Model Checking of Distributed Component-based Control Systems

Atef Gharbi

1

, Hamza Gharsellaoui

1

, Mohamed Khalgui

2

and Samir Ben Ahemd

3

1

INSAT, Tunis, Tunisia

2

ITIA-CNR, Milan, Italy

3

FST, Tunis, Tunisia

Keywords:

Functional Safety, Control System, Petri Net.

Abstract:

The paper deals with the functional safety of distributed control systems following the component-based ap-

proach. A control component is classically defined as a software unit allowing the control of a physical

process. When a fault occurs in the plant, the system should be reconfigured dynamically to be adapted by

adding-removing or updating software components for the safety of the controlled physical processes. An

agent-based architecture is proposed therefore to control the plant’s evolution before applying any possible

reconfiguration scenario of the system. When the system is distributed on networked controllers, we propose

a control agent for each device but we need also a coordination agent to allow safety distributed reconfigura-

tions. The unique coordinator uses well-defined matrices and a protocol for this coordination. We model the

whole architecture by using ordinary Petri nets and apply SESA for the verification of CTL properties of the

system. The paper’s contribution is applied to two benchmark production systems at Martin Luther University

in Germany.

1 INTRODUCTION

In (SZYPERSKI et al., 2002), the author gives the

following definition for a Component: ”A software

component is a unit of composition with contractu-

ally specified interfaces and explicit context depen-

dencies only. A software component can be de-

ployed independently and is subject to composition

by third parts”. New generations of component-

based technologies have recently gained popularity

in industrial software engineering since it is possi-

ble to reuse already developed and deployed soft-

ware components from rich libraries. Besides, the

embedded Component-based technology is largely

used in industry. We find many applied technologies

in industrial systems such as Koala (van Ommering

et al., 2000), Function Block (Diedrich and all, 2004),

...Each one technology has to reduce the time to mar-

ket and to meet extra-functional properties (the most

important ones are real-time properties and resource

consumption) (Goessler et al., 2007). As we need

to study a distributed control architecture, the Multi-

Agent System appears as an attractive solution in this

domain (Jennings et al., 1998). Various kinds of com-

munication strategies can be found in (Wittig, 1992).

Some are based on broadcasting of messages, others

on the existence of a central communication agent.

The objective of our work is to ensure a safety

control of distributed systems with the verification of

some requirements to test its reliability. These con-

trol systems require some correction to respect espe-

cially functional and temporal constraints. To achieve

this goal, our methodology is based on three essential

steps:

1. The description of functional behavior in order to

study the system in more details;

2. The specification with the Net Condition/Event

Systems (abbr. NCES) formalism introduced by

Rausch and Hanisch in (Rausch and Hanisch,

1995) and further developed through last years, in

particular in (Hanisch and Luder, 1999). The use

of Net Condition/Event Systems is well justified

for the following reasons: (i) the NCES formal-

ism is an extension of Petri nets, (ii) it permits to

represent concurrent process, (iii) there are sev-

eral tools associated to NCES enabling the gen-

eration of reachability graph, the verification of

some properties, (iv) the entire graph is obtained

connecting the modules by condition and event

arcs;

3. The verification of some properties using the

Computation Tree Logic (CTL) (Roch, 2000)

with the model checker SESA.

As our goal is to ensure the Control safety in any

distributed System. For that reason, we affect a Con-

512

Gharbi A., Gharsellaoui H., Khalgui M. and Ben Ahemd S..

Model Checking of Distributed Component-based Control Systems.

DOI: 10.5220/0004492605120519

In Proceedings of the 8th International Joint Conference on Software Technologies (ICSOFT-PT-2013), pages 512-519

ISBN: 978-989-8565-68-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

trol Agent to each device and a Coordinator Agent to

ensure a right interaction between the different Con-

trol Agents. Our main interest is how to model with

Petri nets the whole architecture and how to check

that all devices behave correctly after each reconfigu-

ration scenario. In fact, we want to be sure that each

applied reconfiguration in a device does not affect

the behavor of remote devices. To do so, we define

the communication protocol between Control Agents

and Coordination Agent. We specify the communica-

tion protocol with the Net Condition/Event System.

To be sure that the specification is correct, we use

the model checker SESA to verify some properties.

Finally, we implement the communication protocol

through the ”ProtocolReconf”tool developedwith the

Qt language.

Our current work is based on our previous pub-

lished papers, but we study the problem of verification

of protocol as well as the implementation of simual-

tor.

The next section presents the background i.e. the

set of articles published related to our study. We de-

fine in Section 3 a multi-agent architecture and the

communication protocol to ensure safety in a dis-

tributed control systems. The Section 4 presents the

model checking of the communication protocol. The

section 5 introduces the ”ProtocolReconf”tool to sim-

ulate the communication protocol. We finally con-

clude the paper in the last section.

2 BACKGROUND

Until now, we have published a set of previous papers

dealing with reconfigurable control systems. We

define in (Gharbi et al., 2009) the concept of Control

Components as generic independent components

of any component-based technology. The Control

Component (abbr. CC ) defined as an event-triggered

software unit composed of an interface for any

external interactions and an implementation allowing

control actions of physical processes. A control

system is assumed to be a composition of compo-

nents with precedence constraints to control the plant

according to well-defined execution orders.

We define in (Khalgui et al., 2009) a new software

architecture for intelligent agents to control and

adapt systems to their environments. This Control

Agent reacts as soon as an error occurs in the plant.

The decision taken may vary from changing the set

of Control Components that constitute the system,

modifying the connection between different Control

Components, substituting the behavior of some

Control Component by another behavior or even

modifying data. According to these functionalities, it

is possible to define the architecture of the agent as

based on four levels: (i) First level: (Architecture

Unit) this unit checks the plant evolution and changes

the system’s software architecture (adds/removes

Control Components) when particular conditions

are satisfied, (ii) Second level: (Control Unit)

for a particular loaded software architecture, this

unit checks the plant’s evolution and reconfigures

compositions of corresponding Control Components,

(iii) Third level: (Implementation Unit) for a

particular composition of Control Components, this

unit reconfigures their implementations, (iv) Fourth

level: (Data Unit) this unit updates data if particular

conditions are satisfied. To verify the correctness

of its behavior, we specify the whole architecture

according to the formalism Net Condition/Event

Systems which is an extension of Petri Nets. To avoid

the combinatory explosion, we apply in (Gharbi et al.,

2010b) a refinement-based approach to verify step

by step subsets of components. We study in (Gharbi

et al., 2011b) the fault management by intelligent

agents.

To guarantee correct and feasible distributed

reconfigurations, we define in (Gharbi et al., 2010a)

an inter-agents communication protocol. To ensure

the interaction between Control Agents, we define the

communication protocol. For that reason, we define

a Coordination agent having a set of matrices named

’Coordination matrix’ which indicates for each

Control Agent the reconfiguration to apply. In fact,

whenever an error occurs, the corresponding Control

Agent sends a request to the Coordination agent to

apply a new reconfiguration. The Coordination agent

informs the other Control Agents concerned by this

modification to preserve the system in a safe state.

Our contributions are applied to two benchmark

production systems at Martin Luther University in

Germany. The first benchmark production system

FESTO is composed of three units: Distribution,

Test and Processing units. We assume that there

are two drilling machines Drill

machine1 and

Drill

machine2 to drill pieces. Three production

modes of FESTO are considered according to the rate

of input pieces denoted by number

pieces into the

system : High production, Medium production and

Light production.

The second Benchmark Production

System EnAS (Website: http://at.iw.uni-

halle.de/forschung/enas

demo) transports pieces

from production systems to storing units. The pieces

shall be placed inside tins to be closed with caps.

Two different production strategies are assumed to

be applied : we place in each tin one or two pieces

ModelCheckingofDistributedComponent-basedControlSystems

513

according to production rates of pieces, tins and caps.

The EnAS system is mainly composed of a belt, two

Jack stations (J

1

and J

2

) and two Gripper stations (G

1

and G

2

). According to production parameters, we

distinguish two cases : First production policy and

second production policy. More details describing

the benchmark production systems can be obtained

in our previous articles.

In (Gharbi et al., 2011a), we have studied a

centralized system controlled by an intelligent soft-

ware agent manipulating faults. However, in this

work we want to extend this study by considering

a distributed system controlled by several agents

interacting together through a communication pro-

tocol. We continue our research by proposing the

model checking of communication protocol to prove

its correctness in order to be sure that any applied

reconfiguration in a device does not affect the correct

execution of the rest of devices. We want also to

check the correct behavior of Coordinator Agent for

a correct coordination between devices.

3 COMMUNICATION

PROTOCOL SPECIFICATION

We define a multi-agent architecture for distributed

safety systems. Each control agent is affected in this

architecture to a device of the execution environment

to ensure safety. It is specified by nested state ma-

chines that support all reconfiguration forms. Never-

theless, the coordination between agents in this dis-

tributed architecture is extremely mandatory because

any uncontrolled automatic reconfiguration applied in

a device can lead to critical problems, serious dis-

turbances or also inadequate distributed behaviors in

others. To guarantee safe distributed reconfigurations,

we define the concept of Coordination Matrix that de-

fines correct reconfiguration scenarios to be applied

simultaneously in distributed devices and we define

the concept of Coordination Agent that handles co-

ordination matrices to coordinate between distributed

agents. We propose a communication protocol be-

tween agents to manage concurrent distributed recon-

figuration scenarios.

Running Example. When a hardware problem oc-

curs at run-time in a platform, a reconfiguration of

the other is required as follows:

• If one of the Jack stations J1 and J2 or the Grip-

per station G2 is broken in the EnAS Production

System, Then the corresponding Agent has to de-

crease the productivity by applying the First Pro-

duction mode, and in this case the FESTO Agent

has also to follow the Light Production mode in

order to guarantee a coherent behavior.

• If one of the drilling machines Drill

machine1

and Drill

machine2 is broken, Then the FESTO

Agent has to decrease the productivity, and in this

case the EnAS Agent has to follow the First Pro-

duction mode where only one piece is put in a tin.

We are interested to ensure Safety to a set of

Software Control Components to be distributed on

networks of devices where a coordination between

agents is necessary because any uncontrolled auto-

matic reconfiguration applied by any agent as a re-

sult to error occuring in a specific device can lead to

serious disturbances in others. We define in this sec-

tion the concept of Coordination Matrix to handle co-

herent reconfiguration scenarios in distributed devices

and we propose thereafter an architecture of multi-

agent distributed safety systems where a communica-

tion protocol between agents is defined to guarantee

safe behaviors after any distributed reconfigurations.

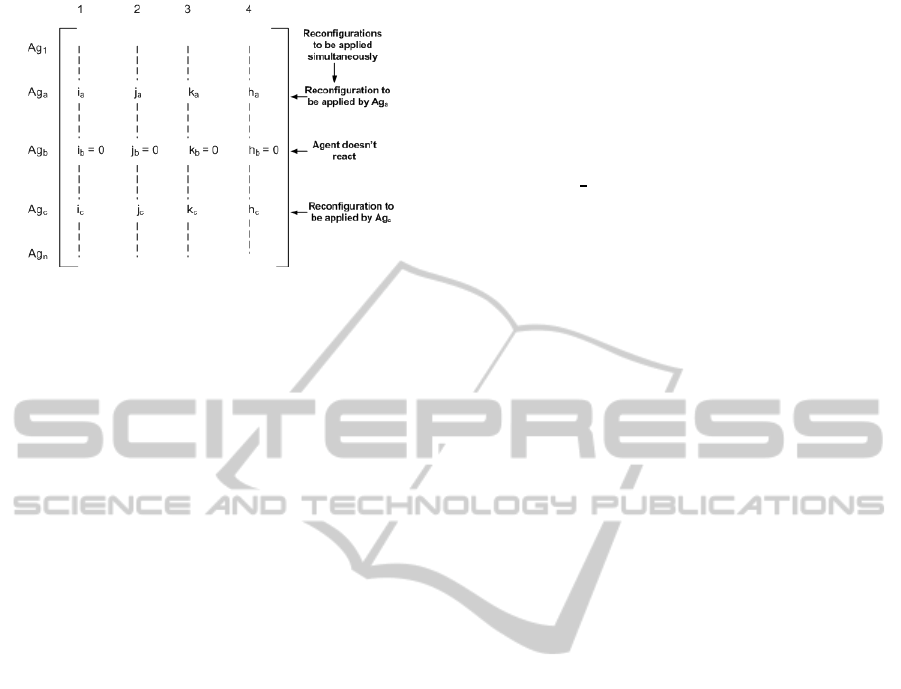

3.1 Distributed Reconfigurations

Let Sys be a distributed reconfigurable system of n

devices, and let Ag

1

,..., Ag

n

be n agents to han-

dle automatic distributed reconfiguration scenarios

of these devices. We denote in the following by

Reconfiguration

a

i

a

, j

a

,k

a

,h

a

a reconfiguration scenario

applied by Ag

a

(a ∈ [1, n]) as follows: (i) the corre-

sponding ASM state machine is in the state ASM

i

a

.

Let cond

a

i

a

be the set of conditions to reach this state,

(ii) the CSM state machine is in the state CSM

i

a

, j

a

.

Let cond

a

j

a

be the set of conditions to reach this state,

(iii) the DSM state machine is in the state DSM

k

a

,h

a

.

Let cond

a

k

a

,h

a

be the set of conditions to reach this

state. To handle coherent distributed reconfigurations

that guarantee safe behaviors of the whole system Sys,

we define the concept of Coordination Matrix of size

(n,4) that defines coherent scenarios to be simultane-

ously applied by different agents. Let CM be such

a matrix that we characterize as follows: each line a

(a ∈ [1, n]) corresponds to a reconfiguration scenario

Reconfiguration

a

i

a

, j

a

,k

a

,h

a

to be applied by Ag

a

as fol-

lows:

CM[a, 1] = i

a

; CM[a, 2] = j

a

; CM[a, 3] = k

a

;

CM[a, 4] = h

a

According to this definition: If an agent Ag

a

ap-

plies the reconfiguration scenario Reconfiguration

a

CM[a,1],CM[a,2],CM[a,3],CM[a,4]

, Then each other agent

Ag

b

(b ∈ [1, n]\{a}) has to apply the scenario

Reconfiguration

b

CM[b,1],CM[b,2],CM[b,3],CM[b,4]

(Figure

1). We denote in the following by idle agent each

ICSOFT2013-8thInternationalJointConferenceonSoftwareTechnologies

514

Figure 1: A Coordination Matrix.

agent Ag

b

(b ∈ [1, n]) which is not required to ap-

ply any reconfiguration when others perform scenar-

ios defined in CM. In this case:

CM[b, 1] = CM[b, 2] = CM[b, 3] = CM[b, 4] = 0

cond

a

CM[a,1]

= cond

a

CM[a,2]

= cond

a

CM[a,3],CM[a,4]

= True

We denote in addition by ξ(Sys) the set of coordi-

nation matrices to be considered for the reconfigura-

tion of the distributed system Sys. Each Coordination

MatrixCM is applied at run-time if for each agent Ag

a

(a ∈ [1, n]) the following conditions are satisfied:

cond

a

CM[a,1]

= cond

a

CM[a,2]

= cond

a

CM[a,3],CM[a,4]

= True

On the other hand, we define Concurrent Coor-

dination Matrices, CM

1

and CM

2

two matrices of

ξ(Sys) that allow different reconfigurations of same

agents as follows: ∃b ∈ [1, n] such that:

• CM

j

[b, i] 6= 0 ∀ j ∈ {1, 2} and i ∈ [1, 4],

• CM

1

[b, i] 6= CM

2

[b, i] ∀i ∈ [1, 4].

In this case, the agent Ag

b

is disturbed because

it has to apply different reconfiguration scenarios at

the same time. To guarantee a deterministic behavior

when Concurrent Coordination Matrices are required

to be simultaneously applied, we define priority lev-

els for them such that only the matrix with the highest

priority level should be applied. We denote in the fol-

lowing by:

• Concur(CM) the set of concurrent matrices of

CM ∈ ξ(Sys),

• level(CM) the priority level of the matrix CM in

the set Concur(CM) ∪ {CM}.

Running Example. For the sake of simplicity, we

take as example only two matrices CM

2

and CM

6

(in

(Gharbi et al., 2010a) the reader will find more details

on all possible coordination matrices).

• the matrix CM

2

is applied when the FESTO Agent

applies the High Production mode (i.e. the states

ASM

2

, CSM

21

and DSM

21

are activated and

Reconfiguration

2,1,2,1

is applied) and the EnAS

Agent is required to increase the productivity by

applying the Second Production mode to put two

pieces into each tin (i.e. the states ASM

1

, CSM

11

are activated and Recon figuration

1,1,0,0

is ap-

plied),

• the matrix CM

6

is applied when the Drilling ma-

chine Drill

machine1 is broken in FESTO (i.e.

the states ASM

2

, CSM

23

and DSM

23

are activated

and Reconfiguration

2,3,2,3

is applied). In this

case EnAS system is required to decrease the pro-

ductivity by applying the First Production mode

(i.e. the states ASM

2

, CSM

21

are activated and

Reconfiguration

2,1,0,0

is applied),

3.2 Coordination between Distributed

Agents

We propose a multi-agent architecture for control sys-

tems following the Standard IEC61499 to handle au-

tomatic distributed reconfigurations of devices. To

guaranteea coherent behaviorof the whole distributed

system, we define a Coordination Agent (denoted by

CA(ξ(Sys))) which handles the Coordination Matri-

ces of ξ(Sys) to control the rest of Control Agents (i.e.

Ag

a

, a ∈ [1, n]) as follows:

• When a particular Control Agent Ag

a

(a ∈

[1, n]) should apply a reconfiguration scenario

Reconfiguration

a

i

a

, j

a

,k

a

,h

a

(i.e. under well-defined

conditions), it sends the following request to

CA(ξ(Sys)) to obtain its authorization:

request(Ag

a

,CA(ξ(Sys)), Reconfiguration

a

i

a

, j

a

,k

a

,h

a

).

• When CA(ξ(Sys)) receives this request that cor-

responds to a particular coordination matrix CM

∈ ξ(Sys) and if CM has the highest priority be-

tween all matrices of Concur(CM) ∪ {CM}, then

CA(ξ(Sys)) informs the Control Agents that have

simultaneously to react with Ag

a

as defined in

CM. The following information is sent from

CA(ξ(Sys)):

For each Ag

b

, b ∈ [1, n] \ {a} and CM[b, i] 6= 0, ∀

i ∈ [1, 4]:

reconfiguration(CA(ξ(Sys)), Ag

b

,

Reconfiguration

b

CM[b,1],CM[b,2],CM[b,3],CM[b,4]

)

• According to well-defined conditions in the de-

vice of each Ag

b

, the CA(ξ(Sys)) request can be

accepted or refused by sending one of the follow-

ing answers:

– If cond

b

i

b

= cond

b

j

b

= cond

b

k

b

,h

b

= True

Then the following reply is sent from Ag

b

to

CA(ξ(Sys)):

ModelCheckingofDistributedComponent-basedControlSystems

515

possible reconfig(Ag

b

,CA(ξ(Sys)),

Reconfiguration

b

CM[b,1],CM[b,2],CM[b,3],CM[b,4]

).

– Else the following reply is sent from Ag

b

to

CA(ξ(Sys)):

not

possible reconfig(Ag

b

,CA(ξ(Sys)),

Reconfiguration

b

CM[b,1],CM[b,2],CM[b,3],CM[b,4]

).

• If CA(ξ(Sys)) receives positive answers from all

Control Agents, Then it authorizes reconfigura-

tions in the concerned devices:

For each Ag

b

, b ∈ [1, n] and CM[b, i] 6= 0, ∀ i ∈

[1, 4],

apply(Reconfiguration

b

CM[b,1],CM[b,2],CM[b,3],CM[b,4]

)

in device

b

.

Else If CA(ξ(Sys)) receives a negative answer

from a particular Control Agent, Then

CA(ξ(Sys)) permits Ag

a

, on the one hand, to apply

the requested reconfiguration scenario by sending

the following reply:

apply(Reconfiguration

a

CM[a,1],CM[a,2],CM[a,3],CM[a,4]

).

CA(ξ(Sys)) informs the other Control Agent Ag

b

,

on the other hand, to cancel the new reconfigura-

tion.

For each Ag

b

, b ∈ [1, n] and CM[b, i] 6= 0, ∀ i ∈

[1, 4],

cancel(Reconfiguration

b

CM[b,1],CM[b,2],CM[b,3],CM[b,4]

)

in device

b

.

Running Example. In our FESTO and EnAS Bench-

mark Production Systems, we show in Figure 2 the co-

ordination between these Control Agents when Jack1

is broken in EnAS. In this case, the Coordination

Agent uses the Matrix CM to decrease the productiv-

ity in FESTO.

4 MODEL CHECKING OF

COMMUNICATION

PROTOCOL

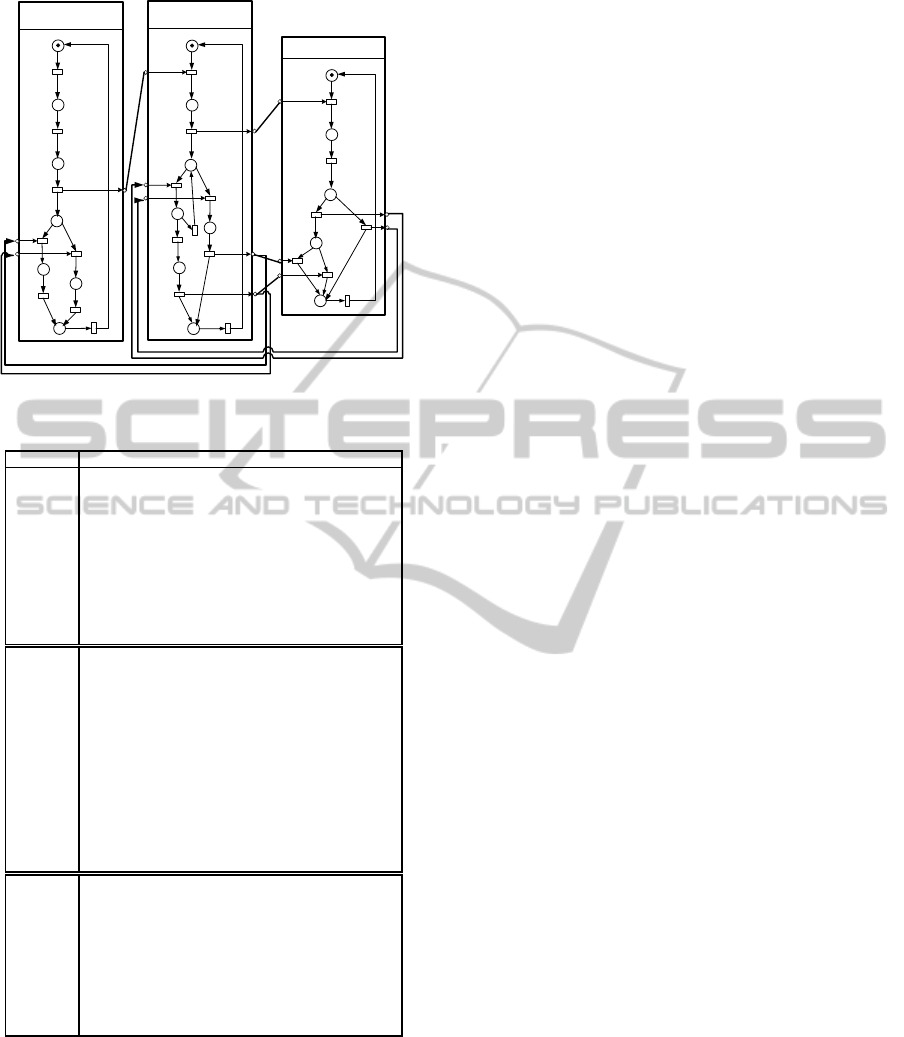

To verify some properties, the use of Model-Checker

SESA is well justified. In fact, it offers a wide range

of functionalities. At first, the NCES formalism is

an extension of the Petri Net. Secondly, it permits to

represent concurrent process. Thirdly, there are sev-

eral tools associated to NCES enabling the generation

of reachability graph, the verification of some proper-

ties, Finally, the verification of some properties using

the Computation Tree Logic (CTL) (Roch, 2000) with

the model checker SESA.

EnAS agent

FESTO agent

Coordination agent

Request(EnAS, CA, Reconfiguration

1,2,0,0

)

Reconfiguration(CA, FESTO, Reconfiguration

1,1,1,1

)

Jack1 is broken

Drill station D1 is OK

Possible_reconf(FESTO, CA, Reconfiguration

1,1,1,1

)

Apply(Reconfiguration

1,2,0,0

) Apply(Reconfiguration

1,1,1,1

)

1 1 1 1

1 2 0 0

CM

Figure 2: Coordination between the FESTO and EnAS

agents when Jack1 is broken.

In this section, we aim to specify and verify the

Communication Protocol through the NCES editor

and the model checker SESA. This is the real contri-

bution of this paper which is based on related previous

published papers.

In the Communication Protocol, we distinguish three

kinds of participating agents:

• The Control Agent

i

: it is the Control Agent which

starts the communication. In fact, wheneveran er-

ror occurs in a specific plant, the associate Control

Agent tries to correct it and if it decides the neces-

sity of reconfiguration the whole system (i.e. the

other Control Agents must be aware of this modi-

fication) it informs the Coordination agent.

• The Coordination agent (CA): it is the main agent

which has as task the coordination between the

different Control Agents. Thus, when the coordi-

nation agent receives the request of reconfigura-

tion, it searches the list of Control Agents which

must be informed. It sends a request to these Con-

trol Agents and waits the response from them.

• The Control Agent

j

: it is the j

th

Control Agent

that receives a request from Coordination agent

for reconfiguration. Firstly, it checks the possi-

bility to apply a reconfiguration. If it is possible,

it sends a positive answer. If it is not possible,

it sends a negative answer (see Figure 3). For

further information, we refer to Table 1.

CTL Properties

The following CTL properties are proven to be true

by the model checker SESA:

Property 1. Always, when an error occurs in the

plant, the Control Agent

i

informs the Coordination

Agent.

AG (P2 => EF P9)

This property is proven to be true by SESA tool.

Property 2. During the negotiation, the Coordination

Agent waits the response from the other agents

ICSOFT2013-8thInternationalJointConferenceonSoftwareTechnologies

516

P1

t8

t1

t2

t3

P4

P6

t6

t4

P2

P3

t5

P5

t7

P7

P8

t17

t9

t10

P10

P13

t15

t11

P9

t12

P11

t16

P14

t13

P12

P15

t24

t18

t19

P17

P19

t23

t20

P16

t22

t21

P18

Control Agent

i

Coordination Agent

Control Agent

j

ei1

ei2

ei3

ei4

ei5

ei6

eo1

eo3

eo4

eo5

eo6

ei7

ei8

eo2

N-1

t14

Figure 3: Communication Protocol.

Table 1: The meaning of transitions related to Figure 3.

Transition Meaning

t

1

An error occurs

t

2

The Control Agent

i

decides a new reconfiguration

t

3

The Control Agent

i

informs the coordination agent

t

4

The Control Agent

i

receives a negative answer

from the coordination agent

t

5

The Control Agent

i

applies the new reconfiguration

t

6

The Control Agent

i

receives a positive answer

from the coordination agent

t

7

The Control Agent

i

applies the new reconfiguration

with the other

t

8

The end of communication process

t

9

The Coordination Agent receives a request

t

10

The Coordination Agent sends to other agents

t

11

The Coordination Agent receives a positive answer from

a specific agent

t

12

The Coordination Agent receives a positive answer from all

concerned agents

t

13

The Coordination Agent asks the other agents to apply a new

reconfiguration

t

14

The Coordination Agent waits (either positive or negative)

response from the other agents

t

15

The Coordination Agent receives a negative answer

t

16

The Coordination Agent asks the initiator to apply

the reconfiguration

t

17

The end of communication process

t

18

An Control Agent

j

receives the request for

reconfiguration

t

19

The Control Agent

j

verifies some constraints

t

20

The Control Agent

j

accepts the new reconfiguration

t

21

The Control Agent

j

receives disapproval from

the coordination agent

t

22

The Control Agent

j

receives approval from

the coordination agent

t

23

The Control Agent

j

refuses the new reconfiguration

t

24

The end of communication process

(Control Agent

j

) or receives disapproval from a

specific agent.

EF P10 AND EF (P11 OR P14)

This formula is proven to be true by SESA tool.

Property 3. The Control Agent

i

could not receive

two different notifications from the Coordination

Agent at the same time (i.e. notification that the other

agents accept and refuse the new reconfiguration ).

NOT EF (P5 AND P7)

This property is proven to be true by SESA tool.

eCTL properties

The following eCTL properties are proven to be true:

Property 4. Whenever the Control Agent

j

accepts

the new reconfiguration, it waits the final decision

from the Coordination agent which can be a confir-

mation to apply a new reconfiguration or to cancel

the new reconfiguration.

AGA t20 XAGA (t21 OR t22) X p19

Property 5. We want to check the correctness of the

communication protocol:

1. Firstly, an error occurs, so the associated agent

(Control Agent

i

) decides a new reconfiguration;

2. The Control Agent

i

informs the Coordination

Agent to start the negotiation with the other

agents;

3. The Coordination Agent sends a request to other

agents (each agent is considered as Control

Agent

j

);

4. The Control Agent

j

receives the request, verifies

its constraints (to check the feasibility) and then

decides to accept or refuse the new reconfigura-

tion.

AG A t1 X AG A t3 X AG A t9 X AG A t10 X AG A

t18 X AG A t19 X p17

This property is checked to be true.

5 COMMUNICATION

PROTOCOL

IMPLEMENTATION

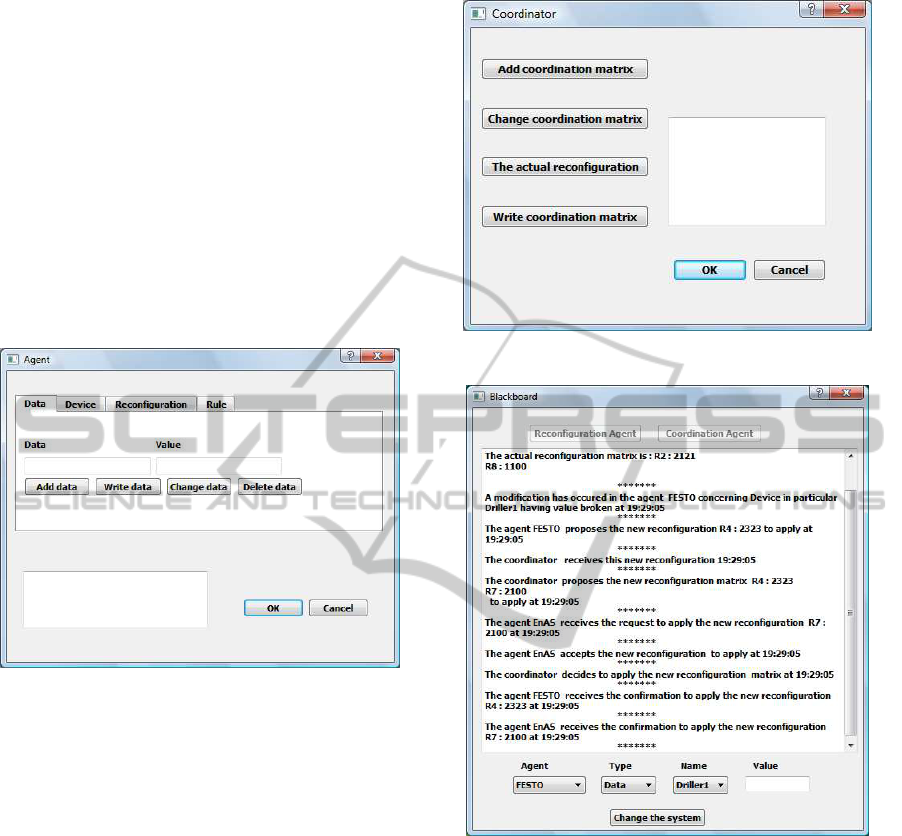

We developed a complete tool ”ProtocolReconf” at

INSAT Institute by using Qt Creator 2.0.0 (for more

information we refer to http://qt.nokia.com/products).

We firstly present its different graphic interfaces be-

fore we show a simulation verifying the communi-

cation protocol. The tool ”ProtocolReconf” offers

the possibility to create the Control and Coordina-

tion Agents by introducing their parameters. For the

Control Agent (Figure 4), it is necessary to define the

Data, Devices, Reconfigurationsand Rules. Each data

must be defined by indicating its name and value, and

each device is characterized also by its identifier and

state (functional or broken). It is required to define the

different scenarios that the Control Agent can support

so that when a modification occurs in the system, it

should look for the convenient reconfiguration. For

ModelCheckingofDistributedComponent-basedControlSystems

517

the Coordination Agent (Figure 5), it is necessary to

define the set of Coordination Matrices and especially

the current matrix to apply to the whole system. The

communication between the different Control Agents

follows the specific protocol defined in the previous

section. To ensure a new reconfiguration, a Control

Agent sends a request to the Coordination Agent in-

dicating the new reconfiguration to apply. Conse-

quently, this Coordinator searches the right Coordina-

tion Matrix and sends a request to the rest of Control

Agents. After receiving all the feedbacks, the Coor-

dination Agent decides to apply this new coordina-

tion matrix (if all Control Agents accept this modifi-

cation) or to cancel the corresponding reconfiguration

scenario.

Figure 4: Control Agent.

Running Example. In FESTO and EnAS Benchmark

Production Systems (Figure 6), we assume that the

matrix CM

2

is applied i.e. the FESTO’s agent applies

the High Production mode and the EnAS’s agent ap-

plies the Second Production strategy. To verify the in-

teraction between these agents when a particular hard-

ware problem occurs, we change the state of the de-

vice Driller1 which becomes broken. Consequently,

the FESTO’s agent should decrease the production by

sending a request to the Coordination Agent in order

to look for the most convenient matrix which is CM

6

.

The Coordination Agent sends a request to decrease

the production in EnAS. The EnAS’s agent studies

the feasibility of this new reconfiguration in order to

accept the decrease of production. In this case, the

Coordination Agent sends a final confirmation to of-

ficially apply this new coordination matrix.

6 CONCLUSIONS

This paper deals with the Model Checking of dis-

tributed safety control systems by following a multi-

Figure 5: Coordination Agent.

Figure 6: Example of Communication Protocol.

agent architecture. We define an agent-based archi-

tecture where each agent (associated to a defined de-

vice) controls the environment evolution and applies

automatic reconfigurations when hardware errors oc-

cur at run-time to guarantee a functional safety of

the whole system. Each control agent is affected in

this architecture to a device of the execution envi-

ronment to ensure safety. Besides, the Coordination

Agent is responsible for the interaction between Con-

trol Agents in order to ensure a mutual agreement

with the others on a reconfiguration to apply. We

present therefore a communication protocol between

these agents using Coordination Matrix specifying for

each Control Agent the reconfiguration to apply ac-

cording to predefined conditions. The model check-

ing is very interesting method to prove the correctness

ICSOFT2013-8thInternationalJointConferenceonSoftwareTechnologies

518

of the communication protocol represented with the

NCES. Finally, the ”ProtocolReconf” tool is used to

simulate the communication protocol.

In the future work, we plan to study the failure re-

covery functionality realized by the Control Agent in

order to provide the corrective measures to avoid the

failures due to hardware or software default. We aim

to study also the functionality covering the acquisi-

tion of data from and the forwarding of commands

(through the sensors and the actuators) to the physical

plant ensured by the Control Agent.

REFERENCES

Diedrich, C. and all (2004). Function block applications in

control systems based on iec 61804. ISA Transactions,

43:123131.

Gharbi, A., Khalgui, M., and Ahmed, S. B. (2010a). Inter-

agents communication protocol for distributed recon-

figurable control software components. The Interna-

tional Conference on Ambient Systems Networks and

Technologies (ANT), 8-10 Novembre.

Gharbi, A., Khalgui, M., and Ahmed, S. B. (2010b). Model

checking optimization of safe control embedded com-

ponents with refinement. 5th International conference

on Design and Technology of Integrated Systems in

Nanoscale Era.

Gharbi, A., Khalgui, M., and Ahmed, S. B. (2011a). Agent-

based fault management of embedded control sys-

tems. 6th International Conference on Software and

Data Technologies (ICSOFT), 18-21 Juillet.

Gharbi, A., Khalgui, M., and Ahmed, S. B. (2011b). Func-

tional safety of discrete event systems. First Workshop

of Discrete Event Systems.

Gharbi, A., Khalgui, M., and H-M.Hanisch (2009). Func-

tional safety of component-based embedded control

systems. 2nd IFAC Workshop on Dependable Control

of Discrete Systems.

Goessler, G., Graf, S., Majster-Cederbaum, M., Martens,

M., and Sifakis, J. (2007). An approach to modeling

and verification of component based systems.

Hanisch, H.-M. and Luder, A. (1999). Modular mod-

elling of closed-loop systems. in Colloquium on

Petri Net Technologies for Modelling Communication

Based Systems, pages 103–126.

Jennings, N. R., Sycara, K., and Wooldridge, M. (1998).

A roadmap of agent research and development. Au-

tonomous Agents and Multi-agent Systems, 1:7–38.

Khalgui, M., H-M.Hanisch, and Gharbi, A. (2009).

Model-checking for the functional safety of con-

trol component-based heterogeneous embedded sys-

tems. 14th IEEE International conference on Emerg-

ing Technology and Factory Automation.

Rausch, M. and Hanisch, H.-M. (1995). Net condition/event

systems with multiple condition outputs. in Sympo-

sium on Emerging Technologies and factory Automa-

tion, 1:592–600.

Roch, S. (2000). Extended computation tree logic: Im-

plementation and application. In Proceedings of the

AWPN2000 Workshop.

SZYPERSKI, C., GRUNTZ, D., and MURER, S. (2002).

Component Software Beyond Object-Oriented Pro-

gramming. The Addison-Wesley Component Soft-

ware Series.

van Ommering, R., van der Linden, F., Kramer, J., and

Magee, J. (2000). The koala component model

for consumer electronics software. IEEE Computer,

33:78–85.

Wittig, T. (1992). Archon: An architecture for multi-agent

system. Ellis Horwood, Chichester.

ModelCheckingofDistributedComponent-basedControlSystems

519