/panels/air/control-of-odour.aspx

Dias L. G., Peres A. M., Barcelos T. P., Sá Morais J.,

Machado A.A.S.C. (2011) Semi-quantitative and

quantitativeanalysis of softdrinks using an

electronictongue, Sens. Actuators B, 154(2), 111-118.

Jurs P.C., Bakken G. A., McClelland H. E. (2000).

Computational methods for the analysis of chemical

sensor array data from volatile analytes, Chem. Rev.,

100, 2649-2678.

Lemke M., Fernández-Trujillo R., Löhmannsröben H.G.

(2005) In-situ LIF Analysis of Biological and

Semi-quantitativeMonitoringofVOCsEmissionDecaybasedonGasSensorArrayandGraphicalDisplay

169

Petroleum-based Hydraulic Oils on Soil, Sensors, 5,

61-69.

Scott S. M., James D., Ali Z. (2007) Data analysis for

electronic nose systems, Microchim. Acta, 156, 183-

207.

Snopok B. A., Kruglenko I. V. (2002) Multisensor system

for chemical analysis: state-of-the-art in Electronic

Nose technology and new trends in machine olfaction,

Thin Solid Films, 418, 21-41.

SENSORNETS2013-2ndInternationalConferenceonSensorNetworks

170