An Experimental Platform Aimed at Long Lasting

Electrophysiological Multichannel Recordings of Neuronal Cultures

G. Regalia

1

, E. Biffi

1

, A. Lucchini

2

, M. Capriata

1

, S. Achilli

1

, A. Menegon

3

, G. Ferrigno

1

, L.

Colombo

2

and A. Pedrocchi

1

1

Department of Electronics, Information and Bioengineering, Politecnico di Milano, via G. Colombo 40, Milan, Italy

2

Energy Department, Politecnico di Milano University, via Lambruschini 4, Milan, Italy

3

Advanced Light and Electron Microscopy Bio-Imaging Centre, San Raffaele Institute, via Olgettina 58, Milan, Italy

Keywords: Microelectrode arrays, Neuronal cultures, Long-term recordings

Abstract: The elucidation of physio-pathological mechanisms expressed by a neuronal network over extended time

scales (i.e., from hours to weeks) is the goal of many neurophysiological and neuropharmacological in vitro

studies. In this context, a challenging technological requirement is the establishment of an experimental

setup able to collect long-term neuronal signals. In this work we report the development of a compact

environmental chamber designed to perform prolonged recordings of the bioelectrical activity exhibited by

neuronal networks grown on MicroElectrode Arrays (MEAs). To reproduce an environment suitable for

cells growth (temperature, pH and humidity) the chamber was coupled with a temperature control system

and an air humidifying module. Validation tests demonstrated that the environment inside the portable

chamber is comparable to standard cell incubators environment. To collect neuronal extracellular signals,

custom multichannel pre-processing boards have been developed and integrated with the chamber. With this

equipment, we were able to reliably record spontaneous neuronal electrical activity from hippocampal

cultures grown inside the chamber for several hours, which is not possible with the standard MEA recording

setup due to environmental fluctuations. This system can collect multichannel data from neuronal cultures

over long periods, providing an effective solution for long-term studies of neural activity.

1 INTRODUCTION

A central goal of the modern neuroscience is to

understand the relationship between the functional

connectivity of neuronal circuits and their

physiological or pathological features. The

dissociated culture of primary central neurons

provides a convenient test system to reach this aim.

Indeed, in vitro cultures retain many characteristics

of their in vivo counterparts, but they are simpler

and more accessible for investigations and

manipulations (Eckmann et al., 2007). In this

context, neuronal cultures grown on MicroElectrode

Arrays (MEAs) represent a powerful tool thanks to

the non invasive and multisite approach (Johnstone

et al., 2010, Rossi et al., 2011). However, in vitro

neuronal ensembles are extremely sensitive to

changes in the surrounding environment

(temperature, pH, humidity) (Biffi et al., 2012).

Thus, the establishment of an experimental setup

able to maintain stable conditions is an absolute

requirement in order to design truly significant

experiments and collect reliable data with MEAs.

Nowadays, standard MEA-based experimental

platforms are well-established setups for several

neurobiological applications where short recordings

(i.e., from 10 minutes to a couple of hours) are

adequate to gather the information of interest.

Nevertheless, the possibility to perform longer

investigations of neuronal activity is a challenge to

throw light on physiological or pathological

mechanisms evolving over longer time windows

(e.g. degeneration of functional connectivity).

Some effort has been already directed at

improving standard setups in order to reach this aim

(Potter and DeMarse, 2001). Among the proposed

solutions, an effective solution is represented by

551

Regalia G., Biffi E., Lucchini A., Capriata M., Achilli S., Menegon A., Ferrigno G., Colombo L. and Pedrocchi A..

An Experimental Platform Aimed at Long Lasting Electrophysiological Multichannel Recordings of Neuronal Cultures.

DOI: 10.5220/0004659005510557

In Proceedings of the 5th International Joint Conference on Computational Intelligence (SSCN-2013), pages 551-557

ISBN: 978-989-8565-77-8

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

compact commercial top stage incubators for

microscopy analysis (e.g., Ibidi GmbH, Okolab

s.r.l.) which provide an effective environment

control but they are hardly modifiable to be coupled

to MEA technology. On the other hand, custom

setups built up for MEA-based experiments, do not

include the control of all environmental parameters

and they usually provide temporary solutions

(Novellino et al., 2011). Recently, it was devised a

novel system which merges an effective

environmental control and multisite recordings

capability. This system is a pilot environmental

chamber for a single neuronal culture grown on a

MEA coupled to external commercial electronics

(Biffi et al., 2012). However, more effort has to be

done to improve the osmolarity control, to advance

the quality of recorded neuronal signals and to

increase the throughput of the system.

To tackle the challenge of environmental

stability during in vitro electrophysiological

experiments and to fulfil the requirements of

environmental stability, good quality recordings and

multi-MEA format, we designed and validated a

stand-alone platform for multi site experiments with

neuronal networks. In particular, we present here: (i)

the design of the environmental chamber and a

preliminary quantitative characterization of the

environmental control (ii) the design and validation

of a custom modular multichannel front-end and (iii)

preliminary results regarding prolonged recordings

with this experimental platform.

2 MATERIALS AND METHODS

2.1 Multi-MEA Environmental

Chamber Realization

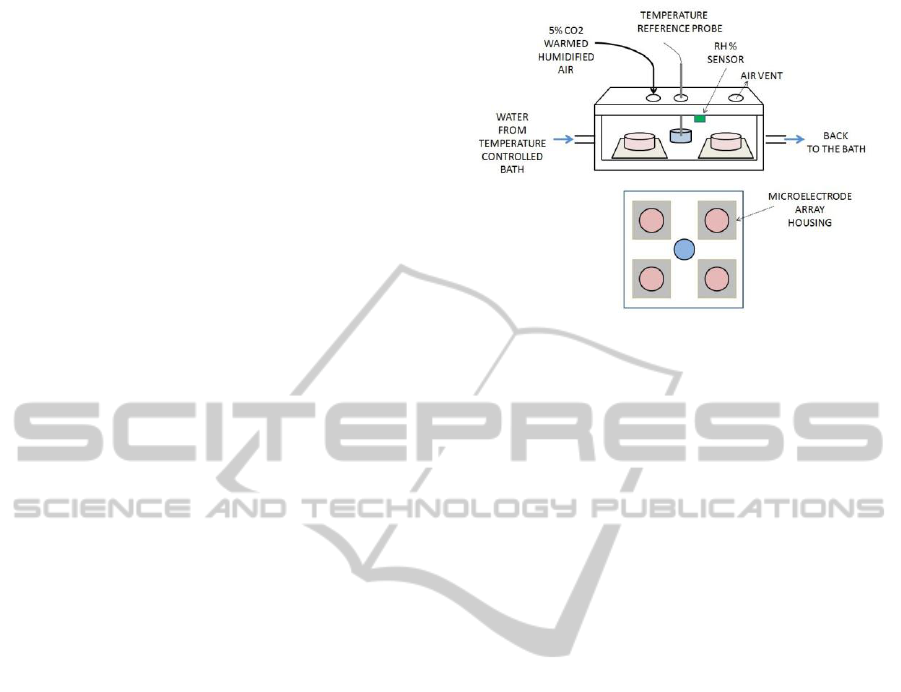

Figure 1 reports a schematic representation of the

environmental chamber. The chamber has been

realized by assembling two PMMA boxes: an

external one (220x220x45 mm) and an internal one

(180x180x30 mm), the latter being surrounded by a

water jacket. Both boxes are sealed with an airtight

top plate, through which we drilled openings for air

inlet and outlet, for the insertion of a temperature

probe and for medium exchange from outside. In the

internal box, we placed a reference well in the centre

and four 50x50 mm housings for 60 channel MEA

chips in the corners. The recording electronics

(paragraph 2.2) contacts the 60 pads of each MEA

chip by means of vertical gold spring probes. Signals

are carried outside by means of a 68-pin connector

inserted and sealed through the top plate. Openings

Figure 1: Schematic representation of the environmental

chamber (top) and top view of MEAs housings (bottom).

for microscope objective insertion were drilled

below the four MEA housings.

2.1.1 Temperature Control

The chamber heating is obtained by means of a

circulating bath (E306, Ecoline, Lauda GmbH) and a

feedback Proportional-Integral control, as previously

described (Biffi et al., 2012). Preliminary

simulations of the temperature distribution in the

MEA housings were performed with a FEM code

(Comsol). During experiments, the temperature of

culturing medium contained in Petri dishes located

in the four MEA housings was monitored by

thermo-couples to verify its maintenance in a

physiological range (37 ± 0.5 °C).

2.1.2 PH Stabilization

To maintain the pH of the medium in a physiological

range (7.2-7.4), an air flow enriched with CO

2

is

injected in the chamber from a gas cylinder.

Experimental tests have been conducted to link the

air flow rate to the CO

2

content inside the chamber.

20% O

2

, 75% N

2

, and 5% CO

2

air flow rates

spanning from 70 to 500 ml/min were set by means

of a flow meter (NG series, Platon SaS). For each

flow rate, the gaseous CO

2

percentage in the

chamber was measured by a CO

2

tester (Heraeus,

Thermo Scientific).

2.1.2 Humidity Regulation

To slow medium evaporation, the flow is warmed

and humidified by an independent bubbling module

placed onto the lab bench. This unit is formed by a

glass bottle containing a glass micro-filter candle to

improve the creation of bubbles, and thus the air

IJCCI 2013 - International Joint Conference on Computational Intelligence

552

humidification. A Nickel-Chrome heating wire (10

W), insulated by a silicon sheath, is placed into the

bottle to worm up the gas flow. This element is

powered on when a miniaturized humidity sensor

(SHT15, Sensirion AG), integrated into the chamber,

measures values of relative humidity (RH) lower

than 85% and it is switched off when RH reaches

95%. In its first version, the control is implemented

by software (USB6009 and Labview, National

Instruments). An heating resistive wire is bound to

the tube which connects the bubbling module to the

chamber, to prevent air cooling. To have a reference

for the miniaturized sensor, RH measurements after

the bubbling column and inside the environmental

chamber have been performed with a commercial

probe (HMP233, Vaisala Inc.).

A high RH level could induce condensation in

the chamber, thus raising the probability of water

droplets to drain on the cells and decreasing

visibility from outside. Condensation of the water

vapour over the inner face of the top plate would

arise if its temperature lowers under the dew point.

To avoid this drawback, heating elements could be

placed on the top plate. To suitably design the

heaters, a FEM model of the steady-state heat

transfer through the whole environmental chamber

has been implemented (Comsol).

2.2 MEA Recording Boards Design

To perform electrical recordings from cultures

grown on four 60-channel MEA chips, custom pre-

processing boards have been designed and coupled

to a multichannel commercial data acquisition

system (USB-ME240, 50 kHz, 16 bit, Multi Channel

Systems, MCS, GmbH).

The whole processing chain was designed to

fulfil the main following requirements: (1) high gain

(~ 60 dB), suitable for the amplification of neuronal

signals in vitro (20-400 μV peak to-peak ) (2)

neuronal spike bandwidth (300Hz - 5 kHz), (3) low

noise (< 20 μV peak-to-peak, i.e., typical thermal

and background biological noise at the

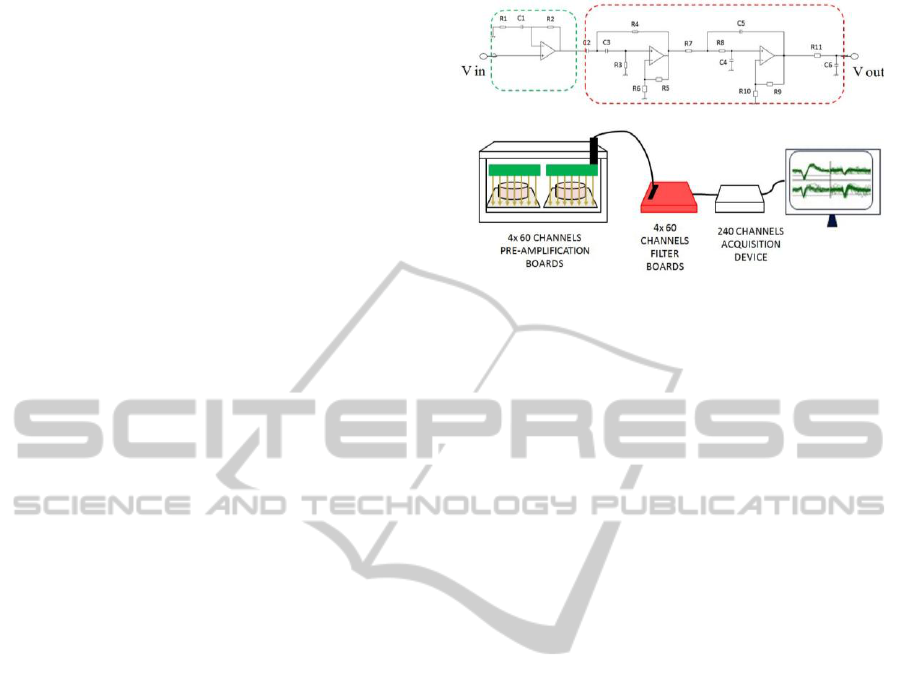

microelectrodes). The defined circuitry (Figure 2,

top) consists of a pre-amplification stage (gain 100,

high pass cut frequency at 300 Hz), a Butterworth

high-pass filter (gain 3, cut frequency at 300 Hz) and

a Butterworth low pass filter followed by a RC low

pass (gain 3, cut frequency at 5 kHz). The

performance of the circuit was simulated with Spice

software (LTSpice, Linear Technology).

Figure 2: Schematic of the custom front-end circuitry (top)

and assembly of the boards (bottom).

For each 60 channel MEA, the pre-amplification

stage was designed to be implemented on two 30-

channel boards (65x65 mm) placed inside the culture

chamber (Figure 2, in green), in order to avoid the

degradation of the signal-to-noise ratio (SNR) of

recordings. A squared hole has been drilled in the

centre of each board in order to allow visibility of

the cultures and to insert tubes from medium

exchange from the top. The following filter stage

was implemented on two 100x100 mm 30-channel

external boards (Figure 2, in red). Surface mounted

components and low noise, precision opamps were

chosen. Four copies of pre-amplifiers and filter

modules were realized in order to record

simultaneously from four MEAs (i.e., 240 channels).

The assessment of the real frequency response

gain of each board was obtained by providing sine

waves (peak-to-peak amplitude equal to 100 μV for

the pre-amplification stage and 10 mV for the filter

stage) by means of a sinusoidal wave generator with

frequency varying between 1 Hz and 10 kHz, for

each channel. The input-referred noise (300 Hz - 5

kHz) of each board was tested measuring the

channel output and dividing it by the overall

nominal gain, with inputs connected to ground. The

channel crosstalk was measured by sending a 1 kHz

controlled sine wave to one channel, and recording

from directly adjacent ones (with inputs grounded).

After testing each board independently, pre-

amplification and filter boards were connected and

tested together.

2.3 Electrophysiological Recordings

From Neuronal Cultures

An Experimental Platform Aimed at Long Lasting Electrophysiological Multichannel Recordings of Neuronal Cultures

553

Neuronal cultures on MEAs were obtained with a

standard protocol, described in (Ghezzi et al., 2008,

Biffi et al., 2012 b). Short recordings (< 30 min)

from hippocampal neurons (CD1 mice, E17.5,

200.000 cells/MEA) grown on standard MEA chips

(60 electrodes, MCS GmbH) were performed during

the 2

nd

and 3

rd

week of maturation, with the aim of

evaluating signal quality and spikes morphology.

Moreover, to evaluate the feasibility of prolonged

experiments with the system, we performed

recordings lasting several hours (>2 h). Spikes were

detected by a comparison with a threshold based on

noise level (as described in Biffi et al., 2010). Then,

time stamps were analyzed by means of standard

signal processing (Matlab®) (Biffi et al., 2011). The

SNR for a single channel has been defined averaging

the spikes amplitudes over the recording window

and dividing by the noise over the first 500 ms. The

mean firing rate was chosen as a global descriptor of

network activity (Biffi et al., 2011), computed as the

ratio between the total number of spikes and the

number of active channels, reported in Hz.

3 RESULTS

3.1 Multi-MEA Environmental

Chamber

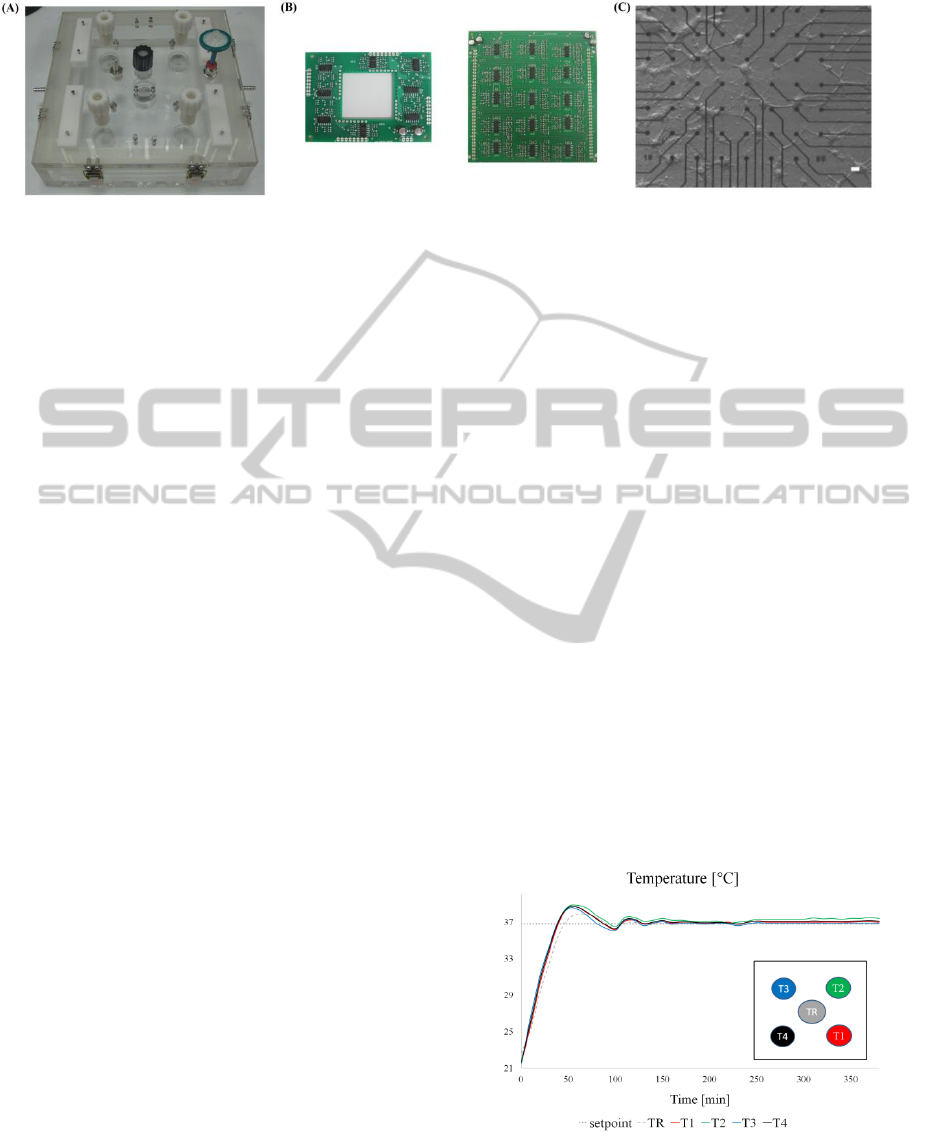

Figure 3A reports the chamber assembled. Figure 3B

shows the custom pre-amplifier board (left) and

filter board (right). Figure 3C shows a neuronal

network on microelectrodes of a MEA chip. The

image was taken by using an inverted microscope

(Axiovert 135 TV, Zeiss). The 5x differential

interference contrast objective was inserted beneath

the MEA housing through the opening in the bottom

wall. The quality of the picture attests the possibility

of duly monitoring cells inside the chamber during

network maturation.

3.1.1 Temperature Control

The FEM simulations confirm that in all the possible

operative conditions, the temperature difference

among the MEA allocations is negligible. To

maintain the desired temperature in the MEA

housings the set-point has been set to 36.8 °C. After

the initial heating phase (almost 60 minutes),

temperature measurements compare well among the

4 housings and show small oscillations around 37°C

(i.e., <0.5°C peak-to-peak) (Figure 4).

3.1.2 PH Stability

As a result of the air flow rate characterization, flow

rates ranging from 140 ml/min to 500 ml/min allow

to balance CO

2

losses occurring along the tubing

system and in the chamber and to reach 5% CO

2

,

i.e., the value needed to maintain cell culture pH at

7.4 (Biffi et al., 2012). After these experiments we

chose a flow rate equal to 200 ml/min for further

experiments as a trade-off between a physiological

pH value, a good humidification (better for higher

flow rates) and the gas cylinder consumption.

Figure 4: Temperature time course measured at the

reference well (dotted line) and at the four MEAs

allocations (T1-T4). The insert is a top view of the

temperature measurement points.

Figure 3: (A) Picture of the realized environmental chamber. (B) Assembled electronic boards for the internal pre-amplifier

stage (left) and external filter stage (right). (C) Inverted microscope image of a neuronal culture grown on a MEA taken

from the chamber (bar scale 10 μm).

IJCCI 2013 - International Joint Conference on Computational Intelligence

554

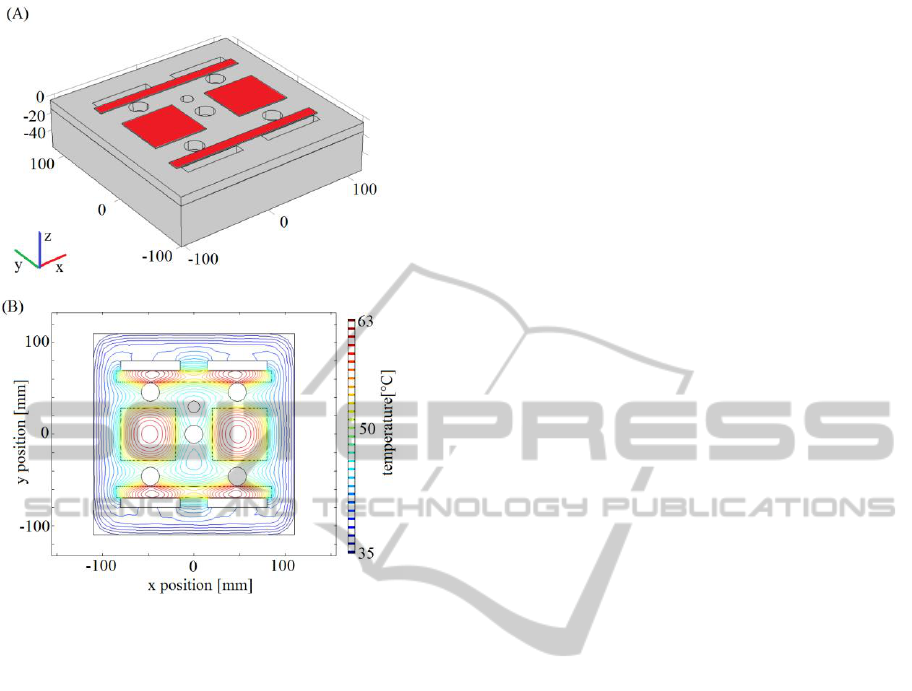

Figure 5: (A) 3D chamber geometry with heating elements

on the top plate (red). (B) Temperature contour in the

lower side of the top plate.

3.1.3 Humidity Maintenance

With the selected flow rate of 200 ml/min, the

control system maintains almost 95% RH in the

bubbling column (water temperature 65 °C, air

temperature 27 °C), which corresponds to almost

85% RH in the chamber (air temperature 35°C). The

simplest solution to overcome condensation on the

inner side of the top plate turns out to be the use of

electrical strip heaters on the outer surface of the

cover. A suitable heater configuration consists of

two couples of heaters (170×12 mm, 0.75 W and

60×57 mm, 1 W, respectively), shown in Figure 5A.

They keep the top plate inner surface temperature

above the dew point (i.e., 35 °C, 85% RH) inducing

a maximum temperature of almost 60°C, which is

lower than PMMA melting point (Figure 5B).

Moreover, their allocation preserve visibility from

the outside of the chamber. To limit the power

consumption and to avoid accidental contact with

hot surfaces, an insulating, removable layer of

rubber foam, 10 mm thick, has been simulated above

the heaters. Preliminary experiments with real

heaters seem to confirm the simulations (maximum

temperature of almost 58 °C) but further tests have

to be performed to verify that the heaters do not

interfere with cells viability and quality of the

recordings.

3.2 Boards Performances

The defined front-end circuit is suitable for the

analog processing of in vitro neuronal signals. The

measured whole gain of pre-amplifiers and filter

boards is in agreement with calculations and Spice

simulations (absolute error equal to ~1.6 dB in the

bandwidth, Figure 6). Also, noise performances of

the whole chain in terms of input-noise (4 μV RMS,

mean of the 60 channels) and cross-talk gain (-36

dB, mean of the 60 channels) are comparable to

noise as measured from the commercial equipment

and other custom setups (Bottino et al., 2009,

Rolston et al., 2009).

3.3 Long Lasting Recordings of

Neuronal Networks

The environmental chamber and the custom

electronic described above, were used to perform

electrophysiological multichannel recordings from

hippocampal neuronal cultures. We observed a mean

SNR equal to 5.4 dB, which is comparable to

recordings performed with standard equipment in

our lab. Furthermore, the recorded biphasic spike

waves compare well to those described in the

literature (Rolston et al., 2009) (Figure 7).

Moreover, preliminary results show that neuronal

cells inside the controlled environment do not

undergo the activity decline, that typically occurs

with the standard setup when the recording time

windows is longer than 2 hours. Several cultures

were recorded for time windows lasting from 3 to 12

hours. As an example, Figure 8 reports the spike rate

of a neuronal culture briefly recorded in the standard

setup (with only temperature control) and

immediately after in the environmental and

recording chamber for almost 4 hours (temperature,

RH% and gaseous CO

2

control). Apart from the

initial adaptation due to the repositioning, neuronal

activity inside the chamber is stable over the time

window. Furthermore, it is characterized by a mean

value (2.6 Hz) and fluctuations (± 0.78 Hz)

comparable to the activity recorded by the standard

setup over a shorter time window (2.3 Hz ± 0.68

Hz), which demonstrates the reliability of long-term

data (i.e., the culture kept staying in a physiological

state throughout the 4 hours).

An Experimental Platform Aimed at Long Lasting Electrophysiological Multichannel Recordings of Neuronal Cultures

555

Figure 6: Comparison between the simulated gain and the

measured one (pre-amplifiers + filter boards).

Figure 7: Overlapped neuronal spikes recorded from a

MEA channel inside the environmental chamber.

Figure 8: Spike rate of a neuronal culture recorded in the

standard setup and in the environmental recording

chamber. Mean spike rates over 1minute bins are reported.

4 DISCUSSION

To tackle the challenge of environmental stability

during in vitro electrophysiological experiments, we

designed and validated a stand-alone platform aimed

at maintaining a controlled environment while

growing and recording from neuronal networks on

MEAs.

To realize a controlled environment, we

connected the chamber to a temperature controller

and a system to inject air enriched with CO

2

and

water vapour. We demonstrated that the chamber

maintains a stable physiological temperature in each

of the four MEA housings. Moreover this

preliminary measurements suggest that a flow rate of

200 ml/min is optimal to obtain (i) a CO

2

percentage

almost equal to the quantity contained in the air

delivered by the gas source (ii) a quite high level of

RH in the chamber, i.e. 85% RH, which is

comparable to other commercial top stage incubators

(Ibidi GmbH).

Regarding the custom front-end, it is suitable to

be coupled with the chamber, both in terms of sizes,

environmental compatibility and recording

performances. Moreover, the realized boards are

cheaper and more easily replicable than commercial

recording front-end devices or custom CMOS-based

systems (Rolston et al., 2009). Preliminary results

assessed the feasibility of performing experiments

with MEAs longer than standard ones (i.e., 2 hours)

thanks to the stable, physiological environment.

Regarding the throughput of the system, the actual

prototype houses four 60-channel MEA chips, which

means up to 24 cultures if 6-well MEAs (9

electrodes per well) are used (MCS GmbH).

Future work will include an improvement of the

humidification system, the integration of gas sensors

in the chamber and repeated experimental tests to

assess the reproducibility of the system.

5 CONCLUSIONS

In this work we presented the design and

preliminary validation of a challenging stand-alone

platform for parallel prolonged experiments from

neuronal cells grown on MEAs. Our final aim is to

provide a compact technological tool for an

electrophysiological laboratory, independent from

both bulky incubators and expensive front-end

equipments, and easy to handle for experimenters.

This system provides new perspectives for in vitro

long-term, high-throughput electrophysiological

studies on neuronal cultures on MEAs.

ACKNOWLEDGEMENTS

Authors would like to thank people from the

Alembic facility for their support and Dr. De Ceglia

for the dissection of hippocampi.

REFERENCES

Biffi, E., Ghezzi, D., Pedrocchi, A. et al., 2010.

Development and validation of a spike detection and

classification algorithm aimed to be implemented on

hardware devices. Comput Intell and Neurosci. DOI

10.1155/2010/659050.

Biffi, E., Menegon, A., Regalia, G. et al., 2011. A new

cross-correlation algorithm for the analysis of "in

vitro" neuronal network activity aimed at

IJCCI 2013 - International Joint Conference on Computational Intelligence

556

pharmacological studies. J Neurosci Methods.

199:321-327.

Biffi, E., Piraino, F., Pedrocchi, A. et al., 2012b. A

microfluidic platform for controlled biochemical

stimulation of twin neuronal networks. Biomicroflu.

6:24106-2410610.

Biffi, E., Regalia, G., Ghezzi, D. et al., 2012a. A novel

environmental chamber for neuronal network multisite

recordings. Biotechnol Bioeng. 109:2553-2566.

Bottino, E., Massobrio, P., Martinoia, S. et al., 2009. Low-

noise low-power CMOS preamplifier for multi-site

extracellular neuronal recordings. Microelec J.

40:1779- 1787.

Eckmann, J., Feinerman, O., Gruendlinger, L., Moses, E.

et al., 2007. The physics of living neural networks.

Physics Reports 449: 54-76.

Ghezzi, D., Menegon, A., Pedrocchi, A. et al., 2008. A

Micro-Electrode Array device coupled to a laser-based

system for the local stimulation of neurons by optical

release of glutamate. J Neurosci Methods. 175:70-78.

Johnstone, A.F., Gross, G.W., Weiss, D.G. et al., 2010.

Microelectrode arrays: a physiologically based

neurotoxicity testing platform for the 21st century.

Neurotoxicology. 31:331-350.

Novellino, A., Scelfo, B., Palosaari, T. et al., 2011.

Development of micro-electrode array based tests for

neurotoxicity: assessment of interlaboratory

reproducibility with neuroactive chemicals. Front

Neuroeng. DOI 10.3389/fneng.2011.00004.

Potter, .SM., DeMarse, T.B., 2001. A new approach to

neural cell culture for long-term studies. J Neurosci

Methods. 110:17-24.

Rolston, J.D., Gross, R.E., Potter, S.M., 2009. A low-cost

multielectrode system for data acquisition enabling

real-time closed-loop processing with rapid recovery

from stimulation artefact. Front Neuroeng. DOI

10.3389/neuro.16.012.2009.

Rossi, S., Muzio, L., De Chiara et al., 2011. Impaired

striatal GABA transmission in experimental

autoimmune encephalomyelitis. Brain Behav Immun.

25:947-56.

An Experimental Platform Aimed at Long Lasting Electrophysiological Multichannel Recordings of Neuronal Cultures

557