Towards a “Holistic” Safety Monitoring in Intelligent Vehicle Control

Tim K

¨

ohler

1

and Martin Schr

¨

oer

2

1

DFKI GmbH, Robotics Innovation Center, Bremen, Germany

2

University of Bremen, Robotics Research Group, Robert-Hooke-Straße 5, 28359 Bremen, Germany

Keywords:

Intelligent Vehicle Control, Car Safety, Electric Vehicle, Model-Based Prediction, Fault Detection, Human-

Machine Interface.

Abstract:

Today, the state of the art in vehicle safety follows an explicit design flow. Specific sensors measure a particular

dimension (e.g. distance to other vehicles) and “safety” is defined as a specific range of allowed values (e.g.

minimal distance). The disadvantage of such an approach is that safety issues which were unconsidered

at design time are not detectable. Furthermore, a detection of issues that are only indirectly measurable is

difficult to realize. In this paper, a holistic safety monitoring approach is presented that makes use of all

available sensor data and tries to find an implicit definition of “safety”. By such an inverse approach vehicle

safety issues which are hard to be directly measurable might be detectable, too. For instance, an identification

of driver-initiated critical situations (e.g. caused by distraction) could be possible if taking multiple sensor

modalities into account and having an implicitly defined “safe” state.

Furthermore, the article describes the selection of potential test platforms and shows already collected test data

of a mobile robot platform. Presented in this work-in-progress paper is the concept of definition, implementa-

tion, and detection of implicit vehicle safety.

1 INTRODUCTION

Intelligent vehicle safety mechanisms are currently

following an explicit design: safety is designed ex-

plicitly in specific modalities. For example, distance

sensors measure explicitly the distance to other vehi-

cles or obstacles in the vicinity and “safety” is defined

as a certain minimum distance related to the current

speed. For lane-keeping assistants and airbags it is the

same, having “safety” defined as certain thresholds of

distances/angles or accelerations, respectively.

While these methods ensure a safe state in the

respective modality, the question arises if a general,

multi-modal definition of safety is possible (and de-

tectable), too. The point is that on the one hand side a

combination of several slightly increased safety mea-

sures may – altogether – indicate a critical safety issue

while on the other hand a single threshold exceeding

might be tolerable. Besides, such a “holistic safety

monitoring” could perhaps even cover cases which

are not known at design time. As the driver’s be-

haviour influences the system and its sensor readings,

it could be possible (up to a certain extent) to detect

driver-initiated safety issues, too.

Furthermore, in single-modality setups a drop out

of a single sensor is a potential cause for a “false-

positive” triggering of a safety mechanism or for a

“false-negative” rejection of executing safety means.

Addressing such drop-outs, the field of fault detec-

tion, isolation, and recovery arose. Here, implicit or

explicit models are used to generate predictions (ex-

pectations) of monitored sensor states. By the differ-

ence between expectation and measured value, mis-

behaviour can be detected. Using a (learnable) model

for multi-modal predictions and a multi-modal evalu-

ation is a candidate for a holistic safety monitoring.

In the following two sections, related work and a

proposition for a holistic safety monitoring system is

described. In section 4 sample data of a mobile robot

is shown. The section 5 presents potential vehicles to

test the proposed system. In the last section a conclu-

sion and an outlook are given.

2 RELATED WORK

One typical class of vehicle safety systems focuses on

the detection of particular safety-harming conditions.

In case of detection, either the driver is warned or the

system triggers a fixed pre-defined countermeasure.

583

Köhler T. and Schröer M. (2013).

Towards a “Holistic” Safety Monitoring in Intelligent Vehicle Control.

In Proceedings of the 10th International Conference on Informatics in Control, Automation and Robotics, pages 583-588

DOI: 10.5220/0004633905830588

Copyright

c

SciTePress

control

commands traction

ext. forcesacceleration

visual feedback sensory feedback

Driver Environment

Monitoring

Model Based Prediction

Vehicle

Figure 1: Overview of the proposed safety monitoring.

A recent example for this class is the pedestrian de-

tection method presented by Van Beeck et al. in 2012

(Van Beeck et al., 2012).

A learned generation of expectations of sensor

consequences was published by Pastor et al. (Pastor

et al., 2011). Based on sensor training data, expec-

tations (mean and variance) are learned. The appli-

cation presented in that publication is a manipulating

two-arm robot.

In the field of fault detection and identifica-

tion several model-based approaches have been pre-

sented. The specific case of combining multiple sen-

sor modalities and learning the model was studied, too

(K

¨

ohler et al., 2013). But the objective in approaches

like that one is different: There, a fault, e.g. drop out,

of a part of the system is to be detected while in vehi-

cle safety monitoring a certain state or range of states

in correct sensor readings is to be found. However, the

proposed methods for fault detection are good can-

didates to be adapted for the application of vehicle

safety monitoring.

3 LEARNING AND EVALUATION

OF VEHICLE STATE

The main components needed for the proposed safety

monitoring are a) a learnable and multi-modal model,

b) predictions (“expectations”) based on the model,

and c) a monitoring and triggering mechanism to de-

tect “unsafe” or “unusual” conditions. In figure 1 the

single components are depicted.

Different methods of model and expectation gen-

eration have been studied in previous work (to be pub-

lished). These methods have been tested on a four-

wheeled mobile robot. Their application to a human-

driven vehicle needs to be tested. However, the sensor

modalities used there are a subset of the modalities

to be used in a vehicle safety system (see sections 4

and 5). Examples of such explicit vehicle safety

systems are anti-lock braking system (ABS), elec-

tronic stability control (ESC), traction control sys-

tem (TCS) / anti-slip regulation (ASR), airbag, intel-

ligent speed adaptation (ISA) / distance warning / dis-

tance control, lane departure warning system (LDWS)

/ lane keeping assist, and driver attention monitor.

These systems use single sensor modalities and are

designed aiming for a particular unsafety condition

(and triggering a particular safety measure). The sen-

sor modalities needed in the mentioned examples are

wheel speeds, accelerations and gyroscopes, distance

sensors, and cameras. These are typical candidates

for the “sensory feedback” data in figure 1.

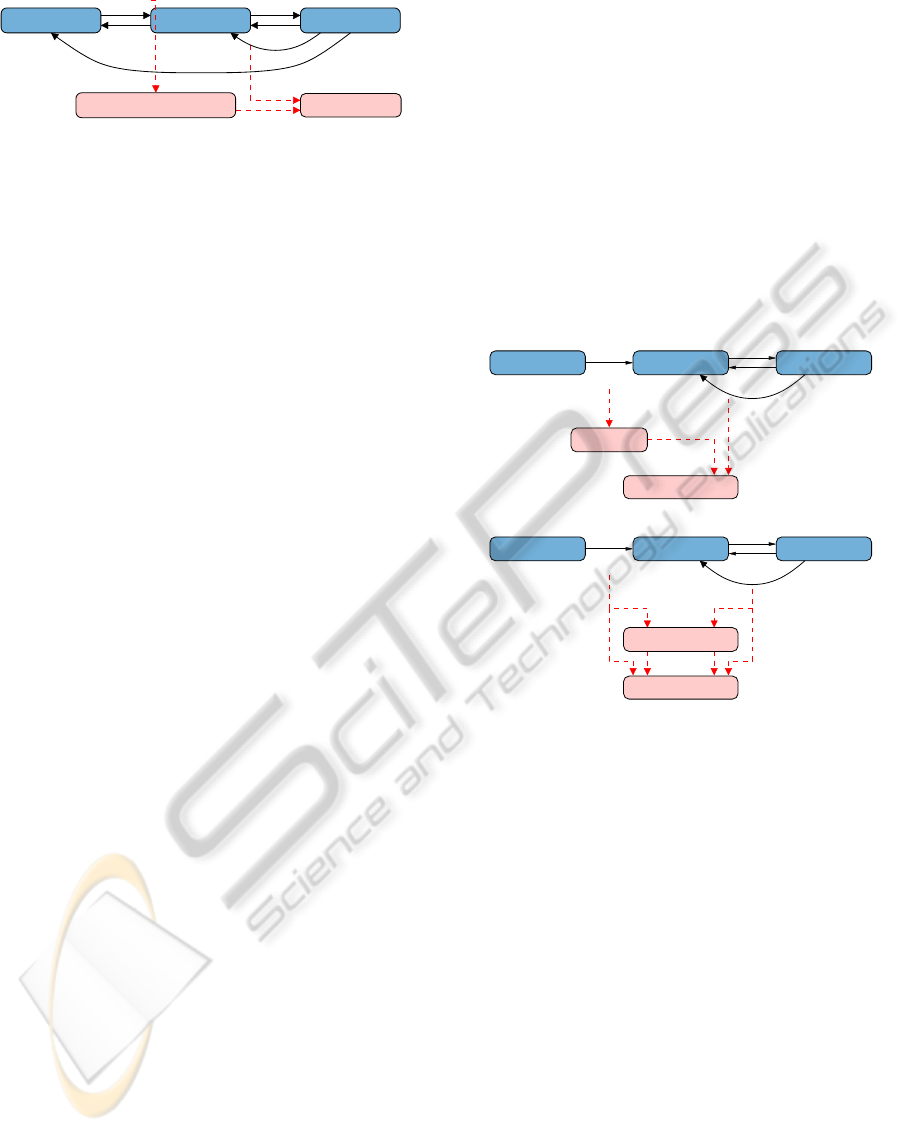

Figure 2 shows two different modes of using mod-

els for the prediction and monitoring. In mode 1, the

model covers the loop from the control commands to

the sensor feedback. Commands given by the driver

are used to generate expectations of the sensor feed-

back. The monitor compares these predictions with

the actual measurements of the sensors.

traction

ext. forces

traction

ext. forces

control

comands

sensory feedback

control

comands

sensory feedback

Driver EnvironmentVehicle

Mode 2:

Driver EnvironmentVehicle

Mode 1:

Monitoring

Model

predicted feedback

prediction

Monitoring

Model

Figure 2: The proposed safety monitoring could be run in

two different modes.

In mode 2, the commands and the sensor feed-

back are used to generate an estimation derived from

the learned model. Furthermore, the model generates

expectations for the sensor readings and the motion

commands. The expectation of motion commands

can be used to identify unusal driver behaviours.

In both modes, the monitoring can be realized by

either a distance computation (e.g. euclidean dis-

tance of normalized vectors) and comparison with a

fixed threshold or a standard deviation based adapt-

able threshold.

Model-based prediction and monitoring can be

used targeting different objectives. One possibility

is, to have a particular detection (and potentially re-

action) in mind. As an example, a model trained to

a specific driver’s steering, accelerating, or breaking

behaviour can be used to detect conditions where ad-

ditional steering forces or a virtual “kick-down” is

applied for comfortability purposes, or an emergency

breaking is triggered earlier then standard if a driver

usually tends to be more conservative when deceler-

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

584

ating.

A second possibility is to target a specific device

or function but to not define the unusual/unsafe case

(and neither the appropriate reaction). An example

is to monitor a specific device like the battery of an

electric vehicle (EV). However, the model is trained

with the usual normal operating behaviour (in case of

the battery in terms of voltage, current, temperature).

This example is selected as a use-case described in

section 4.2.

Finally, the third possibility is to take multiple or

all available (sensor and acutator) modalities to train

the model with usual, i.e. normal, expected behaviour.

After learning the model, deviations from expecta-

tions could be detected – independend of the reason

for the deviation and without any knowledge needed

at design time.

4 EXAMPLARY EXPERIMENTAL

DATA

First experimental results have been collected with

a mobile robot platform. The robot is not compa-

rable to combustion-engined or electric vehicles in

terms of size, weight, typical and maximum veloci-

ties, and typical and maximum accelerations. How-

ever, it serves as a first testbench for the study and

selection of potential sensor modalities.

To test the methods and sensor modalities studied

on the mobile robot, different vehicle platforms are

proposed (see section 5). As a first demonstrational

use-case, a battery defect or battery handling error of

a standard electric vehicle (EV) is chosen.

4.1 Motion Test Data of a Mobile Robot

Three methods for model generation and prediction

have been tested in previous work (to be published).

The test setup used was a four-wheeled and skid-

steered mobile robot. As sensors wheel encoders, ac-

celerometers, and gyroscopes were used.

In figure 3 example data of a turning of the plat-

form is shown. As can be seen, a change of the

motion command (e.g. starting to turn) is followed

by changes in the different sensor modalities with

potentially varing latencies. The sensor response

behaviours may depend on vehicle-related parame-

ters (weight, load, engine power, technical malfunc-

tions) or external conditions (environment, street con-

ditions, obstacles).

For the second plot in figure 3, the sensor data

of multiple turning trials have been used to train a

model of the actuator–sensor relationship. Based on

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

0 2 4 6 8 10 12 14

Sensor Response [digit]

Time [s]

Motion Cmd (Rot.)

Left wheel vel

Right wheel vel

Gyro Z axis

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

0 20 40 60 80 100 120 140

Sensor Response [digit] / Prediction [digit]

Sample [Index]

Left wheel vel (prediction)

Right wheel vel (prediction)

Gyro Z axis (prediction)

Left wheel vel

Right wheel vel

Gyro Z axis

Figure 3: Example plot of measured and predicted sensor

data of a turning mobile robot.

the learned model predictions, i.e. expectations, of

the sensor responses are generated and are plotted

alongside the real measured data in the plot on the

right. Depending on the method used to generate the

model and depending on its parameters, expectations

and measured sensor values match better or worse.

The results of different methods and test conditions

have been compared in previous work.

4.2 Test Case Scenario: EV Battery

For electric vehicles the battery is one of the parts be-

ing most crucial for the vehicle’s function. Due to the

fact electric drives are more robust and simpler than

combustion engines they do not need an as extensive

monitoring as combustion engines demand. On the

other hand, the batteries used in electric vehicles are

more complex than their siblings used in combustion

engine vehicles.

The values to be monitored for a proper opera-

tion of the vehicle differ a lot (in selection and be-

haviour) between common combustion engines and

electrically driven ones. Whereas in combustion en-

gines the values to be monitored, e.g. fuel level, oil

Towardsa"Holistic"SafetyMonitoringinIntelligentVehicleControl

585

242

245

248

idle state

Temperature (°C)

-0.2

0

0.6

Current (A)

371

371.4

371.8

372.2

Voltage (V)

80

85

90

0h

1h

2h

3h

4h

5h

6h

SoC (%)

242

245

248

charging

-5

-4

-3

-2

-1

0

1

370

375

380

80

85

90

0h

1h

2h

3h

4h

5h

6h

242

245

248

driving

-20

0

20

60

120

240

300

360

80

85

90

0m

5m

10m

15m

20m

Figure 4: Values measured for an electric vehicle’s traction battery (Na-NiCl) in various operation states.

pressure, and motor temperature do only vary slightly

in a proper operation, therefore mostly have to be

monitored for being within certain boundaries, the

corresponding values of a traction battery in an elec-

tric vehicle, e.g. battery state of charge, voltage, cur-

rent, and temperature tend to show a lot more variance

– even in idle states (see figure 4).

This is due to the fact that (depending on the type

of battery) certain values have to be kept inside cer-

tain ranges for a proper operation at all times. E.g.,

the Na-NiCl battery whose data is depicted in figure 4

has to maintain a certain operation temperature (ap-

prox. 245

◦

C), so even in idle states there has to be

a certain flow of current (for the corresponding bat-

tery heating element). This load also has an influence

on the voltage measured. Thus, the different sensor

signals may vary a lot during normal operation, but

certain variations may be allowed only in a specific

state.

Obviously, those rather specific conditions for a

proper operation are hardly to supervise just monitor-

ing some thresholds as typically encountered in com-

mon combustion engine driven cars. Instead, learning

a model of the battery parameters and state-related

parameters like driver commands or motor current

could lead to a relatively simple solution. Com-

paring model-based predictions and sensor measure-

ments could allow a detection of many possible faults

or handling errors, like for instance a battery heating

defect, different kinds of battery defects, a (poten-

tially unwanted) initialization of the battery storage

mode, or a defect in the battery charging control. Us-

ing the proposed approach, the specific defect or its

influence to the measured parameters not necessarily

needs to be known. Of course only such problems

can be detected that lead to deviations in one or mul-

tiple of the monitored parameters of the ”‘normal”’

state previously learned. However, a defect that does

not lead to measurable deviations in those parameters

might be considered as negligible.

5 VEHICLE SETUPS FOR DATA

COLLECTION AND TESTS

Two setup categories have been selected as suitable

test and data collection platforms. The first one are

standard electric vehicles (EV). The use of electric

vehicles compared to combustion-engined vehicles is

advantageous because of accessible interfaces on the

actuation and the sensing side of the engine. Using

standard EV in serial production supports a transfer-

ability of the results to later applications.

On the other hand, a more complex vehicle setup

with additional sensor modalities might yield a more

reliable safety detection. Therefore, in the second

setup category a more complex vehicle with 23 DOFs

was chosen.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

586

5.1 Electrically Driven Common

Vehicles

Even though todays modern cars already feature a

large number of electrical sensors the data collected

by those sensors is generally rather sparsely used. Es-

pecially many warning and error notifications are im-

plemented in a very basic and mostly linear way.

For instance, if the oil level of a common com-

bustion engine car reaches a certain – pre-defined –

critical value, some warning light flashes up, signal-

ing a certain urge to act to the user, e.g. to add some

oil. This way of using the sensor data works fine to

indicate a problem that had become present; but it

remains unclear why and when it actually did arise.

This poses the potential issue that the specific prob-

lem can be solved, but without knowing why it did

arise it may as well occur again soon.

Additionally, there are certain states to be con-

sidered critical which do arise from a certain com-

bination or succession of rather minor effects – none

of which would have to exceed their individual fixed

critical value and therefore wouldn’t be detectable.

Also, other effects like excessive wearing of certain

components is detected only when its wear level even-

tually hits a critical value, ignoring the actual source

of the excessive wearing itself.

The concept presented in this article supplies an

approach to solve those difficulties. Using a defini-

tion of normal operation over the specification of cer-

tain fixed critical values enables to detect “unusual”

or “deviating” states of operation as outlined in the

examples stated before. Beyond those rather vehicle-

focused applications the concept also allows to moni-

tor the driver’s behaviour, resp. driving performance,

e.g. by contrasting the current state of operation by

the driver against a certain “normal” state for detec-

tion of emergency or high stress states (e.g. extraor-

dinarily strong braking, accelerating or steering be-

haviour) to which then appropriate reactions can be

applied.

Duchrow et al. (Duchrow et al., 2012) presented

a system for large-scale recording and analysis of EV

fleet data. The data (like vehicle GPS position and

battery state) is stored in a central data base. Such

a large data base allows for additional fruitful uses

like a definition of the normal/safe states needed for

the concept based on the multiple data sources (e.g.

vehicles normally operated, in terms of interindivid-

ual comparison), wear level monitoring (in terms of

intra-vehicle runtime data comparison) or driver per-

formance monitoring (in terms of intra-personal com-

parison) to just name some of the possible applica-

tions. The example data shown in section 4.2 is taken

from this large-scale data base, too.

5.2 Multi-DOF Electric Vehicle

A more complex vehicle like the multi-DOF vehicle

EO smart connecting car (EO scc, (Jahn et al., 2012))

not only allows for the implementation of additional

sensors and the monitoring of extra data sources; its

complexity also requires a more complex interface for

its operation.

Figure 5: The electric vehicle EO scc (Jahn et al., 2012)

which serves as a scentific test platform (

c

DFKI GmbH,

Foto: PR Fotodesign).

It can be compared to the large amount of instru-

ments and gauges in an aircraft which have to be mon-

itored by the pilot. Whereas only some of those ele-

ments have to be permanently monitored, all of them

can become important in certain situations and are

therefore present in the pilots viewing area. It can be-

come somewhat difficult to decide which element is

of importance and has to be observed, which explains

the rather extensive training that is needed to learn the

correct operation of such a vehicle.

The approach presented in this article can help in

such situations, as it can be used to monitor even the

slightest deviations from the state of normal opera-

tion, which can then be used to emphasize the corre-

sponding operation element.

For instance, instead of having a large variety of

instruments and gauges to monitor and use at the same

time (or, to be more specific: to decide from what to

observe and use), the pilot or driver would only have

to observe those elements that have been detected to

be of special importance or showing a deviation from

Towardsa"Holistic"SafetyMonitoringinIntelligentVehicleControl

587

the normal state of operation, posing a great value of

assistance in the operation of such rather complex ve-

hicles.

Technically, the EO scc would be a suitable plat-

form because of its way of implementation. Be-

ing more similar to a mobile robot than to an EV

the control is implemented in software on embedded

PC hardware. It uses the robot software framework

“Rock” which is used for the tests described in sec-

tion 4.1, too. Though such a system may yet not be-

ing suitable for usr in standard vehicles made in serial

production; being a scientific test platform it allows

even larger system changes in software or hardware

with minimum additional effort.

6 CONCLUSION AND OUTLOOK

Presented was the concept of a holistic, model-based

safety monitoring system for the application of intelli-

gent vehicle control. Two main properties are a waiv-

ing of an explicit definition of unsafety and an inte-

gration of potentially multiple modalities (up to all

available sensor and actuator modalities). Instead of

defining an unsafe condition it is tried to learn the safe

state (measured by one or muliple sensors). By this,

in the application of the learned system any deviation

from the “safe” (learned) state of a sufficent degree

can be detected. This includes conditions which are

not known at design or learning time.

The integration of multiple different modalities

is supposed to a) allow to detect unsafe conditions

which are hardly detectable on a single modality but

which are pronounced on the whole set of measure-

ments or to b) reject safe conditions which cause

strong deviations on single modalities but none on

other sensor readings.

As main components a learnable model, a predic-

tion generation based on the model, and a monitor-

ing of predictions (expectations) and measured sensor

values are proposed. Besides the concept, a use-case

aiming at potential electric vehicle defects or misop-

erations is presented.

After finishing tests of the proposed methods on a

mobile robot platform, the same methods have to be

tested with data collected on electric vehicles men-

tioned in this paper.

ACKNOWLEDGEMENTS

Supported by the Federal Ministry of Economics and

Technology on the basis of a decision by the German

Bundestag, grant no. 50RA1113 and 50RA1114.

REFERENCES

Duchrow, T., Schr

¨

oer, M., Griesbach, B., Kasperski, S.,

Bermpohl, F., Kramer, S., and Kirchner, F. (2012).

Towards electric mobility data mining. In Electric

Vehicle Conference (IEVC), 2012 IEEE International,

pages 1–6. IEEE.

Jahn, M., Schr

¨

oer, M., Yoo, Y.-H., Y

¨

uksel, M., and Kirch-

ner, F. (2012). Concept of actuation and control for

the eo smart connecting car (eo scc). In Su, C.-Y.,

Rakheja, S., and Liu, H., editors, Intelligent Robotics

and Applications, volume 7506 of Lecture Notes in

Computer Science, pages 87–98. Springer Berlin Hei-

delberg.

K

¨

ohler, T., Bergh

¨

ofer, E., Rauch, C., and Kirchner, F.

(2013). Sensor fault detection and compensation in

lunar/planetary robot missions using time-series pre-

diction based on machine learning. In Proc. IJCAI-

13 Workshop on Artificial Intelligence in Space. (ac-

cepted).

Pastor, P., Kalakrishnan, M., Chitta, S., Theodorou, E., and

Schaal, S. (2011). Skill learning and task outcome

prediction for manipulation. In Robotics and Automa-

tion (ICRA), 2011 IEEE International Conference on,

pages 3828–3834.

Van Beeck, K., Goedem

´

e, T., and Tuytelaars, T. (2012). A

warping window approach to real-time vision-based

pedestrian detection in a trucks blind spot zone. In

Proceedings of the ninth International Conference on

Informatics in Control, Automation and Robotics, vol-

ume 2, pages 561–568.

ICINCO2013-10thInternationalConferenceonInformaticsinControl,AutomationandRobotics

588