Selection of Sensors that Influence Trouble Condition Sign Discovery

based on a One-class Support Kernel Machine for Hydroelectric

Power Plants

Hiroshi Murata, Yasushi Shinohara and Takashi Onoda

System Engineering Research Laboratory, Central Research Institute of Electric Power Industry, Tokyo, Japan

Keywords:

Outlier Detection, Feature Selection, Support Kernel Machine, Hydroelectric Power Plant, Sensor.

Abstract:

Trouble conditions rarely occur in the equipment of hydroelectric power plants. Therefore, it is important to

find indicator signs for trouble conditions. In a previous study, we proposed a trouble condition sign discovery

method, which consists of two detection stages. In the first stage, we can discover trouble condition signs,

which are different from the usual condition data. In the second stage, we can monitor aging degradation, with

plant experts confirm these trouble condition signs in daily operations. Hence, there is a need to detect these

trouble condition signs using a small number of sensors. In this paper, we propose a method for narrowing

down the sensors used in trouble condition sign discovery. This paper shows the experimental results of

trouble condition sign detection for bearing vibration based on the collected data from different sensors using

our proposed method and our previously proposed method. The experimental results show that even if the

number of sensors is reduced, our proposed method can find trouble condition signs, which are different from

the usual condition data. Therefore, the proposed method may be useful for trouble condition sign discovery

in hydroelectric power plants.

1 INTRODUCTION

In order to realize efficient maintenance and re-

duce its cost, electric power companies recently be-

gan attempting to shift from a time-based mainte-

nance (TBM) to condition-based maintenance (CBM)

for electric equipment management (Yamana et al.,

2005), (Jardine et al., 2006). With TBM, equipment

is checked and changed based on the manufacturer’s

guarantee period. In contrast, with CBM, equipment

is checked, repaired and changed based on the state of

the equipment. This state consists of the actual condi-

tion of the equipment, its operation period, the opera-

tional load, etc.

It is important for electric power companies to col-

lect equipment data to realize CBM. In particular, it

is necessary to collect and analyze the previous trou-

ble condition data to discover trouble condition signs

for the power equipment. For instance, this might

include the discovery of trouble condition signs for

bearing vibration from the sensor information of the

hydroelectric power plant and the discovery of trouble

condition signs from the operation data of the power

generation plant. Trouble conditions rarely occur in

power equipment in Japan. Moreover, it is difficult to

construct an experimental power generation plant to

collect trouble condition data.

Thus, Kyushu Electric Power Co.,Inc. and Central

Research Institute of Power Industry are investigating

a detection method for the trouble condition signs of

bearing vibration in hydroelectric power plants. In

our research, we consider that the trouble condition

signs can be given by an increase in the occurrence of

special unusual condition data, because we can only

measure the normal condition data during the regular

operation of a hydroelectric power plant.

Thus, we are developing a detection method for

the occurrence of unusual condition data in the regu-

lar condition data, along with a management method

for trends in the generation of special unusual condi-

tion data related to bearing vibration from the regular

condition data for a hydroelectric power plant (Onoda

et al., 2009). This method consists of two detection

stages. In the first stage, we can discover trouble con-

dition signs, which are different from the usual condi-

tion data. In the second stage, we can monitor aging

degradation. Our proposed method is based on a one-

class support vector machine (one-class SVM) and a

normal support vector machine (SVM).

In the first stage, the detection method determines

466

Murata H., Shinohara Y. and Onoda T..

Selection of Sensors that Influence Trouble Condition Sign Discovery based on a One-class Support Kernel Machine for Hydroelectric Power Plants.

DOI: 10.5220/0004542704660473

In Proceedings of the 5th International Joint Conference on Computational Intelligence (NCTA-2013), pages 466-473

ISBN: 978-989-8565-77-8

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

the relevance between the degree of an unusual con-

dition and various pieces of sensor information using

the weights of the one-class SVM. However, it is dif-

ficult for plant experts to evaluate whether or not sen-

sors that have weights close to zero affect an unusual

condition. If our detection method is introduced in

an actual plant, plant experts will have to confirm the

trouble condition signs in daily operations. Hence,

there is a need to be able to confirm the trouble con-

dition signs using a small number of sensors.

In this paper, we propose a method for narrowing

down the sensors that influence an unusual condition.

This method is based on the one-class support kernel

machine (one-class SKM).

In Section 2 of this paper, we briefly explain our

proposed method for discovering a trouble condition

sign. We briefly describe the previously proposed

method to detect unusual condition data, and we pro-

pose a new method for the selecting sensors that influ-

ence an unusual condition. The experimental results

are shown in Section 3. Finally, we present conclu-

sions in Section 4.

2 PROPOSED METHOD

In this section, we give an outline of the trouble condi-

tion sign discovery method using the special unusual

condition data. In addition, we explain the previously

proposed method for detecting an unusual condition

pattern. Finally, we propose a new method for com-

bining the unusual condition pattern detection and the

sensor reduction.

2.1 Trouble Condition Sign Discovery

Approach

Generally, the discovery of a trouble condition

sign relies on the detection of a peculiar case that

appears only before an existing trouble condition

by comparing the regular condition data and trouble

condition data. However, it is a fact that the trouble

condition data for electric power equipment are

limited, because electric power plants are designed

with the high safety factors and are appropriately

maintained. Currently, our bearing vibration data for

hydroelectric power plants also do not include trouble

condition data. Therefore, it is impossible to discover

a peculiar case before the occurrence of trouble

condition data, because it is difficult to obtain trouble

condition data, and it is impossible to compare

regular condition data with trouble condition data.

Thus, we believe that the relation between a peculiar

condition before the occurrence of trouble condition

Figure 1: Image of Trouble Condition Sign Discovery.

data (hereafter, we call this the trouble condition

sign) and special unusual condition data is as follows.

The trouble condition sign ≈

A strong rise in the occurrence

of special unusual condition data.

It is possible to change the discovery of the

trouble condition sign to the detection of the special

unusual condition data in the regular condition data.

In other words, we suppose that the special unusual

condition data with a low probability of existing in

the regular condition data has a high probability of

being a trouble condition sign.

For the condition-based maintenance of hydro-

electric power plants, it is very important to discover

trouble condition signs. Our proposed trouble con-

dition data discovery method integrates the detec-

tion method for special unusual condition data and

a method of tracing the trends for the generation of

special unusual condition data.

Figure 1 shows an image of the trouble condition

sign discovery for the condition based maintenance

of hydroelectric power plants. Our proposed trou-

ble condition sign discovery method is an interactive

method. Our system mainly consists of two methods.

The first method is a selection method for the

special unusual condition data, which relate to the

trouble condition sign. This method consists of two

phases. The first phase is an unusual condition pat-

tern detection phase based on the one-class SVM or

one-class SKM. The next phase is the special unusual

condition data selection. The detected unusual con-

dition data may include unusual condition data gener-

ated by sensor faults and so on.

In our method, human experts detect strange data

such as the data generated by sensor faults using their

expertise, operation reports, etc., and then select the

data related to a trouble condition sign in the unusual

condition data. This selected unusual condition data

are defined as the special unusual condition data.

SelectionofSensorsthatInfluenceTroubleConditionSignDiscoverybasedonaOne-classSupportKernelMachinefor

HydroelectricPowerPlants

467

Figure 2: Image of Unusual Condition Data Detection.

The other method is the generation trend tracing

method based on a normal SVM. The unusual con-

dition data detection method detects some rare case

data in the regular condition data and displays these

patterns to experts. From the displayed patterns, the

experts select some data that may indicate a trouble

condition sign and teach them to the computer.

After this, the computer has the regular condition

data and the selected unusual condition data. Now, the

computer can generate an optimal hyperplane, which

can classify the two classes, by using an SVM. The

hyperplane classifies unseen data and finds some data

that are similar to the selected unusual condition data.

Therefore, the computer can trace the trend for the

generation of special unusual condition data.

2.2 Unusual Condition Pattern

Detection

Figure 2 shows the concept for the detection of un-

usual condition data in the regular condition data. In

this figure, the gray area denotes the regular condition

data area. In this research, the unusual condition data

are detected from this regular condition data. From

Figure 2, if we can find a hyper-sphere, that can cover

99% of the regular condition data, we can consider

the other 1% to be unusual condition data. This 99%

of the regular condition data are called “usual condi-

tion data.” In Figure 2, the inside of a circle shown

by a solid black line is the usual condition data area,

and the black stars denote the unusual condition data.

Therefore, if we can correctly find the boundary for

an area of α% in the regular condition area, it is pos-

sible to detect the unusual condition data that do not

belong to this α% area of the regular condition data.

We adopt a one-class SVM or one-class SKM to cor-

rectly find this boundary.

2.3 One-class Support Vector Machine

Sch

¨

olkopf et al. suggested a method of adapting the

SVM methodology to a one-class classification prob-

lem (Sch

¨

olkopf et al., 2000). Essentially, after trans-

forming the feature via a kernel, they treat the origin

as the only member of the second class. By using “re-

laxation parameters,” they separate the image of the

one class from the origin. Then, the standard two-

class SVM techniques are employed.

One-class SVM (Sch

¨

olkopf et al., 2000) returns

a function f that takes the value −1 in a “small” re-

gion, capturing most of the training data points, and

+1 elsewhere.

Let the training data be x

1

, . . . , x

N

, belongs to one

class X, where X is a compact subset of R

N

, and N

is the number of observations. Let Φ : X → H be a

kernel map that transforms the training examples into

a feature space. The dot product in the image of Φ

can be computed by evaluating some simple kernels,

k(x, y) = (Φ(x) · Φ(y)). (1)

Then, in order to separate the data set from the

origin, one needs to solve the following quadratic pro-

gram:

min

w,ξ,ρ

1

2

∥w∥

2

− νNρ +

∑

N

ξ

i

subject to (w · Φ(x

i

)) ≥ ρ − ξ

i

,

ξ

i

≥ 0.

(2)

Using multipliers α

i

, β

i

≥ 0, we introduce a La-

grangian

L(w, ξ, ρ, α, β) =

1

2

∥w∥

2

− νNρ +

∑

i

ξ

i

−

∑

i

α

i

((w · Φ(x

i

)) − ρ + ξ

i

) −

∑

i

β

i

ξ

i

(3)

and set the derivatives with respect to the primal

variables w, ξ

i

, ρ equal to zero, yielding

w =

∑

i

α

i

Φ(x

i

), (4)

α

i

= 1 − β

i

≤ 1,

∑

i

α

i

= νN. (5)

Substituting Eqs. (4) and (5) into Eq. (3), we obtain

the dual problem:

min

α

1

2

∑

i, j

α

i

α

j

Φ(x

i

) · Φ(x

j

) (6)

= min

α

1

2

∑

i, j

α

i

α

j

k(x

i

, x

j

) (7)

subject to 0 ≤ α

i

≤ 1,

∑

i

α

i

= νN . (8)

All patterns {x

i

: α

i

> 0, i = 1. . . N} are called support

vectors. These patterns correspond to the hyperplane.

From Eq. (8), ν ∈ (0, 1) is an upper bound on the

IJCCI2013-InternationalJointConferenceonComputationalIntelligence

468

fraction of outliers, and a lower bound on the fraction

of support vectors. The decision function

f (x) = sgn((w · Φ(x)) − ρ) (9)

will be positive for most examples of x

i

contained in

the training set, while the fraction of support vectors

will still be small. The actual trade-off between these

two is controlled by ν. For a new point x, the value

of f (x) is determined by evaluating which side of the

hyperplane it falls on. One can show that at the op-

timum, the two inequality constraints of Eq. (2) be-

come equalities if 0 < α

i

< 1. Therefore, we can re-

cover ρ by exploiting the fact that, for any such α

i

,

the corresponding pattern x

i

satisfies

ρ = w · Φ(x

i

) =

∑

j

α

j

k(x

j

, x

i

) (10)

2.4 One-Class Support Kernel Machine

One-class SKM was developed based on support ker-

nel machine (SKM) (Bach et al., 2004). SKM is a

kind of the multiple kernel learning problem defined

by Lanckriet et al. (Lanckriet et al., 2004). SKM is

able to combine feature selection and optimization.

Eq. (6) is transformed into

min

α

∑

j

(

∑

i

α

i

Φ(x

i, j

))

2

. (11)

This square sum is transposed to maximize the square

min

α

max

j

(

∑

i

α

i

Φ(x

i, j

))

2

, (12)

and transposed to maximize the absolute value

min

α

max

j

|

∑

i

α

i

Φ(x

i, j

)|. (13)

Eq. (13) is transformed into

min

α

w

0

subject to |w

j

| = |

∑

i

α

i

Φ(x

i, j

)| ≤ w

0

0 ≤ α

i

≤ 1,

∑

i

α

i

= νN.

(14)

Eq. (14) is a linear programming problem and leads

to a sparse w with good generalization properties.

Therefore, this equation can be solved quickly and it

selects efficient features. Here, the decision function

of the one-class SKM is the same as Eq. (9).

3 EXPERIMENT

In this section, we describe our experiment. In par-

ticular, we briefly introduce the measurement data,

our experimental setup, experimental results, and the

evaluation.

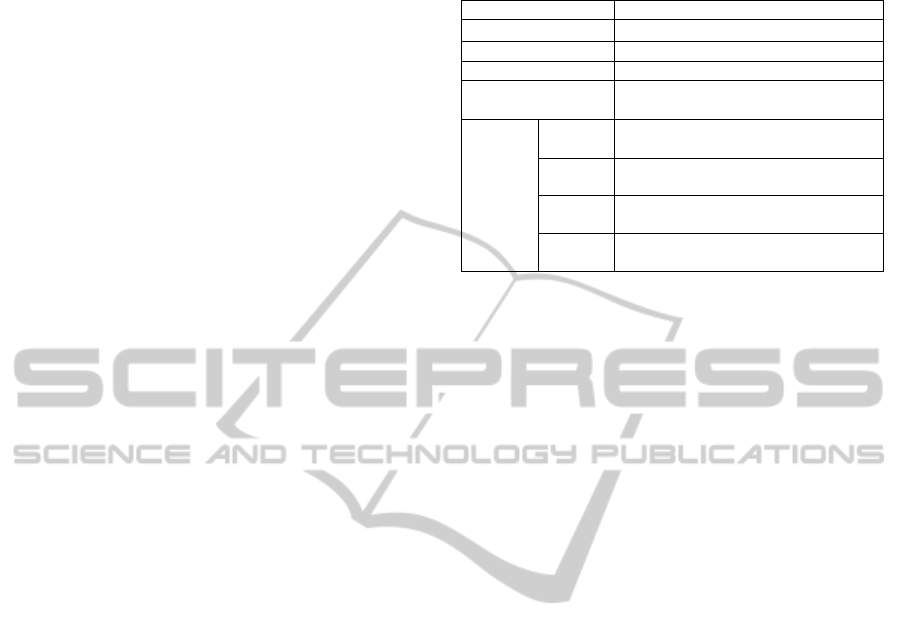

Table 1: Outline of Ooyodo River First Hydroelectric Power

Plant.

Generated Output 13,500kW

Working Water 42m

3

/s

Effective Head 38.40m

Turbine Type Vertical Shaft Francis Turbine

Rated Revolutions 200rpm

Per Minute

Upper Oil Self Contained Type Segment

Bearing Bearing (Oil Feeding)

Bearing Bottom Oil Self Contained Type Cylindrical

Bearing Bearing (Natural Cooling)

Type Turbine Oil Self Contained Type Segment

Bearing Bearing (Natural Cooling)

Thrust Oil Self Contained Type Michell

Bearing Bearing (Natural Cooling)

3.1 Measurement Data

Table 1 shows the outline of the Ooyodo River First

hydroelectric power plant. This hydroelectric power

plant has various sensors to measure data related to

bearing vibration. The measured operation data were

collected from the hydroelectric power plant and an-

alyzed using our proposed method. The measured

operation data related to bearing vibration were col-

lected from June 14, 2006, to January 31, 2008, at the

Ooyodo River First hydroelectric power plant.

One data set was composed of the sensor and

weather information from 38 measurement items for

a measurement interval of 5 s. All of the measurement

data were regular condition data and did not include

the trouble condition data.

3.2 Experimental Setup

Our experiment analyzed the measurement data,

which were explained in 3.1. The measurement data

were composed of 38 measurement items. However,

in order to detect the unusual condition data for bear-

ing vibration, we extracted the measurement items re-

lated to the bearing vibration from all of the measure-

ment items. Therefore, 16 measurement items were

selected based on the bearing vibration knowledge of

the experts to analyze the unusual condition data. Ta-

ble 2 shows these selected 14 measurement items.

The power generator operation consists of the

starting condition, parallel condition, parallel off

condition and stopping condition. The number

of starting condition data points and parallel off

condition data points was relatively very small in our

dataset. The number of parallel operation condition

data points was very large. If we analyzed all of the

measurement data to detect the unusual condition

data, the detected condition data consisted of the

SelectionofSensorsthatInfluenceTroubleConditionSignDiscoverybasedonaOne-classSupportKernelMachinefor

HydroelectricPowerPlants

469

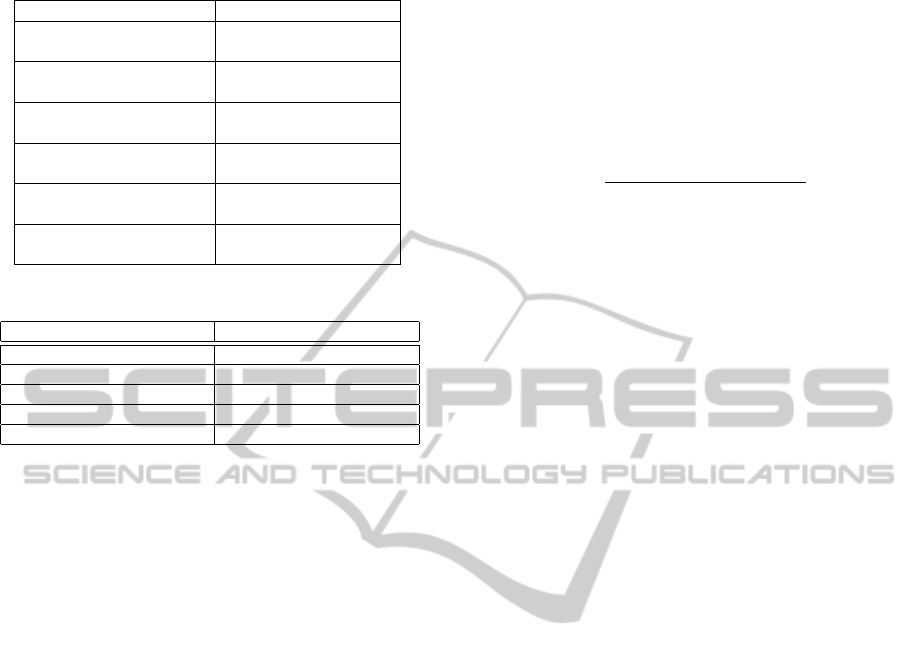

Table 2: Measurement Items.

A. Generated Output (MW) B. Revolutions Per Minute

C. Upper Bearing Oil Temp. − D. Turbine Bearing Oil

Oil Cooler Inlet Air Temp. (

◦

C) Temp. (

◦

C)

E. Thrust Bearing Temp. (

◦

C) F. Bottom Oil Tank Oil

Temp. (

◦

C)

G. Bottom Bearing Inlet Air H. Turbine Shaft Vibration

Temp. (

◦

C) (X axis) (µm)

I. Upper Bearing Vibration J. Upper Bearing Vibration

(Perpendicular) (µm) (Horizon) (µm)

K. Bottom Bearing Vibration L. Bottom Bearing Vibration

(Perpendicular) (µm) (Horizon) (µm)

M. Wheel Cover Vibration N. Wheel Cover Vibration

(Perpendicular) (µm) (Horizon) (µm)

Table 3: Number of Data Points for Each Condition.

Group The number of data points

Stopping condition 2,430,295

Starting condition 6,629

Parallel operation condition 4,346,259

Parallel off condition 672

Total 2,804,113

starting condition data or the parallel off condition

data, which were different from the parallel operation

condition data. This was not a good situation for our

analysis. Therefore, all of the measurement data were

divided into the following four groups based on the

expertise of the experts.

Starting condition:

Generator Voltage (V-W) < 10kV, Guide Vane

Opening ≥ 10% and Revolutions per Minute ≥ 200

rpm.

Parallel operation condition:

Generator Voltage (V-W) ≥ 10kV and

Revolutions per Minute ≥ 200 rpm.

Parallel off condition:

Generator Voltage (V-W) < 10kV, Guide Vane

Opening < 10% and Revolutions per Minute ≥ 200

rpm.

Stopping condition:

Otherwise.

These groups were defined by the experts. Ta-

ble 3 shows the number of data points in each

group.

In the stopping condition group, the bearing does

not rotate. Moreover, only one or less than one paral-

lel off condition data point was found for each actual

parallel off condition. Therefore, these data groups

were omitted from the analyzed data. In other words,

the unusual condition data were detected in the other

group, which were the starting condition and paral-

lel operation condition. We use a linear kernel in our

experiments because it is impossible to tune the ker-

nel parameters using only the regular condition data.

In order to ignore the different measurement units

and define the unsafe condition, the measurement

data were normalized using the following equation for

each measurement item for the one-class SVM.

value = −

actual value − min. value

max. value − min. value

+ 1

For the hydroelectric power plant, a high value for

any sensor denotes an unsafe condition. Therefore,

our method adopted the normalization.

The one-class SKM is equivalent to a one-class

SVM that applies optimized scaling. Therefore, the

measurement data were normalized to maintain the

variances of the features, and the origin became the

high value of each sensor. Additionally, the measure-

ment data points were multiplied by −1.

3.3 Unusual Condition Discovery

Experiment

The unusual condition data were discovered in the

starting condition data and the parallel condition data

by applying the one-class SVM or one-class SKM.

This experiment used the operation data measured

from June 14, 2006, to May 31, 2007, to find the

special unusual condition data. The discovered un-

usual condition data were determined to be special

unusual condition data based on the knowledge of hu-

man experts. In the starting condition, 0.1% of the

starting operation condition data was determined to

be unusual condition data. In the parallel condition,

0.002% of the parallel operation condition data was

determined to be unusual condition data. Tables 4

and 5 show the detected unusual condition data from

the starting operation condition data from the Ooyodo

River First hydroelectric power plant. The unusual

condition data that were detected by our system were

presented to experts to identify special unusual con-

dition data. These human experts pointed out a spe-

cial feature of the detected data. This feature was that

unusual values were detected in data point no. 15 of

Table 4 and data point no. 10 of Table 5. The human

experts checked the daily operation report for this day

and found the following fact. Oil leakage at bearing

was found and repaired on this day. This was a very

rare case and showed a trouble condition sign.

3.4 Discussion

Figures 3 and 4 show the monthly distributions of un-

usual condition data. From these figures, the results

IJCCI2013-InternationalJointConferenceonComputationalIntelligence

470

Table 4: Detected Unusual Condition from Starting Operation Condition using One-class SVM.

Data Point No. 1(1) 2 3 4 5(2) 6(3) 7 8 9(6)

Revolutions Per Minute 197.0 198.8 199.7 196.6 199.8 200.2 199.0 196.1 198.7

Upper Bearing Oil Temp. −

Oil Cooler Inlet Air Temp. (

◦

C) 13.8 10.8 12.4 12.0 12.7 13.4 11.3 12.6 13.4

Turbine Bearing Oil Temp. (

◦

C) 52.4 46.0 48.5 49.8 49.8 50.1 46.6 50.4 47.9

Thrust Bearing Temp. (

◦

C) 50.2 45.0 50.2 49.1 50.1 51.5 49.1 49.9 .48.6

Bottom Oil Tank Oil Temp. (

◦

C) 43.9 40.8 45.8 45.8 45.8 45.9 45.2 46.0 43.3

Bottom Bearing Inlet Air Temp. (

◦

C) 29.8 29.1 31.0 30.6 30.1 29.8 30.8 31.2 27.6

Turbine Shaft Vibration (X axis) (µm) 190 146 139 140 152 155 145 156 139

Upper Bearing Vibration (Perpendicular) (µm) 6 20 8 13 11 9 9 13 16

Upper Bearing Vibration (Horizon) (µm) 19 21 20 18 20 21 20 19 20

Bottom Bearing Vibration (Perpendicular) (µm) 12 14 13 12 13 13 13 12 14

Bottom Bearing Vibration (Horizon) (µm) 1 1 13 12 1 14 14 1 2

Wheel Cover Vibration (Perpendicular) (µm) 2 2 3 6 2 2 2 29 2

Wheel Cover Vibration (Horizon) (µm) 28 23 0 0 28 0 0 0 24

Data Point No. 10 11(7) 12 13 14(8) 15(10) 16 17 18

Revolutions Per Minute 196.3 197.0 202.5 198.2 198.5 198.8 195.6 196.3 196.2

Upper Bearing Oil Temp. −

Oil Cooler Inlet Air Temp. (

◦

C) 13.9 13.8 14.0 14.6 14.7 21.9 22.2 22.4 22.4

Turbine Bearing Oil Temp. (

◦

C) 48.8 48.5 48.6 48.8 38.5 40.0 42.4 43.5 43.8

Thrust Bearing Temp. (

◦

C) 48.0 48.8 46.0 47.2 41.0 41.3 50.0 49.8 49.8

Bottom Oil Tank Oil Temp. (

◦

C) 44.4 44.4 43.0 43.1 36.5 34.0 35.3 36.2 36.3

Bottom Bearing Inlet Air Temp. (

◦

C) 27.8 27.5 27.0 26.5 21.1 13.9 16.2 16.1 16.0

Turbine Shaft Vibration (X axis) (µm) 162 155 133 140 130 126 251 280 278

Upper Bearing Vibration (Perpendicular) (µm) 15 22 3 21 27 22 32 28 29

Upper Bearing Vibration (Horizon) (µm) 18 18 18 19 16 15 21 20 19

Bottom Bearing Vibration (Perpendicular) (µm) 12 13 12 14 15 16 13 13 13

Bottom Bearing Vibration (Horizon) (µm) 2 2 1 2 1 8 1 1 1

Wheel Cover Vibration (Perpendicular) (µm) 2 2 25 2 22 4 2 2 2

Wheel Cover Vibration (Horizon) (µm) 24 26 1 20 0 0 2 2 2

Note: The data point numbers from Table 5 are shown in parentheses.

Table 5: Detected Unusual Condition from Starting Operation Condition using One-class SKM.

Data Point No. 1(1) 2(5) 3(6) 4 5 6(9) 7(11) 8(14) 9

Revolutions Per Minute 197.0 199.8 200.2 198.5 199.1 198.7 197.0 198.5 197.2

Upper Bearing Oil Temp. −

Oil Cooler Inlet Air Temp. (

◦

C) 13.8 12.7 13.4 12.8 11.5 13.4 13.8 14.7 21.5

Turbine Bearing Oil Temp. (

◦

C) 52.4 49.8 50.1 50.1 46.8 47.9 48.5 38.5 39.8

Thrust Bearing Temp. (

◦

C) 50.2 50.1 51.5 50.0 50.0 .48.6 48.8 41.0 40.8

Bottom Oil Tank Oil Temp. (

◦

C) 43.9 45.8 45.9 46.3 44.8 43.3 44.4 36.5 33.9

Bottom Bearing Inlet Air Temp. (

◦

C) 29.8 30.1 29.8 30.8 31.2 27.6 27.5 21.1 14.1

Turbine Shaft Vibration (X axis) (µm) 190 152 155 168 140 139 155 130 130

Upper Bearing Vibration (Perpendicular) (µm) 6 11 9 7 7 16 22 27 15

Upper Bearing Vibration (Horizon) (µm) 19 20 21 20 21 20 18 16 14

Bottom Bearing Vibration (Perpendicular) (µm) 12 13 13 24 26 14 13 15 15

Bottom Bearing Vibration (Horizon) (µm) 1 1 14 2 1 2 2 1 1

Wheel Cover Vibration (Perpendicular) (µm) 2 2 2 0 0 2 2 22 16

Wheel Cover Vibration (Horizon) (µm) 28 28 0 2 2 24 26 0 3

Data Point No. 10(15) 11 12 13 14 15 16 17 18

Revolutions Per Minute 198.8 198.7 196.0 203.3 199.1 200.7 198.7 199.0 197.2

Upper Bearing Oil Temp. −

Oil Cooler Inlet Air Temp. (

◦

C) 21.9 23.7 22.2 20.5 13.8 16.1 15.4 11.3 11.2

Turbine Bearing Oil Temp. (

◦

C) 40.0 37.9 42.2 43.9 29.2 35.7 43.0 28.8 27.8

Thrust Bearing Temp. (

◦

C) 41.3 40.5 50.1 43.1 37.2 42.8 45.9 39.8 39.3

Bottom Oil Tank Oil Temp. (

◦

C) 34.0 31.8 35.2 35.8 30.2 35.2 39.3 32.6 31.9

Bottom Bearing Inlet Air Temp. (

◦

C) 13.9 11.4 16.2 17.2 17.9 19.8 22.3 22.9 23.8

Turbine Shaft Vibration (X axis) (µm) 126 120 295 135 73 86 111 65 72

Upper Bearing Vibration (Perpendicular) (µm) 22 14 23 4 6 22 9 8 14

Upper Bearing Vibration (Horizon) (µm) 15 12 20 14 14 16 15 14 15

Bottom Bearing Vibration (Perpendicular) (µm) 16 16 14 15 19 17 17 29 29

Bottom Bearing Vibration (Horizon) (µm) 8 0 1 9 1 1 11 1 1

Wheel Cover Vibration (Perpendicular) (µm) 4 14 2 3 19 20 2 0 0

Wheel Cover Vibration (Horizon) (µm) 0 2 2 0 2 0 0 1 1

Note: The data point numbers from Table 4 are shown in parentheses.

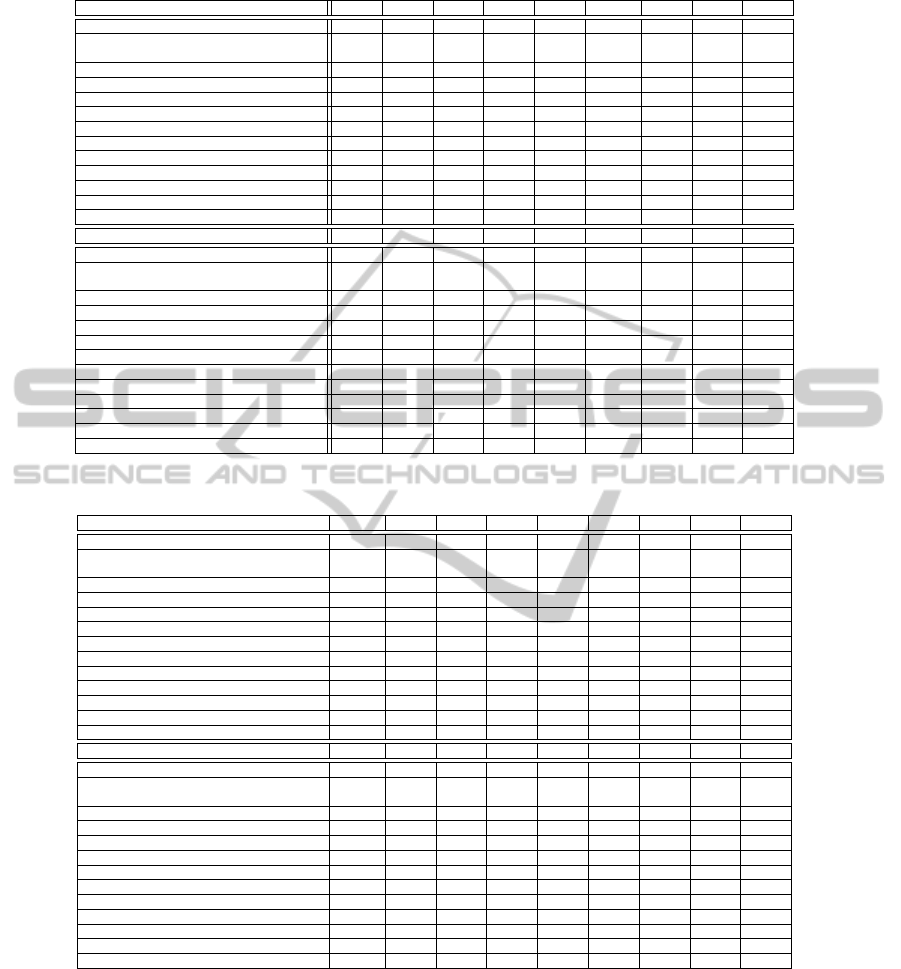

for the one-class SVM (OCSVM) were highly biased

in summer. On the other hand, the one-class SKM

(OCSKM) reduced this bias.

Tables 6 and 7 show the weight factors w for the

starting condition data and parallel condition data. In

OCSKM, the turbine bearing oil temperature, thrust

bearing temperature, and bottom oil tank oil temper-

ature are zero. These temperature features reach high

values in summer. Therefore, the unusual condition

data of OCSVM increase in summer.

4 CONCLUSIONS

There are two kinds of trouble condition signs. The

first indicates an accidental trouble condition, where

the data are different from the usual condition data.

The other kind of trouble condition sign indicates

SelectionofSensorsthatInfluenceTroubleConditionSignDiscoverybasedonaOne-classSupportKernelMachinefor

HydroelectricPowerPlants

471

Figure 3: Monthly Distribution of Unusual Condition Data

(Starting Operation Condition).

Figure 4: Monthly Distribution of Unusual Condition Data

(Parallel Operation Condition).

aging degradation. If aging degradation occurs in

a hydroelectric power plant, then this second kind

of trouble condition sign increases year by year. In

our method, we identified this second kind of trou-

ble condition sign using special unusual condition

data, which were discovered by an interaction be-

tween computers and human experts. However, it is

difficult for human experts to evaluate whether or not

sensors with weights of nearly zero affect an unusual

condition. If our detection method is introduced in

actual plant, human experts will need to confirm the

trouble condition signs in daily operations. Hence,

there is a need to be able to confirm trouble condition

signs using a small number of sensors. In this paper,

we proposed a method for narrowing down the sen-

sors that indicate an unusual condition. This method

was based on a one-class SKM.

Our unusual condition discovery experiment

showed that the one-class SKM found the trouble con-

dition signs in a hydroelectric power plant by using a

Table 6: Weighting Factors for Starting Operation Condi-

tion.

OCSVM OCSKM

Revolutions Per Minute 8.13 0.54

Upper Bearing Oil Temp. −

Oil Cooler Inlet Air Temp. (

◦

C) 9.16 0.72

Turbine Bearing Oil Temp. (

◦

C) 2.62 0

Thrust Bearing Temp. (

◦

C) 2.02 0

Bottom Oil Tank Oil Temp. (

◦

C) 2.38 0

Bottom Bearing Inlet Air Temp. (

◦

C) 4.22 0

Turbine Shaft Vibration (X axis) (µm) 7.70 1.68

Upper Bearing Vibration (Perpendicular) (µm) 9.22 0.29

Upper Bearing Vibration (Horizon) (µm) 3.45 0

Bottom Bearing Vibration (Perpendicular) (µm) 10.33 2.98

Bottom Bearing Vibration (Horizon) (µm) 11.81 2.15

Wheel Cover Vibration (Perpendicular) (µm) 13.23 2.45

Wheel Cover Vibration (Horizon) (µm) 10.86 2.20

ρ 52.72 10.71

Table 7: Weighting Factors for Parallel Operation Condi-

tion.

OCSVM OCSKM

Generated Output (MW) 1.58 0.09

Revolutions Per Minute 3.34 1.26

Upper Bearing Oil Temp. −

Oil Cooler Inlet Air Temp. (

◦

C) 9.83 3.35

Turbine Bearing Oil Temp. (

◦

C) 0.73 0

Thrust Bearing Temp. (

◦

C) 1.20 0

Bottom Oil Tank Oil Temp. (

◦

C) 1.49 0

Bottom Bearing Inlet Air Temp. (

◦

C) 2.09 1.72

Turbine Shaft Vibration (X axis) (µm) 7.72 0.75

Upper Bearing Vibration (Perpendicular) (µm) 9.68 1.20

Upper Bearing Vibration (Horizon) (µm) 6.17 0.24

Bottom Bearing Vibration (Perpendicular) (µm) 9.80 1.36

Bottom Bearing Vibration (Horizon) (µm) 10.50 1.37

Wheel Cover Vibration (Perpendicular) (µm) 10.59 1.39

Wheel Cover Vibration (Horizon) (µm) 9.76 1.27

ρ 48.65 11.95

large quantity of usual condition data. In addition,

a one-class SKM was found to reduce the extraction

bias in summer for the one-class SVM.

In future work, we plan to apply our method to

evaluate the soundness of real hydroelectric power

plants in Japan and verify the effectiveness of our

method for risk management in hydroelectric power

plants.

REFERENCES

Bach, F. R., Lanckriet, G. R. G., and Jordan, M. I. (2004).

Multiple kernel learning, conic duality, and the SMO

algorithm. In Proceedings of the twenty-first interna-

tional conference on Machine learning, ICML ’04.

Jardine, A. K., Lin, D., and Banjevic, D. (2006). A review

on machinery diagnostics and prognostics implement-

IJCCI2013-InternationalJointConferenceonComputationalIntelligence

472

ing condition-based maintenance. Mechanical Sys-

tems and Signal Processing, 20(7):1483 – 1510.

Lanckriet, G. R. G., Cristianini, N., Bartlett, P., Ghaoui,

L. E., and Jordan, M. I. (2004). Learning the ker-

nel matrix with semidefinite programming. Journal of

Machine Learning Research, (5):27–72.

Onoda, T., Ito, N., and Hironobu, Y. (2009). Trouble condi-

tion sign discovery based on support vector machines

for hydroelectric power plants. In Proceedings of the

2009 international joint conference on Neural Net-

works, IJCNN’09, pages 1201–1208.

Sch

¨

olkopf, B., Smola, A. J., Williamson, R. C., and Bartlett,

P. L. (2000). New support vector algorithms. Neural

Computation, 12(5):1207–1245.

Yamana, M., Murata, H., Onoda, T., Ohashi, T., and Kato,

S. (2005). Development of system for crossarm reuse

judgment on the basis of classification of rust images

using support vector machine. In Proceedings of the

17th IEEE International Conference on Tools with Ar-

tificial Intelligence, ICTAI ’05, pages 402–406, Wash-

ington, DC, USA. IEEE Computer Society.

SelectionofSensorsthatInfluenceTroubleConditionSignDiscoverybasedonaOne-classSupportKernelMachinefor

HydroelectricPowerPlants

473