A Computerized System, the FANDAS Code, for Design, Flow,

Performance and Noise Predicitions of Industrial Axial FAN

Chan Lee and Hyun Gwon Kil

Department of Mechanical Engineering, University of Suwon, Hwaseong, Korea

Keywords: FANDAS, CFX, Design, Analysis, Optimization, Performance, Noise.

Abstract: FANDAS (FAN Design and Analysis System) code is developed for the design, the performance and the

noise predictions of industrial axial fan. In the FANDAS code, the 3-D geometrical designs for impeller

blades and casing of fan are made through blade angle distribution, camber line determination and blade

airfoil thickness distribution processes along blade span height, and their results are shown in GUI( Graphic

User Interface ) window. Based on the design fan geometry, the FANDAS code automatically predicts the

flow field inside fan and the overall performance map of fan by using flow deviation and pressure loss

models. The noise level and spectrum of designed fan are also evaluated by the FANDAS code which

contains noise analysis models for discrete frequency and broadband noise components of axial fan. All the

performance and the noise prediction results are displayed on GUI windows. The simulation technique of

the FANDAS code is coupled with the CFX code and applied to an actual air-conditioning fan design

practice for optimizing design variables to maximize efficiency and minimize overall noise level of fan. The

optimal fan design obtained from the FANDAS simulation results shows about 10% efficiency

improvement and 11dB noise reduction compared with the commercial market product of a reference

model, and its simulation results are well-agreed with the measurement within a few percent relative error.

1 INTRODUCTION

Axial flow fans are widely used rotating machines in

industrial, ventilation and air-conditioning systems.

However, air-born noise of the axial flow fan is strongly

related with the aerodynamic flow field and the

performance of fan, so the noise control and reduction of

fan must be attempted with the consideration of the

interaction between aerodynamic and acoustic

characteristics. For this reason, the actual fan design

practice in industry calls for reliable analysis method for

predicting both performance and noise level. With the

recent advances in computational fluid dynamics and aero-

acoustic methods, the flow, the performance and the noise

predictions have been being attempted by many previous

researchers (Belamri et al., 2005; Carolus et al., 2007).

However, because their methods are based on

computational fluid dynamics techniques so have still

shortcomings requiring a lot of input data, complicated

modeling work, long computing time and skillful

engineer’s experience for successful iterative computation,

they still remain as analysis tools and can’t be applied to

the actual design stage of axial fan.

Therefore, the present study introduces a simpler and

less time consuming fan design-analysis method,

FANDAS( FAN Design and Analysis System ), for design

and performance/ noise predictions. The fan design

process of FANDAS gives 3-D rotor and stator blade

geometries from fan design requirements and

specification, and can transfer them to CFD code.

FANDAS also analyzes the internal flow field and the

performance of designed fan by combining quasi-3D

inviscid computation scheme, flow deviation and pressure

loss models. With the predicted fan flow field and

performance data, FANDAS predicts the discrete

frequency fan noise at blade passing frequency and its

harmonics due to rotating steady aerodynamic lift and

blade by secondary and tip leakage flows. Broadband

noise of fan is predicted with the use of the correlation

model expressed in terms of the performance parameters.

The present study applies the FANDAS method

coupled with CFX code to optimize actual air conditioning

fan. Through the parametric study by FANDAS, optimal

fan design variables are firstly determined for high

efficiency and low noise, and more optimized fan

geometry is achieved by the 3-D CFD simulation of CFX

code. Furthermore, the FANDAS prediction results are

compared with measured results to verify the reliability

and the prediction accuracy of FANDAS.

331

Lee C. and Gwon Kil H..

A Computerized System, the FANDAS Code, for Design, Flow, Performance and Noise Predicitions of Industrial Axial FAN .

DOI: 10.5220/0004403303310336

In Proceedings of the 3rd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2013),

pages 331-336

ISBN: 978-989-8565-69-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

2 DESIGN AND ANALYSIS

METHOD OF FANDAS

2.1 FAN Blade Design Method

Once fan design requirements are given from the GUI of

FANDAS as shown in Fig. 1(a), FANDAS determines fan

rotor and stator blade geometries by using conventional

design processes through spanwise blade angle

distribution, camber line determination, airfoil thickness

distribution to blade section element stacking. Fig. 1(b)

shows the fan blade geometry designed by FANDAS. For

the design versatility of fan, FANDAS contains various

airfoil geometry data base for NACA, DCA, C4 and even

curved plate, and also can export the designed fan blade

geometry to CFD code.

2.2 FAN Flow and Performance

Analysis Models

Based on designed fan blade geometry, FANDAS

conducts internal fan flow field analysis by the through-

flow technique using the assumption of axisymmetric flow

within fan blades, so all the flow variables such as flow

angle, velocity, pressure loss and so on, are computed on

the pitch-averaged flow surface. The computing scheme of

the present through-flow is applied to each streamline

from hub to tip, and uses and combines inviscid pitch-

averaged Navier-Stokes equation, Euler work equation,

flow angle and pressure loss models. The present flow

angle and pressure loss models use already well-verified

correlations available from open literature and previous

related researches (Lieblein, 1959; Lieblein, 1960;

Horlock and Lakshiminarayana, 1973; Koch and Smith,

1976; Lee and Chung, 1991).

It is noted all the flow angle and pressure loss models

are very complicated functions expressed in terms of

various fan blade design parameters and flow variables, so

the through-flow analysis requires iterative computation

process. Once iterative computation on flow filed is

carried out until satisfying overall and local mass

conservations, spanwise flow distributions for all the flow

variables can be achieved and then overall performance

parameters such as pressure rise, power and efficiency are

also calculated by the mass-averaging of computed flow

variables along blade span height( Refer to Fig. 1(c) and

Fig. 1(d) ).

2.3 FAN Noise Analysis Models

After the flow distribution and the fan operating condition

are determined by above-mentioned through-flow method,

fan noise level and spectrum are predicted by the noise

analysis method of FANDAS that is constructed as a

combination of two models for the discrete frequency

noise due to BPF ( blade passing frequency ) and blade

interaction, and for the broadband noise due to turbulent

boundary layer and wake vortex shedding. The discrete

(a) Input data window

(b) 3-D blade geometry design

(c) Spanwise flow velocity and angle distributions

(d) Aeroacoustic performance map

Figure 1: FANDAS input and output results.

frequency noise for rotating steady fan blade thrust is

analyzed by Gutin’s theory(Wright, 1976 ) where fan

blades are assumed as compact moving sources, and its

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

332

sound pressure level at BPF or its harmonics can be

expressed by the following equation:

baemB

eo

T

mB

mBMmBJ

MRa

NL

SP

)cos()

sin

sin(cos

dr

sc

cVBdrBL

m

span span

T

)]tan(tancos

)/(

2

2

1

[

21

2

o

e

e

ee

b

e

a

a

Nr

M

Mr

b

r

c

mBx

x

x

2

,

cos2

,

2

,,

sin

(1)

where SP

mB

is peak sound pressure at mB mode( B: no. of

fan blade, m: 1,2,3 … ), N is fan rotating frequency, L

T

is

total steady lift of fan blades which is determined by

combining cascade theory for section lift(l) and predicted

through-flow field results for flow angle(), and

velocity(V). Here, r

e

is effective radius as the 80% of fan

blade tip radius and c, b and β are fan blade chord, span

and setting angles. In addition, a

o

, R and σ represent the

speed of sound, the measuring distance and the elevation

angle form fan blade tip respectively.

The blade interaction noise due to the secondary flow

and the tip leakage flow within fan blades is produced also

at multiple BPFs ( mB mode ), and its sound pressure is

expressed by

bawwp

e

e

mB

mBELD

Rr

M

SP

sec

2

e

w

w

w

w

r

w

nB

mB

2

,

)sin(

,

o

o

p

if

if

D

90)sin(

0sincos

(2)

where L

sec

is the lift fluctuation due to secondary and tip

leakage flows, w and E are the width and the number of

load excursion, and means the azimuth angle between

blade tip and sound measuring location. In calculating

L

sec

, the present study assumes the lift fluctuation due to

secondary flow as 20% of steady lift, L

T

, and uses the

Sarajona’s correlation for the tip leakage flow (Lee and

Chung, 1991; Sjolander and Amrud, 1987 ).

The broadband noise is modeled by the Mugridge’s

correlation (Mugridge, 1976 ) as shown in eqn.(3). In his

model, fan sound power level and its spectrum are

expressed in terms of fan performance parameters such as

efficiency, flow and pressure rise coefficients, which can

be predicted through the through-flow analysis mentioned

before in the section 2-1 of this paper.

PWL(f)=K

2

+25 log

10

P

s

–2 +10log

10

Z +F

2

(f) [dB]

Z=[(1-

s

)/

s

] [(

2

+1-+

2

/2)/ ]

3/2

(3)

where Ps, , and s are fan static pressure, flow

coefficient, pressure rise coefficient and efficiency. In

addition, K

2

and F

2

(f) are given by Fig. 2.

As shown in Fig. 3, fan noise levels, sound power and

pressure spectra are obtained from the prediction results

by the above-mentioned fan noise models.

Figure 2: Flow (K

2

) and correction (F

2

) factors.

Figure 3: Fan noise spectrum predicted by FANDAS.

3 FAN DESIGN OPTIMIZATION

BY FANDAS

3.1 FAN Design Requirements

and Specifications

For verifying the reliability of FANDAS in actual fan

design practice, FANDAS is applied to the actual air-

conditioning fan design problem under the following

design requirements:

- Static pressure: 30 mmAq

- Flow capacity: 200 m

3

/min

- Efficiency: maximum

- Sound pressure level: lower than 84 dBA @ 1m

Table 1 also summarizes fan design specifications of this

study.

AComputerizedSystem,theFANDASCode,forDesign,Flow,PerformanceandNoisePredicitionsofIndustrialAxial

FAN

333

Table 1: Fan design specifications and methods.

RPM 1170 Stator chord 0.1 m

Tip diameter 0.63 m No. of stators 11

Hub/tip ratio 0.44 Angle distrib. Free vortex

Rotor chord 0.09-0.11 m

Camber design Circular arc

No. of rotors 8-12

Rotor airfoil NACA65-010

Tip clearance 0.0025 m Stator airfoil Cambered plate

3.2 Parametric Study and CFD

Verification

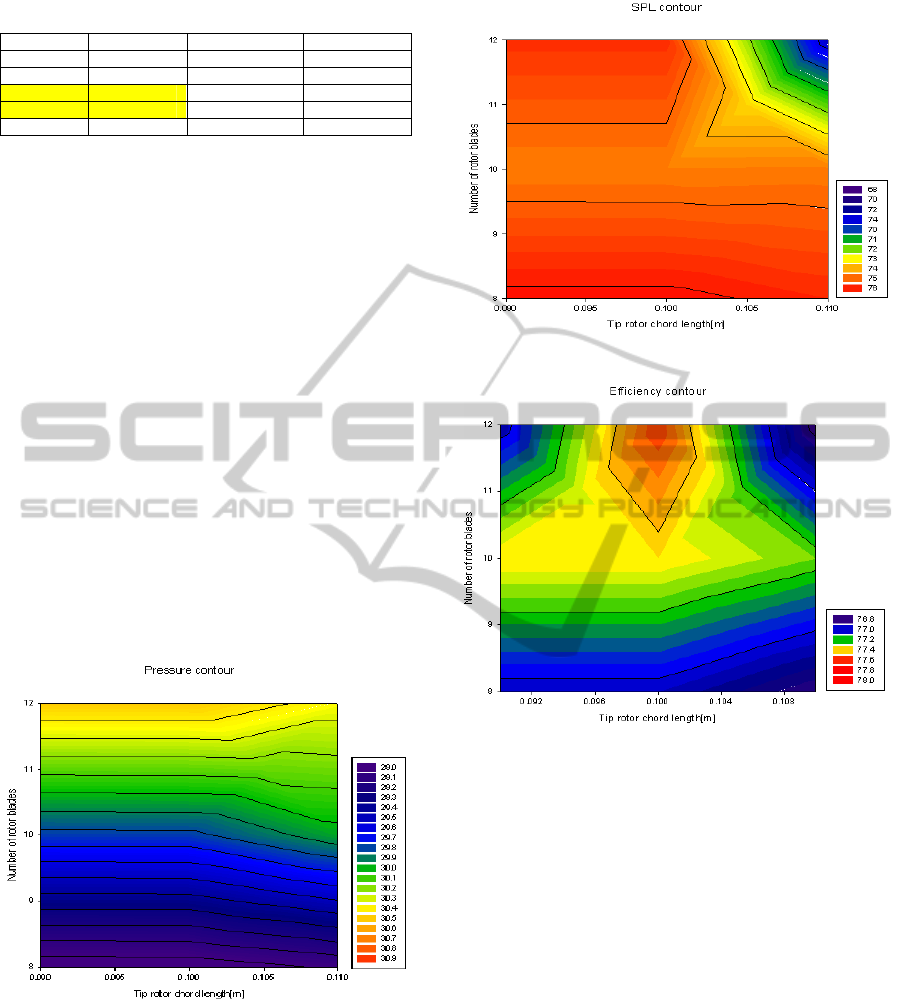

As shown in Table 1, this study is focused to optimize fan

rotor blades design variables such as chord length and

number of rotor blades for maximizing fan efficiency. The

parametric study results on the two design variables by

FANDAS are represented in Figs. 3-5.

From the results of Figs. 4 and 5, it is noted that the

number of rotor blades should be larger than 11 to meet

the design requirements for fan static pressure and noise

level. In addition, Fig. 6 shows the best fan efficiency of

78% is achieved at the rotor chord length of 0.1 m and the

number of rotor blades of 12, which are optimum design

conditions

.

The 3-D CFD simulation by CFX code is carried out

on the firstly optimized fan blades, and uses frozen-rotor

scheme and SST( shear stress transport ) turbulence model

for numerical computation. Fig. 7 shows the computed

results at three spanwise locations by CFX code and they

are compared with FANDAS quasi 3-D analysis results.

The predicted flow angle and velocity distributions are

well agreed between the FANDAS and the CFX.

Figure 4: Parametric studies for fan pressure.

As shown in the CFD results of Fig. 7, the effect of tip

leakage flow is very remarkable at 90% span location

while air flows at hub and mid-span regions are

streamlined along blade section surfaces with no flow

separation. However, in the aspect of pressure loss, the

CFD analysis results show the hub region produces more

pressure loss than the mid-span region. From these CFD

analysis results, it can be judged that the chord length of

rotor blade section at hub can be somewhat reduced to

Figure 5: Parametric studies for fan noise.

Figure 6: Parametric studies for fan efficiency.

decrease the pressure loss within the range to secure

attached and streamlined flow along hub blade surface.

Therefore, final optimal design of fan rotor blade is chosen

with the spanwise chord length distribution from

0.07m(hub) to 0.1m(tip) and the number of blades of 12.

3.3 FAN Performance and Noise Tests

The 3-D shapes of optimized rotor and stator are presented

in Fig. 8, and manufactured fan model is shown also in

Fig. 9. The performance and noise tests for the optimized

fan model are conducted in the chamber test facility of

KTC( Korean Testing Certification ) according to AMCA

and ISO standards. The test results at design point are

compared with the FANDAS prediction results in Table 2,

and they are very well agreed within a few percent relative

error. It is also shown from Table 2 that the optimization

by FANDAS can improve fan efficiency by 10% and

reduce noise level by 10 dB compared with the market

product of Korea, not optimized one.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

334

Figure 7: Flow analysis results by FANDAS and CFX.

Figure 8: 3-D Fan blade geometries(optimized).

Figure 9: Manufactured fan model(optimized).

Table 2: Performance and noise test results.

M

odel

Pred

Flow

m

3

/min

Pressure

mmAq

Effici.

%

PWL

dB

SPL

dBA

O

ptimal

m

odel

FANDAS 200 32.4 78.2 91.3 78.09

Test 200 36.0 75.0 90.0 79.00

M

arket

p

roduct

Test 210 34.5 65.0 101.0 90.00

Figure 10: Aero-acoustic performance map.

Figure 11: FAN noise spectrum.

Fig. 10 compares the aero-acoustic performance

results by FANDAS with the test, and the FANDAS

analysis method is known to give reliable prediction for

the performance and noise level at off-design condition.

Fig. 11 also shows the good agreement between the

FANDAS prediction and the test results on the noise

spectrum at Q=220 m

3

/min.

4 CONCLUSIONS

The FANDAS code is developed with GUI for design,

flow, performance and noise analyses of axial flow fan.

AComputerizedSystem,theFANDASCode,forDesign,Flow,PerformanceandNoisePredicitionsofIndustrialAxial

FAN

335

The FANDAS code is applied to high-efficiency and low-

noise air conditioning fan development case, and its

design results are verified by the comparison with CFD

and test results within a few percent relative errors. The

fan design optimization by the FANDAS code can

improve fan efficiency by 10% and reduce noise level by

10 dB compared with the conventional market product as

baseline one.

ACKNOWLEDGEMENTS

This research work was conducted under the research

grants of the High Efficiency and Low Noise Fan

Technology Development Corporation, the Ministry of

Knowledge Economy.

REFERENCES

A T. Belamri, S. Kouidri, D. Fedala, and R. Rey, 2005,

“Comparative Study of the Aeroacoustic Behavior of

Two Axial Flow Fans with Different Sweep Angles,”

Proceedings of ASME FEDSM'05.

T. Carolus, M. Schneider and R. Hauke, 2007, “Axial

Flow Fan Broad-band Noise and Prediction,” J. of

Sound & Vibration 300, pp.207.

S. Lieblein, 1959, “Loss and Stall Analysis of Compressor

Cascades,” ASME J. of Basic Eng., 81, pp.387-400.

S. Lieblein, 1960, “Incidence and Deviation Angle

Correlations for Compressor Cascades,” ASME J. of

Basic Eng., 82, pp.575-587.

J. H. Horlock and B. Lakshminarayana, 1973, “Secondary

Flows: Theory, Experiment and Applications in

Turbomachinery Aerodynamics,” Annual Review of

Fluid Mechanics, 5, pp. 247-280.

C. C. Koch and L. H. Smith, Jr., 1976, “Loss Sources and

Magnitudes in Axial-Flow Compressors,” ASME J. of

Eng. for Power, 98, pp. 411-424.

C. Lee and M. K. Chung, 1991, “Secondary Flow Loss

and Deviation Models for Through-Flow Analysis of

Axial Flow Turbomachinery,” Mechanics Research

Communications, pp. 403-408.

S. E. Wright, 1976, “The Acoustic Spectrum of Axial

Flow Machines,” J. of Sound & Vibrations, 45(2),

pp.165-223.

S. I. Lee, 1991, A Study on the Development of Acoustical

Design Software for Rotating Machinery, KAITECH-

91-PNR0140.

S. A. Sjolander and K. K. Amrud, 1987, “Effects of Tip

Clearance on Blade Loading in a Planar Cascade of

Turbine Blade,” ASME J. of Turbomachinery, 109(2),

pp. 237-245.

B. D. Mugridge, 1976, “Noise Characteristics of Axial and

Centrifugal Fans as Used in Industry”, Shock and

Vibration Digest, 45(3).

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

336