Job Order Assignment at Optimal Costs in Railway Maintenance

Franziska Heinicke

1

, Axel Simroth

1

, Roberto Tadei

2

and Mauro M. Baldi

2

1

Fraunhofer Institute for Transportation and Infrastructure Systems IVI, Dresden, Germany

2

DAUIN, Politecnico di Torino, Turin, Italy

Keywords:

Railway Maintenance Planning, Job Order Scheduling, Operations Research.

Abstract:

Tamping is an important part of railway maintenance. Well tamped ballast reduces track irregularities and

increases travel safety and comfort. But if the ballast is in a bad condition, the train speed must be restricted,

which leads to delays and penalty costs for the operator. In this paper a novel model for the tamping scheduling

problem in a short-term planning horizon is presented. In contrast to other railway maintenance scheduling

problems the penalty costs caused by deferring tamping activities are considered in the scheduling process

beside the travel costs. Three greedy heuristics are presented and compared in different benchmarks. An

outlook discusses issues of interest for further research.

1 INTRODUCTION

Tamping is an important part of railway maintenance.

Well tamped ballast reduces track irregularities and

increases travel safety and comfort. But if the bal-

last is in a bad condition, the train speed must be re-

stricted, which leads to delays and penalty costs for

the operator. By scheduling the tamping works these

penalty costs should be minimised together with in-

curred travel costs.

Within the ACEM-Rail project of the Europeans

Seventh Framework Programme a novel solution ap-

proach for the tamping scheduling problem will be

developed. In this paper the model is presented, first

solution approaches are shown and a look out of the

further research is given.

There are different papers dealing with railway

maintenance scheduling.

Higgins and Ferreira (1999) develop an integer

programming model to reduce train delays caused by

maintenance activities. The problem is solved with a

Tabu-Search heuristic.

Budai develops solution approaches for the pre-

ventive maintenance scheduling problem (PMSP)

(Budai et al., 2004, 2009). Aim of the PMSP is

to minimize track possession costs caused by sched-

uled routine activities and projects. For this purpose

they combine as much tasks as possible. The prob-

lem is formulated as integer programming model and

solved with heuristics and evolutionary computation

approaches.

In (Miwa, 2002; Oyama and Miwa, 2006) an in-

teger programming model for optimally scheduling

a multiple tie tamper is shown. The objective is to

maximize the improvement of track condition under

bounded maintenance costs. The resulting schedule

defines for each 10 day term where to locate the tam-

per and which lots to be maintained.

Gorman and Kanet (2010) and Peng et al. (2011)

present a time-space network to schedule larger

projects to maintenance crews and execution weeks.

They consider the specification of the crews (not ev-

ery crew could execute all tasks), time windows (ear-

liest start and latest resolving time of a project), travel

costs, and cross-job constraints (precedence, non-

concurrent, simultaneity).

An integer programming model to minimize the

tamping effort is presented by Vale et al. (2012). The

optimal time-allocation to 90 day terms is searched,

such that the track quality keeps a given level. They

take into account four aspects of tamping: the time

dependent deterioration process, the track layout, the

imperfect track quality after maintenance and the

track quality limits that depend on the maximal per-

missible train speed.

In (Quiroga and Schnieder, 2010) a heuristic ap-

proach for the tamping scheduling problem is pre-

sented. Aim is to find a set of N interventions, one

per night, which maximise a defined objective func-

tion, e.g. the expected track condition one year later.

An intervention is defined by a start depot, the tamp-

ing works, and an end depot.

156

Heinicke F., Simroth A., Tadei R. and M. Baldi M. (2013).

Job Order Assignment at Optimal Costs in Railway Maintenance.

In Proceedings of the 2nd International Conference on Operations Research and Enterprise Systems, pages 304-309

DOI: 10.5220/0004343603040309

Copyright

c

SciTePress

The model presented here is different. On the one

hand the planning horizon is short-termed – a few

weeks or months – and the schedule defines explicitly

the execution times of small tamping works. On the

other hand so-called daily costs – penalty costs for re-

strictions in railway services caused by the untamped

track – are considered in the decision process and will

be minimised together with the costs for traveling be-

tween the tamping works.

The paper is organised as follows: In section 2

the short-term tamping scheduling problem is defined.

Three Greedy Heuristics are presented and compared

in section 3. Issues of interest for further research

– extensions of the model and concepts for general

solution approaches – are presented in section 4.

2 PROBLEM FORMULATION

The short-term tamping scheduling problem is de-

fined as follows. Given a set of jobs that are defined

by

• working duration

• daily costs

• location in the network.

There is a single tamping machine operating at the

network and resolving jobs one after the other. The

jobs are executed during the night in an eight hour

working shift. For each job the execution time has to

be assigned in order to minimize maintenance costs.

At the time at which the plan is calculated the tamping

machine is located in section A and when all jobs are

resolved, the machine will be parked at section B (the

depot).

Each job refers to a small section of the track with

a short working duration (about half an hour) such

that the planning flexibility is high, but the number

of jobs is not too large. The daily costs are caused

by traffic restrictions (like speed limitations) result-

ing from a bad track condition. They have to be paid

for every day from the beginning until the job is re-

solved. If the track condition is still acceptable, the

daily costs of the corresponding job are zero. Be-

cause of the short planning horizon (a few weeks or

months) the time-dependence of track condition and

thus the time-dependence of the daily costs is not con-

sidered. The costs and time for traveling between jobs

are calculated based on the locations in the network.

The travel times contain 15 minutes for changeover

between travel and working mode. Between jobs of

consecutive track sections the time and costs for trav-

elling are zero. In practice they are executed within

one larger working step and without traveling. If the

work will be continued in the next night at the same

location the machine stays nearby over day. Thus no

costs and time for travelling to a machine depot are

incurred. If the work starts next night on another loca-

tion the machine travels over day to the new location.

The material costs, machine rent and the employee’s

wages are not included in the model, because they are

fixed and must be paid no matter if the job is executed

today or in a week. Thus only the travel costs and the

daily costs must be considered in an objective func-

tion.

The problem could be described as an integer pro-

gramming model. Given a set of jobs J, |J| = n. Let

for each job j ∈ J

• d( j) the working duration

• c

d

( j) the daily costs

• c

t

( j, k) the travel costs between the jobs j, k ∈ J

• t

t

( j, k) the travel time between the jobs j, k ∈ J

Aim of the optimisation is to assign an execution time

t

e

( j), such that the maintenance costs are minimal.

For the start point A and the end point B two ar-

tificial jobs j

A

and j

B

, are defined and J

AB

:= J ∪

{ j

A

, j

B

}. For both working duration and daily costs

are zero. The travel costs and time are calculated from

the locations in the network.

The execution time t

e

= (t

e

1

,t

e

2

) consists of two

components: the execution day t

e

1

≥ 1 and the ex-

ecution minute t

e

2

∈ [T

1

, T

2

]. The execution minute

is restricted by the working shift, that starts at

T

1

b= 10:00 p.m. and ends at T

2

b= 6:00 a.m. For j

A

the execution time is set to t

e

( j

A

) = t

start

, which is the

time at which the plan is calculated.

The problem can be formulated as follows:

min z =

∑

j∈J

AB

∑

k∈J

AB

c

t

( j, k)· x( j, k)

+

∑

j∈J

AB

t

e

1

( j) · c

d

( j)

(1)

with

t

e

( j

A

) = t

start

t

e

( j

B

) = (∞, 0)

(2)

x( j,k) =

1 , if @l ∈ J

AB

: t

e

( j) < t

e

(l) < t

e

(k)

0 , else

(3)

subject to

t

e

(k) ≥ t

e

( j) + d( j)+t

t

( j, k)

∀ j,k ∈ J

AB

: x( j, k) = 1

(4)

t

e

1

( j) ≥ 1

t

e

2

( j) ≥ T

1

t

e

2

( j) + d( j) ≤ T

2

∀ j ∈ J (5)

With the objective function (1) the maintenance costs,

i.e. the sum of the costs for traveling between the jobs

and the daily costs, are minimised.

JobOrderAssignmentatOptimalCostsinRailwayMaintenance

157

The maintenance machine starts at t

start

in track

section A and will be parked at track section B, when

all jobs are resolved. The execution times of the re-

spective jobs j

A

and j

B

are defined in equation (2).

Binary variables x( j, k) state whether two jobs are re-

solved directly one after the other and thus if travel

costs occur or not (see (3)). A distinction whether two

jobs are on consecutive track sections is not necessary

because the travel time and travel costs between jobs

of consecutive track sections are zero. By constraint

(4) and (5) it is ensured that the scheduled execution

times are feasible.

The problem can be reduced to a job order

assignment problem. Instead of determining the

explicit execution time for each job, the order

J

O

= ( j

1

, j

2

, ..., j

n

) to resolve the jobs j

i

∈ J has to be

specified. Then for the order ( j

A

, j

1

, j

2

, ..., j

n

, j

B

) the

minimal feasible execution times are calculated based

on the equations (2)–(5).

The tamping scheduling problem is similar to the

travelling salesman problem. Instead of visiting cities

jobs are resolved. The main difference is the objective

function. Not only the costs for travelling between

the jobs are minimised, but also the daily costs, that

depends on the execution day, have an influence on

the solution quality.

Also, the problem shows resemblance to the rural

postmen problem (a variant of the Chinese postman

problem). There a shortest closed path is searched in

a graph that pass through an edge subset. The graph is

given by the track network and the edges are the track

sections with a job. Again, the objective function dif-

fers because of the daily costs.

Both problems are NP-hard, thus the tamping

scheduling problem is NP-hard, too.

3 GREEDY HEURISTICS

Dependent on the ratio between daily and travel costs

different solution approaches are reasonable. For ex-

ample, if the daily costs of all jobs are zero or very

small, a heuristic that minimises travel costs leads

to good results. Contrariwise, if the travel costs are

much lower than the daily costs it is important to pre-

fer jobs with high daily costs, even if this causes de-

tours. Three different greedy heuristics are presented,

which show good results in different benchmarks. All

greedy heuristics follows the same procedure, see Al-

gorithm 1.

Starting with an arbitrary job k ∈ J the job order

J

O

(k) = (k) is built up step-by-step: A job j ∈ J that

is not contained in the job order so far is selected by a

heuristic-specific selection criterion and added to the

Algorithm 1: General Greedy Heuristic procedure.

J

∗

O

:= ();

z

∗

:= ∞;

for k ∈ J do

J

O

(k) := (k);

repeat

select j ∈ J \ J

O

(k);

append j at the end of J

O

(k);

until J \ J

O

(k) ==

/

0;

determine execution times;

calculate maintenance costs z(J

O

(k));

if z(J

O

(k)) < z

∗

then

z

∗

:= z(J

O

(k));

J

∗

O

:= J

O

(k);

end

end

return J

∗

O

end of J

O

(k). This step is repeated until all jobs are

contained of the job order. Then j

A

and j

B

are added

to complete the order, the execution times are deter-

mined based on the equations (2)–(5), and the costs of

the job order are calculated.

To improve the solution quality a job order J

O

(k)

is generated for each job k ∈ J and the best of these

job orders is selected.

In the following the three selection criterions are

presented. In section 3.4 a comparison of the three

heuristics is made.

3.1 Nearest Job

At each step of Algorithm 1 the nearest uncontained

job, thus the one with the lowest travel costs to the

last job in the order, is selected and added. If there

are two or more jobs with the same distance, then the

job with the highest daily costs is chosen.

With the Nearest Job Greedy Heuristic the travel

costs are kept small, but the daily costs play a minor

role in the decision process.

3.2 Most Expensive Job

At each step of Algorithm 1 the most expensive job

is selected and added to the job order. If there is

more than one job with the same costs, the nearest

of them is selected. In our model it is assumed that

the daily costs of consecutive track sections typically

fluctuate. Then these selection criterion leads to high

fragmented solutions. Often the machine travels to re-

solve only a single job, and then travels to a different

track section for the next job. To avoid such a frag-

mentation of the job order, direct neighboured jobs

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

158

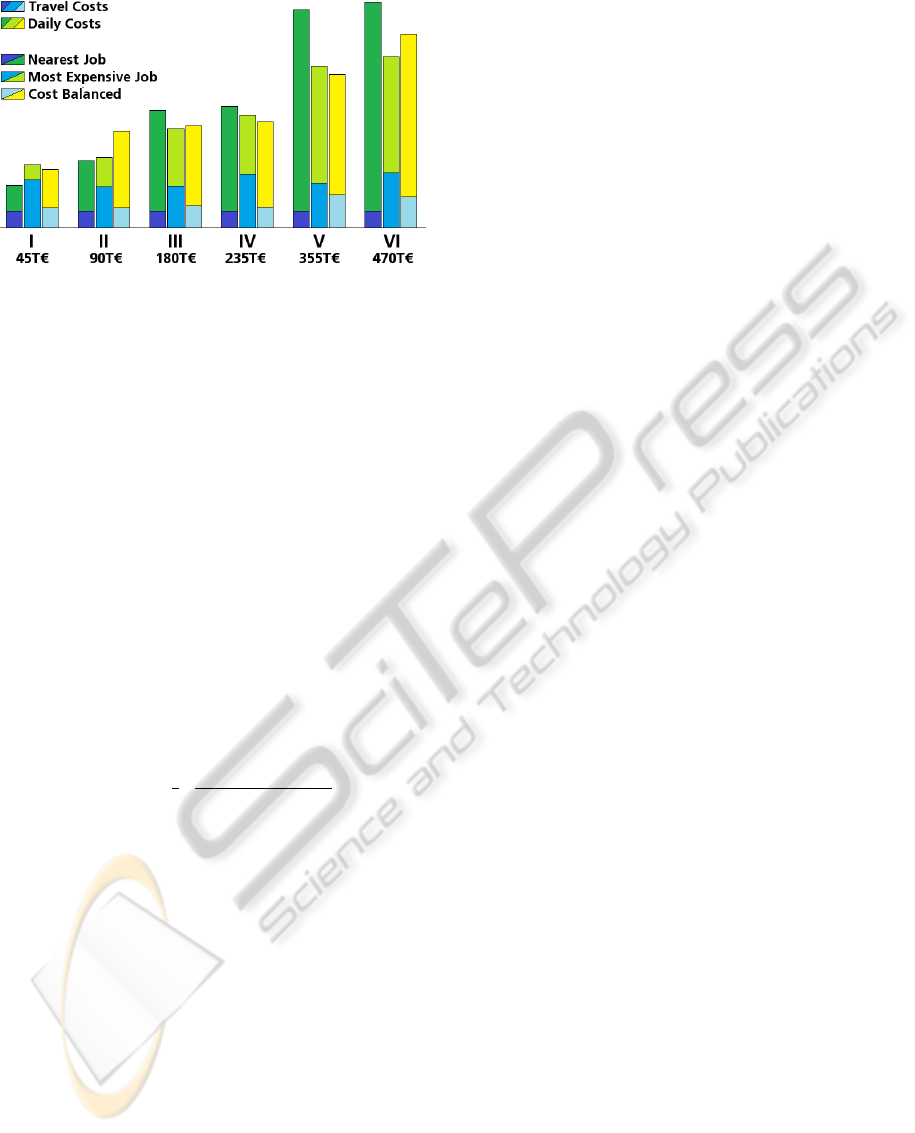

Figure 1: Results of the three greedy heuristics in six bench-

marks.

are preferred. That means if there is a job that could

be reached without traveling and has daily costs in the

same cost range as the most expensive one, this job is

added instead of the most expensive job.

The Most Expensive Job Greedy Heuristic usually

results in a job order where the jobs with non-zero

daily costs are always added first. The jobs with-

out daily costs are added similar to the Nearest Job

Greedy Heuristic.

3.3 Cost Balanced

Here, both costs are considered by defining a com-

bined cost measure. With this the travel costs and a

very rough estimation for the savings in daily costs

are summed. For each job that is not contained in the

job order the cost measure is calculated by

m

c

( j) = c

t

( j

l

, j)− α · c

d

( j)

with α =

1

2

·

# unresolved jobs

# jobs resolved per day

(6)

where j

l

is the last job in the current order and α is

an estimation on the number of days the job will stay

unresolved until now. If one of the direct neighboured

jobs has daily costs in the same cost range as j

l

, this

job is chosen. Again, this avoids a fragmentation of

the solution like in the Most Expensive Job Greedy

Heuristic. Otherwise the job with the minimal cost

measure m

c

is selected.

With the Cost Balanced Greedy Heuristic both

kinds of costs are considered in the decision process.

3.4 Comparison

The three greedy heuristics are tested in different

benchmarks. In Figure 1 the results of the heuristics

are compared in six benchmarks (I–VI). All bench-

marks are built up of 1415 jobs on a network with

more than 1400 km of track. 353 of them are af-

flicted with daily costs ranging from 45,000 e per day

(benchmark I) up to 470,000 e in benchmark VI. The

jobs with non-zero daily costs are located in the cen-

tre of the track network. The travel costs are 1000 e

per kilometre. To resolve all jobs at least 184,500 e

have to be paid for travelling.

In the bar graphs the travel costs (lower part) and

the daily costs (upper part) are stacked. The left bar

shows the results of the Nearest Job Greedy Heuristic

(short NJ), in the middle bar the results of the Most

Expensive Job Greedy Heuristic (MEJ) are plotted,

and the right bars represents the results of the Cost

Balanced Greedy Heuristic (CB).

Due to the fact that the benchmarks only differ in

the daily costs, NJ always generates the same solu-

tion for a certain first job k ∈ J. In each benchmark

the same job order J

∗

O

is selected and thus always the

same travel costs occur. Only the daily costs differ

due to the different daily costs in the benchmarks.

Benchmark I – III and V are very similar: in

benchmark II the daily costs of benchmark I are dou-

bled, in benchmark III they are fourfold and in bench-

mark V the costs are eightfold.

In benchmark I and II the share of the daily costs is

low. NJ starts with the most expensive track sections

and resolves the other jobs without much traveling.

This leads to a plan with low travel and daily costs.

The heuristic CB leads to a solution with higher daily

and higher travel costs than NJ. One reason is that

the daily costs are underestimated and that the jobs

with non-zero daily costs are resolved as long as the

detour is short. So the travel costs are higher as with

NJ and there are no savings in daily costs. By MEJ the

jobs afflicted with daily costs are resolved first. This

leads to long detours and to an increase in travel costs,

which cannot be compensated by the savings in daily

costs.

In benchmark III NJ obtains the same plan as in

benchmark I and II, but the daily costs are much

higher, so the expensive jobs should be preferred.

Also with CB the daily costs are underestimated and

thus they have a high share in the costs of the job or-

der. By MEJ the most expensive jobs are resolved first

with long detours, but this time this can be is compen-

sated by the savings in daily costs.

In benchmark V the daily costs have a huge share in

the overall costs. The cost measure of jobs with non-

zero daily costs is low and these jobs will be resolved

first. Because of the consideration of travel costs in

the decision process CB leads to better results than

MEJ. The detours are shorter, but the jobs afflicted

with daily costs are nevertheless resolved first.

In the benchmark IV and VI the daily costs differ

even more. There are 115 jobs with high daily costs

in the centre of the network on a line. The other jobs

JobOrderAssignmentatOptimalCostsinRailwayMaintenance

159

have only small daily costs and are located around.

Resolving the jobs with small daily costs first leads

to long detours, which could be compensated by the

savings in daily costs only in benchmark VI. In bench-

mark IV the small daily costs are low enough, so that

long detours to resolve them are not necessary. There-

with CB obtains the best result.

The heuristics have also been tested in further

benchmarks, with different jobs on the network and

different assignments of daily costs to jobs. We no-

ticed that it is hard to predict which heuristic obtains

the best result. But some statements are possible:

• If the daily costs have a small share in the mainte-

nance costs, then NJ and CB obtains good results,

because they minimise the travel costs.

• If the daily costs are high and scattered over the

track network, then CB obtains the best results.

MEJ resolves the expensive jobs more ordered by

daily costs and thus travels crisscross through the

network, where CB resolves the expensive jobs

first, too, but ordered by location. The resulting

savings in travel costs compensate the small in-

crement in daily costs.

• If the daily costs are medium or high and clus-

tered, then MEJ obtains good results, because of

the lower travel effort. Within CB the daily costs

often are underestimated in this type of bench-

marks, which leads to worse results.

4 ISSUES OF INTEREST FOR

FURTHER RESEARCH

The model presented in section 2 will be extended by

some additional points, see section 4.1.

In the further research solution approaches will

be developed that are suitable for arbitrary ratios be-

tween daily and travel costs, and that can handle the

additional restrictions from the model extension. The

metaheuristic Simulated Annealing (section 4.2) and

a multilevel solution approach (section 4.3) will be

implemented and compared in terms of solution qual-

ity and computation time in different benchmarks.

4.1 Model Extension

(1) K machines are available to resolve the jobs. So

K disjunctive job orders have to be defined and non-

simultaneous restrictions must be considered (e.g. a

minimal distance must be kept between two tamping

machines).

(2) Maintenance is not always possible. Due to night

trains, freight traffic, and other maintenance activities

the possible execution times of a certain job will be

restricted. In the model time windows will be defined

for each job when maintenance is possible. If the time

window ends before the maintenance works are fin-

ished, the crew must leave the track and wait for the

next time window.

(3) Consideration of depots. In some railway net-

works it is not possible or not common that the main-

tenance machine stays close to the track over the day.

There the machine stays in a depot. Then not only the

jobs are scheduled, but also the best depot to stay over

day must be determined and additional travel costs

must be considered.

4.2 Simulated Annealing

The basic idea of Simulated Annealing comes from

annealing processes in metallurgy. After heating the

metal the atoms are inordinated. Through the slow

cooling process they have enough time to order them-

self and to form crystals. This leads to a low-energy

state.

The algorithm starts in the “hot stage” with a

initial solution s and a high temperature T . Then

the solution ˜s is created by modifying s. Depen-

dent on the temperature T , the probability P(s, ˜s,T ) =

min{1, e

z(s)−z(˜s)

T

} to accept ˜s is calculated. If ˜s is ac-

cepted, then s := ˜s. After that the temperature is

cooled. This step – modify solution s, accept the mod-

ified ˜s with probability P(s, ˜s, T ), cool T – is repeated

until a given minimal temperature is reached. Then

the best solution is returned.

The challenge in the design of a proper Simulated

Annealing approach for an optimisation problem is

the definition of a modification heuristic to get the so-

lution ˜s and of a cooling schedule for T . For out tamp-

ing scheduling problem at first methods from solving

the TSP are implemented. The SA starts with a ran-

dom job order. The solution is modified by a 2-opt

method Meer (2007): Two indices 0 ≤ i < j ≤ n + 1

are chosen randomly and the suborder between i and

j is inverted. The temperature T is cooled exponen-

tially. This leads to a fast improvement of the solution

quality, but at the end the solution remains a bit frag-

mented. To smooth the solution a post-optimisation

method will be developed. With this, irregularities –

like jumping over a few jobs and resolve them later –

will be removed without losing the solution structure.

4.3 Multilevel Branch and Bound

Multilevel solution approaches are common methods

in graph partitioning Karypis and Kumar (1996) and

VLSI-design Cong et al. (2005). A multilevel solution

approach consist of three steps:

ICORES2013-InternationalConferenceonOperationsResearchandEnterpriseSystems

160

1. Coarsening: merge objects to super objects

2. Solving: find a (nearly) optimal solution for the

super object problem

3. Refinement: transfer the solution back to the orig-

inal problem and post-optimise

Step 1 is repeated until the number of super objects

fall below a given threshold. Then the small prob-

lem is solved (step 2). Step 3 is executed as often

as step 1. On each level the post-optimisation step

can be used to improve the solution quality. For the

tamping scheduling problem a multilevel Branch and

Bound method seems to be a promising approach. In

practise, mostly some consecutive jobs are resolved

in one working step without travelling. Thus jobs of

consecutive track sections can be merged to one su-

per job. Therewith the problem size is decreased and

the application of exact methods, like a Branch and

Bound approach, is possible. The solution obtained is

transferred back to the original problem. In the post-

optimisation step the super job structure will be bro-

ken by rearranging single jobs in order to improve the

solution.

ACKNOWLEDGEMENTS

We acknowledge the financial support from the Eu-

ropean Communitys Seventh Framework Programme

under Grant Agreement no. 265954, ACEM-Rail

project. The EC is not liable for the use that can be

made of the information contained herein.

REFERENCES

Budai, G., Dekker, R., and Kaymak, U. (2009). Genetic

and memetic algorithms for scheduling railway mainte-

nance activities. Technical report, Econometric Institute,

Erasmus University Rotterdam.

Budai, G., Huisman, D., and Dekker, R. (2004). Schedul-

ing preventive railway maintenance activities. Technical

report, Econometric Institute, Erasmus University Rot-

terdam.

Cong, J., Fang, J., Xie, M., and Zhang, Y. (2005). Mars-a

multilevel full-chip gridless routing system. Computer-

Aided Design of Integrated Circuits and Systems, IEEE

Transactions on, 24(3):382 – 394.

Gorman, M. F. and Kanet, J. J. (2010). Formulation and

solution approaches to the rail maintenance production

gang scheduling problem. Journal of Transportation En-

gineering, 136:701–708.

Higgins, A. and Ferreira, L. (1999). Scheduling rail track

maintenance to minimise overall delays. In Proceedings

of the 14th International Symposium on Transportation

and Traffic Theory.

Karypis, G. and Kumar, V. (1996). Parallel multilevel graph

partitioning. In Parallel Processing Symposium, 1996.,

Proceedings of IPPS ’96, The 10th International, pages

314 –319.

Meer, K. (2007). Simulated annealing versus metropo-

lis for a TSP instance. Information Processing Letters,

104(6):216 – 219.

Miwa, M. (2002). Mathematical programming model anal-

ysis for the optimal track maintenance schedule. QR of

RTRI, 43:131–136.

Oyama, T. and Miwa, M. (2006). Mathematical modeling

analyses for obtaining an optimal railway track mainte-

nance schedule. Japan J. Indust. Appl. Math., 23:207224.

Peng, F., Kand, S., Li, X., and Ouyang, Y. (2011). A heuris-

tic approach to the railroad track maintenance scheduling

problem. Computer-Aided Civil and Infrastructure Engi-

neering, 26:129–145.

Quiroga, L. M. and Schnieder, E. (2010). A heuristic ap-

proach to railway track maintenance scheduling. WIT

Transactions on The Build Environment, 114:687–699.

Vale, C., Ribeiro, I. M., and Calc¸ada, R. (2012). Integer

programming to optimize tamping in railway track as

preventive maintenance. Journal of Transportation En-

gineering, 138:123–131.

JobOrderAssignmentatOptimalCostsinRailwayMaintenance

161