Improving Flow-based Modeling of Enterprise Systems and Modeling

of Custom Warehouse Systems in d

3

fact

Hendrik Renken and Wilhelm Dangelmaier

Heinz Nixdorf Institute, University of Paderborn, F

¨

urstenallee 11, Paderborn, Germany

Keywords:

Material Flow Simulation, Discrete Event Simulation, Material Flow Modeling, Warehouse Modeling.

Abstract:

Due to a restrictive design, current enterprise simulation software has shortcomings when it comes to modeling

complex business processes and custom warehouse systems. Often, standard processes are altered to add

desired functionality. Also, custom (often complex) warehouse components are created by merging readily

available components. Typically, this customization has to be done programmatically, which usually results

in error-prone and hard to maintain simulation models. In this paper we present a concept to improve the

modeling of complex business processes and warehouse systems. Our flexible design allows the combination

of business-processes without any programming. It even allows a process to control several information flows

at once. This comes in handy when implementing custom warehouse systems.

1 INTRODUCTION

Simulating a system to understand its behavior for

certain inputs is a well established scientific method

and is broadly used in both research and the indus-

try. Innovative products as well as their corresponding

manufacturing processes are to be reviewed at regu-

lar intervals in order to improve their efficiency and

productivity. For this task enterprise simulation soft-

ware is widely accepted as an optimization and deci-

sion making tool.

Enterprise systems are characterized by a set of

processes (often also called building blocks) that are

applied in a specific order on simple objects (enti-

ties). Standard-processes found in (almost) every en-

terprise building block library are e.g. entity sources

and sinks, queues, services, buffers, etc. The building

blocks are typically implemented as “black boxes”,

each providing a well-defined function. The blocks

can be connected to form a network of functions

through which the entities will flow during simula-

tion. This allows for rapid and easy development of

processing networks and is called flow-based model-

ing. In a material flow system typically tokens (the

entities) flow through a network of production pro-

cesses (the building blocks). Other examples are: A

document-workflow in a company or pedestrians that

move along a network to reach certain check points.

However, the black box design of the building

blocks found in current simulation software can be

QC

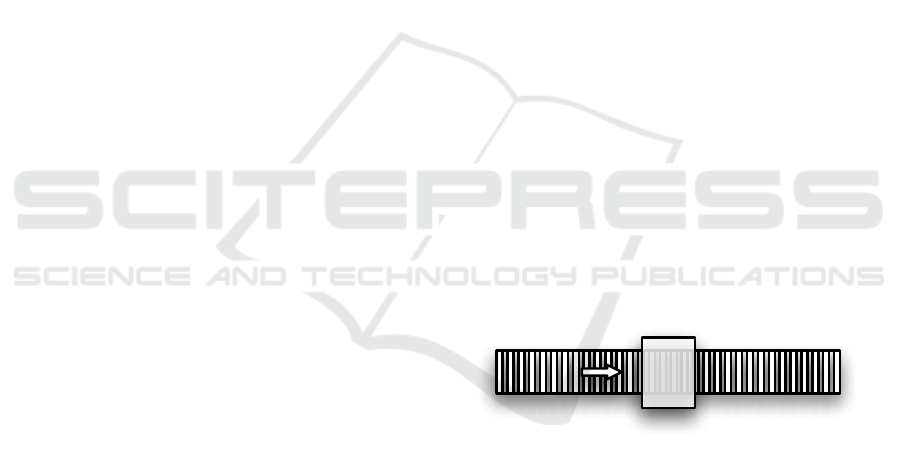

Figure 1: The desired building block: A Conveyor coupled

with a quality control process (QC).

very restrictive. Consider, that you want to extend a

simple conveyor with a quality control process (cp.

Figure 1). Since this is not an of the shelf building

block, you would have to implement a new compo-

nent with the desired behavior. To ease things, most

simulation software allows to extend the integrated

blocks. This is done using a specific programming

language, e.g. Anylogic uses Java (XJ Technologies

Company, 2012b) while Enterprise Dynamics uses its

own Scripting Language called “4D Script” (Incon-

trol Simulation Software, 2012c). That means, you’ll

have to learn the programming language and the inner

workings of the simulation framework you are using.

This workflow is complicated and hard to learn. Cus-

tom building blocks are difficult to create and main-

tain. Usually, they are complex and cannot be reused

in other models. To ease this problem, we propose a

new building block design for flow-based modeling.

Our design distinguishes between the location of an

entity and the function that is applied to it while it

resides in this particular location. For our conveyor

example we would set up a location representing the

conveyor belt and add two processes: The conveyor

94

Renken H. and Dangelmaier W..

Improving Flow-Based Modeling of Enterprise Systems and Modeling of Custom Warehouse Systems in d3fact.

DOI: 10.5220/0004431900940101

In Proceedings of the 3rd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2013),

pages 94-101

ISBN: 978-989-8565-69-3

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

logic to move the tokens within the location and the

quality control process to test the bypassing tokens.

Another advantage is the possibility to associate

a process with several locations at once. This fea-

ture is particularly useful when implementing custom

warehouse systems. Then the process can act as a su-

pervisor while local processes maintain the structural

integrity of the storage locations.

In the following section we briefly present the

concept and its usage. After that an overview over

current flow-based implementations and warehouse

modeling is given. In Section 4 the concept is pre-

sented in detail, followed by a section where the ben-

efits for custom warehouse implementations are dis-

cussed. We will give details about the integration

of the concept into our research simulation platform

d

3

fact and close with a summary and an outlook.

2 CONCEPT OVERVIEW

Earlier we mentioned that in general the black box de-

sign of current enterprise building blocks becomes a

problem when it comes to customizing and extending

readily available building blocks. In order to make the

design more flexible and easier to extend, we wanted

to make the different blocks easy to combine to form

new ones. Also we wanted to be able to do this with-

out having to program any code.

Reconsider the example of the conveyor which we

want to extend with a quality control process (Figure

1). Unfortunately, such a building block is not avail-

able as a standard component in the simulation soft-

ware. Therefore, we have to implement a building

block with the desired behavior by ourselves. Let’s

assume, that each of the two distinct functionalities

Conveyor and Quality Control (QC) are available as

separate standard processes.

This opens up several possibilities:

• First of all, if we have access to the source code,

we can copy it and merge the separate functionali-

ties into a new component. Usually, to implement

this approach we have to learn a new program-

ming language and we need detailed knowledge

about the inner workings of the simulation frame-

work. Furthermore, it is error-prone as we would

have to merge and handle code that is not our own.

• Second, we can attach the standard components to

form the desired building block. This approach is

depicted in Figure 2. The problem here is, that

this setup does not match the original problem.

Here the quality control instance is distinct from

the conveyor and furthermore, there are two con-

veyors used. In this example this argument does

QC

Figure 2: The second approach to implement a conveyor

with a quality control.

not look like a big deal. However, a superior or

customer may question this specific setup and be-

cause of that, the simulation results.

However, with our approach where the location of

an entity is separated from the process behavior, such

a process implementation is quite simple. Because

of the separation, we can associate several processes

with a specific location. Therefore, we can combine

the conveyor-process with the quality control into one

component. This setup closely resembles the reality

and can be implemented by simply combining stan-

dard components (without any programming).

By separating the storage (or location) of the en-

tities from the actual processes we gain a new level

of flexibility. Of course, this approach is not applica-

ble in every situation. Also, this approach cannot be

used to create any desired behavior just through com-

bination. However, with a set of predefined generic

processes, this approach allows for a more fine granu-

lar process and model customization. We can add new

features to a model completely without programming

and without copying code.

3 RELATED WORK

3.1 Flow-based Modeling

Today’s simulation software packages offer very pow-

erful solutions for the modeling, simulation and anal-

ysis of enterprise systems. Often coupled with a

graphical user interface and a dynamic process an-

imation, the user is allowed to model and analyze

a system via drag and drop, e.g. ((Siemens, 2012;

Rockwell Automation, Inc., 2011; XJ Technologies

Company, 2012b)). In the following the general ap-

proach of most professional and commercial pack-

ages will be discussed. The simulation software suites

“Enterprise Dynamics”, build by Incontrol (Incontrol

Simulation Software, 2012a), and “Anylogic” from

XJ-Technologies (XJ Technologies Company, 2012a)

will be used as examples. Modeling a specific system

can be done in many different ways. The set of rea-

sonable approaches often depends on the system that

will be modeled and the used simulation software. To

help the user getting started, current simulation soft-

ware provides specialized products for different mod-

ImprovingFlow-BasedModelingofEnterpriseSystemsandModelingofCustomWarehouseSystemsind3fact

95

eling areas, like “logistics”, “warehouse” or “airport”

(Incontrol Simulation Software, 2012b). The men-

tioned software packages offer flow-based modeling

as an approach to implement enterprise related sys-

tems. Flow-based modeling means to connect build-

ing blocks through defined inputs and outputs to ex-

change entities. Each block then stands for a function

or a behavior that is applied to the entities flowing

through it. The connected building blocks form a net-

work of functions and behaviors.

3.2 Building Block Architectures

In “Enterprise Dynamics” the basic simulation object

is called atom. An atom primarily is an unspecified

object with certain properties, that can react on events

occurring during a simulation run. Using a scripting

language of their own (called “4D Script”) changes

to the behavior of an atom can be made. A simple

inheritance mechanism is available where a derived

atom inherits the script code from the parent.

Anylogic ships with a library for modeling

(generic) enterprise systems and is based also on the

flow-based modeling paradigm. Extending the build-

ing blocks with a new features must be done by ex-

tending the building blocks using the normal java in-

heritance mechanism. To implement our “conveyor

with quality control” example we would have to de-

rive new java types from the available building block

types and re-implementing the new quality control

feature. More flexible simulation language frame-

works, e.g. Simula or GPSS ((Nygaard and Dahl,

1978; St

˚

ahl and AB, 2011)), offer a wider flexibil-

ity, since the model libraries are defined on a less de-

tailed level. Since the programmer is aware of the en-

tire programming interface (API), he is able to easily

implement a new feature. Nevertheless, those frame-

works base their model elements in most cases on a

specific hierarchical type approach. As mentioned by

(Gregory, 2009) and (Renken et al., 2011) these ex-

tension and customization technics can produce hard

to maintain and hard to reuse code and model struc-

tures. Furthermore, they lower the users acceptance

because typically the user has to learn a programming

language and the created structures tend to be error-

prone and hard to debug.

3.3 Warehousing

While there are many applications of warehouse

simulations the number of related works, address-

ing generic and easy-to-use modeling approaches for

warehouse simulations, are very scarce. (Muller,

1989) identifies components that need special atten-

tion when building an automated warehouse system.

He describes three modeling approaches and notes

that the modeling complexity differs for different ob-

jectives and uses. Unlike us he does not outline

generic components which lower the modeling time,

but gives general advices what to consider when mod-

eling a warehouse for different types of simulation re-

sults.

(Takakuwa, 1996) is focuses on AS/RS and uti-

lizes a component (building block) approach. He

presents predefined AS/RS and Automated Guided

Vehicles (AGVs) components that can be combined to

serve different applications. Due to the focus on Au-

tomated Storage and Retrieval Systems (AS/RS) sys-

tems with AGVs the presented components for the

warehouse are not as highly customizable as ours.

The only layout that is supported, is the aisle based

rack layout of AS/RS which is one building block for

which some parameters could be set. Therefore, split-

ting a warehouse in different components is imple-

mented by making AGVs and conveyors parts of the

warehouse. In our simulator there also exists compo-

nents for AGVs and conveyors, but we do not limit

their application to warehousing scenarios.

4 FLEXIBLE BUILDING BLOCK

DESIGN

Let’s review the conveyor example from Section 1 in

detail. The initial problem was to add a quality control

element to an available conveyor component. How-

ever, due to a restrictive component design in most

enterprise simulation software this setup has to be im-

plemented as a custom component. This has to be

done most likely in a specific programming language,

making the whole workflow unintuitive and hard to

master (Gregory, 2009; Renken et al., 2011).

To ease the development of custom components

we propose a different base design for components for

flow-based process networks. Our approach separates

the location of an entity from the processes that are

applied by a specific building block. Figure 3 shows

the concept in general.

On the left side, a typical building block is dis-

played. It encapsulates a process (or function) and

Process

Entities

Behavior

Behavior

Process

Entities

Figure 3: A typical building block (left side) consists of a

function and a location to store entities. In our design (on

the right side) they are separated.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

96

The set of places

Inaccessible entities

Accessible entities

Accessible empty places

Inaccessible empty places

Figure 4: The structure of a location.

a data structure to store entities. During simulation

the function is applied to all entities passing through.

However, in our concept we deliberately separate the

process and data structure (location). Such a location

does not have any functionality. Instead, processes

can be associated with a location, so that they apply

certain functions to entities passing through.

Therefore, we represent the conveyor from the In-

troduction as a location with a conveyor process. The

location resembles the conveyor belt, as the conveyor

belt stores the entities as long as they move over the

conveyor. The process implements the logic to move

the entities over the conveyor belt. By simply adding

the quality control to the location we can implement

the solution discussed in Section 2. We will examine

the different aspects of this solution in more detail in

the upcoming paragraphs.

4.1 Locations

A location represents a place where entities can be

stored until they are processed or requested by another

location. The location concept is a generalization of

storage concepts. It covers a wide range of storages

like workplaces and -tables, warehouses and shelves.

Consider a simple shelf that stores some boxes with

unknown content. Some of the places in the shelf are

occupied by boxes and some are free. Because the

shelf is tightly packed, places in the back of the shelf

can be inaccessible due to boxes in the front. System-

atizing this example results in the following observa-

tions: A storage system of some sort has a specific

number of places (may be infinite) to store entities.

The places may be free or occupied by entities and

they may be accessible or inaccessible. Combining

these two attributes gives us four sets of places as de-

picted in Figure 4.

The location lacks rules or logic to handle model

dynamics, which are added through processes. Pro-

cesses that are attached to the location can make

changes to the four sets by adding(removing) entities

or by setting a place (in-)accessible. The conveyor

process from our example treats places of the location

as discrete places on the conveyor belt. This means,

it has a specific order of the places, treating the first

place as the beginning of the conveyor and the last as

the end. By moving a token from its current place

to the next one (if it’s not blocked) the conveyor me-

chanics are simulated.

4.2 Processes

Processes are associated with one or more locations.

That means, that a process can alter the state of every

place of these locations and may create new entities

and put them into a specific place. A process that

is associated with a location also is informed about

all changes made. Therefore, it is able to react on

changes made by other associated processes.

The conveyor process works as follows: As de-

picted earlier, it has a certain ordering of the places

within the location. The first place, resembling the be-

ginning of the conveyor is always accessible. Tokens

from other locations will arrive here. Arriving tokens

are then moved along the ordered list of places, re-

flecting the movement of the conveyor belt. Also, the

last place (which depicts the end of the conveyor) is

always accessible. That means, that tokens that arrive

at this place can be picked up by adjacent locations

for further processing.

The initial problem was to add a quality control

to the conveyor belt (cp. Figure 1). Implemented as a

process within our concept, this component can be as-

sociated with the conveyor location and furthermore

with a specific place, e.g. as depicted in Figure 1 with

the one in the middle. Now the conveyor process will

move every token past the quality control, where it

can test the token for defects. If a token fails the con-

trol the component can simply remove the token from

the location, making space for the next token.

4.3 Connecting Locations

We use a system that is similar to the channels used

ImprovingFlow-BasedModelingofEnterpriseSystemsandModelingofCustomWarehouseSystemsind3fact

97

by Incontrol in “Enterprise Dynamics” to connect

their building blocks (Incontrol Simulation Software,

2009). But instead of connecting port objects, we are

aware of the different places of a location. Therefore

we can connect the places of the locations (cp. Fig-

ure 5). Several connections are then packed into one

channel.

Figure 5: Three locations (circles) are connected through

channels (lines) with each other. A channel can contain sev-

eral connections (indicated by the number of ends on each

channel side).

A channel moves entities from one location to an-

other (in an atomic transition) only if three conditions

are met:

1. All places on both ends of a channel must be ac-

cessible.

2. All places at the beginning of a channel must con-

tain an entity.

3. All places at the end of a channel must be empty.

Because of these rules, a process can manage how

and when entities move from one location to another

just by managing the state of the places. As shown in

Figure 5 even more complex channel setups are pos-

sible, connecting three locations at once (through one

channel).

Of course, it is possible to implement channels

with additional conditions. This e.g. allows to im-

plement channel-based forks, where a simple switch

controls the destination for the next tokens.

4.4 Analytics Made easier

Another advantage of the representation of arbitrary

storages by a generic location concept is an easy im-

plementation of model analytics. With the black box

design found in common simulation software pack-

ages, arbitrary analytics components are needed for

the different building blocks (Incontrol Simulation

Software, 2009). However, because of the generic

representation and full access to the ongoings within

such an entity location, analytics of common ratios

like lead time, work in process, throughput or uti-

lization can be easily implemented. For example, the

work in process of a set of building blocks simply is

the sum of all entities contained in the associated loca-

tions. Furthermore, the ratios can be reused through-

out different problem domains as long as the entity

storages can be represented by the generic location

concept.

A very deep analysis of the ongoings in a ware-

house are also possible. For example, the utilization

for every single place in the warehouse. With the

full access to the entity movement, we are capable of

tracking the movement for every single entity.

5 CUSTOM WAREHOUSE

BUILDING BLOCKS

The previous section laid the focus on the combina-

tion of different processes into one component. As

mentioned before, our concept also allows the associ-

ation of one process with several locations simultane-

ously. In this section we want to explore this possibil-

ity and its benefits when implementing custom ware-

house processes.

5.1 A Simple Block Storage

Let’s start with a rather simple example - that of a

block storage. A block storage usually holds pal-

letized goods of some sort. There is no supporting

structure like a rack, the goods are just stacked upon

each other.

21

B

D

C

A

3 4

Figure 6: Side view of a block storage. Each rectangle is a

place. The pattern describes the state of the place.

Figure 6 depicts the state of a block storage. Some

goods (e.g. A1, B1, A4, ...) are inaccessible while oth-

ers (C1, C2, A3, B4) can be access (e.g. with a fork-

lift). However, as with the goods, some empty places

are inaccessible, namely C3, D3, D4), and also there

are places where additional goods can be stored (D1,

D2, B3, C4). This concept perfectly matches with

the structure of our locations introduced earlier (Fig-

ure 4). The places of the location are simply mapped

to specific three dimensional coordinates of the block

storage space. A specific block storage process de-

scribes the dynamics of the storage, e.g. that a palette

cannot be stored in midair. Consider that we add a

new palette to B3, then the process would set A3 in-

accessible and C3 accessible.

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

98

5.2 A Complex Rack Storage Setup

Another advantage of the separation of the locations

from processes, is the simultaneous association of a

process with several locations. Figure 7 depicts a

model of a container rack storage with four racks,

three AS/RS and three load/unload areas on each side.

The whole model is described in (Asef-Vaziri and

Khoshnevis, 2000).

(a) The simulated rack storage.

A

0

A

1

A

2

(b) Diagram of the rack storage.

Figure 7: A rack storage for maritime containers. It consists

of four racks, three AS/RS and three load/unload areas on

each end (dotted rectangles).

The storage is used as a buffer in a maritime con-

tainer terminal. Container unloaded from a ship are

stored in the racks until trucks become available to

transport them inland. The same applies for the other

way round. In this scenario the AS/RS take contain-

ers from both ends and store them in one of the two

racks accessible to them. When a ship or truck ar-

rives specific containers are brought to the appropri-

ate load/unload stations. As depicted, each rack can

be accessed from both sides and therefore from two

AS/RS.

In a previous attempt standard components where

used to model the setup. A single AS/RS had to be

implemented as two different entities, one for each

reachable rack. Also, the racks had two rows instead

of one so that two AS/RS could not get into conflict

when accessing a storage place. This approach didn’t

match the originating setup (cp. Figure 7(a)) and fur-

thermore, the synchronization of the two entities rep-

resenting one AS/RS was very cumbersome and error-

prone. In the end we had to reprogram this storage

from scratch to make it functioning as intended.

However, with the architecture described in this

paper such a complex warehousing component can be

implemented much more easily. The most interesting

part in this implementation is the communication of

the AS/RS with each other to avoid conflicts in ac-

cessing the storage and load/unload areas. As we will

see, this communication can be done solely through

state changes on the locations. The initial setup for

A

1

is shown in Figure 8.

A

1

L

R

3

R

2

L

r

L

l

A

0

A

2

Figure 8: The setup for AS/RS A

1

. It is connected to five lo-

cations: Two racks (R

2

, R

3

) and two load/unload areas (L

l

,

L

r

) and a location to store the currently carried container

(L).

The AS/RS itself has one location L where it

stores the one container that it currently carries. Fur-

thermore, it has access to the two load and unload

areas at both sides, depicted as L

l

and L

r

. And, of

course, it can access the two racks R

2

and R

3

- as the

other two AS/RS can (also shown in the figure).

5.2.1 Handling the Load/unload-Areas

The load/unload-areas serve as gateways to the rest

of the model. At any point in time trucks can arrive,

blocking the areas until they have been served by the

AS/RS. However, due to simulation of a warehouse

with particular orders, a supervisor will deploy jobs

for the AS/RS as needed. Such a job contains specific

instructions how to handle a certain container or how

to serve a specific truck.

5.2.2 Accessing the Racks

The places within a rack can be accessed from

both sides and therefore by two independent AS/RS.

Therefore, a synchronization has to take place to

avoid conflicts during access. For example, each of

the two AS/RS might want to store a container in the

same place. This conflict can be resolved in several

ways: First of all, one can make the AS/RS more in-

telligent, allowing them to directly communicate with

each other. Due to the asynchronous setting such a

ImprovingFlow-BasedModelingofEnterpriseSystemsandModelingofCustomWarehouseSystemsind3fact

99

communication protocol can be come very complex

and hard to maintain. Another approach would be

to implement a supervisor for the warehouse system.

This leads to a very complex supervisor which has the

same drawbacks as the solution before.

Instead, in our implementation both AS/RS can

easily communicate through the states of the places.

The places can be seen as a resource that has to be

locked before it can be accessed. An AS/RS can indi-

cate the (future) usage of a particular place simply by

setting a place inaccessible. Either to store a container

(if it’s an empty place) or to handle the container that

is stored in that place.

The communication through the states of the

places within the locations has the advantage that no

explicit communication is required, that is is asyn-

chronously and that no external supervisor or conflict

solver is needed. This makes this approach simple,

clean and easy to understand and implement.

6 IMPLEMENTATION DETAILS

As mentioned earlier, we implemented our concept

into our research simulation platform d

3

fact. Here we

report on some interesting details of the implementa-

tion.

Let a location have n associated processes

p

0

, . . . , p

n

. Now an arbitrary process p

s

∈

{p

0

, . . . , p

n

} makes changes to the location. This cre-

ates an update u

s

containing all information about the

changes, i.e. added and removed entities, now acces-

sible or inaccessible places. Unfortunately u

s

starts an

update cascade. That means, another process p

k

re-

sponds with its own update u

k

to the update u

s

. Now

u

k

again causes another process p

r

to respond, and so

on. A trivial update mechanism would inform each

of the n processes of every update. This can lead to

an efficiency problem. For example one process oc-

casionally creates new entities while another process

destroys them to replace them with completely new

entities. Every associated process now gets both up-

dates, even if the entities created in the first place do

not last long or have been destroyed already. Carry-

ing out each update can lead to a huge overhead when

updates contain oppositional or obsolete information.

Also, processes would have to be capable of deter-

mining the obsolete information in the update or the

differences between the last known and the current

state of the location. This would make the implemen-

tation of new processes more difficult, especially for

new users.

Instead of informing all processes about all up-

dates, we accumulate updates. This reduces the times

a process is informed about updates to a minimum

and the updates do not contain stale information. The

update mechanism we came up with can be found in

Listing 1. It resides in the location implementation.

Changes made by a process to the location trigger the

UPDATE() method. Here the parameter p is the pro-

cess initiating the changes and u is the update initiated

by p.

#p i s t h e s o u r c e p r o c e s s and u t h e u p d a t e

UPDATE( p , u )

put ( u ) → s t a c k

5 # i n f o r m p r o c e s s e s i n f r o n t o f p ab o u t u

0 → i

peek ( s t a c k ) → u

w h i le ( P [ i ] 6= p )

{

10 u → in form ( P [ i ] )

i +1 → i

}

# do n o t i n f o r m p a b o u t u

15 i f ( | s t a c k | > 1 )

{

# merge u w i t h p r e v i o u s u p d a t e

p o l l ( s t a c k ) → v

p o l l ( s t a c k ) → w

20 put ( v ∩ w) → s t a c k

}

e l s e

{

# t h e r e i s o n l y on e u p d a t e l e f t on t h e s t a c k

25 i +1 → i

peek ( s t a c k ) → u

w h i le ( i < | P | )

{

u → info rm ( P [ i ] )

30 i +1 → i

}

p o l l ( s t a c k ) # c l e a r s t a c k

}

Listing 1: The Update-algorithm.

We inform the processes in the order they were

added. If one process happens to start a new update

during a running update we suspend the current up-

date and start from the beginning (with the new up-

date).

Figure 9 shows an exemplified update cascade.

Horizontal lines indicate which process is informed

about which update at which point in time. Horizon-

tally the processes p

0

, . . . , p

n

are shown. The time

line is displayed vertically. A back pointer indicates

the accumulation of two updates. Basically the pro-

cedure starts with an update u

s

. Now we consider

p

k

to be the next process responding to the changes

made by u

s

. That means, that u

s

is applied to all pro-

cesses before process p

k

. Upon informing p

k

about

SIMULTECH2013-3rdInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

100

u

s

p

n

p

0

u

k

u

s+k

u

r

u

l

u

j

u

l+j

u

r+l+j

u

s+k+r+l+j

t

p

l

p

k

p

r

p

j

p

j

p

l

p

r

p

k

p

s

Figure 9: Generic example showing how our update method

works. Horizontally all processes are displayed while the

time line is plotted vertically.

u

s

it triggers a new update u

k

. As stated before we

now start from the beginning, informing all processes

before p

k

(cp. Listing 1, Lines 5-12). After doing so,

all processes p < p

k

are informed about the updates

u

s

and u

k

. Before informing the processes p > p

k

we

merge both updates into the new update u

s+k

elimi-

nating all oppositional information (Line 20, Listing

1). As depicted in Figure 9 this update algorithm can

also handle recursively triggered updates.

7 CONCLUSIONS

In this paper we report on a concept that enhances the

flow-based modeling found in current enterprise sim-

ulation software. The presented concept splits the cur-

rent building block design into a location where enti-

ties are stored and the building block behavior (pro-

cess). Through this separation an arbitrary number of

processes can be associated with a location, enabling

the combination of them. Another advantage is the

possibility to associate a process with a set of loca-

tions. This enables the easy implementation of man-

agement logic like those used in warehousing sys-

tems. Other advantages are the simple analysis of the

systems behavior and the code portability and flexibil-

ity. We showed that our location design covers a wide

range of storage types, like working places, trucks,

machines, shelfs, block storages, etc.

REFERENCES

Asef-Vaziri, A. and Khoshnevis, B. (2000). Performance

analysis of automated technology in maritime con-

tainer terminals. Progress in Material Handling Re-

search, pages 165–178.

Gregory, J. (2009). Game engine architecture. A K Peters,

first edition.

Incontrol Simulation Software (2009). Tutorial ed 8.

Incontrol Simulation Software (2012a). Enter-

prise dynamics. Accessed April, 2012. http://

www.incontrolsim.com.

Incontrol Simulation Software (2012b). Enterprise dy-

namics products. Accessed April, 2012. http://

www.incontrolsim.com/en/products.html.

Incontrol Simulation Software (2012c). Enterprise dynam-

ics technical overview. Accessed April, 2012. http://

www.incontrolsim.com/en/ed-platform/technical-

over view.html.

Muller, D. (1989). As/rs and warehouse modeling. In Pro-

ceedings of the 21st conference on Winter simulation,

pages 802–810. ACM.

Nygaard, K. and Dahl, O.-J. (1978). The development of

the simula languages. SIGPLAN Not., 13(8):245–272.

Renken, H., Fischer, M., and Laroque, C. (2011). An easy

extendable modeling framework for discrete event

simulation models and their visualization. In Proceed-

ings of The 25th European Simulation and Modelling

Conference - ESM’2011.

Rockwell Automation, Inc. (2011). Arena simulation soft-

ware by rockwell automation. Accessed Feb. 1, 2011.

http://www.arenasimulation.com/.

Siemens (2012). Simulation & testing. Accessed April,

2012. http://www.industry.siemens.com/industry

solutions/global/en/cross industry solutions/automat

ion it/simul test/Pages/Default.aspx.

St

˚

ahl, I. and AB, B. (2011). Webgpss - simula-

tion made simple. Accessed Feb. 1, 2011. http://

www.webgpss.com/.

Takakuwa, S. (1996). Efficient module-based modeling for

a large-scale as/rs-agv system. In Proceedings of the

28th conference on Winter simulation, pages 1141–

1148. IEEE Computer Society.

XJ Technologies Company (2012a). Discrete event simu-

lation modeling tool. Accessed April, 2012. http://

www.xjtek.com/anylogic/approaches/discreteevent/.

XJ Technologies Company (2012b). Why anylogic sim-

ulation software? Accessed April, 2012. http://

www.xjtek.com/anylogic/why anylogic/.

ImprovingFlow-BasedModelingofEnterpriseSystemsandModelingofCustomWarehouseSystemsind3fact

101