Molding Microchannel and Brain Implant Scaffolds from

Microstructured Double Layer Photo Resin Master Casts

Concepts and Examples

Rouhollah Habibey, Asiyeh Golabchi and Axel Blau

Fondazione Istituto Italiano di Tecnologia (IIT), Dept. of Neuroscience and Brain Technologies (NBT),

Neurotechnologies (NT), Via Morego 30, 16163 Genoa, Italy

1 OBJECTIVES

Replica-casting finds wide application in soft

lithography (Qin et al., 2010) and microfluidics

(Bettinger et al., 2010). Most commonly, structures

are molded with micro- to nano-patterned

photoresists as master casts into

polydimethylsiloxane (PDMS). PDMS features

many favorable properties. It reproduces geometric

details with nanometer fidelity, has low cytotoxicity,

is transparent in the visible spectrum, biostable both

in vitro and in vivo, can be plasma-bonded to itself,

has low water permeability and is simple to handle

and process. After curing, the PDMS can be easily

peeled from the master and the latter usually be

reused (Anderson et al., 2000) if patterns are not

undercut (Yun et al., 2008). Here, we demonstrate a

straightforward replica-molding process that can be

exploited for the generation of perforated

microchannel scaffolds for the in vitro use in axonal

guidance and regeneration studies on microelectrode

arrays (MEAs) or the production of tissue-conformal

in vivo MEAs for neuroprosthetic applications,

respectively.

2 METHODS

Bi-level casting patterns in high-aspect ratio

negative photoresist (e.g., SU-8) to generate

microchannels (lower level) and perforating vias

(second level) are made by standard

photolithography. A first mask defines all features, a

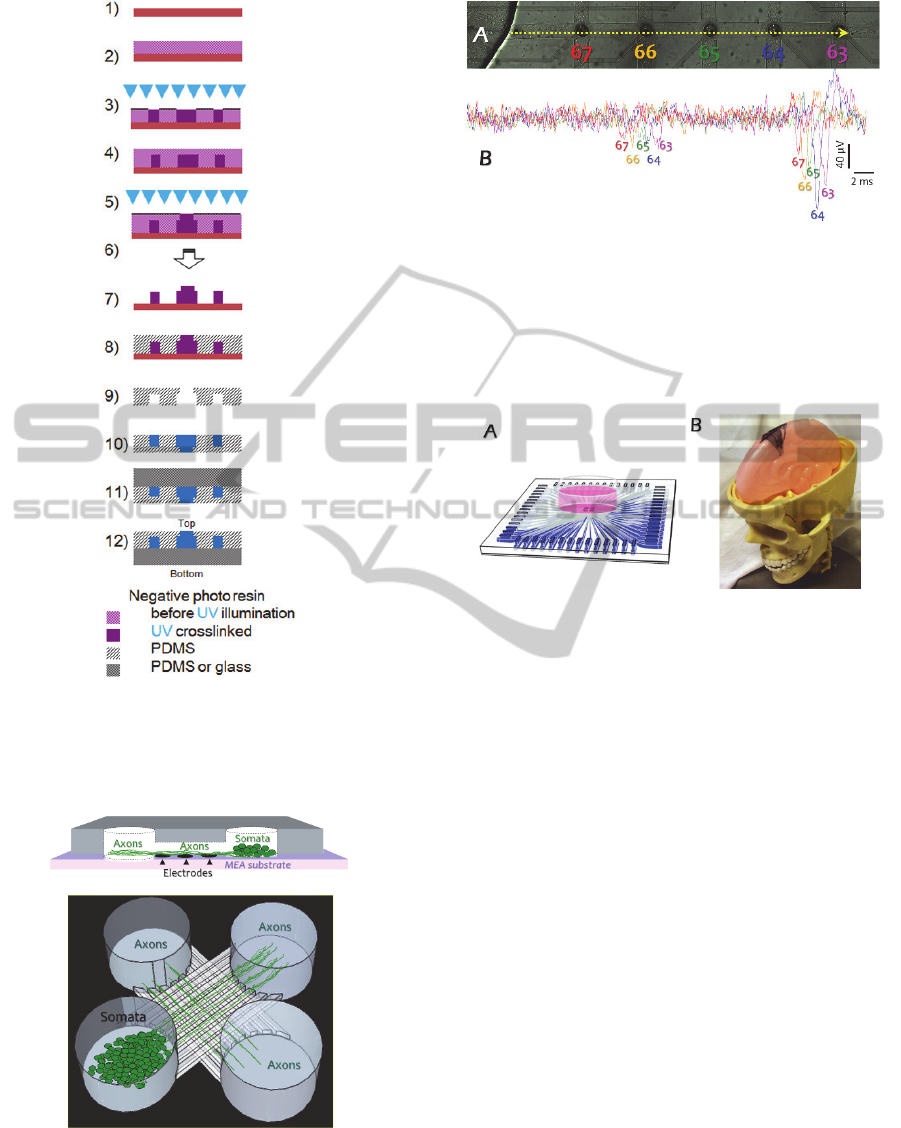

second mask just the through holes. Figure 1

summarizes the following fabrication steps: (1) A

clean silicon wafer is spin-coated (2) with a 1

st

negative photo resin layer (<50 µm) and (3) UV

photo-crosslinked through a first photomask to

define both channels and sockets for vias. The

procedure is repeated in (4) and (5) for a 2

nd

photoresist layer (< 150 µm) to define the via

through-holes. After removing uncured photoresin

(6), the bi-level microstructure (7) can be coated

with PDMS pre-polymer (8), cured after its leveling,

and peeled to result in a microchannel scaffold with

via holes (9).

Such microchannels can either be used as

physical guidance cues for axons and dendrites or be

filled with conductive polymers (e.g., PEDOT:PSS,

carbon-polymer composites) (10) and backside-

insulated (11) to yield MEAs with electrodes and

contact pads at the via holes for in vitro and in vivo

application (12).

3 RESULTS

Figure 2 depicts a conceptual cartoon of a

microchannel tile with via holes for cell seeding

(somata) and guidance channels for axonal

elongation into target wells (axons). If the substrate

is a MEA, electrodes can extracellularly record

action potentials (Figure 3). This allows for studying

neural development and axonal regeneration e.g.,

after inflicting injury by laser microdissection

(Difato et al., 2011).

Furthermore, micro-channels will help in gaining

a better understanding of the electrode

characteristics and underlying biophysics of signal

generation and spread.

If instead microchannels and through-holes are

filled with a biocompatible electrical conductor,

MEAs can be inexpensively produced for both in

vitro and in vivo application (Figure 4).

The flexibility of PDMS allows for the

fabrication of highly tissue-conformal devices with

softness that matches that of brain tissue. This

promises the reduction of implant-inflicted tissue

damage and the increase of MEA long-term

stability.

Habibey R., Golabchi A. and Blau A..

Molding Microchannel and Brain Implant Scaffolds from Microstructured Double Layer Photo Resin Master Casts - Concepts and Examples.

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: Process flow of master generation and

microchannel replica molding in PDMS therefrom (9).

The scaffold can either be used directly in neural guidance

studies or be functionalized e.g., with conductive polymers

(10-12).

Figure 2: PDMS microstructure including 4 big reservoirs

interconnected by an 8 × 8 matrix of channels. Channel

crossing points match the electrodes grid.

Figure 3: (A) Axons of rat cortical neurons in the left well

grow through a 40 µm wide microchannel thereby passing

over five Ø 30 µm electrodes with 200 µm pitch along

their way (Multi Channel Systems, Germany). (B) Despite

the slightly varying signal shapes, a signal delay of less

than 2 ms suggests that activity was recorded from the

very same axon.

Figure 4: (A) Cartoon of an 5x5 cm

2

in vitro polymer

MEA with conductive microchannels after their filling

with conductive polymers. An 8x8 matrix of ~Ø 80-

120 µm through-holes at the center allows for the

extracellular recording and stimulation of action potentials

from neurons or cardiomyocytes in in vitro studies. (B)

Mockup of a 40 µm thin in vivo MEA with conductive

polymer pads, tracks and electrodes to demonstrate high

tissue conformity.

4 DISCUSSION

We exemplarily demonstrated that the replica-

fabrication of bi-level PDMS microchannel devices

allows for their use in different contexts. Besides its

cost-efficiency and ease of handling, the main

advantage of this strategy is the automatic formation

of through-holes (perforations) without further post-

processing steps (e.g., manual punching). These

through holes permit the localized placing of cells in

microchannel tiles for in vitro neurite guidance

studies. However, microchannel scaffolds can also

be functionalized by filling channels and vias with

electroconductive material, thereby turning them

into MEAs. If such conductive material forms thin

films only, a channel feature may still serve for the

delivery of anti-inflammatory or neuroactive drugs.

The concept furthermore leaves a wide degree of

freedom in choosing scaffold materials with tissue-

matching stiffness.

ACKNOWLEDGEMENTS

Many thanks to Marina Nanni and Claudia

Chiabrera for excellent assistance in cell culture

preparation. Thanks also to Francesco Difato and

Mattia Pesce for their advice in imaging techniques.

Intramural funding is highly appreciated.

REFERENCES

Anderson, J. R., Chiu, D. T., Jackman, R. J.,

Cherniavskaya, O., McDonald, J. C., Wu, H.,

Whitesides, S. H., & Whitesides, G. M. (2000).

Fabrication of Topologically Complex Three-

Dimensional Microfluidic Systems in PDMS by Rapid

Prototyping. Anal Chem, 72(14), 3158-3164.

Bettinger, C. J., & Borenstein, J. T. (2010). Biomaterials-

based microfluidics for engineered tissue constructs.

Soft Matter, 6(20), 4999-5015.

Difato, F., Schibalsky, L., Benfenati, F., & Blau, A.

(2011). Integration of optical manipulation and

electrophysiological tools to modulate and record

activity in neural networks. International Journal of

Optomechatronics, 5(3), 191-216.

Qin, D., Xia, Y., & Whitesides, G. M. (2010). Soft

lithography for micro- and nanoscale patterning. Nat

Protoc, 5(3), 491-502.

Yun, K.-S., & Yoon, E. (2008). Fabrication of complex

multilevel microchannels in PDMS by using three-

dimensional photoresist masters. Lab on a Chip, 8(2),

245-250.