Development of a Process Assessment Model for Assessing Security of

IT Networks Incorporating Medical Devices against ISO/IEC 15026-4

Anita Finnegan, Fergal Mc Caffery and Gerry Coleman

Regulated Software Research Group, Dundalk Institute of Technology & Lero, Dundalk, Co Louth, Ireland

Keywords: Medical Device Security, Process Assessment, ISO/IEC 15026-2, ISO/IEC 15026-4, IEC 80001-2-2, IEC

62443-3-3, ISO/IEC 15504, ISO 27799, ISO/IEC 27001, ISO/IEC 27002.

Abstract: Advancements in medical device design over the last number of years have allowed medical device

manufacturers to add more complex functionality particularly through the use of software. Such

advancements include the ability for devices to communicate wirelessly across networks, from device to

device and over the Internet. However, with such advancements comes additional risks; these are security

risks, vulnerabilities and threats. In the past twelve months, concern within the medical device community

has led to the US Government calling upon the FDA to take responsibility of medical device security. In

support of this, this position paper details a research proposal to address medical device security issues

through the development of a Process Reference Model (PRM) and a Process Assessment Model (PAM) to

assess the capability of the processes used to develop medical devices intended to be incorporated onto

healthcare networks and also determine the product security capability through the development of security

assurance cases created following the lifecycle process. Further, in support of IEC 80001-2-2, the output

from this PRM will be an assurance case with a security assurance level, which will be used to communicate

the security capabilities of the product between Medical Device Manufacturers (MDMs) and Healthcare

Delivery Organisations (HDOs). The intent is to build a better awareness of vulnerability types, threats and

related risks to assist in reducing the likelihood of harm resulting from a security risk.

1 INTRODUCTION

Medical devices have made substantial innovative

design improvements over the last number of years

due to the growing incorporation of software in the

devices. Following on from the addition of software

came the introduction of interoperable medical

devices bringing with it, a new set of security risks

for consideration. Although there have been no

reports of malicious attacks on interoperable medical

devices, there have been quite a number of

controlled hacking demonstrations. One such

demonstration was at the Black Hat Security

Conference in Las Vegas in 2011. A security

researcher, Jeremy Radcliffe, manipulated the

settings of his own insulin pump during a

presentation. The ease with which the insulin pump

was hacked created a lot of concern within the

medical device community. Then in October 2012,

Barnaby Jack, a researcher at IOActive, presented

research results at the Breakpoint Conference in

Australia, which looked at the security of

pacemakers. Jack’s research identified a bug in

several manufacturers’ pacemakers that allowed an

attacker to deliver a potentially lethal shock to a

patient’s heart by sending a signal to the pacemaker

by simply using a laptop. The pacemaker contained

a coding error that allowed it to send a wireless

command to the device that returned the model and

serial number of the device.

Consequently, in a letter to the US Office of

Management and Budget, the Information Security

and Privacy Advisory Board (ISPAB) called upon

the government to assign the responsibility of

medical device security to a federal entity such as

FDA. In August 2012, the Government

Accountability Office (GAO) released a report of an

audit carried out on the FDA for the assessment of

two implantable medical devices that highlighted

shortfalls in the assessment of intentional and

unintentional risk (Government Accountability

Office, 2012).

In addition to this quite a number of medical

device security information and guidance documents

250

Finnegan A., Mc Caffery F. and Coleman G..

Development of a Process Assessment Model for Assessing Security of IT Networks Incorporating Medical Devices against ISO/IEC 15026-4.

DOI: 10.5220/0004327502500255

In Proceedings of the International Conference on Health Informatics (HEALTHINF-2013), pages 250-255

ISBN: 978-989-8565-37-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

have been recently released. One example, the US

Department of Homeland Security (DHS) issued a

bulletin “Attack Surface: Healthcare and Public

Health Sector”(DHS, 2012) which discusses security

related risks associated with using medical devices

on IT networks, including those risks to patient

safety and theft or loss of medical information.

Addressing this recent concern, the aim of this

research is to build security assurance into the

product lifecycle through a set of strategic processes,

activities and tasks and to establish and

communicate the product security capabilities of a

medical device between Medical Device

Manufacturers, vendors and Healthcare Delivery

Organisations. This will create awareness for both,

the Medical Device Manufacturers in understanding

the needs of the Healthcare Delivery Organisation,

and also for Healthcare Delivery Organisation IT

admin staff, to understand the capabilities of the

medical device that could potentially be acquired for

use on their IT network.

Section two of this paper outlines the most

relevant standards and documents currently used

within the software industry in relation to process

assessment, software lifecycle assurance and

security. Section three looks at related work in the

area of process assessment models and security.

Section four then discusses the future work planned

for this research, including the validation of the

model and also the impact this research is expected

to have in the medical device domain for regulators,

Medical Device Manufacturers, IT vendors and

Healthcare Delivery Organisations.

2 CURRENT LANDSCAPE WITH

STANDARDS

With the substantial transformation in medical

device design over the last few years to incorporate

software and communication functionality, the

medical device communities around the world have

published many standards and guidance documents

to assist with the development of safe medical

devices. This has resulted in an abundance of

published security guidance documents and a sense

of confusion among Medical Device Manufacturers

and Healthcare Delivery Organisations with regards

which guidelines and best practices to follow.

This section outlines the most applicable

standards and guidance documents which are

deemed most relevant in establishing and controlling

security risks. A broad range of standards have been

reviewed for this research, with the most

fundamental being discussed here. Additional

standards identified and incorporated into this

research to date are discussed in Section three.

2.1 ISO/IEC 15026-4

ISO/IEC 15026-4 (IEEE, 2011) provides

recommendations and guidelines for implementing

software and systems development processes that

require additional assurance for a particular property

of that system or software; in this case the critical

property is security. This standard presents a list of

recommended processes, activities and tasks

required in order to achieve a claim in relation to

that critical property of a system or software.

Through the development of an assurance case

(further discussed in section 2.2), the entire

development and maintenance of the product is

addressed which also includes project-planning

considerations. It is intended that this standard be

used coupled with an already defined life cycle

model.

2.2 ISO/IEC 15026-2

ISO/IEC 15026-2 (IEEE, 2011) defines

requirements for the structure and content of an

assurance case. An assurance case is a body of

evidence organised into an argument demonstrating

some claim that a system holds i.e. ‘Is Assured’. An

assurance case is needed when it is important to

show that a system exhibits some complex property

such as safety, security, or reliability (Goodenough

et al., 2012).

A security assurance case is often compared with

a legal case where there are two elements to the

case, the argument and the evidence to support a

claim. For an assurance case to be effective it must

satisfy the following points:

Must make a claim or set of claims about a

property of a system;

Provide a set of arguments;

Make clear the assumptions and judgements

underlying the arguments;

Associate different viewpoints and levels of detail.

Produce the supportive evidence;

2.3 IEC 80001-2-2

IEC 80001-2-2 (IEC, 2011c) is a technical report

which provides a framework for the communication

and disclosure of medical device needs, risks and

controls which are to incorporated onto a IT

DevelopmentofaProcessAssessmentModelforAssessingSecurityofITNetworksIncorporatingMedicalDevicesagainst

ISO/IEC15026-4

251

network. This technical report presents 20 security

capabilities (Table 1) e.g. Authorization, Audit

Controls etc. These capabilities provide Healthcare

Delivery Organisations, Medical Device

Manufacturers and IT vendors with information

regarding user needs, security related requirements

and required security control types.

This information is critical prior to development,

acquisition, installation and use of medical devices

for IT networks. Each of these security capabilities

represents a potential security risk control. These

are addressed in the requirement goals, which

identify the risks that can be mitigated against

through the use of that particular security capability.

The user need section develops this further by

detailing particular specific environmental

requirements.

Table 1: IEC 80001-2-2 Security Capabilities.

Security Capability Code

1 Automatic Logoff ALOF

2 Audit Controls AUDT

3 Authorization AUTH

4 Configuration of Security Features CNFS

5 Cyber Security Product Upgrades CSUP

6

Data Backup and Disaster

Recovery

DTBK

7 Emergency Access EMRG

8 Health Data De-Identification DIDT

9

Health Data Integrity and

Authentication

IGAU

10

Health Data Storage

Confidentiality

STCF

11 Malware Detection/Protection MLDP

12 Node Authentication NAUT

13 Person Authentication PAUT

14 Physical Locks on Device PLOK

15 Security Guides SGUD

16 System and Application Hardening SAHD

17

Third-Party Components in

Product Lifecycle Roadmaps

RDMP

18 Transmission Confidentiality TXCF

19 Transmission Integrity TXIG

20 Unique User ID UUID

The security disclosure is a summary statement

provided by the Medical Device Manufacturer

and/or IT vendor that details the security capability

of the medical device. This security disclosure is

then reviewed by the Healthcare Delivery

Organisation to establish the security integrity of the

product and prompt further discussion prior to

acquisition. The risk management team within the

Healthcare Delivery Organisation utilise this further

to perform a risk analysis based on the known

security capabilities.

2.4 IEC 62443-3-3

IEC 62443-3-3 (IEC, 2011a) defines security system

requirements based on a combination of system

functional requirements and a risk assessment. Key

inputs into the development of this document are

security standards ISO/IEC 27002 (ISO/IEC, 2005)

and NIST SP800-53(NIST, 2009). The standard is

adopted by allowing the asset owner for the system

so dictate the target Security Assurance Level (SAL-

T). The standard details seven Foundational

Requirements (FRs) as listed in Table 2. The seven

FRs listed are the baseline for the system Security

Assurance Levels (SALs). Within each of the seven

FRs are applicable System Requirements (SRs).

These are further broken down detailing the

requirement of that SR, the rationale and

supplemental guidance, the Requirement

Enhancements (REs) and guidance for selection of

REs relating to the SR dependent on the chosen SAL

level for establishment of the achieved Security

Assurance Level (SAL-A).

Table 2: IEC 62443-3-3 Foundational Requirements.

Foundational Requirement Code

1 Identification and Authentication Control IAC

2 Use Control UC

3 Data Integrity DI

4 Data Confidentiality DC

5 Restricted Data Flow RDF

6 Timely Response to Events TRE

7 Resource Availability RA

3 SOLUTION DEVELOPMENT

3.1 Related Work

ISO/IEC 15504-2 (ISO/IEC, 2003) provides a

measurement framework for process capabilities and

defines the requirements for performing the

assessment, building the Process Reference Model

(PRMs), Process Assessment Models (PAMs) and

verifying conformity of process models and the

process assessment. Existing generic Software

Process Improvement (SPI) models are available

which include the Capability Maturity Model

Integration (CMMI®) (SEI, 2010) and ISO 15504-

5:2006 (ISO/IEC, 2006) (SPICE), but these models

were not developed to provide sufficient coverage

for regulatory compliance for the security of IT

Networks incorporating medical devices.

While this relates to the development of the PRM

HEALTHINF2013-InternationalConferenceonHealthInformatics

252

and the PAM for establishment of process assurance,

it does not specifically address medical device

product quality. One difference here is that, in

addition to assessing the Medical Device

Manufacturers software processes and practices, the

key to this research is to also address product

capabilities in relation to security of the

interoperable medical devices.

To address the requirement for a PAM for

assessing the security of IT networks incorporating

medical devices, we undertook extensive research in

this area assisted by leading members from the

international standards IEC SC62A JWG7 working

group looking at a medical devices specific SPI

model. This work is being developed in

collaboration with the SPICE User Group. The

approach taken here is in line with the approach

taken for both the development of Automotive

SPICE (Automotive SIG) a domain specific SPI

model for the automotive industry, and Medi SPICE

(Fergal McCaffery and Dorling, 2010).

3.2 Proposal

ISO/IEC 15026-4 (IEC, 2011a) is a process lifecycle

standard and provides a solid foundation for the

PRM. It details processes for risk management

which will be extended to include relevant security

standards and requirements such as ISO/IEC 27002,

ISO 27799 (ISO, 2008), IEC 62443, IEC 80001-2-2,

NIST SP 800-53 and NIST SP 800-23 (NIST, 2009).

All security controls and capabilities from these

named sources will be crossed referenced and

mapped to develop a comprehensive set of security

capabilities which will need to be addressed when

conducting a risk assessment and establishing

relevant risk controls. For example, Automatic Log

Off from IEC 80001-2-2 (Table 1) would use the

requirements of SR.1.10 Session Lock in IEC

62443-3-3 as they relate to each other. All relevant

controls/requirements from guidance docs and

security standards included in the research will

follow a similar mapping.

The PRM will provide a description of the

processes and characterise these in terms of their

purpose and outcome. This Process Assessment

Model will be developed in compliance with

ISO/IEC 15504-2 (ISO/IEC, 2003) which outlines

what is required in the Process Assessment Model.

This will be developed along with a measurement

framework and ISO/TR 24774 (IEC, 2010) will

provide the guidelines for process definition.

These steps take care of the processes to be

addressed for the development of a product.

Establishing process assurance or maturity has many

benefits for both the medical device manufacturers

and third party assessors in terms of meeting

regulatory compliance and also determination of

process quality. However, considering the security

risks associated with interoperable medical devices

consisting of software, a major objective is to

establish a method for the communication of the

final product quality in relation to security

capabilities between the Medical Device

Manufacturer, the IT vendor and the Healthcare

Delivery Organisation. Communication of a security

assurance level to Healthcare Delivery Organisations

will provide a simple and meaningful method for

establishing suitability of the device for the users

need and its environment. To do this, IEC 62443-3-

3 will be used as a guide for establishing the system

security assurance level (SAL) by the Medical

Device Manufacturers. The Healthcare Delivery

Organisation will determine the appropriate security

capabilities from within IEC 80001-2-2, along with

any other validated capabilities from other standards.

With regards the different types of SAL, the critical

property is the achieved SAL (SAL-A) since this is

most valuable to the Healthcare Delivery

Organisation and FDA when establishing the

security capability of the product. A SAL vector

will be developed by the Medical Device

Manufacturer post product development for the

achieved SAL (SAL-A), which will be based on the

target SAL (SAL-T) level (0-4) as determined by the

Healthcare Delivery Organisation as the start of the

acquisition process. The SAL vector that details the

assurance level and security capabilities is presented

here:

SAL-A = ({FR,} domain) = {AC UC DI DC RDF TRE RA}

SAL-A = ({FR,} domain) = {3 3 3 3 2 1 0}

For each of the parameters (refer to table 2 for FR

descriptions) within the vector, a value of zero to

four will be used to represent the SAL level for that

particular requirement. Following on from this, the

Medical Device Manufacturer will then verify the

selected SAL level through the use of the SAL

Mapping Matrix as shown in Annex B of IEC

62443-3-3 (IEC, 2011a), which will also be

included in the PRM.

To further build upon the communication and

disclosure of security capabilities, an assurance case,

compliant with IEC/ISO 15026-2 (IEEE, 2011) will

be developed by the Medical Device Manufacturer.

Delivering the actual product assurance level will be

achieved through the utilisation of a tool. This tool

will be used for the development of the risk

DevelopmentofaProcessAssessmentModelforAssessingSecurityofITNetworksIncorporatingMedicalDevicesagainst

ISO/IEC15026-4

253

assessment and will in turn automatically build the

assurance case and outline in detail the evidence

gathered to support the achievement of each SAL

level.

The outcome of the PRM will be the

development and communication of:

1. A process maturity level for the development of

the product;

2. A security assurance case detailing in-depth the

arguments and evidence supporting the

security/safety claim of the medical device;

3. An achieved security assurance level (SAL-A)

for the product.

4 SOLUTION DEVELOPMENT

It is planned that this model will be trialled in

industry for validation purposes. This will be done

at manufacturing facilities and Healthcare Delivery

Organisations both in Ireland and the U.S. In

addition to this, it is intended that the model will

also be validated by experts from the International

Standards Committee of IEC SC62A.

At present, there is much concern in the area of

medical devices particularly related to security

vulnerabilities, threats and risks of devices with

communication abilities or those incorporated onto

IT networks. Over the past 12 months, this concern

has been highlighted through many federal body

guidance publications and reports, security

researchers’ demonstrations, publications and also

the development of new standards such as IEC

80001-1(IEC, 2011b).

With the publication of the GAO (Government

Accountability Office, 2012) report in August, it is

clearly indicated here that future strategies are

required in order to sufficiently address medical

device security. As medical devices become more

advanced with software and complex wireless

capabilities, it is feared that security vulnerabilities,

threats and related risks will grow with this

development. The GAO has recommended that the

FDA work on addressing these issues following their

assessment of FDA approved implantable

defibrillators and insulin pumps.

IEC 80001-2-2 defines the security capabilities

that a Medical Device Manufacturer or IT vendor

must communicate to the Healthcare Delivery

Organisation in order to enhance knowledge of

security risks and controls the Healthcare Delivery

Organisation IT admin staff should consider. This

research sets out to support this from both a process

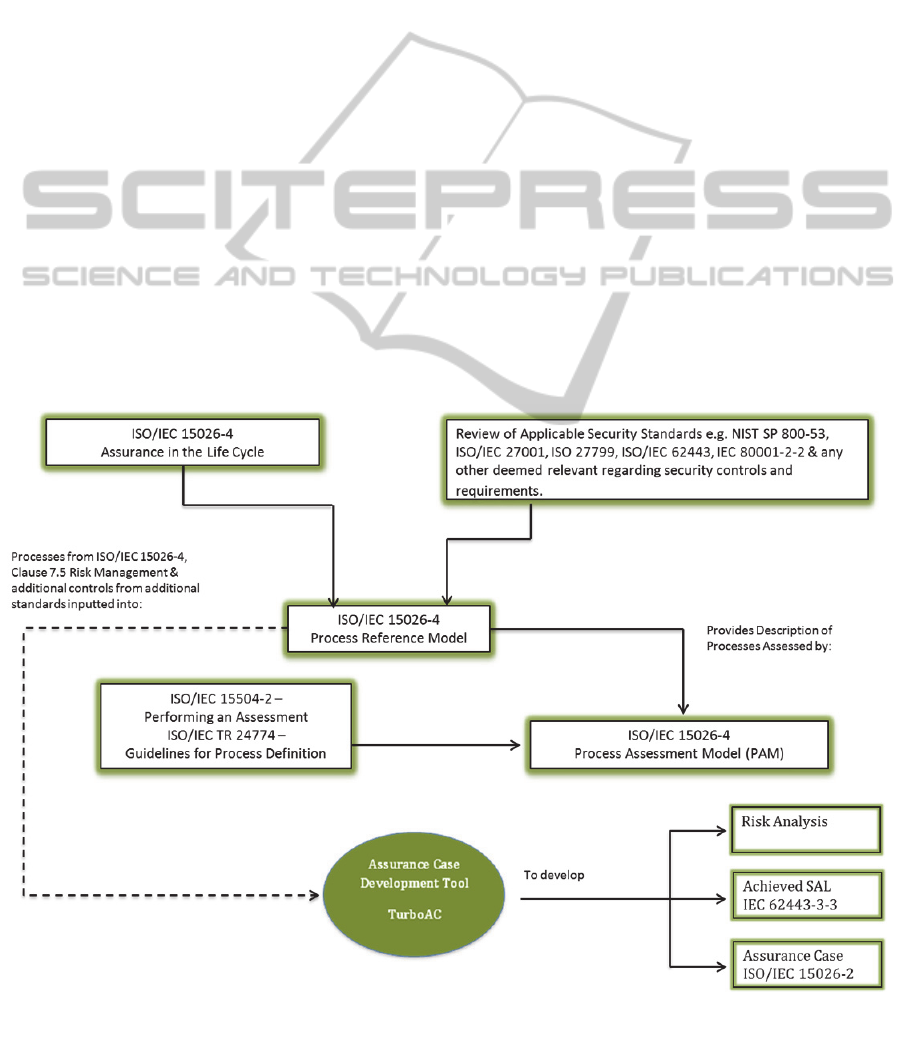

Figure 1: Research approach.

HEALTHINF2013-InternationalConferenceonHealthInformatics

254

and a product point of view.

Developing a model to assess the Medical

Device Manufacturer’s development process

maturity coupled with guidance for the

establishment of a security assurance level addresses

development and output. The product output is the

medical device achieved security assurance level

(SAL-A) reflecting the security capabilities for that

device and also the security controls incorporated.

This output, in the form of a security assurance case,

will be the communication from Medical Device

Manufacturers to Healthcare Delivery Organisations

prior to acquisition. Managing the lifecycle process

and the product security capability between the

Medical Device Manufacturer and the Healthcare

Delivery Organisation would greatly improve the

current processes in the industry at the moment.

Currently there is no methodology to address both

the development processes and the product

capabilities for security in medical devices. This is

the primary focus of this research.

Hence, it is envisaged that the output of this

research will positively impact the medical device

domain by building awareness of security

vulnerabilities, threats and related risks between the

Healthcare Delivery Organisation and the Medical

Device Manufacturer.

ACKNOWLEDGEMENTS

This research is supported by the Science

Foundation Ireland (SFI) Stokes Lectureship

Programme, grant number 07/SK/I1299, the SFI

Principal Investigator Programme, grant number

08/IN.1/I2030 (the funding of this project was

awarded by Science Foundation Ireland under a co-

funding initiative by the Irish Government and

European Regional Development Fund), and

supported in part by Lero - the Irish Software

Engineering Research Centre (http://www.lero.ie)

grant 10/CE/I1855.

REFERENCES

DHS 2012. Attack Surface: Healthcare and Public Heath

Sector.

Fergal McCaffery & Dorling, A. 2010. Medi SPICE

Development. Software Process Maintenance and

Evolution: Improvement and Practical Journal. 255-

268.

Goodenough, J., Lipson, H. & Weinstock, C. 2012.

Arguing Security - Creating Security Assurance Cases.

Government Accountability Office 2012. Medical

Devices, FDA Should Expland Its Consideration of

Information Security for Certain Types of Devices. In:

GAO (ed.).

IEC 2010. IEC/TR 24774 Systems and software

engineering. Life cycle management. Guidelines for

process description.

IEC 2011a. IEC 62443-3-3 Ed. 1.0, Security for industrial

automation and control systems - Network and system

security.

Part 3-3: System security requirements and security

assurance levels Introductory Note. International

Electrotechnical Committee.

IEC 2011b. IEC/TR 80001-1 - Application of risk

management for IT-networks incorporating medical

devices.

IEC 2011c. IEC/TR 80001-2-2 Ed. 1.0 - Draft Technical

Report - Application of risk management for IT-

networks incorporating medical devices. Part 2-2:

Guidance for the disclosure and communication of

medical device security needs, risks and controls.

International Electrotechnical Committee.

IEEE 2011. ISO/IEC 15026-2: 2011 Systems & Software

Engineering, Systems & Software Assurance, Part 2:

Assurance Case.

ISO 2008. EN ISO 27799:2008 Health informatics.

Information security management in health using

ISO/IEC 27002.

ISO/IEC 2003. ISO/IEC 15504-2: 2003 Software

Engineering - Process Assessment - Performing an

Assessment.

ISO/IEC 2005. ISO/IEC 27002:2005 Information

Technology - Security Techniques - Code of Practice

for Information Security Management.

ISO/IEC 2006. ISO/IEC 15504-5: 2006 Information

technology — Process Assessment — Part 5: An

exemplar Process Assessment Model.

NIST 2009. 800-53 Recommended Security Controls for

Federal Information Systems and Organisations. In:

COMMERCE, U. S. D. O. (ed.) Revision 3 ed.

SEI 2010. CMMI-DEV, CMMI for Development.

DevelopmentofaProcessAssessmentModelforAssessingSecurityofITNetworksIncorporatingMedicalDevicesagainst

ISO/IEC15026-4

255