Fabrication of Precise Micro-fluidic Devices using a Low-cost and

Simple Contact-exposure Tool for Lithography

Toshiyuki Horiuchi and Shinpei Yoshino

Tokyo Denki University, 5 Senju-Asahi-cho, Adachi-ku, Tokyo, Japan

Keywords: Micro-fluidic Device, Micro-mixer, Lithography, Thick Resist, Vertical Sidewall, Blue Filter.

Abstract: Various methods have been proposed for fabricating biochemical, pharmaceutical, and medical micro-

fluidic devices. Among them, the new method using groove patterns formed in a thick resist film as the flow

paths is promising. Because the flow paths are directly fabricated only using one lithography process,

complicated flow paths can be obtained easily and precisely. However, it is often required to prepare an

expensive exposure system newly for applying the method to practical fabrications of the devices. For this

reason, the effective method has not been sufficiently utilized practically. Here, a very low-cost exposure

tool was developed to make a breakthrough. In the new tool, functions were minimized, and limited to

indispensable ones. However, because the required pattern widths were in the range of 50-200 μm, flow-

path patterns were nicely fabricated. Assembling the fabricated micro-mixer chips with the vessels and lids,

it was verified that two liquids were simultaneously injected into the mixer paths without leaks. Thus, it was

clarified that the new exposure tool was useful. Micro-patterns fabricated using the new simple exposure

tool will be useful for developing various micro-fluidic devices.

1 INTRODUCTION

Various original and characteristic micro-fluidic

devices are proposed and fabricated for researches,

and investigated in detail (Jacobs, et al., 2009) (Serra,

et al., 2011) (Bouhadda, et al., 2012) (Curto, et al.,

2012) (Kashkary, et al., 2012). However, on the final

practical stage, the devices are generally thrown

away after once used. Accordingly, it is necessary to

fabricate them easily with a low cost. For this reason,

various methods have been proposed for fabricating

practical micro-fluidic devices. In most cases, the

micro-fluidic devices are fabricated by duplicating

the original device to plastic resins. As resins, poly-

dimethyl-siloxane (PDMS), epoxy, and poly-methyl-

methacrylate (PMMA) are used, for example (Lopez,

et al., 2009) (Chen, et al., 2010) (Campbell, et al.,

2011).

On the other hand, it is a very important subject

how to fabricate the original devices or the original

moulds of the device for the use of replicating the

final working devices. Various methods are also

proposed for preparing such original moulds. The

most popular method is the one using the etching of

silicon or glass substrates. In this method, flow-path

moulds are fabricated by etching the substrates

masked by the resist patterns (Avram, et al., 2008)

(Eun, et al., 2008). The final working devices are

fabricated using injection mould, hot stamp, or nano-

imprint technologies (Yang, et al., 2009) (Oakley, et

al., 2009).

In some cases, the original moulds are fabricated

using resist patterns. As resins for this use, SU-8 and

PMMA are mainly used (Riahi, et al., 2012).

Methods for fabricating the moulds using metals

such as nickel are also proposed (Liu, et al., 2013).

Comparing with these methods, the new method

using deep grooves formed in thick resist films

directly as flow paths is notable. Fine and deep fluid

paths with any complicated shapes and rectangular

cross-sections are easily and simply fabricated only

using lithography process, and the fluid paths are

easily but surely sealed only covering them by a flat

plate lid and binding the substrate with fluid paths of

resist and the lid using several bolts and nuts.

Because the resist surfaces are almost perfectly flat

and the resist films have appropriate elasticity, fluid

paths are favourably sealed. In addition, sidewall

profiles and angles of the fluid paths are controllable

by selecting effectual lithography conditions. In

many cases, perpendicular sidewalls or rectangular

cross sections are preferred. For this reason, SU-8 is

mainly used as a resist (Horiuchi, et al., 2010). The

5

Horiuchi T. and Yoshino S..

Fabrication of Precise Micro-fluidic Devices using a Low-cost and Simple Contact-exposure Tool for Lithography.

DOI: 10.5220/0004724900050011

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 5-11

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

main component of SU-8 is epoxy resin, and it is

inert for blood and other body fluids.

However, low-cost and simple exposure tools for

fabricating such resist patterns are not commercially

available, or not accessible from the viewpoints of

costs and flexibility for the applications. Generally

speaking, conventional expensive lithography tools

are unsuitable for small volume productions and

specimen size variations.

In this paper, a very low-cost exposure tool is

handmade to answer these subjects. Key ideas are

the extremely simple contact exposure setup, and the

insertion of a blue filter to the exposure optics.

Whitesides’ group is researching paper-based

micro-fluidic devices by patterning paper using SU-

8 (Martinez, et al., 2008) (Martinez, et al., 2010).

Here, thicker SU-8 film is coated on a silicon wafer,

and sharper and clearer patterns are printed for

obtaining deep grooves.

2 THICK RESIST PATTERNING

USING CONTACT EXPOSURE

Contact exposure is the most simple lithography

method which has been used for a long time. In

general, mask aligners are used for this lithography.

However, if fine and accurate alignment between a

mask and a wafer is not required, indispensable

equipments are limited to a light source for exposure

and an exposure stage for placing the mask and

wafer. For this reason, much simpler tools are

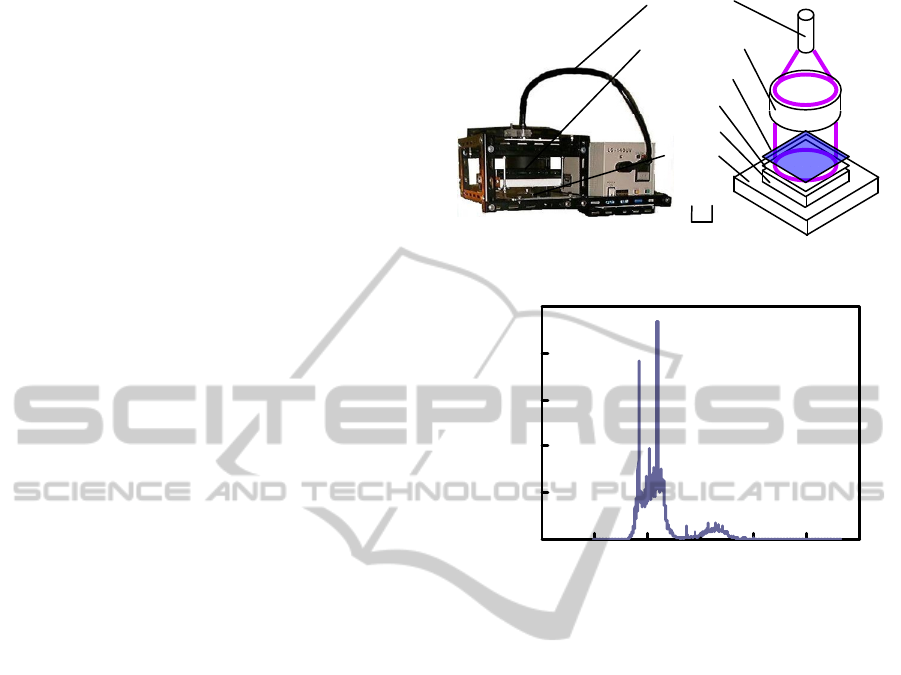

applicable. Here, a versatile Ultra Violet (UV) light

source (Sumita Optical Glass, LS-140UV) was used,

as shown in Fig. 1. The light flux ejected in wide

angles from the light guide was rearranged to almost

parallel flux using a collective lens. In the case of

fabricating fluid paths in a resist film, accurate

alignment between a mask and a substrate is not

required. Accordingly, if a mask is laid on a

substrate as their corners are just fitted together, and

placed on the stage, patterns on the mask are printed

almost at an appropriate position on the substrate

with good repeatability. Therefore, precise micro-

mixers are easily fabricated in spite of using such a

simple and low-cost scheme. The spectral light

intensity distribution of the source is shown in Fig. 2.

Silicon wafers with a size of 50-mm square and a

thickness of 625 μm were used as substrates, and

film masks with a size of 50-mm square and a

thickness of 100 μm were used. The wafers were

coated with a negative resist SU-8 (MicroChem).

The thickness of the resist was controlled to

10cm

Mask

Lightguide

Sta

g

e

Collectivelens

Wafer

Bluefilter

Figure 1: Simple exposure system used for this research.

0

2000

4000

6000

8000

10000

0 200 400 600 800 1000 1200

Wavelength(μm)

Lightintensity(a.u.)

Figure 2: Spectral light intensity of exposure source.

approximately 100 μm. Spectral transmittance of the

resist is shown in Fig. 3. Because light rays in UV

and short-wavelength visible light regions are

absorbed in the resist, the resist is sensitive to the

light rays with wavelengths less than approximately

450 nm. Considering the spectral intensity of

exposure source, it is supposed that the resist is most

sensitive to 365-nm light. However, the absorption

of 60% at 365-nm wavelength is too large to

sensitize the thick resist film appropriately to the

bottom. In other words, the exposure light energy is

absorbed too much near the resist surface, and

slightly absorbed near the bottom. As a result,

patterns with T-shape or inversed-trapezoid cross

sections are obtained. In some cases, eaves of the T-

shape patterns hung down, as shown in Fig. 4. It is

obvious that grooves with such cross-sections are

inconvenient as flow paths.

It was supposed that sidewall profiles of the

patterns would be improved to vertical ones if the

difference of exposure intensity between the surface

and the bottom was decreased. To realize these

improvements, it is effective to remove or reduce the

short UV-wavelength components in the exposure

light rays. For this reason, a blue filter was inserted.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

6

0

20

40

60

80

100

120

300 400 500 600 700

Wavelength(μm)

Transmittance

(

%

)

Beforeexposure

Afterexposure

365

Figure 3: Transmittance of 100-μm thick SU-8 film.

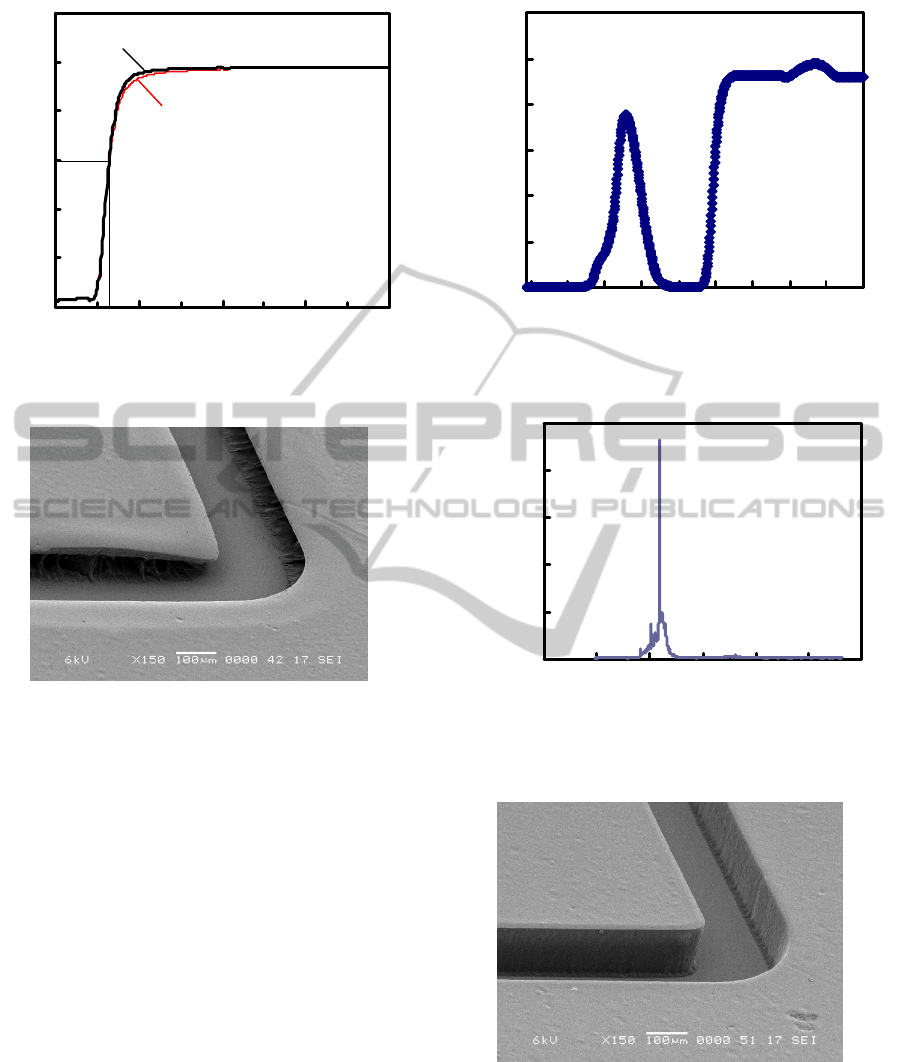

Figure 4: T-shape patterns with eaves hanging down.

The spectral transmittance of the blue filter was

measured, as shown in Fig. 5.

As a result of inserting the blue filter, the

spectral distribution of the exposure light on the

wafer stage was improved, as shown in Fig. 6, and

SU-8 patterns with almost rectangular cross sections

were obtained, as shown in Fig. 7. The round shapes

of corners depend on the mask patterns and are not

caused by the light diffraction. To fabricate patterns

with lower thicknesses is easier. However, deep

grooves are preferable from the viewpoint of

obtaining a Reynolds number as large as possible.

To evaluate the perpendicularity of sidewall profiles,

pattern widths at the resist surface and the bottom

were measured. As a result, differences of pattern

widths between at the top and the bottom were less

than 20 μm, that is almost 10% of the mean pattern

widths, as shown in Fig. 8. Almost same results

were obtained using a 405-nm narrow band-path

filter with a full width half maximum (FWHM) of

10 nm. However, because only a little part of the

exposure light rays were utilized, approximately

0

20

40

60

80

100

120

110

0

1000900800700600500400300200

Wavelength(nm)

Transmittance

(

%

)

Figure 5: Spectral transmittance of the blue filter.

0

2000

4000

6000

8000

10000

0 200 400 600 800 1000 1200

Wavelength(μm)

Lightintensity(a.u.)

Figure 6: Spectral light intensity of exposure source when

the blue filter is inserted.

Figure 7: Trench pattern with perpendicular sidewalls.

twice exposure time was required.

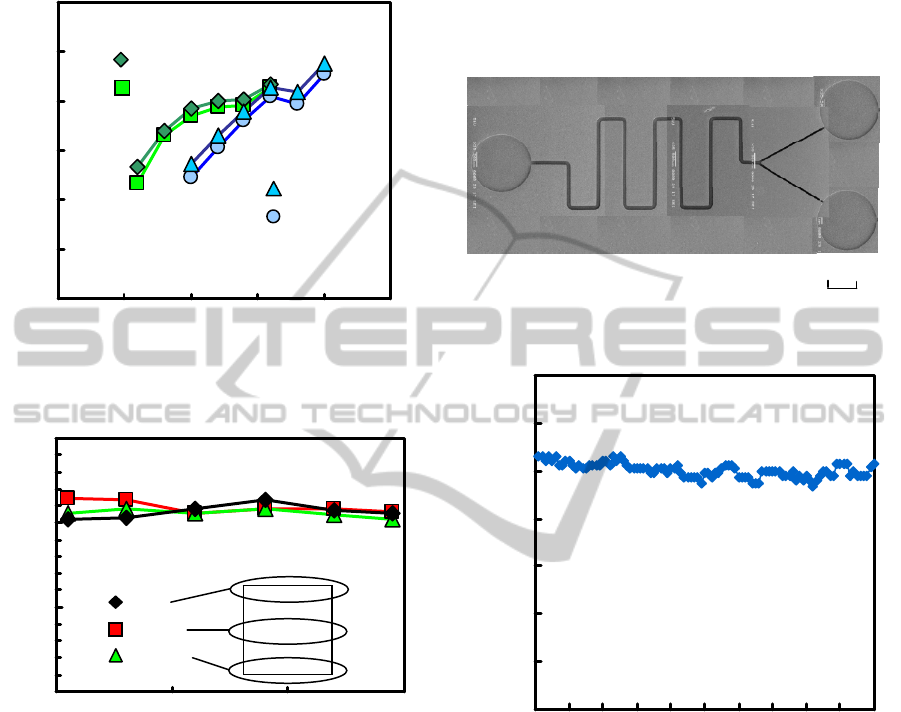

Next, pattern width homogeneity in the exposure

field of 15 mm square was investigated. The widths

were measured using top view photographs of the

patterns. Fig. 9 shows the results. Pattern widths

were measured at 18 points shown in the figure. It

FabricationofPreciseMicro-fluidicDevicesusingaLow-costandSimpleContact-exposureToolforLithography

7

was clarified that the widths were almost

homogeneous, and the deviation were approximately

within ±8 μm.

0

50

100

150

200

250

300

0 5 10 15 20 25

Exposuretime(min)

Patternwidth(μin)

Surface

Bottom

Bluefilter

Surface

Bottom

405‐nmfilter

Figure 8: Evaluation results of sidewall perpendicularity.

0

50

100

150

0 5 10 15

Position

(

μ

m

)

Top

Centre

Bottom

××××××

××××××

××××××

Patternwidth

(

μ

m

)

Measuredpointsintheexposurefield

Figure 9: Homogeneity of pattern width in the exposure

field.

3 FABRICATION OF

MICRO- FLUIDIC DEVICE

PATTERNS

Because the patterning tool was prepared, and the

patterning processes were checked, patterns for the

use of micro-fluidic paths were formed. An example

of micro-mixer pattern is shown in Fig. 10. The

sizes of the devices were 14.3 mm × 5.7 mm, and

the favourable exposure dose was 3.5-4 J/cm

2

. The

designed widths of the Y-shape patterns at both

entrances and the repeatedly winding parts were 50

and 100 μm, respectively. The widths were

measured using the optional function prepared for

the scanning electron microscope (JSM 5510, JEOL).

Measured pattern widths were almost homogeneous,

as shown in Fig. 11. The diameters of two inlet ports

and an outlet port are 2mm.

Figure 10: Flow-path patterns with perpendicular

sidewalls.

Figure 11: Width homogeneity of flow-path patterns.

4 ASSEMBLY OF

MICRO-MIXERS

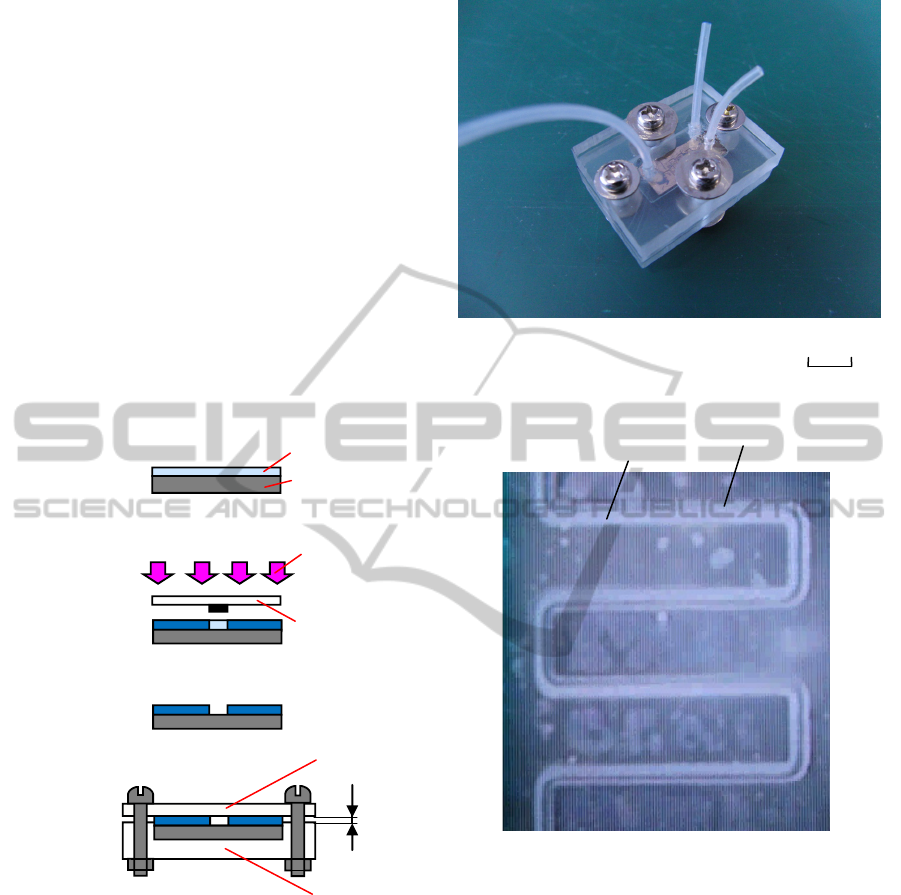

Micro-mixers were assembled using the resist

micro-fluidic paths formed on silicon wafers. Plastic

vessels and lids were fabricated using a simple 3

dimensional milling machine. A silicon wafer chip

with the resist paths was embedded in a concave

made on the vessel, and the resist surface was

slightly stuck out from the top surface of the vessel,

as shown in Fig. 12. As a result, the resist surface

was homogeneously pressed by the flat lid. Each of

the thickness of the vessel and the lid was as large as

1mm

0

20

40

60

80

100

120

140

0 20406080100

Measurement point number

Width of trench

p

attern

(

μ

m

)

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

8

5 mm so as not to be bent and curved when they

were bound by bolts and nuts. Micro-tubes with

inner and outer diameters of 1 and 2 mm were

attached to the inlets and outlet using epoxy

adhesive. No heat treatments were added to the resist

paths after the patterning.

Fig. 13 shows the outside view of the assembled

micro-mixer. The sizes of the device were 23×30×15

mm. The depth of the rectangular concave engraved

on the vessel surface was made a little shallower

than the total thickness of the micro-mixer chip. As

a result, the resist-path surface became higher than

the vessel surface. The height difference or stick-out

height h is almost equal to the gap between the

surface of vessel and the back surface of lid, as

shown in the figure. It was clarified that the stick-out

height h should be controlled between 35 and 45 μm

to prevent the leaks.

Wafer

Resist

Exposurelight

Mask

Lid

Vessel

①

Resist

②

Exposure

③

Development

④

Assemble

h

Figure 12: Fabrication method of micro-mixer.

5 FLOW TEST

Two coloured liquids were simultaneously injected

from the Y-shape inlets for verifying that they did

not leak out though the sealed gaps between the

surfaces of resist patterns and the lid plate. The

liquids were injected using manual syringes at the

initial stage, and automatic syringe pumps at the

final stage. Coloured waters were used as the liquids.

Because the seal depends on the elastic deformation

Figure 13: Outside View of the fabricated micro-mixer

Yellowwater

Bluewater

Figure 14: Non-mixing flow of two coloured waters.

Blue and yellow waters flew without being mixed.

of the resist, it was necessary that the surface of the

resist film was sufficiently stuck out from the vessel

surface, as mentioned above. On the other hand, the

lid plate is bended when it is bound with the vessel

at the four corners, and the bending deformation

increase depending on the stick-out height of the

resist. For this reason, the optimum stick-out height

should be decided considering the rigidity or

thicknesses of the lid and the vessel.

Fig. 14 shows the flow in the mixer. When same

liquids with yellow and blue colours were

simultaneously injected, the two liquids were

separately flown without being mixed together.

In the past research, two liquids prepared

10 mm

FabricationofPreciseMicro-fluidicDevicesusingaLow-costandSimpleContact-exposureToolforLithography

9

100µm

Separated

Mixed

Figure 15: Example of micro-mixing.

similarly were successfully mixed in a snail-shape

channel, as shown in Fig. 15. In this case, liquids

coloured in red and blue were used. Separated red

and blue flows were gradually mixed after they

passed corners. Accordingly, it is thought that the

liquids will be mixed if the shape of the channel is

improved. A lot of papers had been written on

micro-mixing in micro-fluidic devices (Jain, et al.,

2013) (Rahimi, M., et al., 2014). Considering the

reported remarks, vigorous research efforts should

be done hereafter.

6 CONCLUSIONS

A very simple and low-cost exposure tool was

developed, and applied to fabricate micro-fluidic

devices in which resist patterns were directly used as

flow paths. In spite of using such a simple and low-

cost tool, precise flow-paths with perpendicular

sidewalls were successfully fabricated, because a

blue filter was inserted to adjust the light absorption

of the thick resist film. Micro-fluidic device chips

made by the resist were embedded in the plastic

vessels, and capped by the lids. Although the lids

were simply bound with the vessels using small

bolts and nuts, injected fluids were flown without

leaks. The developed tool and the method to

fabricate micro-fluidic devices will be effective and

useful for economical small-volume production.

ACKNOWLEDGEMENTS

This work was partially supported by Research

Institute for Science and Technology of Tokyo

Denki University, Grant Number Q13T-02.

REFERENCES

Avram, M., Iliescu, C., Volmer, M., Avram, A., 2008.

Microfluidic device for magnetic separation in lab-on-

a-chip systems, Digest of Papers, Microprocesses and

Nanotechnology 2008, 21

st

International

Microprocesses and Nanotechnology Conference,

442-443.

Bouhadda, I., Sagazan, O., Bihan, F. L., 2012. Suspended

Gate Field Effect Transistor with an Integrated Micro-

Fluidic Channel Performed by Surface

Micromachining for Liquids Sensing, Procedia

Engineering 47, 754-757.

Campbel, K., McGrath, T., Sjölander, S., Hanson, T.,

Tidare, M., Jansson, Ö., Moberg, A., Mooney, M.,

Elliott, C., Buijs, J., 2011. Use of a novel micro-fluidic

device to create arrays for multiplex analysis of large

and small molecular weight compounds by surface

plasmon resonance, Biosensors and Bioelectronics 26,

3029-3036.

Chen, C. S., Chen, S. C., Liao, W. H., Chien, R. D., Lin, S.

H., 2010. Micro injection molding of a micro-fluidic

platform, International Communications in Heart and

Mass Transfer 37, 1290-1294.Jacobs, T., Kutzner, C.

Kropp, M., Brokmann, G., Lang, W., Steinke, A.,

Kienke, A., Hauptmann, P., 2009. Combination of a

novel perforated thermoelectric flow and impedimetric

sensor for monitoring chemical conversion in micro

fluidic channels, Procedia Chemistry 1, 1127-1130.

Curto, V. F., Fay, C., Coyle, S., Byrne, R., O’Toole, C.,

Barry, C., Hughes, S., Moyna, N., Diamond, D.,

Lopez, F. B., 2012. Real-time sweat pH monitoring

based on a wearable chemical barcode micro-fluidic

platform incorporating ionic liquids, Sensors and

Actuators B 171-172, 1327-1334.

Eun, D. S., Kong, D. Y., Chang, S. J., Yoo, J. H., Hong, Y.

M., Shin, J. K., Lee, J. H., 2008. Micro-PCR Chip

with Nanofluidic Heat-Sink for Faster Temperature

Changes, Digest of Papers, Microprocesses and

Nanotechnology 2008, 21

st

International

Microprocesses and Nanotechnology Conference ,

448-449.

Horiuchi, T., Watanabe, H., Hayashi, N., Kitamura, T.,

2010. Simply Fabricated Precise microfluidic Mixer

with Resist Flow Paths Sealed by an Acrylic Lid,

Proceedings of The third International Conference on

Biomedical Electronics and Devices, 82-87.

Jain, M., Nandakumar, K., 2013. Optimal patterning of

heterogeneous surface charge for improved

electrokinetic micromixing, Computers and Chemical

Engineering 49, 18-24.

Kashkary, L., Kemp, C., Shaw, K. J., Greenway, G. M.,

Haswell, S. J., 2012. Improved DNA extraction

efficiency from low level cell numbers using a silica

monolith based micro fluidic device, Analytica

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

10

Chimica Acta 750, 127-131.

Liu, F., Tan, K. B., Malar, T. P., Bikkarolla, S. K., Kan, J.

A., 2013. Fabrication of nickel molds using proton

beam writing for micro/nano fluidic devices,

Microelectronic Engineering 102, 36-39.

Lopez, F. B., Scarmagnani, S., Walsh, Z., Paull, B., Macka,

M., Diamond, D., 2009. Spiropyran modified micro-

fluidic chip channel as photonically controlled self-

indicating system for metal ion accumulation and

release, Sensors and Actuators B 140, 295-303.

Martinez, A. W., Phillips, S. T., Wiley, B. J., Gupta, M.,

Whiteside, G. M., 2008. Flash: A rapid method for

prototyping paper-based microfluidic devise, Lab Chip

8, 2146-2150.

Martinez, A. W., Phillips, S. T., Whiteside, G. M.,

Carrilho, E., 2010. Diagnostics for the developing

world: microfluidic paper-based analytical devices,

Anal. Chem. 82, 3-10.

Oakley, J. A., Robinson, S., Dyer, C. E., Greenman, J.,

Greenway, G. M., Haswell, S. J., 2009. Development

of a gel-to-gel electro-kinetic pinched injection

method for an integrated micro-fluidic based DNA

analyser, Analytica Chimica Acta 652, 239-244.

Rahimi, M., Azimi, N., Parvian, F., Alsairafi, A. A., 2014.

Computational Fluid Dynamics modelling of

micromixing performance in presence of

microparticles in a tubular sonoreactor, Computer and

Chemical Engineering 60, 403-412.

Riahi, M., 2012. Fabrication of a passive 3D mixer using

CO2 laser ablation of PMMA and PDMS moldings,

Microchemical Journal 100, 14-20.

Serra, N., Maeder, T., Gentsch, O., Ryser, P., 2011.

Fabrication of polymer-based micro devices:

Formulation study of the paste, Sensors and Actuators

A 172, 336-340.

Yang, R., Lu, B. R., Wang, J., Xie, S. Q., Chen, Y., Huq,

E., Q, X. P., Liu, R., 2009. Fabrication of micro/nano

fluidic channels by nanoimprint lithography and

bonding using SU-8, Microelectronic Engineering 86,

1379-1381.

FabricationofPreciseMicro-fluidicDevicesusingaLow-costandSimpleContact-exposureToolforLithography

11