Detection of Hot Pipe Defects using IR Thermography

Kwae Hwan Yoo

1

, Ju Hyun Kim

1

, Man Gyun Na

1

, Jin Weon Kim

1

Kyeong Suk Kim

2

and Chang-Doo Kee

3

1

Department of Nuclear Engineering, Chosun University, 309 Pilmun-daero, Dong-gu, Gwangju, Korea

2

Department of Mechanical Design Engineering, Chosun University, 309 Pilmun-daero, Dong-gu, Gwangju, Korea

3

School of Mechanical Engineering, Chonnam National Univ., 77 Yongbong-ro, Buk-gu, Gwangju, Korea

Keywords: Infrared Thermography, Wall-thinned Defects, Infrared Camera, Cooling Device, Finite Element Analysis

(FEA), Onpower Inspection.

Abstract: Wall-thinned defects, which are attributable to acceleration of corrosion that is occurred by fluid flow in the

inner pipe, appear in various structures of the secondary system in nuclear power plants (NPPs), playing a

role as a major factor to degrade integrity of pipes. It is required to manage wall-thinned defects not only

when the NPP is under maintenance but also when the NPP is in normal operation. To this end, this paper

developed a test technique to manage such wall-thinned defects based on temperature difference on surface

of hot pipe with use of infrared thermography and cooling device. Finite element analysis (FEA) was

conducted to examine tendency of and test conditions for cooling experiment. Based on the FEA results,

equipment was configured before the cooling experiment was conducted. Then, infrared camera was used to

detect defects in the inner pipe of the pipe specimen that had artificially induced defects. The infrared

thermography developed in this study is expected to help resolve issues related to limitations on the non-

destructive inspection that is currently conducted for NPP’s secondary system and expected to be very

useful on the NPP site.

1 INTRODUCTION

Recently, an increasing number of nuclear power

plants (NPPs) have deteriorated due to long-term

operation, which has led to increase in the number of

cases where NPP operation comes to a stop due to

problems in facilities of NPP’s secondary system.

Such cases show that fatigue, corrosion and wall

thinning cause problems in various structures of

NPP’s secondary system. Among these factors, wall-

thinned defects are attributable to acceleration of

corrosion that is occurred by fluid flow in the inner

pipe. The wall-thinned defects can be found

frequently in carbon steel pipe that has the low

content of chromium (Cr). Such wall-thinned defects

can lead to damage without warning sign in advance

while they can be found frequently in base material

part. Therefore, they are known to be one of the

major factors that degrade integrity of pipe.

A systematic management of wall-thinned

defects requires inspection that is conducted on a

regular basis. In particular, the systematic

managemet requires a close inspection even when

the NPP is in operation. The secondary system of the

NPP is the place to which operator or workers get an

access for their work frequently. Unexpected

damage to pipe may cause social impact that cannot

be compared with loss of or damage to person,

which demonstrates the importance of systematic

management of wall-thinned defects. Consequently,

much attention has been paid to non-destructive

inspection in order to examine integrity of major

facilities while there is an increasing demand on the

non-destructive inspection that is relatively safe and

enables conducting measurement in a quick and easy

way.

Currently, various kinds of non-destructive

inspections are conducted such as ultrasonic testing

(UT), eddy current testing (ECT) and magnetic

particle testing (MT). Such non-destructive

inspections include infrared thermography. The

infrared thermography is expected to help resolve

issues related to limitations on the existing non-

destructive inspection because it is used to examine

defects based on measurement of temperature

difference between defect part and non-defect part.

227

Hwan Yoo K., Hyun Kim J., Gyun Na M., Weon Kim J., Suk Kim K. and Kee C..

Detection of Hot Pipe Defects using IR Thermography.

DOI: 10.5220/0004481602270234

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 227-234

ISBN: 978-989-8565-70-9

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

The infrared thermography is also expected to be

very useful on the site.

Against this background, this study used infrared

thermography to develop cooling device and a

reliable test technique in order to detect wall-thinned

defects in the inner pipe of the NPP that was in

normal operation, which is expected to facilitate

maintenance of plumbing fixtures of NPP’s

secondary system. The results of this study will be

used as basic data for inspection of wall-thinned

defects.

2 THEORETICAL

BACKGROUND

2.1 Infrared Thermography

When an object is cooled from the outside, thermal

diffusion is disturbed on surface of target depending

on existence of defects inside the target. In this case,

insulation effect by defects inside the target causes

temperature difference on the target surface. Infrared

thermography is used to measure temperature on the

surface of target and convert the measurement

results to image before providing image in real time.

Based on the real-time image obtained by using

infrared camera (IR camera), it is possible to

measure shape and location of the defects inside the

target.

Infrared thermography has the following features:

Non-contact technique

Full-field image of stress

Ability to measure energy loss

Easy analysis of results thanks to visual effects

Currently, infrared thermography is applied to

military field, stress analysis, welding monitoring,

evaluation of heat transfer characteristics,

deterioration diagnosis of power facilities, defect

inspection in the composites, and medical diagnosis.

2.2 Theory

All of the objects have temperature that is above the

absolute zero while they emit radiant energy that

corresponds to their temperature.

25

/

(, ) 2

1

hc kT

dR T hc

d

e

(1)

Plank’s constant

34

6.626 10

hJs

Boltzmann’s constant

23

1.380546 10

k

Speed of light

81

2.998 10

cms

The equation (1) describes the Plank’s theory of

black body radiation. According to the theory, a

simple relationship is established between

characteristics of black body radiation (energy

intensity and wavelength) and temperature of black

body. Moreover, radiation amount of wavelength

that is emitted per unit time from black body radiator

is determined only by temperature, which is

characteristic of black body radiation. The

characteristic can be used to calculate temperature of

black body. Infrared thermography enables

measuring amount of emitted energy to provide

temperature image based on the correlation between

amount of detected energy and temperature.

4

0

(,)

t

dR T

R

T

d

(2)

Steffan-Boltzmann’s constant

822

5.67 10 /

WmK

The equation (2) describes the Stefan-Boltzmann’s

law. This theory states that the total energy radiated

per unit surface area of a black body and per unit

time is directly proportional to the fourth power of

absolute temperature T. In this case, T represents the

absolute temperature K of an object in Kelvin

temperature while Rt represents the reflection

intensity of a black body. Based on the equation (1)

and equation (2) mentioned above, IR camera is

used to measure temperature.

a

b

R

R

(3)

Actual emissivity

a

R

Blackbody emissivity

b

R

Energy emitted from a black body is R

b.

An ideal

black body emitter does not exist in reality. If energy

emitted from a real object is R

a,

the emissivity of

object to black body surface at the same temperature

is expressed in the equation (3). In this case, if it is

=1, an object is called a black body. Therefore,

for metal that has low emissivity, the emissivity can

be kept at 0.95 if matte colour spray, which is close

to a black body, is applied.

3 OPTIMAL COOLING METHOD

3.1 Cooling Method

In an NPP that is in normal operation, pipes are

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

228

covered with insulators and in high temperature,

transferring heat up to the surface of insulators.

When cooling device is used to cool the pipes in

high temperature, thermal diffusion is disturbed

depending on existence of defects in inside of the

pipes. Insulation effects by defects cause difference

in temperature locally on surface of the pipes. When

IR camera is used to obtain thermal image of the

pipes where such temperature difference occurred,

defects in the pipes are shown in image depending

on existence of defects. Therefore, after examining

various cooling methods and investigating

applicability of such methods, the authors found out

the optimal cooling method to detect defects in

NPP’s pipes with use of infrared thermography.

3.1.1 Tube Air Cooler

A tube air cooler is a cooling device where pathway

of air current is narrowed to increase fluid velocity

as compressed air rotates in high speed, which aims

at separating hot air current from cool air current.

The tube air cooler uses compressed air in a general

compressor to cool air readily. In addition, the

cooler is fundamentally safe because refrigerant,

electricity or any chemicals are not used for the

cooler. The cooler is effective specially for local

cooling even though it has low capacity. However,

the cooler has some drawbacks because it requires

an additional equipment to use compressed air and

needs to be installed with equipment that produces

compressed air in order to be used portably.

3.1.2 Air-cooling and Water-cooling Coolers

A cooler is a device that converts high-temperature

high-pressure gaseous refrigerant to low-temperature

liquid refrigerant. Gaseous refrigerant containing

heat that is taken away from evaporator gets cooled

as it passes through condenser. Therefore, heat is

released to the outside as the gaseous refrigerant is

turned to the liquid refrigerant. Cooler can be

classified to air-cooling cooler and water-cooling

cooler. The air-cooling cooler has the excellent

cooling capability as it prevents degradation of

cooling function that is attributable to increase in

room temperature. Moreover, the air-cooling cooler

enables keeping temperature constant precisely and

can be adjusted in the wide range of use. The water-

cooling cooler uses water from a cooling tower to

work in the condensation cooling method. It

minimizes indoor noise and shows the higher

cooling efficiency than the air-cooling cooler.

3.1.3 Heat Pipe-type Cooler

A heat pipe-type cooler is a cooling device that

transfers heat in large quantity to condenser prior to

using the pin installed in the condenser for cooling

through natural convection or forced convection.

The heat pipe-type cooler uses working fluid of FC-

27 in the maximum thermal load of 1.5 ㎾. In

addition, it has the operating temperature of –

30~120℃ with the high cooling efficiency. Since

water quantity in heat pipe can be adjusted, the heat

pipe-type cooler can be manufactured in various

forms. However, the heat pipe-type cooler has

drawbacks that it takes longer time for cooling than

other coolers and requires the installation of an

additional fan to increase cooling efficiency.

3.1.4 Fan Cooler

A fan is a device that stirs up the wind as wings

installed on the axis of electric motor rotate. The fan

can be classified to desk fan, ventilating fan and

stand fan depending on shape and purpose of use.

Major parts of the fan include stand, pillar, motor,

and wing. It can be adjusted quite freely according

to angle and direction of movement (up and down or

right and left). The pillar of the fan also can be

adjusted upwardly or downwardly. The fan has the

front-side control panel that enables an easy control

as all of the devices are installed on the front side of

stand. The fan can be also classified to turbo fan,

limit fan and sirocco fan depending on shape of

wing. The turbo fan has the wing that its tip is bent

to the backward of rotation direction, which includes

the one with curved wing and the one with straight

wing. The turbo fan shows the high efficiency and

can be operated relatively quietly even at a high

speed. The limit fan is an upgraded version of the

turbo fan and the sirocco fan. It has the streamlined

wing that is manufactured by folding a thin plate.

Therefore, the limit fan can be rotated in a high

speed with low noise. The sirocco fan has a bent

shape as the tip of wing is bent toward the rotation

direction. Compared to other types of fans in the

same capacity, the sirocco fan features the

significantly low number of rotation.

3.2 Selection of a Cooling Method

In this study, the optimal cooling method was

selected to obtain thermal image of defects in

geometric shape in an easier and quicker way with a

view to examining defect size and depth from

DetectionofHotPipeDefectsusingIRThermography

229

surface. The previous cooling methods include the

method for cooling a pipe with use of a cooler, a

tube air cooler or a heat pipe-type cooler and the

method for installation of a cooling device on the

front side of a pipe with use of a fan. The authors

investigated the characteristics of various cooling

methods among the ones explained above in order to

examine the applicability of such methods. The

results are shown in Table 1.

As shown in Table 1, the cooling method with

use of a fan was evaluated to be the best among the

various cooling methods. The fan cooling method

can be combined with other cooling methods or can

be used independently. Therefore, the fan cooling

method was used in this study to detect wall-thinned

defects inside the pipe based on infrared

thermography.

Table 1: Applicability of Cooling Methods.

Cooling Method Applicability

Air Tube Cooler

As compressed air is used for

cooling, the cooler is cheap and

portable. The cooler has the low

capacity, which is effective for

cooling locally. However, it requires

an additional equipment to use

compressed air. Some limitations are

expected when the cooler is used on

the site of NPPs.

Air-cooling and

Water-cooling

Coolers

The coolers enable keeping

temperature constant precisely and

can be adjusted in the wide range of

use. They show the excellent cooling

capability with high efficiency.

However, the initial cost of

manufacturing is high. They are

heavy and not suitable for being used

portably.

Heat Pipe-type

Cooler

The cooler has the high cooling

efficiency while water quantity in

heat pipe can be adjusted, which

enables being manufactured in

various forms. In addition, the

interval of heat pipe itself can be

adjusted. However, the cooler shows

the high cooling efficiency when it is

installed directly on the target. A fan

needs to be installed additionally.

Fan Cooler

A fan is readily available. Its wing

can be manufactured in various

forms. The angle of the cooler can be

adjusted while rotation speed of the

fan can be adjusted continuously and

freely. In addition, the cooler can be

manufactured to be in light weight.

Therefore, it is believed that the

cooler will be easy to be used

portably.

4 SIMULATION

AND EXPERIMENT

In this study, the fan-type cooling device was

selected as equipment to cool a pipe specimen. Prior

to the testing, a finite element analysis (FEA) was

conducted to investigate the cooling effect of the

selected cooling device as well as the optimal test

conditions. The FEA was conducted by using

ANSYS FLUENT 13.0 while GAMBIT program

was used for generating the mesh that was modelled

to conduct the FEA. In addition, based on the FEA

results, cooling tests were performed to detect

defects inside the pipe specimen.

4.1 Specimen and Equipment

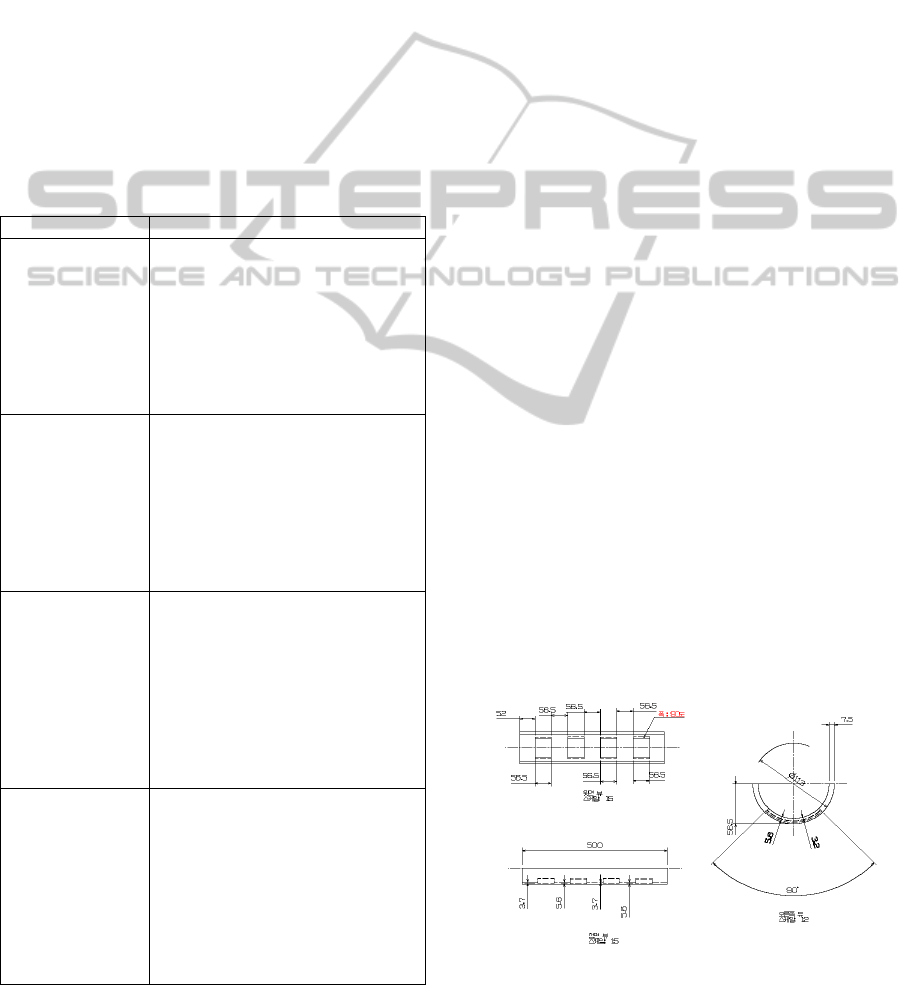

The pipe specimen used for this study has defects

inside for the purpose of cooling test. For the test,

the pipe specimen with 4 inch diameter was

manufactured with the material of Shc.80 ASTM

A106 Gr.B, which was similar to the actual pipe

used in the NPPs. As shown in Figure 1, the pipe

specimen has the total length of 500mm, the

thickness of 7.5mm, and the external diameter of

113mm. On the inner surface, four defects were

created in a constant length. The four defects have

the depth that is 50% and 75% respectively of the

thickness of the pipe specimen. Furthermore, matte

colour spray was applied to the surface of the pipe

specimen in order to ensure the surface emissivity of

0.95, which aimed at minimizing the reflection of

light. Figure 2 shows the pipe specimen that was

manufactured for this study.

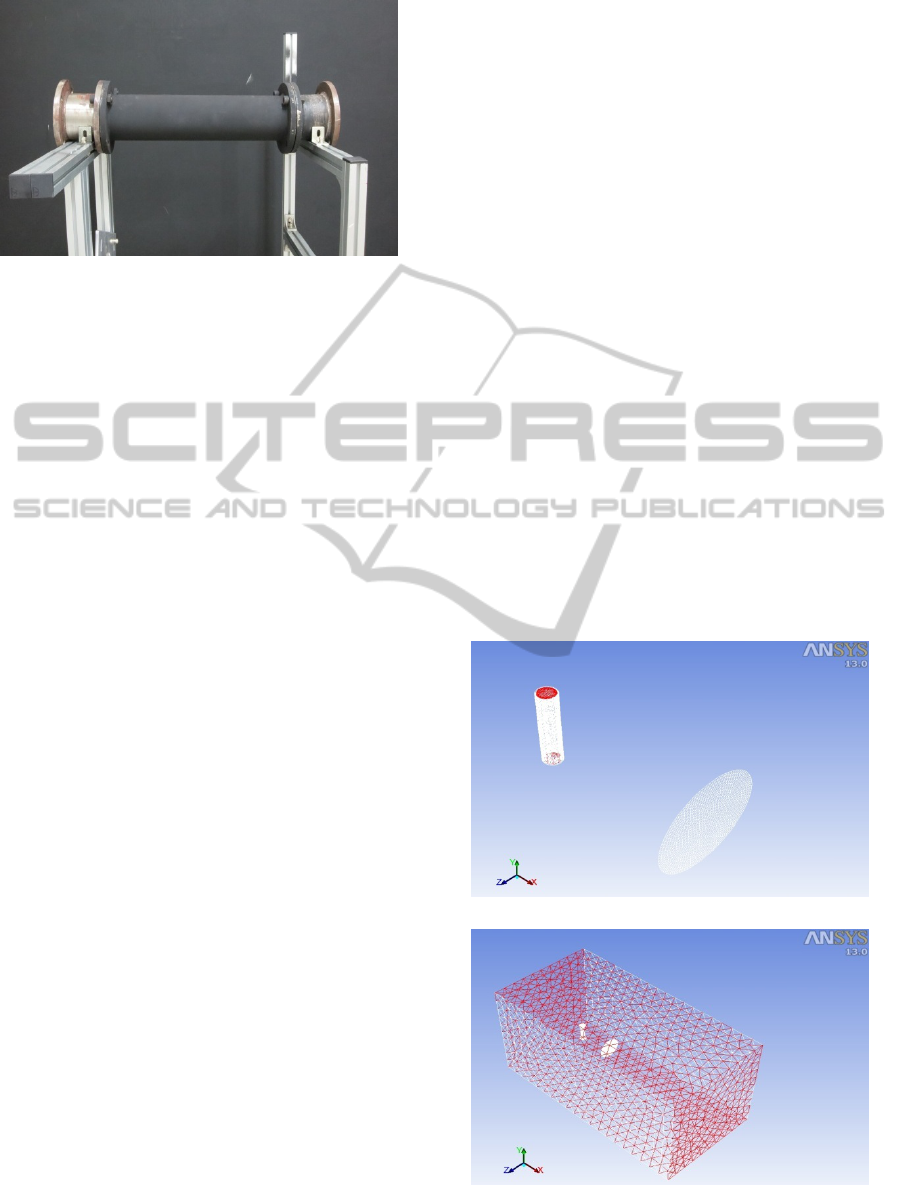

A blower fan was used as a cooling device to

cool the pipe specimen. The blower fan has 6 wings

at the maximum wind speed of 16.5m/s. The size of

its wing is 27cm. The blower fan features a uniform

cooling of the pipe specimen.

Figure 1: Design of a pipe specimen.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

230

Figure 2: The pipe specimen.

4.2 Simulation Method

In regard to testing for wall-thinned defects inside

the pipe, thermal analysis can be figured out based

on the FEA that uses the numerical technique prior

to experiments. The FEA provides the data to predict

problems in thermal distribution of the pipe

specimen based on analysis of simulation results, to

configure the cooling device that can be applied to

an actual environment, and to investigate the optimal

test conditions.

4.2.1 Specimen Modelling and Boundary

Condition

In this study, the pipe specimen used for the

experiment was ASTM A106 Gr.B that was

frequently used for actual pipe of the NPP’s

secondary system, which was manufactured of

carbon steel. Therefore, pipe modelling for the FEA

was performed under the same conditions as the

ones for pipe specimen that was used to test cooling

devices. Modelling of the pipe specimen was

performed in the total length of 500mm, the

thickness of 7.5mm, and the external diameter of

113mm. Four defects in the two types were created

inside to ensure that they had the depth that was 50%

and 75% respectively of the thickness of the pipe

specimen. Moreover, as matte colour spray was

applied to the surface of the pipe specimen in order

to minimize the reflection of light, reflection

conditions were taken into consideration for the pipe

modelling, which aimed at ensuring that the effects

from emissivity were kept constant while the

reflection of light was minimized.

The basic boundary conditions for the FEA were

established as follows. In order to simplify analysis,

symmetric conditions were set to consider half of the

pipe model. A large amount of thermal state and

fluid conditions were entered for fluid that took each

solid or air as thermal fluid medium. In addition,

temperature (25℃) and humidity for the entire space

were kept constant, excluding those for the pipe

model and the cooling device model.

4.2.2 Cooling Method

This study used the cooling device based on the

principles of a fan. Therefore, in order to conduct the

FEA for the cooling device, the principles of a fan

were applied to cool the pipe model through the

forced convection that was occurred by pressure

difference between surfaces of the fan model and the

pipe model. In addition, as a way to describe a hot

pipe in the NPP that was in normal operation, water

was designed to flow inside the pipe model. Mass

flow rate of water was set at 1kg/sec. Figure 3 (a)

shows the diagrams of the pipe model and the fan

model. Figure 3 (b) shows the meshes that were

created to improve the accuracy of the analysis.

ANSYS FLUENT was used to perform the

simulation of the FEA for a cooling device. The

distance between the fan model and the pipe model

and the pressure difference in the fan model were

adjusted. For simulation conditions, the distance

between the pipe model and the fan model was

adjusted to 1m, 2m and 3m while the pressure

difference in the fan model was set at 100Pa and

(a) Diagrams of Pipe Model and Fan Model

(b) Creation of Mesh

Figure 3: Configuration of Modelled Fan and Pipe

Specimen.

DetectionofHotPipeDefectsusingIRThermography

231

150Pa. The temperature of water flowing inside the

pipe model was adjusted to 100Ԩ and 200Ԩ.

4.3 Simulation Results

The FEA was made based on the image at 30

seconds that showed defects the most clearly among

the results of simulation that was conducted for 60

seconds. Figure 4 shows the results of simulations

that were performed when the surface pressure

difference between the fan model and the pipe

model was 100Pa, the temperature of the pipe model

was 100℃ and 200℃, and the distance between the

pipe model and the fan model was adjusted to 1m,

2m and 3m. The deviation of temperature in the

defect part was observed to be conspicuous under all

of the test conditions regardless of distance between

the pipe model and the fan model. In addition,

Figure 5 shows the results of simulations that were

performed when the surface pressure difference

between the fan model and the pipe model was

150Pa, the temperature of the pipe model was 100℃

and 200℃, and the distance between the pipe model

and the fan model was adjusted to 1m, 2m and 3m.

The shape of defects was observed with the naked

eye while the defects looked clearer as the pressure

difference in the fan model increased regardless of

depth of defects. Moreover, as the distance between

the pipe model and the fan model was shorter such

as 1m and 2m, the defects became more distinct.

(a) 100Ԩ, 1m (b) 100Ԩ, 2m (c) 100Ԩ, 3m

(d) 200Ԩ, 1m (e) 200Ԩ, 2m (f) 200Ԩ, 3m

Figure 4: Pressure Difference of 100Pa in Fan Model.

(a) 100Ԩ, 1m (b) 100Ԩ, 2m (c) 100Ԩ, 3m

(d) 200℃, 1m (e) 200℃, 2m (f) 200℃, 3m

Figure 5: Pressure Difference of 150Pa in Fan Model.

Consequently, the FEA simulation could confirm the

cooling effects of the fan cooling device. The

optimal test conditions include the pressure

difference in the fan at 150Pa and the close distance

such as 1m and 2m between the pipe specimen and

the fan cooling device.

4.4 Experiment Method

The FEA that was conducted based on the numerical

technique prior to the experiment could confirm the

cooling effects of a cooling device. In this study, an

IR camera and a cooling device were configured

according to the test conditions that were established

based on the FEA results with a view to detect wall-

thinned defects inside the manufactured pipe

specimen.

The temperature of pipes should be kept high

since it is assumed that inspections are conducted for

wall-thinned defects inside pipes of the NPP that is

in normal operation. Therefore, the experiment for

this study was conducted when the temperature of

the pipe specimen was kept high. To this end, a

heating device in the pipe was manufactured before

it would be inserted to the inside of the pipe

specimen. The inner heating device was

manufactured to ensure that the support was close to

the inner wall of the pipe specimen and that the

support could be wrapped up with two heating tapes

that could heat up to 400℃. Figure 6 shows the inner

heating device that was used to implement a hot pipe.

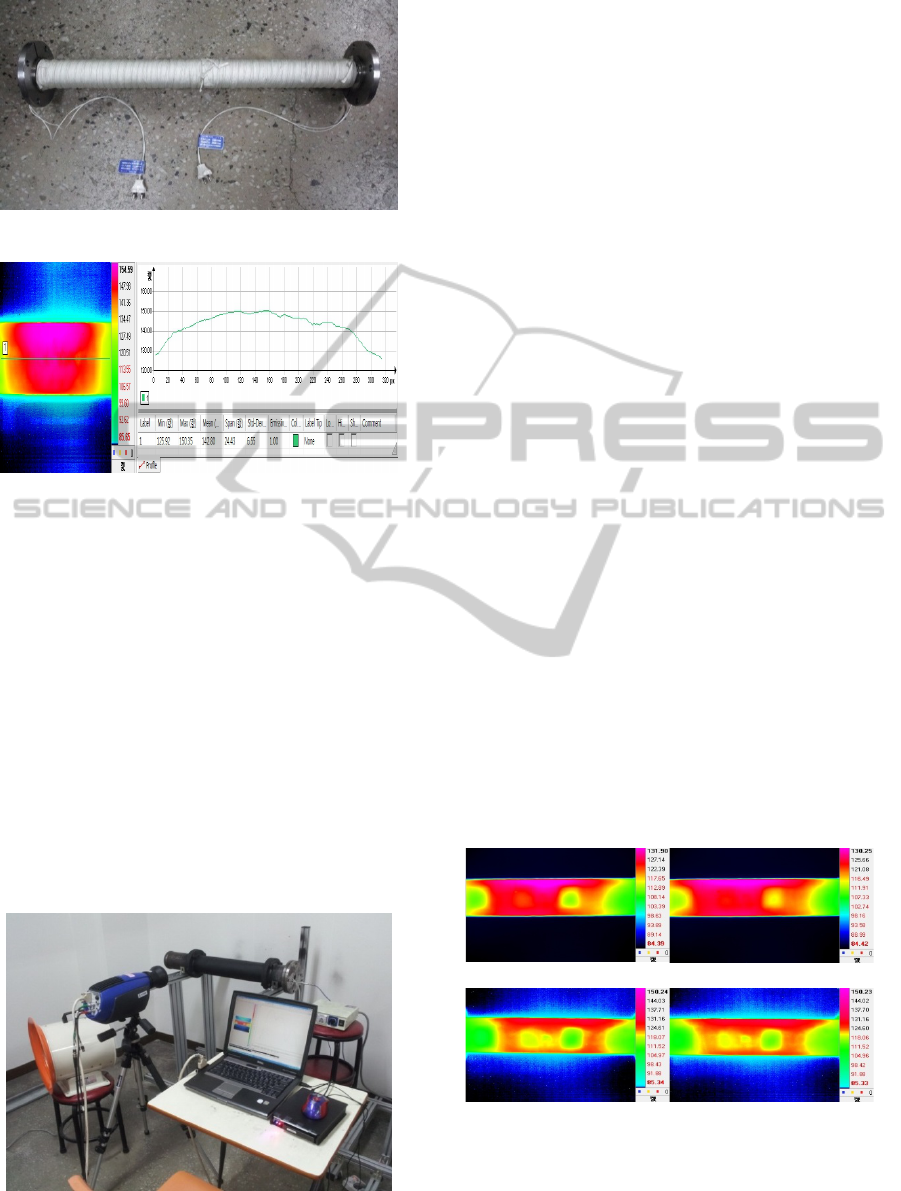

In order to verify the heating performance of the

inner heating device, the device was installed inside

the pipe specimen before being heated up. Then, an

IR camera was used to measure temperature

distribution. The measurement results showed that

the surface temperature of the 4-inch pipe specimen

was kept at 142℃~150.35℃ depending on location

when the temperature of two heating tapes was set at

320℃ for each. Figure 7 shows the surface

temperature of the pipe specimen that was measured

by using the IR camera when the maximum surface

temperature of the pipe specimen was kept at 150℃.

According to the measurement results, the highest

temperature was observed in the center of the pipe

specimen while the temperature tended to decrease

as the distance from the center increased.

As shown in Figure 8, the authors configured the

experimental equipment for detection of wall-

thinned defects inside the pipe that included an IR

camera, a fan, a pipe specimen, heating tapes, a

heating tape controller, and a PC. The experiment

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

232

Figure 6: Inner Heating Device for a Pipe Specimen.

Figure 7: Temperature Distribution in an Inner Heating

Device.

was conducted in a closed space while the

temperature in the laboratory was kept constant at

25℃ with use of an air conditioner.

In order to describe the pipe of the NPP that was

in normal operation, the inner heating device was

used to maintain the temperature of the pipe

specimen at 150Ԩ while the experiments were

conducted with variables that included the distance

between the pipe specimen and the fan and the

number of fans. The distance between the pipe

specimen and the IR camera was fixed at 1m while

the distance between the pipe specimen and the fan

was adjusted to 1m and 2m. In addition, the number

of fans was adjusted to 1 and 2 while each

experiment was conducted for 120 seconds.

Figure 8: Experimental Equipment with Use of Cooling

Device.

4.5 Experiment Results

Cooling tests for detection of wall-thinned defects

inside the pipes of the NPPs that were in normal

operation were conducted as an heating device was

inserted to the inside of the pipe specimen at the

temperature of 150Ԩ, which aimed at implementing

high temperature. In addition, the cooling tests were

conducted as the number of fans was adjusted to 1

and 2 and the distance between the pipe specimen

and the fan was adjusted to 1m and 2m based on the

FEA results.

Figure 9 (a) and Figure 9 (b) show the

experiment results when one fan was used with the

distance between the pipe specimen and the fan

adjusted to 1m, 2m and 3m. According to the

experiment results, when the distance was 1m, the

cooling effect was confirmed to be at around 34Ԩ.

When the distance was 2m, the cooling effect was

confirmed to be at around 28Ԩ. The defects created

at the 75% depth inside the pipe specimen were

detected at the distance of 2m. The defects were

detected more clearly as the distance between the

pipe specimen and the fan became shorter. Figure 9

(c) and Figure 9 (d) show the experiment results

when two fans were used to cool the pipe specimen

in the distance of 1m and 2m. When the distance

was 1m, the cooling effect was confirmed to be at

around 32Ԩ. When the distance was 2m, the cooling

effect was confirmed to be at around 27Ԩ. In

addition, it was possible to detect the defects that

were artificially created not only with the 75% depth

but also with the 50% depth inside the pipe

specimen. The defects were detected more

conspicuously as the distance between the pipe

specimen and the cooling device became shorter.

(a) One Fan in 1m (b) One Fan in 2m

(c) Two Fans in 1m (d) Two Fans in 2m

Figure 9: Pressure Difference of 150Pa in Fan Model.

DetectionofHotPipeDefectsusingIRThermography

233

5 CONCLUSIONS

In this study, infrared thermography was used to

detect wall-thinned defects inside the pipe of the

NPPs that were in normal operation. The pipe model

and the pipe specimen that had the same physical

properties as those for the actual pipe of the NPP

were used for the FEA and experiment. Moreover,

the size of defects applied to the pipe specimen was

equal to that of defects applied to the pipe model for

the FEA.

According to the results of the FEA that was

conducted to examine the cooling effects of a

cooling device and the optimal test conditions, the

detection capability of defects was predicted to

increase as the distance between the pipe and the fan

decreased and the wind speed of fan increased. The

prediction was applied to the experiment.

Defects could be detected partially in the test that

was conducted by using the cooling device of a fan

based on the FEA results. Unlike the analysis results,

defects with the 75% depth of the pipe thickness

could be detected clearly when the distance between

the pipe specimen and the fan was 1m. In order to

detect wall-thinned defects in the NPP that is in

normal operation based on such results, the distance

between the pipe and the fan should be short such as

1m while the wind speed and air flow of the fan

should be high.

In conclusion, infrared thermography enabled

detecting wall-thinned defects inside the pipe while

it was expected to be very useful on the NPP site

compared to the existing non-destructive inspection.

Moreover, since the infrared thermography

facilitates performing the maintenance of facilities

of the NPPs that are in normal operation or the NPPs

that are in maintenance period, it is expected to

maximize the operation efficiency of NPP facilities

and minimize the energy loss and economic loss that

are attributable to the operation stop.

REFERENCES

Frank, M., Hans, R. and Helmut, S., 2001. Experience

with piping in German NPPs with Respect to Ageing-

Related Aspects, Nuclear Engineering and Design,

Vol. 207, No. 3, pp. 307-316.

G. Gaussorgurs, 1994. Infrared thermography Translated

by S. Chomet, Champmam & Hall.London, pp. 415-

452.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

234