The Intelligent Container

A Cognitive Sensor Net for Fruit Logistics

Walter Lang, Steffen Janßen and Reiner Jedermann

Institute for microsensors, -actuators and –systems (IMSAS) and Microsystems Center Bremen (MCB),

University of Bremen, Bremen, Germany

Keywords: Fruit Logistics, Sensor Net, Remaining Shelf Life, Dynamic FEFO, Ethylene Detection.

Abstract: The Intelligent Container is a wireless sensor network for the control of perishable goods such as

vegetables, fruits or meat. Several data interpretation tools are implemented in the sensor nodes. These can

estimate temperature related quality losses, supervise sensor deployment and measurement intervals, and

detect malfunctioning sensors. In order to retrieve information about the ripening directly from the

transported fruits, the ripening indicator ethylene is detected using a newly developed highly sensitive and

selective gas measurement system. The intelligent container allows the realisation of the new logistic

paradigm of dynamic FEFO (First Expire First Out): the remaining life time—estimated shelf life—of the

transported fruits is used to control the logistic process. This paper describes the developments performed

on the Intelligent Container by the University of Bremen and its partners.

1 INTRODUCTION

In fruit logistics up to 35% of the cargo is lost during

transport (Scheer, 2006). Only 5% loss is attributed

directly to transport processes, but a large amount is

lost indirectly due to insufficient conditions on the

way, especially due to insufficient cooling and

temperature control. It is known that within a reefer

there may be temperature differences of several

degrees from bottom to top, but today in most

systems temperature is measured by only 2

temperature sensors. This way, large temperature

gradients may easily be overlooked. A better control

of the transport conditions due using Wireless

Sensor Networks will allow a considerable

improvement of transport quality.

Generally, fruits do not have sell-by date

imprinted on the package, but the quality is

estimated by the customer when he or she buys it.

Often, fruits cannot be sold any more and have to be

disposed of, it also may happen that a reseller rejects

accepting a load after opening it. To control the

transport process continuously would have a number

of important advantages:

- When in time data about the specific load of a

container are available, logistic processes may be

re-adjusted accordingly and losses can be

minimised. E.g. when it is known that a specific

container with banana from Central America has a

“hot spot”, this container can be processed first to

save as many fruit as possible (FEFO).

- Often containers are directly forwarded from the

ship to the reseller without opening them. When

the reseller refuses to accept, this is high cost for

the wholesale dealer in terms of money and

reputation. This situation may be prevented if

sensor information is available. The rotting fruit

are stopped and replacement can be launched

instantly.

- In case the cargo of a container is known to be lost,

there is no use in transporting it further on and in

paying customs duty.

- When the state of the fruit at unpacking indicates a

quality problem on the farm, there will be already

two ships on sea with the same quality problem. If

we had a sensor warning us two weeks earlier

while the fruit are still travelling over the Atlantic

ocean, we could inform the farm immediately and

take action there.

- In some cases of fruit logistics counteraction

during transport is possible, such as lowering the

temperature set point of a reefer.

- For chilled and frozen food a proof of an

uninterrupted cold chain is demanded by the

authorities and by the customers.

Considering the market volume of fruit worldwide,

351

Lang W., Janßen S. and Jedermann R..

The Intelligent Container - A Cognitive Sensor Net for Fruit Logistics.

DOI: 10.5220/0004705703510359

In Proceedings of the 3rd International Conference on Sensor Networks (SENSORNETS-2014), pages 351-359

ISBN: 978-989-758-001-7

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

reducing the loss by only a fraction of a percent

means a considerable win in terms of money, and,

furthermore, in terms of carbon dioxide footprint.

In logistic planning the paradigm applied is

FIFO: First in – first out. Fruit which come first are

moved on first. With the availability of sensor data,

this paradigm might change to the new paradigm of

dynamic FEFO: first expire – first out. The task is to

estimate time before decay, the “remaining shelf

life”. Then, the fruit with short remaining shelf life

are moved on first and to near bydestinations. The

fruit with longer shelf life are moved secondly and

attributed to longer distances. The fruit with expiring

shelf life finally are stopped this way avoiding

unnecessary transport. The shelf life estimation can

be done by a decision support tool implemented in

the sensor net. The term dynamic reflects the fact,

that the remaining shelf life is continuously re-

estimated according to the development of the fruit

within time.

The advantage of FEFO compared to FIFO was

verified in several studies. Koutsoumani

(Koutsumani, 2005) calculated the probability

density functions for the duration of local and

international transports and temperature in retail

shelves or customer refrigerators based on field

studies. A simulation combined the resulting

temperature curves with a biological model. The

study showed that the share of products arriving at a

critical bacteria load could be reduced from 16% to

8.2% by the FEFO approach. A similar study by the

same group for seabream resulted in a reduction of

losses from 15% to 5% (Tsironi, 2008). A study on

strawberries by the University of Florida

[Jedermann, 2008] showed that losses can be

reduced from 36.9% to 22.8%. In summary, a

delivery planning based on remaining shelf life can

avoid between 8% and 14% of losses compared to

planning without use or availability of quality

information (Fig. 1).

Figure 1: Case studies for product losses due the quality

defects for FIFO (no quality information) and FEFO

(based on remaining shelf life) planning.

To bring these features into reality, the “Intelligent

Container Project” has been initiated (MCB, 2013).

The research started in 2004 as a research project of

Bremen University founded by “Deutsche

Forschungsgemeinschaft”.

In 2008 a transfer project was initiated in

cooperation with two logistic partners: Dole Fresh

Fruit Europe doing fruit transport on sea and Rungis

express doing road transport. As an industrial

technical partner, the trailer company Cargobull

Telematics was a member of the consortium. First

field tests on sea and land were performed. This

research work was followed by a broad cooperation

of industry and university, the “Innovation Alliance

for the Intelligent Container”, founded by the

Federal Ministry of Education and Research of

Germany. The Alliance for Innovation has been

running from 2010 to 2013. In this paper we will

discuss the most important results and findings of

these projects.

2 THE SENSOR NETWORK

2.1 Layout of the Measurement Task

What tasks must this sensor net perform? When

looking closer, the list of tasks to do becomes long

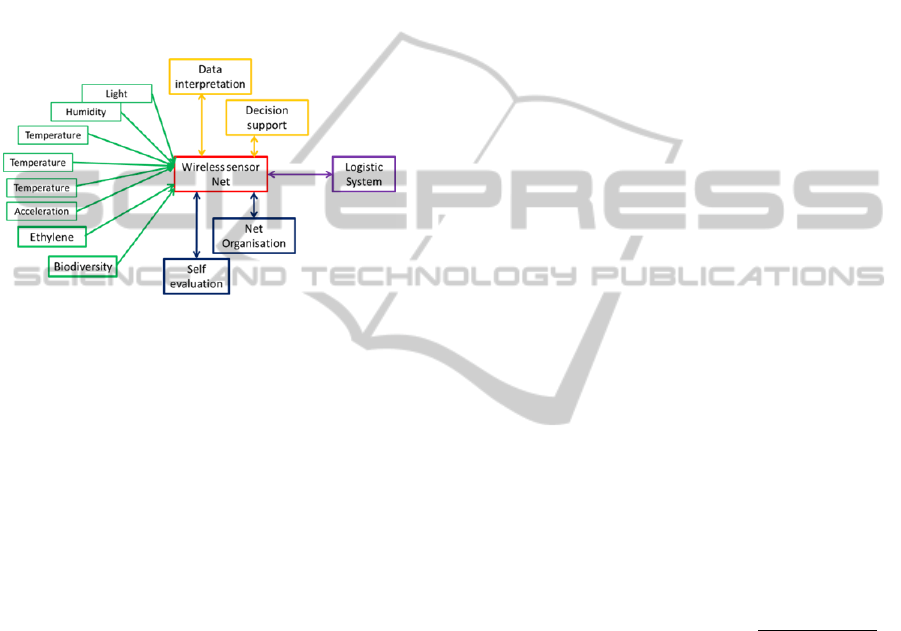

and challenging. Fig. 2 shows the information flow

within the system.

2.1.1 Quantities to Be Measured

Concerning quantitites to be measured, the first task

is temperature. Today, 2 or 3 temperature sensors

are usually used in a reefer. We deployed a number

of 40 for test and we found that the temperature

variation in reality is much larger than expected.

On the other hand, 40 sensor nodes per container

are not a realistic scenario for practical application

in every container. This way, the path has to be from

2 to 40 and then back to 12 again. Then, with the

improved knowledge how to locate the sensors,

interpolation can be done to calculate the whole

temperature profile. This way, the systems also need

data interpretation tools such as numerical models to

estimate the development of a 3D-model of the

temperature distribution from a few measurement

points.

Temperature is by far the most important

variable to be measured. In transports of ‘dry’

agricultural products humidity is important, since

relative humidity must be kept below 75% to

prevent the growth of mould fungus (Scharnow,

2005). Mould is a major danger when transporting

berries and grain. Grain is highly hygroscopic, this

0%

10%

20%

30%

40%

Mea t

(Athen, 2005)

Fis h

(Athen, 2008)

Straw berries

(Florida, 2006)

No quality information

Remaining shelf life

SENSORNETS2014-InternationalConferenceonSensorNetworks

352

way a container with grain will contain tons of

water. Now imagine a container placed on the top of

a vessel in a cold night in northern Atlantic. The

average temperature in the container is 15°C, the

average relative humidity is 60%, “on the safe side”.

Practically, at side exposed to the wind, the

temperature is only 5°C, relative humidity rises to

100% and condensate will drop down on the grain,

causing locally major mould fungus danger. This

situation will be overlooked if only one humidity

sensor is applied and no advanced data analysis is

performed.

Figure 2: Information flow within the Intelligent

Container.

In fruit logistics, the primary focus is temperature.

Other important sensor functions which are needed

for some transports are acceleration for shock

detection and light. Though they are important, they

cannot be covered in extenso in this paper.

2.1.2 Decision Support Tools

To estimate the remaining shelf life from the data,

decision support algorithms have to be developed

and implemented. Knowing the temperature history,

these tools may estimate the change of the fruit with

time. It soon turned out, that analysing a

development is useful only if we know the starting

point. What is the status of the fruit when loaded?

Unfortunately, the biodiversity at loading is high. A

major parameter is the weather before harvest. If

there is rain before picking, the fruit will take up

more water. A second important influencing factor is

the transport from the farm to the port. Due to

shaking on bad roads and fot the lack of cooling

within a few hours in a truck fruit may lose days of

shelf life. The status at packing is normally

estimated visually by experienced operators during

packing. In the case of bananas, colour patterns with

different appearances—more green than yellow—

are used in the port. Within the project of the

Intelligent Container the company ELBAU

(http://www.elbau-gmbh.de/) has developed an

optical system to automate this analysis.

So far, during transport we only look at external

data, such as temperature. Can we get information

about ripening from the fruits themselves? Actually

the process of ripening of fruits is correlated with the

emission of ethylene gas. This way, measuring the

indicator ethylene gas, a direct observation of the

ripening and decay is possible. These developments

are described separatly in section 3.

2.1.3 Management of Sensor Nodes

The sensor net does not only look at the container

and the fruit, it also observes itself for management

of the sensor nodes and for failure detection.

The system can supervise and change its own

deployment. How many sensors do we need? What

distance between the sensors can we allow? These

questions can be analysed looking at the correlation

of the data of different sensors using a method

developed for geostatistics by D.G. Krige (Krige,

1951) and now transferred to sensor nets

(Jedermann, 2009). During transport sensors cannot

not be removed, but they can be put to sleep this

way augmenting the life time of the batteries. The

sensor nodes measure their remaining energy; the

routing may be changed in the way to allow nodes

with weak batteries to sleep (Behrens, 2007). Also

the dynamic behaviour of the temperature is

analysed to adapt the duty cycle to the situation.

Slow development can be answered with a reduction

of the measurement cycle to save energy (Wang,

2010; Wang, 2011).

2.1.4 Self Evaluation

A last and complicated task is the self-evaluation.

Imagine a sensor node shows anomalous humidity

values at some point: is the sensor node defect or is

there an anomaly, such as a broken can? To analyse

divergent behaviour a neural network has been

developed (Jabbari, 2009).

Fig. 2 gives an overview of the capabilities of the

sensor net. Within the Intelligent Container Project,

we decided to implement the important parameters

within the sensor nodes. An alternative approach

would be to communicate the data and to calculate

models on a higher level, E.g. in a master node. Our

experience is that this approach will not give us the

robustness we need. In an extremely challenging

surrounding such as see transport, failure of a node

is always possible. The system must be able to

rearrange if a node fails, and the maximum

robustness will be achieved if we implement the

TheIntelligentContainer-ACognitiveSensorNetforFruitLogistics

353

important algorithms locally, even if this means that

we have to apply several parallel nodes which are

able to calculate the models.

In the following paragraphs, some of these

aspects will be discussed in detail.

2.2 The Sensor Net

The communication system of the intelligent

container consists of the internal wireless sensor

network, the external network for remote access to

the container, and a gateway to bridge between these

two networks. Whereas the external network can be

implemented by standard components and

commercially available networks, such as the

Iridium satellite system or cellular mobile networks,

the internal networks requires specifically adapted

solutions, and thus be discussed in detail.

Most wireless sensor node devices operate in the

2.4 GHz range according to the 802.15.4 standard.

Our prototype sensors are based on the TelosB from

Crossbow (2005). They were mounted into a IP67

water tight housing with an SHT75 external

temperature and humidity sensor.

In contrast to other sensor network applications

in buildings or farming setups (Ingelrest 2010) with

a typical communication range between 10 and 100

meters, the range dropped to 0.5 meters, if the

sensors were packed into banana pallets (Jedermann,

2011). The network protocol must be able to find

routes in a sparsely connected network (Becker,

2009). In contrast to other applications, the data

volume is very low. Only 6 bytes are required in

addition to addressing and protocol overhead to

transmit temperature, humidity and battery voltage

measurements.

The energy consumption of the sensor nodes

mainly depends on the radio, which draws

approximately 20 mA in both receive and transmit

modes. The MSP430 micro controller requires only

1 mA in full operation and 1µA in sleep mode. The

active radio time should be reduced as much as

possible.

For our field tests, we developed a

communication protocol, the “BananaHop Protocol”

(Jedermann, 2011). It requires an active radio time

of 5 seconds to transmit its own data and forward

those of other sensors per measurement frame of 150

seconds, equivalent to duty circle of 3.3%. The duty

circle can be further reduced, if the measurement

intervals are prolonged.

Only if a sensor loses the synchronization the

duty circle increased to 50% because the sensor has

to listen for an updated time stamp included in a

beacon message from another sensor. The sensors

nodes are supplied by two AA batteries with a

normal capacity of 2950 mAh. After 15 days the

voltage dropped from 3 Volt to 2.845 Volt. During

the subsequent 5 days of testing the voltage dropped

almost linear with 0.029 Volt per day. A critical

voltage of 2.4 Volt below which the humidity sensor

will become unstable, will only be reached after 3

months.

Decision algorithm for processing of the

measurement data can be either implemented on the

gateway or directly on the sensor nodes. As alternate

hardware solution we tested the Preon32 sensor

nodes from Virtenio (Virtenio, 2013), providing a

virtual machine to execute Java code. The

availability of such high programming languages

simplifies the programming of algorithms and makes

it possible to update the sensor node software for

different products loaded to the container.

2.3 Data Interpretation Tools

We want to get a 3D model for the development of

temperature with time, even if there are only a few

measurement points available. The first example is

the estimation of the temperature development of a

banana box. Depending on the way of packaging the

convective flow of cooling air at a specific box may

vary in a wide range (Ambaw 2013). The

temperature of the box at loading may vary, too.

This way, some boxes cool down within 2 days,

others need a week (Jedermann, 2011), which has a

major impact on shelf life, of course. We developed

a model to predict full cooling curve from data

generated within the first 2 days (Palafox, 2011).

Figure 3 shows the development of temperature for

two example boxes A and B. The temperature has

been measured for 3 days. From that, the

development for the next 15 days is predicted. This

prediction correlates well with the further

development of measured temperature. This allows

us a more precise estimation of remaining shelf life

at an early stage.

Bananas are a climacteric ‘living’ product with

biological processes continuing after harvest (Turner

1997). A certain amount of heat is generated by this

respiration activity. When the bananas come close to

a state, in which ripening starts and the colour

changes from green to yellow, the heat production

increases simultaneously. If the heat production is

larger than the amount of heat removed by cooling, a

hot spot develops leading to even higher biological

activity and temperature. If a hot spot develops in

one pallet, in most cases the whole container is lost.

SENSORNETS2014-InternationalConferenceonSensorNetworks

354

Figure 3: Measurement of the temperature development in

two boxes within the same container during sea transport.

The conditions leading to a hot spot can by analysed

by an extended version of the model (Jedermann,

2013). Figure 4 shows the measured and predicted

temperature curves for an ashore experiment

simulating a cooling problem. The set point of the

cooling system was switched from 13°C to up to

16°C for 30 hours. For one box of banana (lower

curves) the temperature rises, but then declines again

as it should. The second box (lower curve) has

insufficient cooling air circulation. Biological

activity starts, and the cooling system cannot bring

down temperature any more. A hot spot is

developing. The lower cooling effect was caused by

deliberately making a “packing mistake” by

completely blocking the air gaps between the pallets.

Figure 4: Measurement of the temperature development in

two boxes within the same container during sea transport.

The model parameter k

P

describes biological activity, k

M

describes the cooling (Jedermann, 2013).

Different pacing schemas were evaluated and

compared by this model (Jedermann, 2013). We

found that it is important to carefully maintain slots

of identical width for the flow of the cold air.

Blocking of convective flow can seriously inhibit the

cooling.

2.4 Decision Support Tools

The most important decision support tool of the

Intelligent Container is the shelf life predictor.

Figure 5 shows the shelf life curve for lettuce

(Tijskens, 1996) using an Arrhenius kinetic

approach. The set point is 6°C, so at 6°C the loss is 1

day per day. At higher temperature the loss rises,

storing the lettuce at 14°C for 1 day will result in a

loss of 3 days in shelf life.

Figure 5: Shelf life estimation: The remaining shelf life is

plotted versus temperature for the example of lettuce

(Tijskens, 1996). At the set point of 6°C the loss is 1 Day

per day. At higher temperature the loss increases and thus

the expected shelf life is reduced.

The figure gives only a very simplified idea of a

shelf life predictor. Actually, there are complicated

biological models behind it which must be

elaborated experimentally for every fruit. In order to

implement shelf life prediction in an algorithm there

are two approaches: the first one supposes reaction

kinetics of the Arrhenius type for the fruit. Reaction

kinetic parameters are experimentally elaborated for

the specific fruit. The decision support tool

continuously calculates the Arrhenius kinetics. The

second approach uses table shifting. Look up tables

for the specific fruit are calculated once and stored.

Today, shelf life predictors are implemented in

sensor nodes. Implementation in smart cards

comparable to RFID data loggers is on its way

(Jedermann, 2008), (Zweig, 2008).

2.5 Field Tests

The sensor system including gateway and external

communication were installed in a prototype

intelligent container. Three test transports from

0 5 10 15

12

14

16

18

20

22

24

26

Time in [Days]

Temperatur in [°C]

PredictedMeasured

Center of Box A

Center of Box B

Supply Air

0 10 20 30 40 50 60 70 80 90

12

13

14

15

16

17

18

19

Time in Hours

Temperature in °C

Center B181 / B187

k

M

= 0.964 / 0.312

k

P

= 0.0462 / 0.0752

Model Output

Measured Output

Supply Air

0

2

4

6

8

10

0 5 10 15 20

Temperature °C

Shelf life / loss in days .

Shelf life(T)

Loss per Day

4.8 days

shelf life at

6 °C

Reference

temperature

6 °C

Tripple speed of

quality decay at

14 °C

A

ctivation

energy for

Lettuce

1

TheIntelligentContainer-ACognitiveSensorNetforFruitLogistics

355

Costa Rica to Europe were carried out in 2012 and

2013. After 2 weeks of sea transportation the

bananas were left in the container for ripening after

gassing with ethylene. The container ripening took 5

or 6 days but showed only a good result with a

similar degree of ripeness in all boxes at the end of

the process, if several measures to improve the air

flow though the boxes were applied (Jedermann,

2013),

In parallel to the sea transportation tests, a

further test was carried out for the automated

supervision of meat during a truck transport from

France to Germany (Dittmer, 2013).

Figure 6: Pallets in test container with antennas for

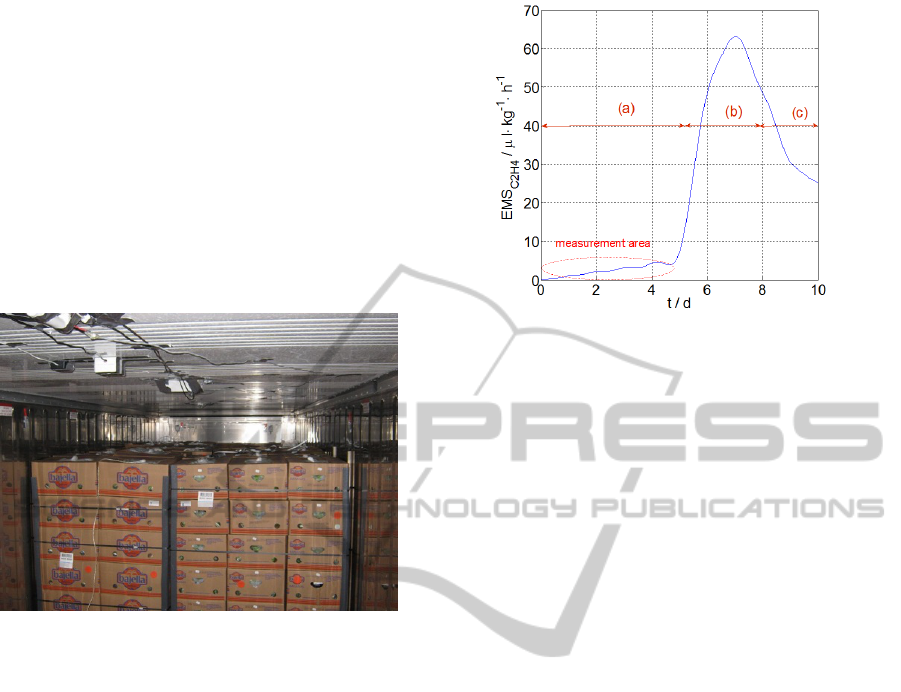

wireless sensors under the roof.

3 ETHYLENE MEASUREMENT

3.1 The Role of Ethylene in Fruit

Ripening

Ethylene is a gaseous ripening hormone for most

fruits. When fruits ripen, they emit ethylene gas. On

the other hand, when a fruit is exposed to ethylene,

ripening is induced. This is why ripening is

contaminous: put a green tomato besides a red one

and it will start induced ripening. Concerning

ripening, fruits are classified as climacteric or non-

climacteric. Non-climacteric fruits such as grapes

and apricots are harvested when fully ripened, they

do not show ripening any more after being picked.

Climacteric fruits such as bananas, apples or

tomatoes have an extended pre-mature phase (green

banana) followed by a sudden rise of ethylene

emission and respiration. When the climacteric event

starts, it cannot be stopped. Bananas are transported

in the pre-climacteric state as green banana. After

unloading they are exposed to ethylene in a ripening

chamber.

Figure 7: The emission of ethylene by climacteric fruits

(banana). To monitor the small rise in the preclimacteric

phase (a) a measurement method with very high resolution

is needed. (Bials, 1954).

Figure 7 shows the ethylene production. Pre-

climacteric (a) the emission is small. The container

air will contain ethylene in the range some 100 ppbv

(parts per billion by volume). In the climacterium (b)

the emission rises strongly and the bananas turn

yellow. After the climacterium (c) the emission

reduces again and the bananas start decaying.

During transport the fruit should stay in the pre-

climacteric state (a), but sometimes, if a package is

not cooled effectively, ripening may start locally.

Ripening bananas emit ethylene and this way trigger

other bananas to start ripening, furthermore ripening

bananas generate heat and temperature is further

increased. These nonlinear effect cause a “hot spot”

of ripening. To detect this dangerous effect, the

ethylene must be measured with a resolution of 50

ppbv.

3.2 Measurement of Ethylene in Very

Low Concentration

At this low level of concentration we find many

organic gases in the container, therefore the

measurement must be sensitive and selective at the

same time. There are gas sensors for ethylene which

can measure in the ppmv range, but they do not

show high selectivity. For this reason, within the

Intelligent Container project we have developed

measurement systems for ethylene which are

sensitive and selective at the same time.

The first approach is non-dispersive infrared

spectroscopy (NDIR). Ethylene shows a specific IR-

absorption line at 10.5 µm wavelength. The NDIR

measurement provides very robust detection in the

lower ppmv range (Sklorz, 2012). For the ppbv

SENSORNETS2014-InternationalConferenceonSensorNetworks

356

range, a more powerful method has to be applied:

gas chromatography (GC).

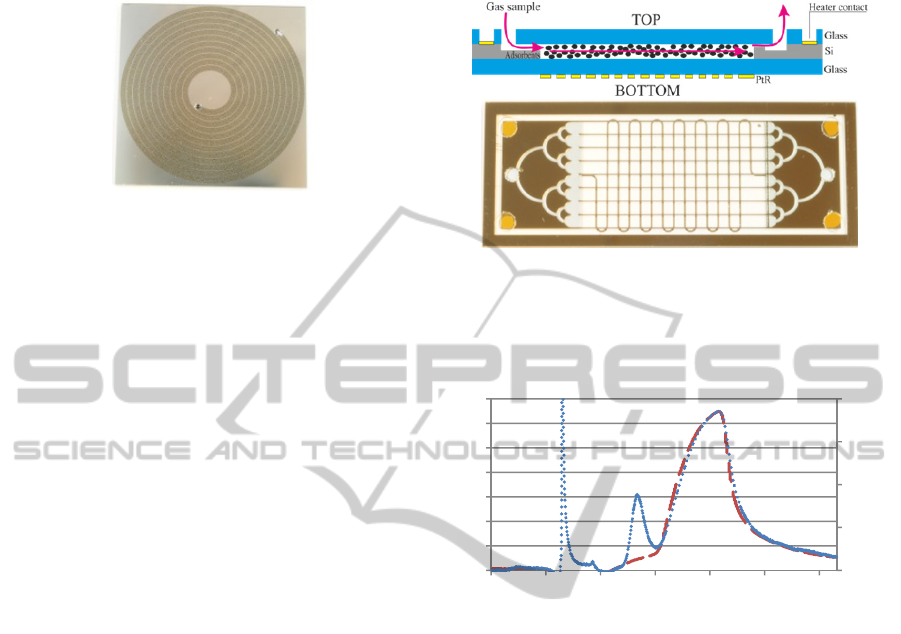

Figure 8: Using the technology of microfluidics, a small

GC-column is made for the µCG (Sklorz, 2012).

A gas chromatograph uses the fact, that the

adsorption and desorption of the gas molecules at a

surface is specific for different molecules. The gas

diffuses through a long tube, the chromatographic

column. This is filled with a material which has been

developed for specific adsorption of ethylene, the

stationary phase. By ad- and desorption the

molecules are retained, and if a mixture of molecules

enters the column at a certain time, each species will

reach the end of the column after a specific retention

time. The species are detected at the end of a column

with a commercial gas sensor. The gas sensor

provides sensitivity, the chromatographic column

provides selectivity.

Gas chromatographic systems are large and

expensive. For the use in transport systems, we

developed a small system which can work

autonomously.

The column of the µCG is made using

micromachining technology as shown in figure 8

(Sklorz, 2013). Using these devices, a resolution of

140 ppmv is achieved. To boost the resolution down

to the ppbv range, a micromachined preconcentrator

has been developed. This is a micro reactor as

shown in figure 9.

The reactor is filled with an adsorption material

which can catch and hold the ethylene. The first step

of measurement is the accumulation of ethylene in

this adsorption material.

When enough gas is assembled, then the reactor

is heated up fast and the ethylene is set free in a

short boost which enters the CG system. This way,

for the first time a resolution below 400 ppbv was

detected [Janßen, 2013]. Figure 10 shows a

chromatogram of a probe gas of 400 ppbv of

ethylene in air. The biggest problem concerning

cross sensitivity is water. In the first attempt, the

water peak was overlapping the ethylene peak. A

new stationary phase (Carbosieve SII) shows

different retention times for water and ethylene. This

way, it is possible to separate these two species as

shown in figure 10.

Figure 9: A micro reactor used as preconcentrator for

ethylene measurement. By using micro-preconentrators, a

resolution in the ppbv-range can be achieved. (Janßen,

2013).

Figure 10: Chromatogram of ethylene (blue line) in air

made by the combination of a micro-preconcentrator and a

micro-gas-chromatograph [Janßen, 2013]. The red curve

shows air with the same humidity but no ethylene content.

The ethylene is clearly detected around sample 5200 (1300

seconds). The proof gas has a concentration of 400 ppbv

ethylene. The needed resolution of 50 ppbv is provided by

this system.

4 CONCLUSIONS

In this paper we described the results of several

projects concerning the application of wireless

sensor nets in fruit logistics. As a conclusion of this

experience we would like to sum up the basic

findings about sensor networks within the following

theses:

Loss of fruit during storage and transport can be

considerably reduced using wireless sensor

networks combined with data interpretation tools

and decision support tools.

The tools must be implemented locally. This

means, that they have to be programmed on the

small platform of a sensor node and that they must

0,00

0,05

0,10

0,15

0,20

15

20

25

30

35

40

45

50

1 2001 4001 6001 8001 10001 12001

Samples

[mS]

[%]

TheIntelligentContainer-ACognitiveSensorNetforFruitLogistics

357

be implemented parallel on several nodes. Central

calculation needs too much energy for the

communication of all the the single data and it

makes the net too vulnerable.

Practically, robustness of the system is the main

issue. Sensor nodes can fail, they also can just

vanish by being forgotten or stolen. For this

reason, parallel and redundant structures are

needed.

The housing of the sensor nodes must stand humid

surrounding and also mechanic stress such as

mechanic impact by pressure and shock.

There is no off the shelf solution for sensor nodes.

Specific surrounding needs specific housings

concerning humidity, temperature and mechanic

stress. Specific deployments also need specific

communication strategies to be able to

communicate in difficult situations such as close

iron walls and loading with water content.

Medium term, sensor nodes have to be powered by

batteries. Energy harvesting only works if area and

light are always available and solar cells can be

applied. The energy need of sensors and

electronics is declining fast, but the amount of

energy which can be scavenged is still too small

for most sensor net deployments.

How will the project go on? The next steps will

be twofold: Some of the industrial partners of the

Alliance for Innovation are now performing

application development together with Bremen

University in order to launch a sensor net for fruit

transport as a product. Second, there is more need on

specific sensor technology. At the moment, IMSAS

is starting a project to detect the growth of mould

fungus in containers during transport.

ACKNOWLEDGEMENTS

The research project “The Intelligent Container” is

supported by the Federal Ministry of Education and

Research, Germany, under reference number

01IA10001. Further information about the project

can be found at http://www.intelligentcontainer.com.

We additionally thank Dole Fresh Fruit Europe for

provision of test facilities.

REFERENCES

Ambaw, A.,Delele, M. A., Defraeye, T., Ho, Q. T., Opara,

L. U., Nicolai, B. M., Verboven, P. 2013. The use of

CFD to characterize and design post-harvest storage

facilities: Past, present and future. Computers and

Electronics in Agriculture. 93, 184-194.

Ali, Syed; Ashraf-Khorassani, Mehdi; Taylor, Larry T.;

Agah, Masoud: MEMS-Based Semi-Packed Gas

Chromatography Columns. In: Sensors and Actuators

B: Chemical Vol. 141 (2009), Nr. 1, S. 309-315.

Agah, M.; Lambertus, G. R.; Sacks, R.; Wise, K.: High-

Speed MEMS-Based Gas Chromatography. In Journal

of Microelectrmechanical Systems Vol. 15 (2006), Nr.

5, S. 1371-1378.

Becker, M., Yuan, S., Jedermann, R., Timm-Giel, A.,

Lang, W., Görg, C.: Challenges of Applying Wireless

Sensor Networks in Logistics. CEWIT 2009.

Behrens, C., Bischoff, O., Lueders, M., Laur, R. 2007.

Energy-efficient topology control for wireless sensor

networks using online battery monitoring. In:

Kleinheubacher Tagung 2006, U.R.S.I.

Landesausschuss in der Bundesrepublik Deutschland

e.V, Kassel.

Bials, Jacob B.; Young, Roy E.; Olmstead, Alice J.: Fruit

Respiration and Ethylene Production. In: Plant

Physiol. Vol. 29 (1954), Nr. 2, S. 168-174.

Crossbow. 2005. TelosB Mote platform.availabe at

http://www.willow.co.uk/TelosB_Datasheet.pdf.

Dittmer, P., Veigt, M., Becker, M., Dannies, A., Nehmiz,

U., Hosse, M. 2013. Quality traceability from

production to retail shelf. In: 5th International

Workshop Cold Chain Management, University Bonn,

Bonn, Germany.

Fonollosa, J., Halford, B., Fonseca, L., Santander, J.,

Udina, S., Moreno, M.,& Marco, S. (2009). Ethylene

optical spectrometer for apple ripening monitoring in

controlled atmosphere store-houses. Sensors and

Actuators B: Chemical, 136(2), 546-554.

Ingelrest, F., Barrenetxea, G., Schaefer, G., Vetterli, M.,

Couach, O., Parlange, M. 2010. SensorScope:

Application-specific sensor network for environmental

monitoring. ACM Trans. Sen. Netw. 6, 1-32.

Jabbari, A., Jedermann, R., Muthuraman, R., Lang, W.

2009. Application of Neurocomputing for Data

Approximation and Classification in Wireless Sensor

Networks. Sensor Journal. 9, 3056-3077.

Janßen, S.; Lang, W., "Ethylene Measurement for Fruit

Logistic Process in a Range of 400 ppbv and below,"

in 5th International Cold Chain Management

Workshop, Bonn, Germany, 2013, p. 6.

Jedermann, R., Edmond, J. P., Lang, W. 2008. Shelf life

prediction by intelligent RFID. In: Dynamics in

Logistics. First International Conference, LDIC 2007,

(H. D. Hassis, H. J. Kreowski, B. Scholz-Reiter, eds.)

pp. 231-238, Springer, Berlin/Heidelberg.

Jedermann, R., Lang, W.: The Benefits of Embedded

Intelligence – Tasks and Applications for Ubiquitous

Computing in Logistics. The internet of things 2008,

pp.105-122.

Jedermann, R., Lang, W. 2009. The minimum number of

sensors - Interpolation of spatial temperature profiles.

In: Wireless Sensor Networks, 6th European

Conference, EWSN 2009, Lecture Notes in Computer

Science (LNCS), (U. Rödig, C.J. Sreenan, eds.) pp.

SENSORNETS2014-InternationalConferenceonSensorNetworks

358

232-246, Springer, Berlin/Heidelberg.

Jedermann, R., Becker, M., Görg, C., Lang, W. 2011.

Testing network protocols and signal attenuation in

packed food transports. International Journal of

Sensor Networks (IJSNet). 9, 170-181.

Jedermann, R., Dannies, A., Moehrke, A., Praeger, U.,

Geyer, M., Lang, W. 2013. Supervision of transport

and ripening of bananas by the Intelligent Container

In: 5th International Cold Chain Management

Workshop 2013, University Bonn, Germany, Bonn,

Germany.

Koutsoumani, K., Taoukis, P. S., Nychas, G. J. E. 2005.

Development of a safety monitoring and assurance

system for chilled food products. International

Journal of Food Microbiology. 100, 253-260.

Krige, D. G. 1951. A statistical approach to some mine

valuations and allied problems at the Witwatersrand.

University of Witwatersrand.

MCB Microsystems Center Bremen. 2013. Homepage of

the Intelligent Container project. Bremen, Germany,

availabe at www.intelligentcontainer.com.

Palafox-Albarrán, J., Jedermann, R., Lang, W. 2011.

Energy-Efficient Parameter Adaptation and Prediction

Algorithms for the Estimation of Temperature

Development Inside a Food Container. In: Lecture

Notes in Electrical Engineering - Informatics in

Control, Automation and Robotics, (A.J. Cetto, J.-L.

Ferrier, J. Filipe, eds.) pp. 77-90, Springer, Berlin.

Scharnow, R. 2005. Die Ware im Container. In:

Containerhandbuch, (Y. Wild, R. Scharnow, M.

Rühmann, eds.) pp. 107-390, Gesamtverband der

Deutschen Versicherungswirtschaft e.V. (GDV),

Berlin.

Scheer, F. P. 2006. Optimising supply chains using

traceability systems. In: Improving traceability in food

processing and distribution, (I. Smith, A. Furness,

eds.) pp. 52 - 64, Woodhead Publishing Ltd.,

Cambridge, England.

Sklorz, A., Janßen, S., Lang, W.: Detection limit

improvement for NDIR ethylene gas detectors using

passive approaches. Sensors and Actuators B,175

(2012) 246-254.

Sklorz, A., Janßen, S., Lang, W.: Application of a

miniaturized packed gas chromatography column and

a SnO

2

gas detector for analysis of low molecular

weught hydrocarbons with focus on ethylene

detection. Sensors and Actuators B 180 (2013).

Tian, W. C.; Pang, S. W.; Chia-Jung, L.; Zellers, E. T.:

Microfabricated Preconcentrator-Focuser for a

Microscale Gaschromatograph. In Journal of

Microelectromechanical Systems Vol. 12 (2003), Nr.

3, S. 264-272.

Tijskens, L. M. M., Polderdijk, J. J. 1996. A generic

model for keeping quality of vegetable produce during

storage and distribution. Agricultural Systems. 51,

431-452.

Tsironi, T. E., Gogou, P., Taoukis, P. S. 2008. Chill chain

management and shelf life optimization of MAP

seabream fillets: a TTI based alternative to FIFO. In:

Coldchain Management . 3rd International Workshop,

(J. Kreyenschmidt, ed.) pp. 83 - 89, Bonn, Germany.

Turner, D. W. 1997. Bananas and plantains. In:

Postharvest physiology and storage of tropical and

subtropical fruits, (S. K. Mitra, ed.) pp. 47-83, CAB

International.

Virtenio. 2013. Preon32 - Wireless Module data sheet.

Berlin, Germany,availabe at http://www.virtenio.com/

en/assets/downloads/datenblaetter/DS_Preon32_v15_2

page%20%5BEN%5D.pdf.

Wang, X., Jabbari, A., Laur, R., Lang, W. 2010. Dynamic

Control of Data Measurement Intervals in a

Networked Sensing System using Neurocomputing.

In: International Conference on Networked Sensing

Systems (INSS 2010), Kassel.

Wang, X., Yuan, S., Laur R., Lang W.: Dynamic

localisation based on spatial reasoning with RSSI in

wireless sensor networks for transport logistics.

Sensors and Actuators A 171 (2011) 421-428.

Zhang, Rhong: Tejedor, M.; Anderson, M.; Paulose, M.;

Crimes, C.: Eythylene Detection Using Nanoporous

PtTiO2 Coatings Aplliedmto Magnetoelextic Thick

Films. In Sensors Vol. 2 (2002), Nr. 8, S. 331-338.

Zweig, S. E. 2008. Life Track technology for smart active-

label visual and RFID product lifetime monitoring. In:

Coldchain Management, 3rd International Workshop,

(J. Kreyenschmidt, ed.) pp. 29-36, University of Bonn,

Bonn, Germany.

TheIntelligentContainer-ACognitiveSensorNetforFruitLogistics

359