Methodologies and Tools to Support Design and Development of

New Products

Ana Dias

1

, António Abreu

1

and João Matias

2

1

Mechanical Engineering Departamental Area, Superior Institute of Engineering of Lisbon, Lisbon, Portugal

2

Electromechanical Engineering Department, Beira Interior University, Covilhã, Portugal

Keywords: New Product Development, Graph, NPD Tools, Innovation, Suppliers, Quality, Project, Decision.

Abstract: Nowadays, companies, even the small ones, need to use more efficient working methods such as

"transnational." The market may still be local or regional, but the competition is global. To be competitive,

companies need to develop innovative products and introduce them to the market at an acceptable price, in

proper time and with a higher quality level. According to some authors, the survival strategy of the

companies is related to the development of methodologies that are able to design, develop and provide,

through efficient processes, innovative products and high quality. In this context, this paper aims to classify

and characterize the main methodologies and tools used in new products development. This aims are

supported by the graphs theory that is briefly addressed.

1 INTRODUCTION

The increasing globalization of markets, especially

in the last decade, caused profound changes in the

structure, organization and manner of operation of

businesses. The working methods and management

of the past are less and less adapted to the turmoil of

the modern world. In the current world scenario, at

the macroeconomic level is possible to identify a set

of variables that influence the competitiveness of

companies, for example, the energy crisis associated

with the continuous increase in oil prices and the

emergence of new trading powers, such as China

and India, have all created new threats to European

Industry (De Feo and Bar-El, 2002).

In order to be competitive companies must

develop capabilities that will enable them to respond

quickly to market needs. Nowadays it’s possible to

identify variables that influence the development of

production processes such as market pressures to:

improving quality, reducing production time and

costs, increased production flexibility and

concentration on core competences (Finster, 2001).

On the other hand, the product life cycle is

becoming shorter which strongly increases the rate

at which the process of design and/or development

of new products occur. The most frequently

introduction of new products in the market with

shorter intervals of time has been, in recent times,

the survival strategy of some companies to win new

customers and as a response to the diversity of

options available (Christopher, 1992) and

(Creveling, 2003).

Based on a survey and applying the graph theory

this article contributes to identify and characterize

the main methodologies and tools used in processes

of new products development (NPD), and their

interrelationships among them.

2 TOOLS USED IN NPD

Base on literature a number of tools/methodologies

focused on different perspectives to support NPD

processes have been proposed over time in various

disciplines.

From literature review carried out, it was found

that there is no consensus regarding the terminology

of methodology and tool, that means these concepts

are mistaken for each other (Sun and Zhao, 2010).

Therefore, in this article, are considered as

“methodological tools” those that are both

methodologies and tools, and as “instrumental tools”

those that are used as support of methodological.

In order to identify the most relevant tools used

in NPD and their inter-relations, a survey on web of

167

Dias A., Abreu A. and Matias J..

Methodologies and Tools to Support Design and Development of New Products.

DOI: 10.5220/0004764901670173

In Proceedings of the 3rd International Conference on Operations Research and Enterprise Systems (ICORES-2014), pages 167-173

ISBN: 978-989-758-017-8

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

science (549 articles were selected, gathering the

period between 2002 and 2013) was conducted.

Taking into account the data collected, the tools

were divided in groups, regarding de theme that

matches with each tool under the NPD. Table 1

shows some examples of associated tools to NPD

processes.

Table 1: Classification of NPD supporting tools.

Discipline

Tools/Methodologies

Methodological Instrumental

Project

TRIZ (theory for

inventive problem

solving)

ARIZ; Matrix of

contradictions; S-

Field model

Creative design

Analogy-based

design

Axiomatic Design

Pugh analysis;

DOE; DFX

Logistics

Suppliers

Development

Involvment (SDI)

Quality

Quality Function

Development

(QFD)

Kano model; House

of quality (HOQ);

Balanced Scorecard

(BSC); Ishikawa or

Fishbone analysis;

Design for Failure

Modes and Effects

Analysis

(DFMEA); Pareto

or ABC analysis

Design for Six

Sigma (DFSS)

DFSS cycles

(DMADV, DCCDI,

DCOV, DDOV,

DMADIC,

DMADOV,

DMEDI, ICOV,

IDOV, ID

2

OV,

I

2

DOV e PIDOV)

Design Support

Robust design

Tolerance design

Modular design

Decision

Support

Analytical

Hierarchy Process

(AHP)

Case Based

Reasoning (CBR);

Data Envelopment

Analysis (DEA);

Delphi panel

3 SURVEY FINDINGS

3.1 Brief Decription of Methodological

Tools to Support NPD

Among the tools to support innovation and

creativity, TRIZ that means in English: "Theory for

Inventive Problem Solving", and is a specific

support for innovation development project, product

or process engineering or technology. More

surprisingly, the reference of the concept TRIZ-

fractal that means self-similarity in transformations

based on TRIZ tools to address knowledge

management TRIZ (Pin et al., 2011) uses the matrix

of contradictions and innovative principles in order

to solve problems (Berdanosov and Redkolis, 2011).

Another tool of this group is known as "Creative

Design". Creativity is necessary to generate

alternative solutions, requiring the involvement of

the designer or the creative team responsible for the

design. This process has not only creative inspiration

and imagination with these people, but also with

methods and tools that allow the manifestation of

creativity. There is research indicating that creativity

to find solutions to product design , comes often in

direct analogy with nature, and hence the concept of

"Bionic" which consists in analyzing the functioning

of natural systems or processes, reproducing after

their early solution (Detanico, 2010). From this

analogy often arise new outstanding contributions in

the process of NPD. These adaptations allow the

creation of forms, functions, or even similar

conduct. A creative design analogy is an important

reasoning process that allows the generation of new

artifacts, using ideas from the fields of technical

and/or scientific sometimes distant. Such is the case

with analogues derived from nature. Here therefore a

good creative genesis for the project: the analogy: it

is designated as “the design approach based on

analogy" (Gomes et al., 2006).

Yet another tool of this group is known as

"Axiomatic Design" that is a tool for creating

solutions synthesized with the aim of developing

products, processes or systems that satisfy perceived

needs through the mapping of customer desires in

"Functional Requirements" (FRs) turning them into

"Design Parameters" (DPs) (Yang and El-Haik,

2009). Functional requirements represent the goals

of the project that means the aims to be achieved (Li

et al., 2011). There are some vulnerabilities

concerning the axiomatic design: violation of their

two axioms, by coupling systems; or by the

complexity. That is why it is understood that the

DFSS can help overcome these problems.

Regardless of the vulnerabilities identified, the

axiomatic design is a methodological tool designed

to analyze in a systematic way, the transformation of

customer needs, FRs into DPs and relating them

(Yang and El-Haik, 2009).

One tool from logistics group corresponds to the

involvement of suppliers in NPD. Many authors

have demonstrated empirically that a NPD draft

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

168

participating vendors, induce many benefits

particularly in terms of reducing lead-times, reduced

project costs, including product and quality

improvement project and product (Wynstra, et al.,

2012). That is, the Suppliers Development

Involvement (SDI) has a decisive effect on the

performance of a NPD project. There were detected

three distinct factors that make up the apparent

involvement of suppliers (Jayaram, 2008):

information sharing and communication,

involvement in the project itself; quality compliance

and development of related infrastructure. That

means supplier involvement in NPD clearly

comprises a multidimensional perspective.

Quality Function Deployment (QFD), following

the philosophy of "Total Quality Management

(TQM)", and has been considered as a strategy that

the entire organization is focused on continuous

improvement (Li et al., 2012) and (Mendonça et al.,

2007). This entrepreneurial attitude has necessarily

to take into account at all times the will and needs of

customers (Ghinato, 1998). Approach in the context

of methodologies and tools based on the Quality

function, integrates undoubtedly the strategy or

methodology is portrayed primarily by its specific

tools or others associated with the project,

production or innovation (Ghinato, 1998). In support

of this assertion, were correlated in a robust manner,

greater speed in NPD with a more demanding of

quality processes and related tools (Sun and Zhao,

2010). As instrumental tools of QFD, the best

known are "House of Quality" (HOQ), Kano model,

BSC/KPIs (Balanced Scorecard/Keys Performance

Indicators), Failure Modes and effects

Analysis/Design Failure Modes and Effects Analysis

(FMEA/DFMEA), cause-effect or fishbone diagram

(also known as the Ishikawa diagram) and Pareto or

ABC analysis.

Design for Six Sigma (DFSS) is a

methodological tool project developed under the Six

Sigma (SS) philosophy in order to support

continuous improvement in the stage of mass

production and whose focus is the design and

development of profitable products, processes and

services, meeting the needs and expectations of

customers (voice of customer) and other

stakeholders (Jou, et al., 2010), including suppliers

as already noted. This aim involves the use of an

integrated set of tools, in order to provide and

improve the quality level obtained before the start of

production or harvesting. SS approach focuses on

the production phase and/or operation and DFSS has

its focus on the design and development phase.

Thus, it is possible to substantially reduce the costs

associated with the life cycle of the product, service

or process, since the DFSS is a preventive approach

(Yang and El-Haik, 2009), which aims to predict the

occurrence of failures and prevent unfold in stages

following. DFSS, whose methodology based (the

first one came and that subsequently led variants, is

the DMADV. SS philosophy was developed

precisely to achieve this goal. DFSS as well as their

tools instrumental also called cycles (Shahin, 2008):

"Define, Measure, Analyze, Improve, Control”

(DMAIC)/"Define, Measure, Analyze, Design,

Verify" (DMADV) among others, can considered as

an integrated whole in the universe’s most

comprehensive quality or DFSS methodology

(Shahin, 2008).

A tool from the support design decision group is

the “Robust Design”. Terminological factors are

referred to as "noise", such as temperature, humidity,

dust, deterioration, and so on. Which are the cause

of these deviations which result is loss of product

quality. Such damage can be evaluated using a

function "loss" which was initially proposed by Lee

and Tang (2000). Such a proposal is to determine the

loss function of the product, to optimize through

statistical techniques. Such analyzes allow us to

identify the optimal parameters of draft which

minimizes or eliminates the harmful influence of

such factors "noise", product performance or NPD.

Thus, instead of isolating the product to develop the

noise factor, which in addition to any hard

execution, can become expensive undoubtedly the

production process, the robust engineering presents

itself instead as a valid proposal to implement

projects that eliminate these same factors noises in

the product's intention. Taguchi method consists in

obtaining products sufficiently robust in order to

achieve high quality with respect to any fluctuations

that influence the environment of the NPD and even

those that may occur during the production process

(Kang et al., 2007).

Another tool from the previous noticed group is

the “Tolerance Design”. DFSS usually uses to drive

defects per million opportunities (DPMO) (Santos,

2009). This measurement is the average number of

defects per unit normalized, if one million, seen

during a production sample mean, divided by the

number of opportunities for the existence of a

product defect, a defect is considered as non-

compliance with requirements. These requirements

are defined in the specification or tolerance of

products or processes, still in the design phase of the

NPD, and can determine one or more forms of

production of each of the component parts, rather

than the use of other processes (Singh, et al., 2005).

MethodologiesandToolstoSupportDesignandDevelopmentofNewProducts

169

It is therefore a tool methodological tools that can

use instruments towards the optimization of

tolerances even before the actual geometric

dimensioning (Zhang et al., 2010). A robust

engineering is not compatible with large projects

with dimensioning of clearances that have tolerated

maintenance costs outside the criteria of a six sigma

production (Hagen and Park, 2013). This is therefore

a design type intended mainly for the production and

construction of machines, organs and parts where

the gaps are tolerated function of the dynamic

equilibrium and stability of the structure as a whole.

The last tool from the same group as the two last

noticed is the “Modular Design”, it corresponds to

the outsourcing, both parts of the project, as

production parts or components to a third logistics

part (3lp), whose integration is a crucial task both

with respect to the phases of the project, such as

when outsourcing regards the production process

(Salvador and Villena, 2013). The modular design

can be presented by the facet of knowledge sharing

in NPD, and conclude that this strategy has positive

impacts on their organizations and products

developed in (Huang et al., 2010). This methodology

of modular design of the product, from the

normalization of constituent parts, it introduces a

large degree of flexibility in the range of range of

the final product. Although it will primarily

economies of scale owing variety of end products

and that also enables power in certain circumstances,

economies of diversity (scope) (Dornier et al.,

1998). With regard to the reporting of this

"modularized design" is the practice of design,

production and assembly of complete products from

different modules from various sources, as occurs

for example in modular computers, automobiles, and

so on.

Finally, the most important tool from the

decision support group is the “Analytical Hierarchy

Process” (AHP). This is a methodology useful in

screening and ranking the various decisions that

must be made in companies engaged in the NPD,

primarily with respect to the various alternatives

under consideration. Due to the consideration of a

large number of quantitative and qualitative criteria

and lack of sufficient and concrete data, it is often

the situation in which the members of the project

group NPD have to make decisions in such

situations of uncertainty. As with other tools or

techniques, for example the DEA or, at the planning

stage when the product specifications, the weighting

(assigning weights) of factors and criteria is an

essential exercise, and should be done in a way as

reliable as possible (Chan et al., 2006). These

criteria need to be considered and evaluated at the

design and like the other methods, the solution may

pass through the involvement of a group of experts

multifunction (Fuzzy-Delphi). In obtaining the

hierarchy adopted for making such decisions, the

application of AHP tool, enables the distribution and

selection of the most important among the various

comparison and evaluation (Ayag and Ozdmir,

2009).

3.2 Graph of the Most used

Methodological Tools in NPD

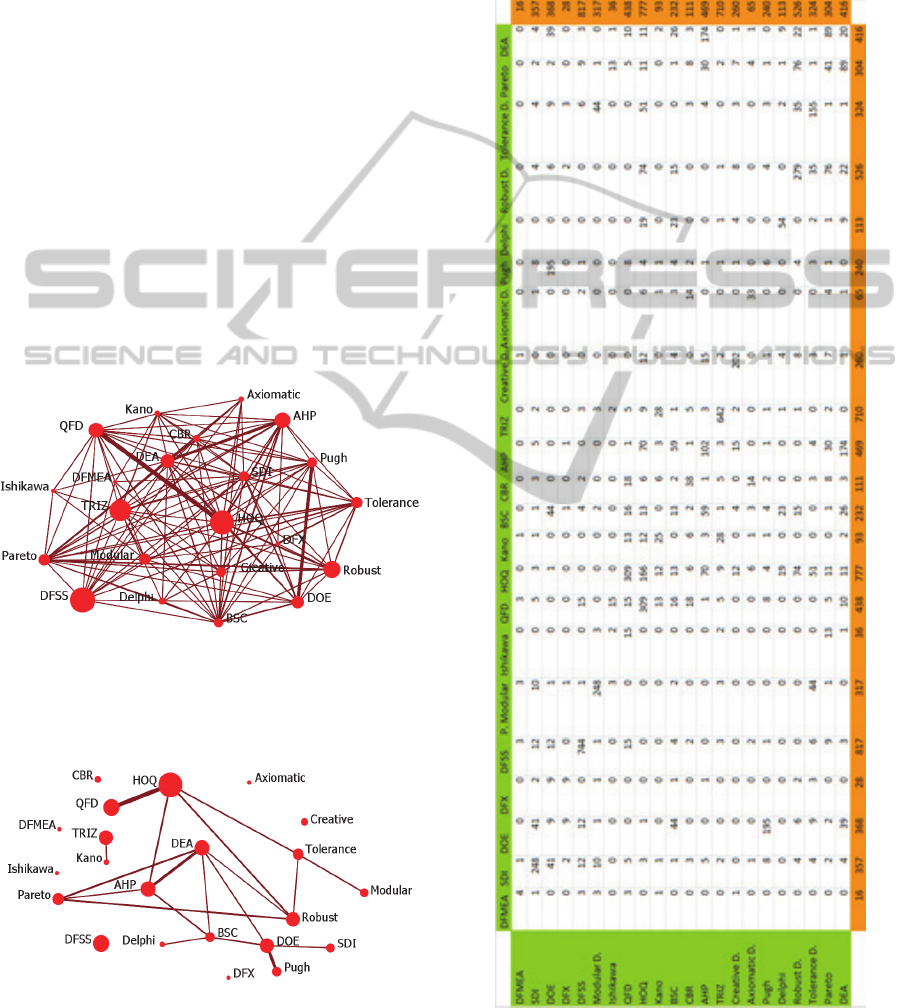

The survey on web of science mentioned in point 2,

leaded to make the matrix shown in figure 3 that

relates the most important and used tools in NPD.

Hence it was found the following:

1. From a first group arise that: the robust design;

AHP and QFD are used very often in NPD (20.6

% of analyzed articles)

2. Of the six tools specified in respect of 22

analyzed (23.5 %) corresponded, on the whole,

more than half of the articles surveyed (51.5 %);

3. The observations were less in the downward

direction: the cause and effect diagram or (fish-

bone or Ishikawa) and DFMEA (about 1 % of

the total products);

4. The tools support the quality function of NPD

lead with 27 % of the articles;

5. The tools supporting innovation function

accounted for 23.8 % of the research articles,

soon followed by tools supporting project

(excluding the DFSS) with 16.6 % of the tools

and decision support with 15.8 %. The tools of

DFSS projects for six sigma productions were

scrutinized with 11.6 % of the total;

6. AS tools focusing on the involvement of

suppliers in collaborative processes stayed with

5.1%. Despite being by far the least scientifically

working group, differentiation which show the

other face is so substantial that do not hesitate

whether to maintain classification as special tool;

7. The tools support the quality function are those

that interact more with the other while being the

tool DFMEA (instrumental) used less and also

less interacts ;

8. Of total tools, articles related to methodological

tools was 65.5 % , while the corresponding

articles of the type tools instrumental presented

with the remaining 34.5 %;

9. The methodological tools used in most scientific

papers were DFSS, TRIZ and the robust project

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

170

with 45.7 % for the set of methodological tools

and 28.1 % of the total;

10. The tools used were more instrumental HOQ, the

DEA and the DOE with 70.2 % of the total of

such tools and 21.4 % of the total sample

However, if it is adopted the term model as a

simplified representation of the study object which

contains not all elements, but only those considered

relevant, graphs can be used to model

interrelationships. Thus, the "nodes" are used to

represent the tools while the "links" are used to

represent the relationships between tools

(Wasserman and Faust, 1994).

The cells of the matrix shown in figure 3 were

used with ORA software, generating the graph

shown in figure 1. This figure illustrates the network

of tools and their inter-relationships in NPD, where

the nodes’ size represents the number of times that a

tool has been given reference in the literature during

the period in analysis, and link’s width represents

the number of times that two tools are used

simultaneously in NPD.

Figure 1: Importance of tools and their interrelationship in

NPD.

In Figure 2, are represented the relations more

relevant.

Figure 2: Simplified graph with the most relevant

interrelationship in NPD.

One interesting advantage of using a graph

approach is the possibility to analyze in detail the

‘sub-structures’ that may be present in the network.

Divisions of tools into cliques, i.e. sub-structures of

a network in which tools are more closely and

intensely linked to one another than they are to other

tools of the network, can be important to detect

patterns of interrelationships between them.

Figure 3: Matrix obtained from a survey conducted on

web of science (594 articles were selected, gathering the

period between 2002 and 2013).

MethodologiesandToolstoSupportDesignandDevelopmentofNewProducts

171

On the other hand, at micro level the knowledge

how a tool is embedded in a sub-structure within a

network, may be important to understand its

applicability. For instance, some tools can act as

‘bridges’ between groups of tools.

Furthermore, applying metrics used in networks

(graphs) for instance the concept of local centrality it

is possible to identify that the most relevant tools

used in NPD, alone or in complementary with others

tools, are respectively, the HOQ DFSS and TRIZ

(29.3 % of total sample).

4 CONCLUSIONS

The literature review involves intrinsically NPD

with a panoply of tools both methodological and

structural root as a mostly instrumental. There were

analyzed 22 of these tools, the most important has

been possible with the survey of about seven

thousand articles referenced in the web of science,

interrelated and viewed graphically with the help of

graphs appropriate. This selection addressed to the

surface 10 to the Methodological tools, nevertheless

accounted for 65.5% of the total sample collected.

The tools in use are classified into two types:

methodological and vehicles. The first, by itself or

as a complement to other, structure a project NPD

(for example: TRIZ, DFSS or SDI). The latter alone

can not structure a project or set of NPD, but which

are recurrently used as support, support or other

instrument (for example: Pareto analysis, balanced

scorecard or BSC and Delphi panel).

REFERENCES

De Feo, J. and Bar-El, Z., 2002. Creating strategic change

more efficiently with a new design for Six Sigma

process, Journal of Change Management, Vol. 3, No.

1, pp.60–80.

Detanico, F. B., Teixeira, F. G. e Silva, T. K., 2010, A

Biomimética como Método Criativo para o Projeto de

Produto, Design & Tecnologia, 02, pp. 101-113.

Finster, M., 2001. From continuous improvement to

continuous innovation, Quality Management Journal,

Vol. 8, No.4.

Christopher, M., 1992. Logistics and Supply Chain

Management, Second Edition, Prentice Hall.

Creveling, C. M., Slutsky J. L., and Antis D. Jr., 2003.

Design for Six Sigma – In Technology and Product

Development, Prentice Hal PTR.

Wasserman, S. and Faust, K., 1994. Social Network

Analysis - Methods and Applications, Cambridge

University press.

Pin, C. S., Haron, F., Sarmady, S., Talib, A. Z. and

Khader, A. T., 2011 Applying TRIZ principles in

crowd management, Safety Science, 49, pp. 286–291.

Berdanosov, V. and Redkolis, E., 2011. TRIZ – Fractality

of mathematics, Procedia Engineering, 9, pp. 461 -

472.

Ulrich, K. T. and Eppinger, S. D., 2002. Product, Design

and Development, 2nd Edition, Irwin McGraw-Hill.

Gomes, P., Seco, N., Pereira, F. C., Paiva, P., Carreiro, P.,

Ferreira, J. L. and Bento, C., 2006. The importance of

retrieval in creative design analogies, Knowledge-

Based Systems, 19, pp. 480 - 488.

Yang, K. and El-Haik, S. B., 2009. Design for Six Sigma –

A Roadmap for Product Development, Second Edition,

McGraw-Hill.

Li, J. Y., Chen, X. B. and Zhang, W. J., 2011. Axiomatic-

Design-Theory-Based Approach to Modeling Linear

High Order System Dynamics, IEEE/ASME

Transactions on Mechatronics, 16, (2), (2011), pp.

341-350.

Wynstra, F., Anderson, J. C., Narus, J. A. e Wouters, M.,

2012. Supplier Development Responsibility and NPD

Project Outcomes: The Roles of Monetary

Quantification of Differences and Supporting-Detail

Gathering, Journal of Production Innovation

Management, 29, pp. 103–123.

Jayaram, J., 2008. Supplier involvement in new product

development projects: dimensionality and contingency

effects, International Journal of Production Research,

46 (13), pp. 3717–3735.

Li, Y-L., Tang, J-F., Chin, K-S., Han, Y. and Luo, X-G.,

2012. A rough set approach for estimating correlation

measures in quality function deployment, Information

Sciences

, 189, pp. 126–142.

Mendonça, M. C. L. V. and Dias, J. C. Q., 2007.

Postponement in The Logistical Systems of the New

Automobiles Marketed in Portugal: The Brands And

Quality, Total Quality Management & Business

Excellence, 18 (6), pp. 681-696.

Ghinato, P., 1998. Quality control methods: Towards

modern approaches through well established

principles, Total Quality Management, 9 (6), pp. 463 –

477.

Sun, H. and Zhao, Y., 2010. The empirical relationship

between quality management and the speed of new

product development, Total Quality Management, 21

(4), pp. 351–361.

Jou, Y. T., Chen, C. H., Hwang, C. H., Lin, W. T. and

Huang, S. J., 2010. A study on the improvements of

new product development procedure performance – an

application of design for Six Sigma in a semi-

conductor equipment manufacturer, International

Journal of Production Research, 48 (19), 1, pp. 2010,

5573–5591.

Shahin, A., 2008. Design for Six Sigma (DFSS): lessons

learned from world-class companies, International

Journal of Six Sigma and Competitive Advantage, 4

(1), pp. 48-59.

Lee, C. L. and Tang, G. R., 2000. Tolerance design for

products with correlated characteristics, Mechanism

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

172

and Machine Theory, 35, pp. 1675 – 1687.

Kang, N., Kim, J. and Park, Y., 2007. Integration of

marketing domain and R&D domain in NPD design

process, Industrial Management & Data Systems, 107

( 5-6), pp. 780-801.

Santos, D., 2009. Beyond Six Sigma - A Control Chart for

Tracking Defects per Billion Opportunities (dpbo),

International Journal of industrial Engineering-theory

Applications and Practice, 16, Special Issue: SI(3),

pp. 227-233.

Singh, P., K., Jain, S. C. and Jain, P. K., 2005. Advanced

optimal tolerance design of mechanical assemblies

with interrelated dimension chains and process

precision limits, Computers in Industry, 56, pp. 179–

194.

Zhang, J., e Li, S. P., Bao, N.S., Zhang, G. J. and Gu, P.

H., 2010. A robust design approach to determination

of tolerances of mechanical products, CIRP Annals -

Manufacturing Technology, 59, pp. 195–198.

Hagen, M. and Park, 2013. Ambiguity Acceptance as a

Function of Project Management: A New Critical

Success Factor, Project Management Journal, 44 (2),

pp. 52–66.

Salvador, F. and Villena, V. H., 2013. Supplier integration

and npd outcomes: conditional moderation effects of

modular design competence, Journal of Supply Chain

Management, 49 (1), pp. 87-113.

Huang, T-T., Le Chen, and Stewart, E. A., 2010. The

moderating effect of knowledge sharing on the

relationship between manufacturing activities and

business performance, Knowledge Management

Research & Practice, 8, pp. 285–306.

Dornier, P. P., Ernest, R., Fender, M. and Kouvelis, P.,

1998. Global Operations and Logistics -Text and

Cases, John Wiley & Sons, Inc.

Chan, F., Chan, H., Lau, H. and Ip, R., 2006 An AHP

approach in benchmarking logistics performance of

the postal industry, Benchmarking: An International

Journal, 13 (6), pp.636–661.

Ayag, Z. and Ozdemir, R. G., 2009. A hybrid approach to

concept selection through fuzzy analytic network

process, Computers & Industrial Engineering, 56, pp.

368–379.

MethodologiesandToolstoSupportDesignandDevelopmentofNewProducts

173