Numerical Model for the Prediction of Final Mechanical Properties

of EPDM Vulcanized with Peroxides

Part II Results

Gabriele Milani

1

and Federico Milani

2

1

Politecnico di Milano, Piazza Leonardo da Vinci 32, 20133 Milan, Italy

2

Chem.Co Consultant, Via J.F. Kennedy 2, 45030 Occhiobello (RO), Italy

Keywords: Kinetic Numerical Model, EPDM Rubber, Peroxides, Comparison with Experimental Data.

Abstract: In the present Part II, the kinetic numerical model discussed in detail in Part I, is applied to the huge amount

of experimental data collected by the authors. Rheometer curves are fitted numerically for three different

curing temperatures, for all the curing agents investigated at a concentration equal to 150%, which have

proved to be the most adequate to obtain optimal crosslinking of the EPDM under consideration. The

comparisons with experimental data at three different temperatures allow estimating partial kinetic constants

of the model as a function of the absolute temperature, with a direct comparison with simplified formulas

provided by the peroxide producers. The application of the numerical kinetic model to a large variety of real

scale examples allows a direct validation of the capabilities of the approach proposed, as well as an

evaluation of the most suitable production parameters to use in practice (curing time and temperature,

concentration and typology of the curing agents) in order to maximize rubber output mechanical properties

and crosslink homogeneity, without the need to perform costly experimental campaign.

1 INTRODUCTION

To propose ad-hoc numerical models for the

interpretation of vulcanization kinetics is paramount

when producers are interested in a fast and less

expensive (when compared with an experimental

approach) evaluation of the most suitable production

parameters to use in order to optimize rubber output

mechanical properties, as for instance average

tensile strength, elongation at break, tear resistance,

etc., Hofmann (1989), Milani et al. (2013).

The procedure of optimization performed on

production parameters includes –but it is not limited

to- the evaluation of the curing temperature,

typology and concentration of peroxide and

exposition time to use to maximize an a-priori

established characteristic of the vulcanized

compound, Milani and Milani (Milani and Milani

2010), (Milani and Milani, 2012a), (Milani and

Milani, 2013b).

Peroxides producers usually provide simplified

kinetic mechanisms for their peroxides, which

always follow a so called first order Arrhenius

equation. By means of the knowledge of the so-

called half-time life of the peroxide, it is possible to

roughly identify a temperatures interval where the

vulcanization has to be conducted. However, no

information is provided on concentrations, which

usually is fixed following well established rules of

thumb and a change of few degrees in the curing

temperature may result into a strong decrease of the

final quality of the crosslinked items, especially for

thick ones.

In addition, it can be affirmed that, while this

simplified approach may be quite effective for a

rough estimation of the most suitable peroxide to

adopt within standard curing conditions, more

sophisticated approaches are needed when mixtures

of peroxides or extreme curing conditions are

utilized.

Such conditions include drastic reduction of the

curing time, always associated to high vulcanization

temperatures and the uniform vulcanization of item

with thickness varying from moderate to large.

For all the aforementioned cases, the adoption of

simplified procedures progressives become no more

effective and more quantitative approaches are

required.

In this framework, it appears particularly

interesting to utilize a comprehensive numerical

66

Milani G. and Milani F..

Numerical Model for the Prediction of Final Mechanical Properties of EPDM Vulcanized with Peroxides - Part II Results.

DOI: 10.5220/0004423800660073

In Proceedings of the 3rd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2013),

pages 66-73

ISBN: 978-989-8565-69-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

model, based on the actual partial reactions

occurring during vulcanization. The kinetic model

proposed in Part I, suitable to obtain a quantitative

interpretation of the vulcanization process for

EPDM rubber vulcanized with peroxides, is applied

in the present paper to analyze the experimental

results discussed in the companying paper.

Rheometer curves obtained experimentally for the

three curing agents considered are fitted numerically

at three different curing temperatures, at a

concentration equal to 150%, which have proved to

be the most adequate to obtain optimal crosslinking

of the EPDM under consideration. The comparisons

with experimental data at different temperatures

allow estimating partial kinetic constants of the

model as a function of the absolute temperature,

with a direct comparison with simplified formulas

provided by the peroxide producers.

2 EXPERIMENTAL DATA

NUMERICAL

POST-PROCESSING

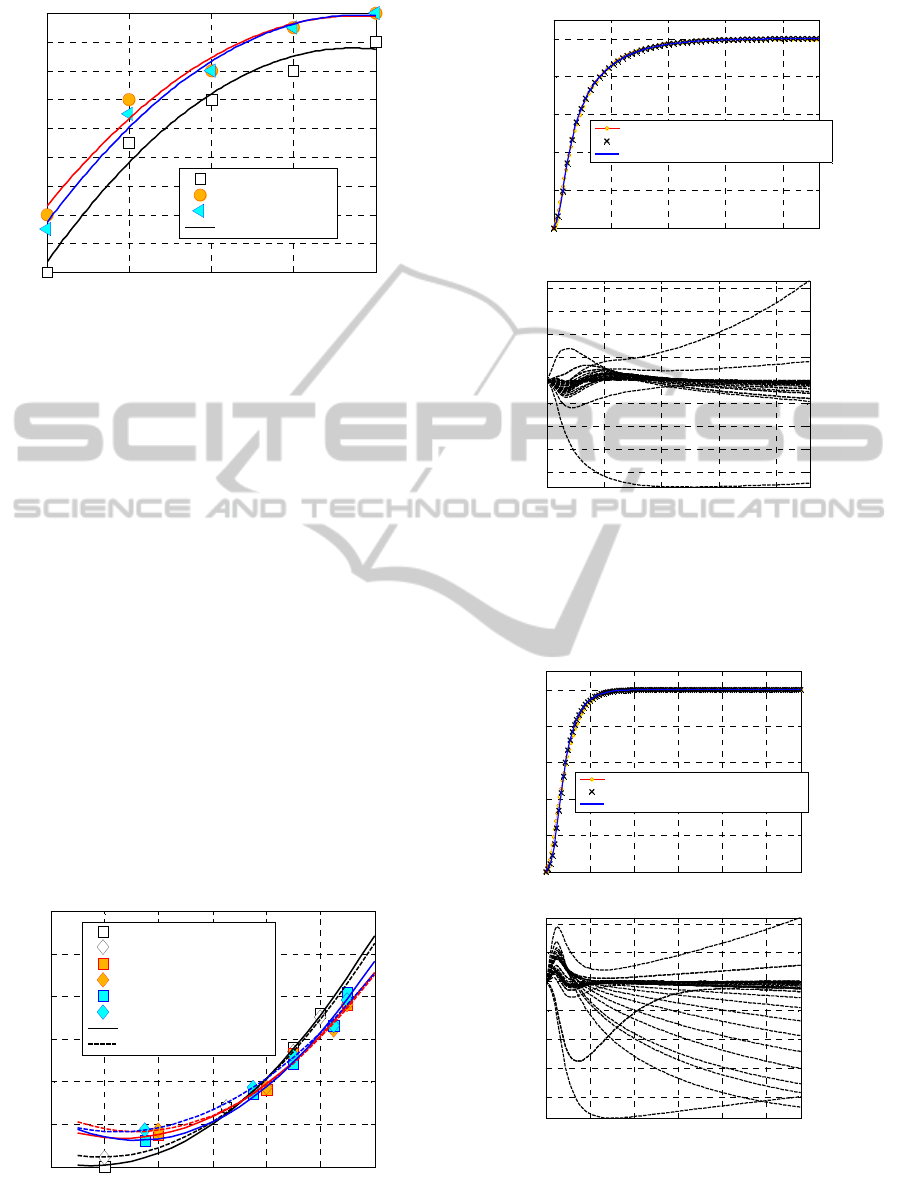

Normalized experimental rheometer curves are

comparatively represented for the three different

peroxides from Figure 1 to Figure 3. In particular, in

Figure 1 results obtained using as curing agent M2

are depicted, in Figure 2 BC-FF data are

represented, whereas in Figure 3 14S rheometer

curves are summarized. Subfigures -a. –b and and –c

refer to temperatures equal to 160°C, 180°C and

200°C respectively.

Normalization is conducted dividing each value

of the torque by the maximum torque, Milani and

Milani (Milani and Milani, 2011), (Milani and

Milani, 2012b), (Milani and Milani, 2013a), which

occurs at the end of the test, since no reversion is

present for all the cases analyzed. The different

curves represented refer to the different

concentrations inspected in the experimental

campaign, namely -50%, +/- 0%, +50%, +100%,

+150%.

As it is possible to notice, there are small but

perceivable differences among the normalized

curves, meaning that curing agent concentration has

some effects on the behavior of the compound

during vulcanization. However, it is particularly

evident that, increasing curing agent concentration,

reticulation exhibits an asymptotic behavior, in all

the cases analyzed. Indeed, rheometer curves

corresponding to +100% and +150% are in practice

superimposable, meaning that, beyond such

concentrations, the reticulation is fully independent

from the curing agent concentration. Experimental

evidences show that crosslinking optimality could be

obtained with at least an amount of peroxide double

with respect to the standard one (100%

concentrations), implicitly stating that the standard

+/- 0% peroxide concentrations provides suboptimal

vulcanized items.

-a

-b

-c

Figure 1: M2 peroxides mixture. Normalized experimental

rheometer curves at different peroxide concentrations. –a:

160 °C. –b: 180 °C. –c: 200 °C.

0 5 10 15 20 25

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [mi n]

Normalized torque M

t

/M

tmax

M2 160°C

-50%

+/-0%

+50%

+100%

+150%

0 5 10 15 20 25

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [mi n]

Normalized torque M

t

/M

tmax

M2 180°C

-50%

+/-0%

+50%

+100%

+150%

0 2 4 6 8 10 12

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [mi n]

Normalized torque M

t

/M

tmax

M2 200°C

-50%

+/-0%

+50%

+100%

+150%

NumericalModelforthePredictionofFinalMechanicalPropertiesofEPDMVulcanizedwithPeroxides-PartIIResults

67

On the other hand, it is worth noting that the

numerical model proposed is independent from

peroxide concentration. As a consequence, data to

consider for the comparisons between numerical

predictions and experimental results should be those

provided with a 150% concentration of the

peroxides.

-a

-b

-c

Figure 2: BC-FF peroxide. Normalized experimental

rheometer curves at different peroxide concentrations. –a:

160 °C. –b: 180 °C. –c: 200 °C.

-a

-b

-c

Figure 3: 14S peroxide. Normalized experimental

rheometer curves at different peroxide concentrations. –a:

160 °C. –b: 180 °C. –c: 200 °C.

Figure 4: Peroxide concentration % versus torque.

Experimental data (points) and parabolic numerical

interpolation.

0 5 10 15 20 25

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [min]

Normalized torque M

t

/M

tmax

BC-FF 160°C

-50%

+/-0%

+50%

+100%

+150%

0 5 10 15 20 25

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [mi n]

Normalized torque M

t

/M

tmax

BC-FF 180°C

-50%

+/-0%

+50%

+100%

+150%

0 2 4 6 8 10 12

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [min]

Normalized torque M

t

/M

tmax

BC-FF 200°C

-50%

+/-0%

+50%

+100%

+150%

0 5 10 15 20 25

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [min]

Normalized torque M

t

/M

tmax

14S 160°C

-50%

+/-0%

+50%

+100%

+150%

0 5 10 15 20 25

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [min]

Normalized torque M

t

/M

tmax

14S 180°C

-50%

+/-0%

+50%

+100%

+150%

0 2 4 6 8 10 12

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time [mi n]

Normalized torque M

t

/M

tmax

14S 200°C

-50%

+/-0%

+50%

+100%

+150%

-50 0 50 100 150

20

25

30

35

40

45

50

55

60

65

Peroxide concentration with respect to standard one [%]

Torque [dNm]

M2 180°C

M2 200°C

BCFF 180°C

BCFF 200°C

14-S 180°C

14-S 200°C

Parabola interpolation 180°C

Parabola interpolation 200°C

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

68

Figure 5: Peroxide concentration % versus tensile strength.

Experimental data (points) and parabolic numerical

interpolation.

To corroborate the idea that a greater concentration

of peroxide with respect to the standard one results

into an optimal crosslink of the EPDM under

consideration, in figures from Figure 4 to Figure 6 a

synopsis of the experimental results available is

represented in graphical form. In particular, in

Figure 4, peroxide concentration % versus torque is

represented for all the curing agents and

temperatures investigated. Experimental data are

represented with points (squares and diamonds refer

to 180°C and 200°C respectively, white, orange and

cyan colors to M2, BC-FF) whereas continuous

(180°C) and dashed lines (200°C) are parabolic

numerical interpolations. In Figure 5, the same

symbols are utilized to represent the relationship

between peroxide concentration and tensile strength,

whereas in Figure 6 tensile strength versus torque is

represented. As it is possible to notice, especially

from Figure 5 , it can be observed that tensile

strength reaches an asymptotic value for 150%

concentrations.

Figure 6: Tensile strength versus torque. Experimental

data (points) and parabolic numerical interpolation.

-a

-b

Figure 7: M2 curing agent, 180°C. Comparison between

experimental data and numerical model. –a: full

normalized curve. –b: difference between numerical

model and experimental normalized torque at successive

iterations.

-a

-b

Figure 8: M2 curing agent, 200°C. Comparison between

experimental data and numerical model. –a: full

normalized curve. –b: difference between numerical

model and experimental normalized torque at successive

iterations.

-50 0 50 100 150

8

9

10

11

12

13

14

15

16

17

Peroxide concentration with respect to standard one [%]

Tensile strength [MPa]

M2

BCFF

14-S

Parabola interpolation

6 8 10 12 14 16 18

20

30

40

50

60

70

80

Tensile strength [MPa]

Torque [dNm]

M2 180°C

M2 200°C

BCFF 180°C

BCFF 200°C

14-S 180°C

14-S 200°C

Parabola interpolation 180°C

Parabola interpolation 200°C

0 5 10 15 20

0

0.2

0.4

0.6

0.8

1

Time [min]

Normalized torque M

t

/M

tmax

M2 +150% 180°C

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

0 5 10 15 20

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

Time [min]

absolute error e

error e=(normalized numeric torque-experimental torque)

N

iter

=1

N

iter

=10

N

iter

=20

N

iter

=30

N

iter

=40

N

iter

=50

0 2 4 6 8 10

0

0.2

0.4

0.6

0.8

1

Time [mi n]

Normalized torque M

t

/M

tmax

M2 +150% 200°C

Present model solution

Experimental data utilized to set numeric al model

Full experimental data curve

0 2 4 6 8 10

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

Time [mi n]

absolute error e

error e=(normalized numeric torque-experime ntal torque)

N

iter

=1

N

iter

=10

N

iter

=20

N

iter

=30

N

iter

=40

N

iter

=50

NumericalModelforthePredictionofFinalMechanicalPropertiesofEPDMVulcanizedwithPeroxides-PartIIResults

69

To perform a numerical optimization of the kinetic

model proposed, experimental cure values are

normalized dividing each point of the curve by the

maximum torque values, so that experimental data

are always within the range 0-1.

A comparison between present numerical curves

and experimental data is provided from Figure 7-a to

Figure 12-a for EPDM vulcanized with M2, BC-FF

and 14-S at 180°C and 200°C respectively. The

resultant kinetic constants found numerically are

summarized in Table 1.

Numerical curves are obtained using a non-linear

least square procedure, for which the convergence

performance is evaluated from Figure 7-b to Figure

12-b. In particular, in the figures, the absolute

difference between normalized experimental torque

and numerical predictions is represented, at

successive iterations and at increasing instants

between the initial and final time of

experimentation. Obviously, as expected, passing

from the initial iteration to the final, such difference

decreases drastically, meaning that the least square

routine is achieving convergence. As it is possible to

notice, the gap between numerical models and

experimental data tends to zero for almost the

instants inspected, exception made for the initial

simulation range, near scorch point.

-a

-b

Figure 9: BC-FF, 180°C. Comparison between

experimental data and numerical model. –a: full

normalized curve. –b: difference between numerical

model and experimental normalized torque.

-a

-b

Figure 10: BC-FF, 200°C. Comparison between

experimental data and numerical model. –a: full

normalized curve. –b: difference between numerical

model and experimental normalized torque.

-a

-b

Figure 11: 14-S, 180°C. Comparison between

experimental data and numerical model. –a: full

normalized curve. –b: difference between numerical

model and experimental normalized torque.

0 2 4 6 8 10

0

0.2

0.4

0.6

0.8

1

Time [mi n]

Normalized torque M

t

/M

tmax

Mixer Perkadox BC-FF 180°C

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

0 2 4 6 8 10

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

Ti me [mi n]

absolute error e

error e=(normalized numeric torque-experimental torque)

N

iter

=1

N

iter

=10

N

iter

=20

N

iter

=30

N

iter

=40

N

iter

=50

0 1 2 3 4 5

0

0.2

0.4

0.6

0.8

1

Time [mi n]

Normalized torque M

t

/M

tmax

Mixer Perkadox BC-FF 200°C

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

0 1 2 3 4 5

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

0

Time [min]

absolute error e

error e=(normalized numeric torque-experimental torque)

N

iter

=1

N

iter

=10

N

iter

=20

N

iter

=30

N

iter

=40

N

iter

=50

0 2 4 6 8 10

0

0.2

0.4

0.6

0.8

1

Time [mi n]

Normalized torque M

t

/M

tmax

Mixer Perkadox 14S-FL 180°C

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

0 2 4 6 8 10

-0.7

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

Time [mi n]

absolute error e

error e=(normalized numeric torque-experimental torque)

N

iter

=1

N

iter

=10

N

iter

=20

N

iter

=30

N

iter

=40

N

iter

=50

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

70

Table 1: numerical results obtained after least square

optimization for kinetic constants

i

K

.

Temp

1

K

2

K

3

K

4

K

[°C] 1/min 1/min 1/min 1/min

M2

0.055 0.190 0.00 0.00 0.055

0.327 0.513 0.00

1.28

e-4

0.327

2.284 1.319 1.13 e-4

8.70

e-4

2.284

BC-

FF

0.069 0.301 0.00 0.00 0.069

0.491 0.602 0.0001 0.0002 0.491

2.401 2.330 0.0002 0.0001 2.401

14-S

0.048 0.191 0.00 0.00 0.048

0.312 0.473 0.00 0.00 0.312

2.221 1.126 9.46 e-5

3.45

e-5

2.221

-a

-b

Figure 12: 14-S, 200°C. Comparison between

experimental data and numerical model. –a: full

normalized curve. –b: difference between numerical

model and experimental normalized torque.

Here the experimental curve exhibits a sudden

increase in the first derivate, meaning that the

initiation of vulcanization is prone to occur. In any

case, this stage is of little interest for the models

proposed, which are designed for a reliable

prediction of final reticulation level. In general, the

agreement with experimental response seems rather

promising, with an almost perfect superposition of

the numerical curves with experimental data.

The convergence map of the least-square

algorithm shows that after around 50 iterations the

best fitting is always achieved, with errors in

practice vanishing. The numerical values of the four

kinetic constants defining completely the reaction

kinetic are summarized for all peroxides

investigated, in

Table.

-a

-b

-c

Figure 13: Linear regression interpolation of the kinetic

constants

1

K

and

2

K

provided by the single differential

equation model, the resultant linear regression obtained as

1

K

+

2

K

and comparison with commercial data provided

by Akzo Nobel for the peroxide under consideration. –a:

M2. –b: BC-FF. –c: 14-S.

0 1 2 3 4 5 6 7

0

0.2

0.4

0.6

0.8

1

Time [mi n]

Normalized torque M

t

/M

tmax

Mixer Perkadox 14S-FL 200°C

Present model solution

Experimental data utilized to set numerical model

Full experimental data curve

0 1 2 3 4 5 6

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

Time [mi n]

absolute error e

error e=(normalized numeric torque-experimental torque)

N

iter

=1

N

iter

=10

N

iter

=20

N

iter

=30

N

iter

=40

N

iter

=50

1.9 2 2.1 2.2 2.3 2.4 2.5 2.6

x 10

-3

-3

-2

-1

0

1

2

3

Mixer M2 curing agent

1/T [K]

log(Ki)

K

1

=K

10

e

E

a

/R

g

T

K

2

=K

20

e

E

a

/R

g

T

1/3[2*log(K

1

)+log(K

2

)]

Numerical data K

1

Numerical data K

2

1.9 2 2.1 2.2 2.3 2.4 2.5 2.6 2.7

x 10

-3

-4

-3

-2

-1

0

1

2

Perkadox BC-FF

1/T [K]

log(Ki)

K

1

=K

10

e

E

a

/R

g

T

K

2

=K

20

e

E

a

/R

g

T

1/3[2*log(K

1

)+log(K

2

)]

AkzoNobel commercial data

Numerical data K

1

Numerical data K

2

1.8 2 2.2 2.4 2.6 2.8

x 10

-3

-6

-5

-4

-3

-2

-1

0

Perkadox 14S

1/T [K]

log(Ki)

K

1

=K

10

e

E

a

/R

g

T

K

2

=K

20

e

E

a

/R

g

T

1/3[2*log(K

1

)+log(K

2

)]

AkzoNobel commercial data

Numerical data K

1

Numerical data K

2

NumericalModelforthePredictionofFinalMechanicalPropertiesofEPDMVulcanizedwithPeroxides-PartIIResults

71

Considering the numerical values obtained for

the first two constants

1

K

and

2

K

, reported in Table

(the other constants are almost zero, indicating that

no reversion is experienced) at two distinct

temperatures, it appears interesting to plot the

straight lines passing from such values in the

Arrhenius plane. In such space, the horizontal axis is

represented by the inverse of the absolute

temperature,

T/1

, whereas the vertical axis is

i

Klog

, where

i

K

is the i-th kinetic constant. It is,

indeed, commonly accepted that the variability of a

single kinetic constant follows the so called

Arrhenius law, which may be written as

TR

E

ii

g

ai

eKTK

0

, where

0i

K

is the value of the i-th

kinetic constant at an infinite temperature,

ai

E

is a

constant typical of the reaction and

g

R

is the

universal gas constant. In a

T/1

-

i

Klog

Cartesian

plane, the Arrhenius law is thus represented by a

straight line, intercepting vertical axis at

0

log

i

K

.

Since experimental data are available at two distinct

temperatures, and accepting that each single constant

follows an Arrhenius law, it is possible to sketch

TK

i

lines in the

T/1

-

i

Klog

plane, for both

peroxides under consideration. Such representation

is particularly useful from a practical point of view,

because it allows a direct evaluation of the kinetic

constants describing the velocity of the partial

reactions at any vulcanization temperature. The

straight lines numerically deduced are depicted

inFigure 13. Subfigures refer to peroxides M2 (-a),

BC-FF (-b) and 14-S (-c) respectively. Numerical

data of Table 1, utilized to plot the straight lines, are

also indicated for the sake of clearness. In order to

evaluate if the numerical approach proposed is in

agreement with simplified procedures commonly

used in practice, it is also possible to compare

numerical results with commercial data available for

both peroxides under consideration. In particular,

Akzo Nobel furnishes in tabular form values of the

kinetic constants of both BC-FF and 14-S at three

different temperatures, corresponding to a half-time

life equal to 0.1, 1 and 10 hours respectively. It is

implicitly assumed that the reaction describing

peroxide decomposition is of first order and that the

single kinetic constant associated to such a reaction

follows and Arrhenius law. It is very straightforward

the deduction of the numerical values of the

constants at the three temperatures considered, from

the experimental knowledge of the half time life

2/1

t

, being simply

2/1

2ln tK

i

. No information is

available for M2, which is indeed a mixture of

peroxides.

Since in our numerical model, first and second

reactions occur in series, and the first reaction

produces 2

R

radicals, the comparison with the

simplified practical approach above discussed, may

be attempted considering the weighted average

between constants

1

K

and

2

K

, i.e. plotting the

straight line 1/3*(2 log

1

K

+log

2

K

), again deduced

from present numerical results and represented with

a dash-dot line in Figure 13-b and Figure13-c for

Perkadox BC-FF and Perkadox 14S-FL respectively.

In the same figures, data deduced from commercial

catalogues provided by Akzo Nobel (2012) are

represented with circles. As it is possible to notice,

the agreement is almost perfect, meaning that the

predictivity of the numerical procedure here

presented is very promising.

3 CONCLUSIONS

In the present Part II, the numerical model proposed

in Part I has been validated using the huge amount

of experimental data obtained by the authors, in

presence of three different curing agents with

different concentrations at three increasing

temperatures. The numerical model provides partial

reactions kinetic constants, which are very useful in

practice to determine the optimal industrial input

parameters to use (as for instance vulcanization

temperature and curing time) to obtain the maximum

mechanical properties of the vulcanized items. A

comparison with simplified approaches based on a

single first order kinetic equation shows that very

reasonable results are obtained and, at the same

time, demonstrates that the model proposed

supersedes the classic limitations of the simplistic

procedures commonly used, especially in presence

of reversion or when a mixture of peroxides is

utilized. An interesting correlation between tensile

strength and maximum torques has been also

obtained.

The traditional methods used by producers to

choose the most suitable production parameters, as

for instance a-priori strategies (essentially based on

the rheometer curves) or a-posteriori considerations

(direct tensile tests on the vulcanized rubber) could

be potentially avoided and superseded, after a

careful calibration of the mathematical approach

proposed, with an undoubted advantage in terms of

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

72

time and cost savings. The approach proposed,

finally, may push the research forward when dealing

with the preparation of new rubber compounds and

vulcanization agents, once that a specific output

parameter is considered as target to optimize at the

end of the vulcanization process.

REFERENCES

AkzoNobel (2012). Brochure of organic peroxides,

available at http://www.akzonobel.com/polymer/

Hofmann, W., 1989. Rubber Technology Handbook,

Hanser Publishers, Munich.

Milani, G., Galanti, A., Cardelli, C., Milani, F., 2013.

Peroxide cross-linking of EPDM for medium voltage

cable applications: experimental insight. In: Proc.

183rd Technical Meeting Akron, Ohio Monday, April

22, 2013 - Wednesday, April 24, 2013

Milani, G., Milani, F., 2010. Journal of Mathematical

Chemistry 47(1): 229-267.

Milani, G., Milani, F., 2011. Journal of Mathematical

Chemistry, 48: 530–557.

Milani, G., Milani, F., 2012a. Computers & Chemical

Engineering, 43: 173–190.

Milani, G., Milani, F., 2012b. Journal of Applied Polymer

Science, 124(1): 311–324.

Milani, G., Milani, F., 2013a. Differential model

accounting for reversion for EPDM vulcanized with

peroxides. Journal of Mathematical Chemisty, In

press.

Milani, G., Milani, F., 2013b. Polymer Engineering and

Science, 53 (2): 353-369.

NumericalModelforthePredictionofFinalMechanicalPropertiesofEPDMVulcanizedwithPeroxides-PartIIResults

73