Throwing and Capturing of Workpieces by Robots

New Transport Services for the Internet-Of-Things in Production Systems

Heinz Frank

1

and Roland Koblinger

2

1

Campus Kuenzelsau, Heilbronn University, Daimlerstrasse 39, Kuenzelsau, Germany

2

Wittenstein AG, Walter-Wittenstein-Str. 1, Igersheim,Germany

Keywords: Intralogistic, Robot, Throwing, Capturing, Internet-Of-Things.

Abstract: In the first part of the paper for the transportation of workpieces within production systems an approach in

which robots are throwing and capturing the workpieces is presented. This concept also can be applied for

elevating, turn-over and commissioning of workpieces. The main advantages of this method are high

speeds, high flexibility and the need of few resources. In the second part of the paper it is described how

throwing and capturing of workpieces can be applied in production systems which are realized according to

the internet-of-things concept.

1 INTRODUCTION

In the past years throwing and capturing by robots

was investigated as a new technology for the

handling and transportation of workpieces in

production systems. It was shown that it is possible,

to throw objects from one robot to another over

distances of several meters. In this paper different

examples for the application of this new method will

be proposed. Further it will be discussed, how such

robots can provide new services for the IOT-concept

(IOT – internet-Of–things) in production systems.

2 STATE OF THE ART

Many research works have been performed in the

past at first to investigate throwing and capturing of

ball shaped objects by robots (Frese et al., 2001);

(Senoo et al., 2008); (Barteit, 2009). During the last

years also throwing and capturing of axial-

symmetric objects was developed (Frank et al.,

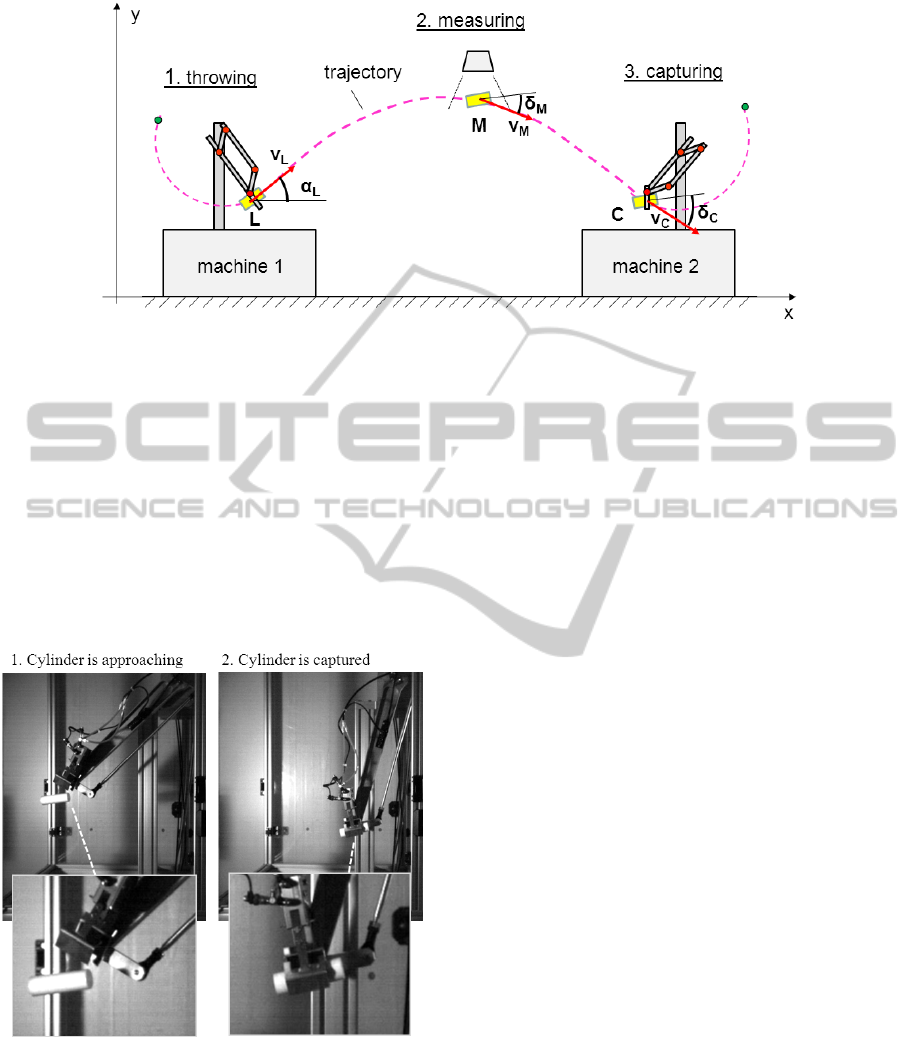

2012); (Frank, 2013). Figure 1 shows a 2-DOF

parallel kinematic robot which is capable to throw

and capture such objects over distances of 3 m. It

consists of an arm-axis which has a length of 50 cm

and a gripper-axis which can be turned in its tool

center point (TCP). Both axes are driven each by a

servo motor.

The concept for throwing and capturing of axial-

symmetric objects in their axial direction is shown in

Figure 2. For launching the objects, the robot

accelerates its arm in a rotary movement until the

object achieves in the launching point L its throwing

angle α

L

and its throwing-speed v

L

. At this point the

object is released from the gripper. The parameters

α

L

and v

L

must be controlled very accurate, so that

the thrown object meets on its trajectory the

predefined capturing point C with a high precision.

Figure 1: 2-DOF parallel kinematic robot for throwing and

capturing of axial-symmetric objects.

During the flight the pose of the object is measure

on its trajectory at a point M. With this measurement

434

Frank H. and Koblinger R..

Throwing and Capturing of Workpieces by Robots - New Transport Services for the Internet-Of-Things in Production Systems.

DOI: 10.5220/0004584004340438

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2013), pages 434-438

ISBN: 978-989-8565-71-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 2: Concept for throwing and capturing of axial-symmetric objects.

the pose of the object at the capturing point C can be

predicted.

For capturing the object the robot arm is also

accelerated in a rotary movement. The gripper must

arrive at the capturing point C at the same time and

with the same speed v

C

as the flying object (Figure

3). Based on the prediction of the pose in the

capturing point, the object can be captured within

the xy-plane in different angles. After clamping the

object during its flight, it will be softly decelerated

with the arm-axis of the robot.

Figure 3: Capturing of a cylinder.

In (Frank, 2013) this concept was validated by

throwing of two different types of cylinders. One of

them was compliant flying, which means that the

orientation of the cylinder was following during its

flight always the direction of its trajectory. This

cylinder was captured in 98 % of the throws.

Another cylinder with a higher mass and a smaller

diameter was not compliant flying. It arrived at the

capturing point with different angles in the xy-plane.

This cylinder could be captured successfully in 85 %

of the throws.

3 APPLICATIONS

FOR THROWING

AND CAPTURING

In this chapter several examples for the application

of throwing and capturing by robots in the intra-

logistic of production systems are presented.

3.1 Transportation of Workpieces

As already shown in Figure 2, throwing and

capturing can be applied for the transportation of

workpieces between two machines. For the safety of

people the space in which workpieces are thrown

must be protected by guards. The following

advantages could be achieved with such a concept:

The workpieces can be thrown with high speeds

directly from the handling robot at one machine to

the handling robot at another machine. So the

transportation times will be very short.

The workpieces can be thrown from a robot to any

random point within a limited space. So the

transportation is for the destination points of the

workpieces very flexible. This is useful not only

for the transportation to different machines within

an area but also when machines are relocated from

time to time.

Already today many machines are equipped with

handling robots to load and unload workpieces

to/from machines. If such handling robots would

be extended with the capability for throwing and

ThrowingandCapturingofWorkpiecesbyRobots-NewTransportServicesfortheInternet-Of-ThingsinProduction

Systems

435

capturing, no additional transportation equipment

would be required to bring the workpieces from

one machine to another.

3.2 Elevation of Workpieces

In production systems workpieces sometimes must

be raised from one level to another. Figure 4 shows

as an example a study for a continuous flow

production, in which vials for pharmaceutical

products were thrown onto a band-conveyor. In this

approach the throwing parameters were controlled

so, that the vials arrived only a few millimeters

above the conveyor and with the same speed as the

conveyor. The main goal of this approach was to

avoid frictions at the vials within an aseptic

environment.

Figure 4: Elevation of vials onto a conveyor.

3.3 Turnover of Workpieces

Workpieces can be turned-over by throwing and

capturing from one orientation to another. For such

an operation a workpiece can be thrown with the

arm of the robot vertical up. At the launching-point

the gripper-axis must give the workpiece also a

certain turning movement. So the robot can capture

the workpiece again like a juggler. Today turn-over

operations are performed either by separate turn-

over devices or by robots which put the workpieces

first on a deposition place, than turn their gripper

and finally grap them again. Such an operation is

generally very time-consuming.

3.4 Commissioning of Parts

from a High-bay Racking

Figure 5 shows a concept for commissioning of parts

from a high-bay racking. From the bin locations

individual parts can be pushed out so that they are

falling down. A robot can capture the parts during

their flight, decelerate them smoothly and then put

them onto a conveyor belt. So a predefined sequence

of parts can be achieved on the conveyor belt. The

main advantage of this concept is its high

commissioning rate.

Figure 5: Commissioning of parts from a high back racket.

3.5 Operations which need

an All-around Access for Parts

In production some operations need for the parts an

all-around access. Examples are inspections by

cameras and coating, painting or surface-treatment

of workpieces. Such operations could be performed

when parts are flying. During the flight time the

parts then can be accessed from each side. The flight

time however is in general only the fraction of a

second.

4 THROWING ROBOTS

FOR THE

INTERNET-OF-THINGS

4.1 IOT-concept

Since the complexity of many production systems is

steadily increasing, today much research work is

performed to adapt the principles of the world-wide-

web (global interconnected network of computers)

for production systems. In such systems production

devices are considered as an interconnected network

of things (IOT – internet of things). The main

features of such systems can be summarized as

follows (Hribernik et al., 2010); (Wagner et al.,

2010), (Hompel et al., 2008), (Vossiek et al., 2010):

Individual production devices like machines,

robots and transport systems shall be realized as

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

436

decentralized autonomous units (things) which

offer production services and which are able to

collaborate with each other. Therefore they must

be connected directly to the internet

communication network.

Like subnets in the internet, production systems

shall provide redundancies and a high robustness.

For an easy adaption to new production

requirements it shall be possible to remove and

add things very easily („Plug’n’Produce“).

Objects which have to be moved through the

network of things, like individual parts, individual

tools or pallets with several parts or tools must be

equipped with an identification-tag (e.g. RFID -

radio-frequency identifi-cation) which can be read

by the transportation devices.

The basic principles for controlling the information

flows in the world-wide-web shall be adapted in

the IOT for the control of the material flow.

Objects shall move self-determined through the

network. According to their desired workflow the

objects are asking themselves for their desired

transportation and processing services.

4.2 Throwing and Capturing

in a Subsystem of an IOT

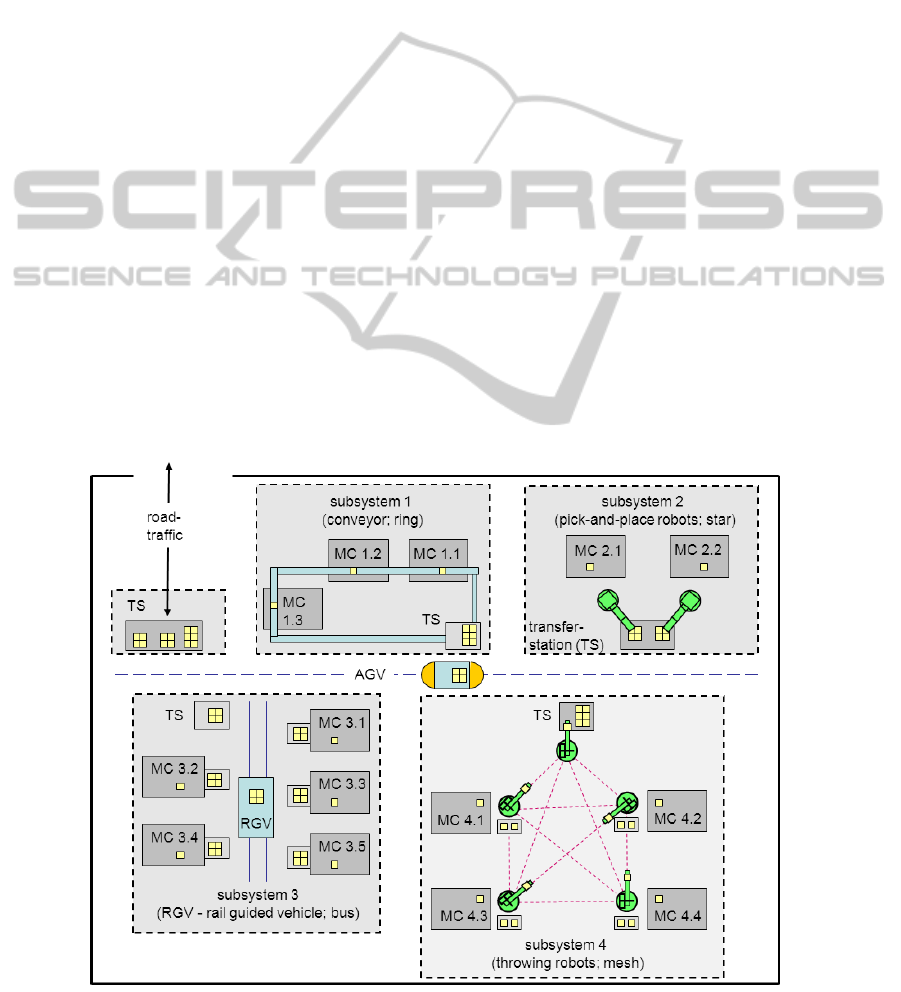

In the world-wide-web subnets can be realized with

different media like fiber optics, twisted pair or

WLAN and different topologies like line, mesh and

ring. As it can be seen in Figure 6 in subsystems of

production systems in an analogy different types of

transport systems like automated guided vehicles

(AGV), conveyors, pick-and-place robots, and rail

guided vehicles (RGV) can be used.

The application of throwing robots is shown

within Figure 6 in subsystem 4. Therefor the robot,

as it is shown in Figure1, would require an

additional axis to turn the whole robot into different

directions. In an IOT-concept the method of

throwing and capturing provides the following

advantages features:

The robots are autonomous devices which need for

the interconnection to their surrounding only a

cable for their power supply. The connection to the

internet can be performed by WLAN. The robots

don’t need any direct mechanical connections to

other devices.

For plug ‘n produce a throwing robot at first must

be toughed with its own location within the

production system. In addition to this it needs the

locations of the other throwing robots, which it can

retrieve from them via WLAN.

For the transportation of parts the robots offer

services for throwing and capturing as they are

described in chapter 3. When e.g. a transport-

service is requested from an object, the throwing

Figure 6: Example for the intra-logistic in a production environment with different types of subsystems.

ThrowingandCapturingofWorkpiecesbyRobots-NewTransportServicesfortheInternet-Of-ThingsinProduction

Systems

437

robot needs further information like dimensions

and the mass. Such information the robot can

retrieve from the internet. Then the throwing-robot

has to request the capturing-service from another

robot. After that the transportation can be

performed.

For the transportation of the objects within the

subsystem alternate paths can be used. For that

automatically routing tables can be generated

within the robots similar to the routing tables

within routers in the internet.

5 CONCLUSIONS

In the first part of this paper for the transportation

and handling of workpieces within production

systems a visionary method for throwing and

capturing them by robots was presented. The

advantages of this method would be short times,

high flexibility and the need of few resources. In

several research works it was already proved, that

this method is basically working. On the other hand

further research work is still required to make this

method for practical applications more reliable. In

the second part of the paper it was shown, that the

features of throwing robots provide good conditions

for their integration in IOT-concepts.

REFERENCES

Frank, T., Janoske, U., Mittnacht, A., and Schroedter, C.,

2012. Automated throwing and capturing of cylinder-

shaped objects. In Proceedings of the 2012 IEEE

International Conference on Robotics an Automation

(ICRA 2012), pp. 5264 – 5270.

Frank, T., 2013. Zur Automatisierung des sanften Werfens

und Fangens von Objekten zum Zwecke des

innerbetrieblichen Transports. Bergische Universität

Wuppertal: Dissertation.

Frese, U., Bäuml, B., Haidacher, S., Schreiber, G.,

Schaefer, I., Hähnle, and M., Hirzinger, G., 2001. Off-

the shelf vision for a robotic ball catcher. In

Proceedings of the 2001 IEEE International

Conference on Intelligent Robots and Systems.

Senoo, T., Namiki, A., and Ishikawa, M., 2008. High-

speed throwing motion based on kinetic chain

approach. In Proceedings of the 2008 IEEE

International Conference on Intelligent Robots and

Systems, pp. 3206 – 3211.

Barteit, D. F., 2009. Tracking of thrown objects. Vienna

University of Technology: Dissertation.

Hribernik, K. A., Warden, T., Thoben, K. D., and Herzog,

O., 2010. An Internet of things for transport logistics –

An approach to connecting the information and

material flows in autonomous cooperating logistic

processes. MITIP 2010 – Conference on Modern

Information Technology in the Innovation Processes ,

Aalborg University. Available: http://www.sfb637.uni-

bremen.de/pubdb/repository/SFB637-C2-10-004-IC.pdf

Wagner, T., Haußner, C., Elger, J., Löwen, U., and Lüder,

A., 2010. Engineering processes for decentralized

factory automation systems. InTech. Available:

www.intechopen.com/ books/ factory-automation/engi-

neering-

processes- for- decentralized- factory-automat-

ion- systems

Ten Hompel, M., and Nagel, L., 2008. Cellular transport

systems – Making things move in the „internet of

things.“ Oldenbourg Wissenschaftsverlag, IT- Infor-

mation Technology 50 (2008) 1, pp 59 -65.

Vossiek, M., Miesen, R., and Wittwer, J., 2010. RF

identification and localization - Recent steps towards

the internet of things in metal production and

processing. In Proceedings on 18

th

IEEE International

Conference on Microwave Radar and Wireless

Communications (MIKON).

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

438