Continuous Core Body Temperature Estimation via SURFACE

Temperature Measurements using Wearable Sensors

Is it Feasible?

Kumar Saurabh

1,4

, Hiteshwar Rao

3

, Bharadwaj Amrutur

2,3

and Asokan Sundarrajan

1,3

1

Department of Instrumentation & Applied Physics, Indian Institute of Science, Bangalore, India

2

Department of Electrical Communication Engineering, Indian Institute of Science, Bangalore, India

3

Robert Bosch Centre for Cyber Physical Systems, Indian Institute of Science, Bangalore, India

4

Robert Bosch Engineering & Business Solutions Ltd, Bangalore, India

Keywords: Core Body Temperature, Hypothermia, Wearable Sensors.

Abstract: Core body temperature is an important indicator of well being of humans. The commonly used methods and

sites of measurement do not lend well for continuous measurement at home. However, continuous

monitoring using non-invasive, small, low cost sensors could have many applications like detection of

hypothermia and fever in low birth weight neonates in rural settings. We investigate the feasibility of

making such measurements using only skin temperature sensors. Our initial sensor prototype is composed of

flexible materials, with embedded high precision thermistors and is based on dual heat flux technique. Our

initial experiments show that the reliable estimation of core temperature under varying ambient conditions

and at different measurement sites is a challenge, but promising. Further work is needed to combine results

from experimental measurements and theoretical simulations to provide good insights and enable accurate

estimation of core body temperature for long term monitoring at home.

1 INTRODUCTION

Even though pulmonary artery temperature is

considered to be the gold standard for core

temperature measurement, it is not used for general

clinical practice. Rectal temperature is close to this

but poses severe constraints due to invasiveness and

concerns about hygiene even though continuous

monitoring probes are available. Digital

thermometers for oral and axillary temperature

measurements have replaced the traditional mercury

in glass thermometers and provide relatively quicker

and easier measurements. However, these are meant

for manual use and do not suit continuous

monitoring needs. Recently, tympanic thermometers

based on infrared measurements have become

popular as they are fast and easy to use. However,

different studies show different results regarding

their accuracy in comparison to the pulmonary artery

temperature (Hooper & Andrews 2006). There have

been some attempts to integrate it into a head gear

similar to headphones (Boano, Lasagni & Roemer

2013). Other techniques like radiometric sensing

(Bonds, Gerig, Weller & Herzig 2012) have been

evaluated. Conductive textiles have been used for

monitoring temperature of neonates in Neonatal

Intensive Care Units (Chen, Dols, Oetomo & Feijs

2010). However, none of these are suitable for

continuous temperature monitoring of neonates at

home due to inconvenience in use, complexity of the

device or power requirements. Skin temperature is

the easiest to measure in a non-invasive manner

using simple sensors. However, single point

measurements of skin temperature vary significantly

with the ambient conditions. As the

thermoregulation of neonates is not well developed,

using fixed offsets to skin temperature would add to

the errors. Hence there is a need for reliable

estimation of core temperature from skin

temperature measurement to develop low cost

sensors that are accurate and reliable for remote

monitoring applications.

181

Saurabh K., Rao H., Amrutur B. and Sundarrajan A..

Continuous Core Body Temperature Estimation via SURFACE Temperature Measurements using Wearable Sensors - Is it Feasible?.

DOI: 10.5220/0004889901810186

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2014), pages 181-186

ISBN: 978-989-758-013-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

2 CORE BODY TEMPERATURE

ESTIMATION FROM BODY

SURFACE MEASUREMENTS

One of the earliest efforts to develop a sensor for

core body temperature measurement from surface

measurements has been based on zero heat flow

method (Fox, Solman, Isaacs & MacDonald 1973).

The method uses a heater to create a zone of zero

heat flux such that the skin temperature under the

sensor reaches the core temperature. Studies have

shown the effectiveness of this method except

during exceptional rapid cooling or heating as the

response time is around 15 to 20 minutes when

applied to forehead (Togawa 1985). There have been

other attempts to evaluate the effectiveness of this

scheme for different applications (Zeiner et.al. 2010)

(Teunissen et.al. 2011). However, the use of a

heating element creates problems for applications

which involve mobility and require low power

consumption. New technique which does not involve

the use of heater and is based on a double sensor has

been reported for monitoring heat strains (Gunga

et.al. 2008) and also for space applications (Gunga

et.al. 2009). The design uses two temperature

sensors separated by an insulating layer whose

thermal conductivity is known. By measuring the

skin temperature and the temperature at the upper

sensor and knowing the thermal conductivity of

human tissue, the core temperature can be

calculated. However, this technique still requires the

correct knowledge of the thermal conductivity of the

epidermal tissues where the sensor is placed.

Another solution has been proposed using two heat

flow channels in parallel (Kitamura, Zhu, Chen &

Nemoto 2010). This work avoids the dependence on

knowledge of the thermal properties of tissue below

the sensor. Its performance has been compared to the

zero heat flux method. Further work has been

presented to improve the response time (Sim, Lee,

Baek & Park 2012). These present interesting ideas

for use in continuous monitoring applications.

However, additional constraints on materials of the

device to conform to body contour have to be added

for it to be acceptable for long term use on neonates.

Also, correspondence between experimental

measurements and theoretical correctness and

assumptions has to be established. We explore these

aspects by considering sensors for neonates. We

study the accuracy under varying conditions and at

different sites of measurement using both

simulations and experiments.

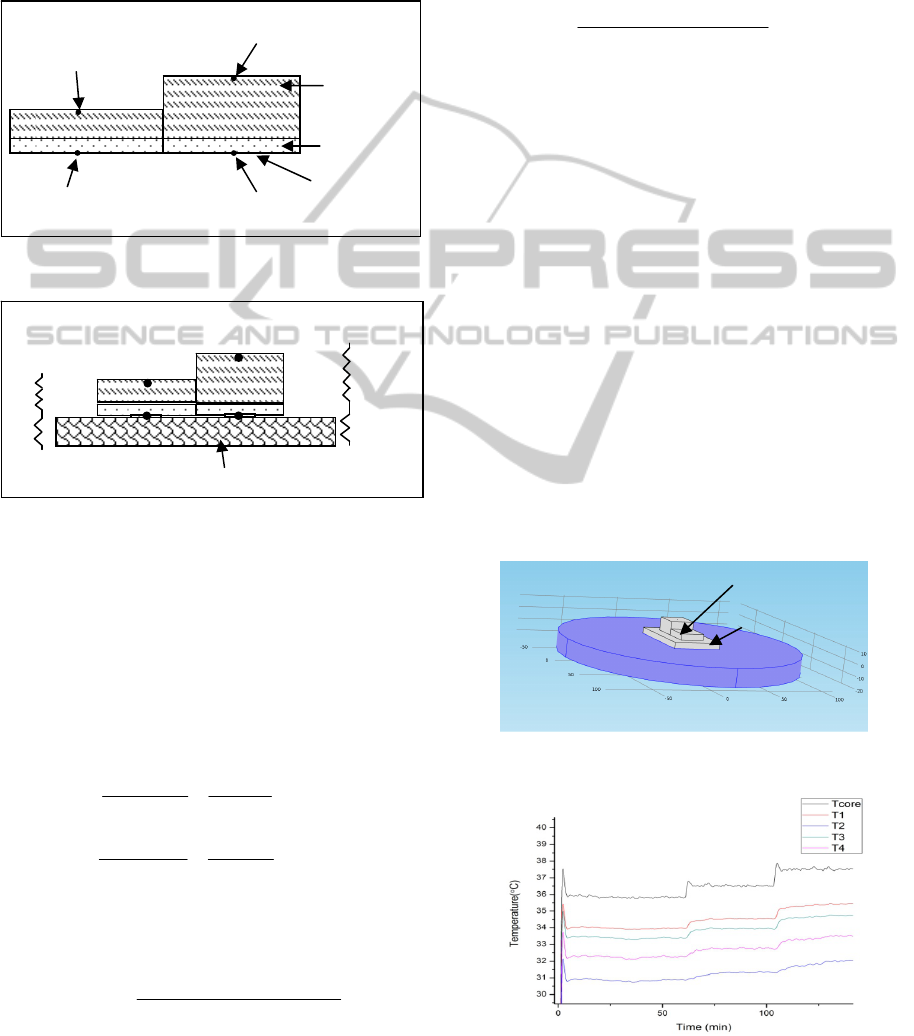

2.1 The Device Structure

For the device to be easily acceptable to parents for

long term use, it has to be such that it does not leave

any mark on the neonate’s skin. Also, it cannot be

taped to the skin as regular application and removal

of tapes create redness. Using a hard metal contact at

the skin interface or an inflexible material for the

sensor cover, would create problems. Hence using a

soft material that bends to conform to the body

contour and also ensure that the sensor is in contact

with the skin is a good option.

PolyDimethylsiloxane (PDMS) can be used as the

material for the device. PDMS provides both

flexibility and biocompatibility. Hence it can be

placed on the delicate skin of neonates over long

periods of time. Another major advantage provided

by PDMS is that it is highly hydrophobic. This

makes it very good for usage where it is likely to be

exposed to water or urine.

We use Dow Corning’s Sylgard 184 elastomer

kit for the purpose. Two different ratios of base and

curing agent have been used for two different layers

of the sensor (shown in Fig 1). For the layer that is

contact with the skin, base elastomer to curing agent

ratio of 10:0.4 is used while and for the top layer, a

ratio of 10:1 is used. The top layer is prepared first

and the lower layer is added after partial curing of

the first layer. This ensures that the two layers bind

together. By following this method, the need for

complex surface modification techniques like use of

oxygen plasma to improve adhesion between the

layers is avoided. The lower layer provides adhesion

to the skin surface and the upper layer provides the

rigidity needed for the sensor. Also, the lower layer

is softer and does not leave any mark when placed

on the skin. Experiments were performed with

different ratios of base and curing agent. It was

observed that a ratio of 10:0.2 provides better

adhesion over a longer time. But the layer is too soft

and can get easily damaged. The ratio of 10:0.4

provides adhesion while being strong enough for

long term use. However, the adhesion of the sensor

is not enough to hold it for a long time over

prolonged removal and placement cycles especially

in the presence of oil or dirt on the skin surface.

Hence a belt has been provided on the side of sensor.

In the presence of a belt, the adhesion is enough to

ensure contact of the sensor with the skin to get

reliable measurements with low pressure from the

belt on the skin. Instead of using IC based

temperature sensors as used in prior work, we use

high precision thermistors (MF51E103E3950). Since

the device can be made in very controlled manner

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

182

with respect to composition and size of moulds, the

thermal properties can be ensured for every device

and extensive calibrations for each sensor would not

be needed after it is in final form. The device also

has an integrated SOC (BLE112) from Bluegiga

Technologies for data acquisition and Bluetooth

®

low energy communication with a gateway device.

Figure 1: Device Structure.

Figure 2: Schematic of device placed on skin and

analogous equivalent circuit with two parallel heat flow

channels and thermal resistances network.

Following the concept as proposed by Kitamura

et.al., heat flow in the two channels can be modelled

using an equivalent thermal resistance network with

two parallel heat flow paths where R1 and R2 are

the respective thermal resistance of the two channels

and Rs is the thermal resistance of skin and

subcutaneous tissue.

1

211

R

TT

Rs

TTcore

(1)

2

433

R

TT

Rs

TTcore

(2)

When the temperatures T1 and T3 (as shown in Fig.

2) are measured close to each other as is the case

here, the core temperature can be calculated as

T

core

= T1 +

KTTTT

TTTT

*)43()21(

)13(*)21(

(3)

where K = R1/R2. Hence the dependence on

knowledge of thermal resistivity of skin and

subcutaneous tissue can be eliminated. The equation

in the published work by Kitamura and used in some

of the work that used the concept has slight error in

the denominator term. We have used a corrected

equation (equation 3). K can be obtained

experimentally by applying a fixed temperature for

Tcore and measuring T1, T2, T3, and T4 as

K=

)43(*)1(

)21(*)3(

TTTTcore

TTTTcore

(4)

2.2 Experimental Setup

and Measurements

To verify the concept, experiments have to be

performed to simulate different core temperatures.

To simulate the effect of skin and human tissues

experiments were tried using different phantoms.

Phantoms made from gelatine (obtained from

porcine cells) as well as poly vinyl alcohol were

tried. However, when these were exposed to

continuous heating especially above 36 degrees for

long durations (30-40minutes), the physical

properties started changing due to loss of water

content. This made it difficult to conduct the

experiments. Hence PDMS (10:1) was used instead

as it has thermal conductivity of 0.15 W/m K which

is very close to that of skin and fat. The sensor was

placed on a PDMS layer of thickness 5mm which in

turn was placed on a well controlled hot plate to

simulate the core temperature.

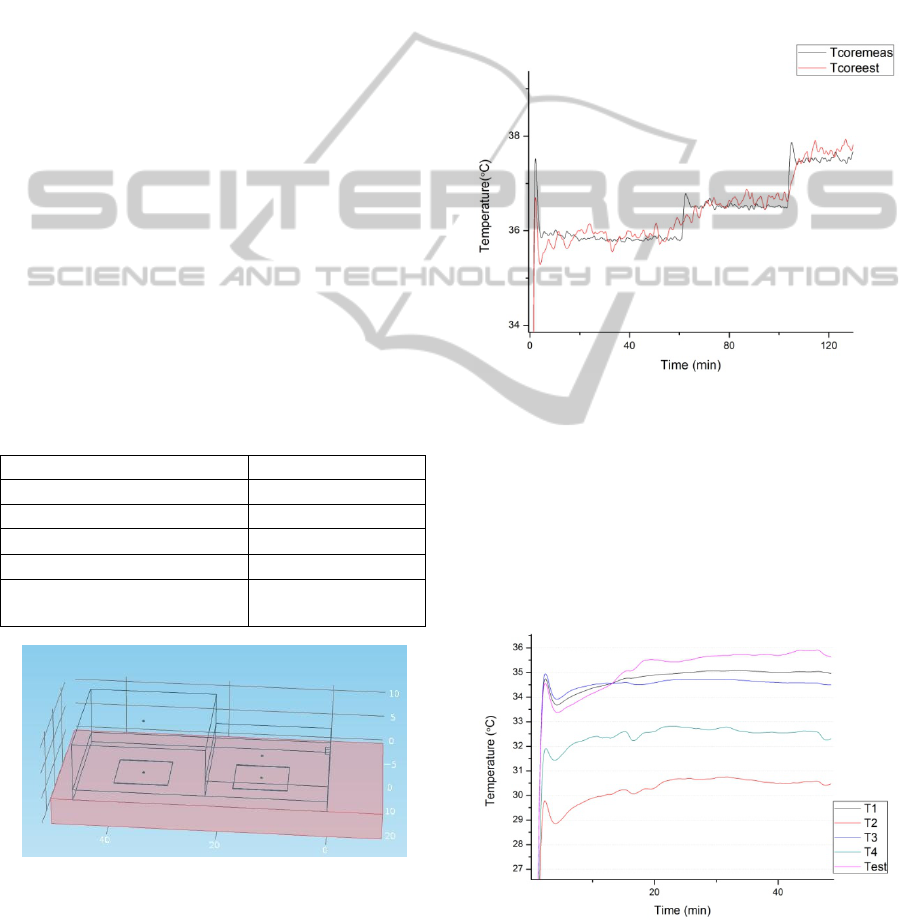

Figure 3: Experimental Setup.

Figure 4: Measured Temperatures during experiment.

PDMS (10:1)

PDMS (10:0.4)

Aluminum tape

Thermistor 2

Thermistor 4

Thermistor 1

Thermistor 3

T1

T2

T3

T4

R1

Rs

Tcore

Rs

R2

Tcore

Skin and tissue

Hot Plate

Device

Layer simulating

skin and tissues

ContinuousCoreBodyTemperatureEstimationviaSURFACETemperatureMeasurementsusingWearableSensors-Isit

Feasible?

183

Three temperature points of 36C, 36.5C and

37.5C were used to cover the normal body

temperature range. Based on the measurements as

shown in Fig 4, the value of K was obtained as 3.5

for all three temperature points.

Calculation of Tcore is very sensitive to the

temperature difference T3-T1. Hence, it justifies the

use of high precision thermistors instead of IC based

temperature sensors as used in earlier work.

2.3 Heat Transfer Simulation

A three dimensional sensor model was created using

COMSOL

TM

as shown in Fig. 3 and heat transfer

simulation was performed to verify the feasibility of

using the concept. In the model, the sensor was

composed of PDMS blocks with four domain point

probes placed at the bottom and top surfaces similar

to that in fig 1. The simulation was performed by

placing it on another PDMS layer similar to the

experimental setup. The bottom boundary of the

lower PDMS layer was assigned the temperature

equivalent to Tcore. Radiation and convection was

specified at the top surface. The convective heat

transfer coefficient was kept very low to have

simulation equivalent to still air in the room. The

parameters were specified as follows and ambient

temperature was specified as 25C which was same

for experimental measurements.

Parameter Value

Thermal Conductivity (k)

0.15 W/(mK)

Density (ρ) 0.97 Kg/m

3

Heat Capacity (Cp)

1460 J/(KgK)

Surface Emissivity ()

0.9

Convective heat transfer

coefficient (h)

2.5 W/(m

2

K)

Figure 5: COMSOL model.

3 RESULTS AND DISCUSSION

Using the value of K as 3.5 obtained in the

experiment, the applied core temperature was

estimated. The mean error was less than 0.2C for

the experimental temperature range. The results are

shown in Fig 4. Intentionally, smoothing is not

performed to show that there are minor fluctuations

in temperature as the core temperature itself has

fluctuations due to the involved PID control of the

hot plate. The response of the sensor is quite fast to

step changes in temperature and hence it can track

varying temperatures with a delay of less than 5

minutes even for step changes.

Figure 6: Comparison of applied Tcore and Estimated

Tcore.

The sensor was placed on the forehead on four

different days and timings to measure the

performance. It takes approximately 20-30minutes

for the temperature to stabilise. This is similar to the

time mentioned in earlier work. Hence, the choice of

PDMS as the material does not increase the

measurement time.

Figure 7: Measurement on forehead.

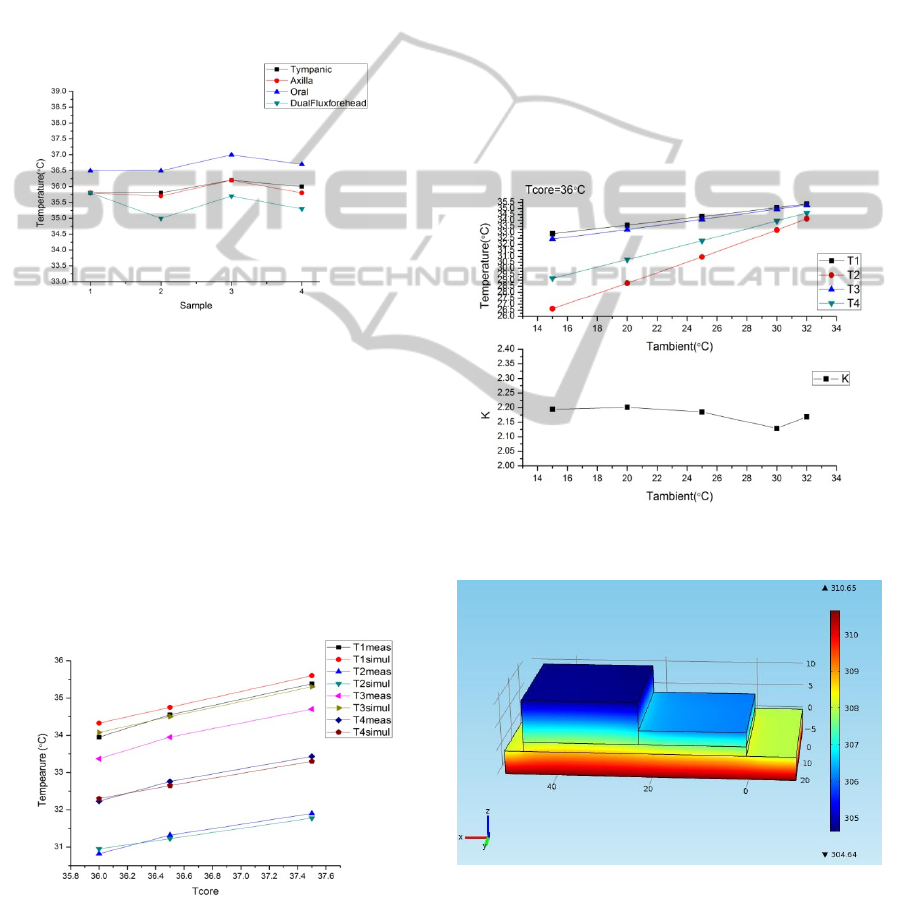

It is important to compare the measured temperature

to other standard sites of measurement used in

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

184

regular clinical use. Tympanic temperature was

measured using an infrared tympanic thermometer

(Omron MC510) and the oral and axillary

temperatures were measured using a digital

thermometer (Neclife). The results show that the

obtained temperatures using dual flux method is

usually lower compared to all three measurements.

However, the variation is consistent across different

temperatures. However, concrete conclusions cannot

be derived based on these measurements as no

temperatures in the hypothermic and fever ranges

were measured.

Figure 8: Comparison of temperature measurements using

different methods and sites of measurement.

Comparison of experimental results and theoretical

simulations can help in improving the design of the

sensor. Hence, a comparison of COMSOL

simulation results and experimental measurements

for the different temperatures measured within the

sensor is presented in Fig 9. T2 and T4 match very

closely for all three points. However, T1 and T3 are

higher is simulation than in experiment. One of the

reasons could be the contact resistance between the

hot plate and the lower PDMS layer.

Figure 9: Comparison of measured temperatures within

the device and COMSOL simulations.

The temperature at different boundaries can be seen

in the simulation results in Fig 11. During

simulation, it can be easily noticed that the presence

of a metallic contact (aluminium foil in this case) at

the bottom layer impacts the absolute value of

temperatures even though it does not significantly

affect the difference in temperatures. Also, there is

significant impact of selection of convection

boundaries.

Since simulation assumes, perfect contact, this

can impact the values. The K value obtained in

simulation 2 as expected. In simulation this value

does not vary significantly over ambient

temperatures ranging from 15C to 32C as seen in

fig. 10. However, as the ambient temperature

increases, T1-T3 becomes very small and hence in

experimental measurements, inaccuracies in the

thermistor calibration can have a significant impact

on the estimated temperature.

Figure 10: Temperatures T1, T2, T3, T4 and the values of

K with varying ambient temperatures.

Figure 11: Temperature at different boundaries in the

COMSOL simulation.

ContinuousCoreBodyTemperatureEstimationviaSURFACETemperatureMeasurementsusingWearableSensors-Isit

Feasible?

185

4 CONCLUSIONS AND FUTURE

WORK

The choice of PDMS as the material and a simple

geometry does not adversely affect the sensor

characteristics compared to results mentioned in

earlier work. However, it is required to understand

in details the reasons for differences in experimental

values and theoretical simulations including the

possibility to overcome the effects of contact

resistance which is dependent on contact resistance

without affecting the flexibility of the sensor. Also,

the effect of ambient variations and convection are

important for accuracy of the sensor. A much more

detailed model is required to compensate for these as

compared to the simple thermal resistance network

model. It might be useful to use dynamic models to

infer the change in ambient conditions and, if

possible, the context of measurements to reduce the

possibility of false alarms. Another important aspect

that has not been studied so far is the use at a

measurement site other than the forehead. If the

sensor can be used at a location between the

abdomen and chest, it can be coupled with other

vital parameter measurements on a single sensing

device. However, the layer of adipose tissues is

significantly lesser for neonates and hence data

obtained on adults and neonates could vary.

Another very important aspect for future work is

to develop a good model incorporating multiple

tissue layers and blood perfusion using Penne’s Bio-

heat equations instead of simple heat transfer

models. It could be interesting if some of the

parameters can be learnt from data obtained through

continuous measurements and be able to predict

conditions like increased blood perfusion due to

exposure to cold and compensate for differences in

core temperature measurements. It would also help

in validating the assumption that the effective

thermal resistance of tissue below the sensor is same

for both parallel heat flow channels.

ACKNOWLEDGEMENTS

We acknowledge the funding provided by Robert

Bosch Centre for Cyber Physical Systems at Indian

Institute of Science, Bangalore to carry out this

work.

REFERENCES

Bonds Q., Gerig J., Weller, T. M., Herzig P., 2012.

Towards core body temperature measurement via

close proximity radiometric sensing. IEEE Sensors

Journal. 12 (3).

Boano, C. A., Lasagni, M., & Roemer, K., 2013. Non-

invasive measurement of core temperature in marathon

runners. Proceedings of the 10th International

Conference on Wearable and Implantable Body

Sensor Networks.

Chen, W., Dols, S., Oetomo, S. B., Feijs, L., 2010.

Monitoring body temperature of newborn infants at

neonatal intensive care units using wearable sensors.

In BodyNets’2010. Fifth Interntional Conference on

Body Area Networks.

Fox, R. H., Solman A. J., Isaacs R., Fry A. J. &

MacDonald I.C. 1973. A new method for monitoring

deep body temperature from the skin surface. Clinical

Science. 44 p. 81-86.

Gunga et.al. 2008. A non-invasive device to continuously

monitor heat strains in humans. Journal of Thermal

Biology. 33. p. 297-307.

Gunga et.al. 2009. The Double Sensor - A non-invasive

device to continuously monitor core temperature in

humans on earth and in space. Respiratory Physiology

and Neurology. 169S. p. 63-68.

Hooper, V. D. & Andrews, J. O., 2006. Accuracy of

noninvasive core temperature measurement in acutely

ill adults: The state of the science. Biological Research

for Nursing. 8. p. 24-34.

Kitamura, K. I., Zhu, X., Chen, W., Nemoto, T. 2010.

Development of a new method for the noninvasive

measurement of deep body temperature without a

heater. Medical Engineering & Physics. 32. p. 1-6.

Mullany, L. C., 2010. Neonatal hypothermia in low

resource settings. Seminars in Perinatology. 34. p.426-

433.

Sim S.Y., Lee W. K., Baek H. J. and Park K.S. 2012. A

non-intrusive temperature measuring system for

estimating deep body temperature in bed. In 34

th

annual conference of the IEEE EMBS.

Teunissen et.al. 2011. Non-invasive continuous core

temperature monitoring by zero heat flux.

Physiological Measurements. 32. p. 559-570.

Togawa, T. 1985. Body Temperature Measurement. Clin.

Phys. Physiol. Meas. 6(2). p. 83-108.

Zeiner et.al. 2010. Non-invasive continuous cerebral

temperature monitoring in patients treated with mild

therapeutic hypothermia: An observational pilot study.

Resuscitation. 81. p. 861-866.

BIODEVICES2014-InternationalConferenceonBiomedicalElectronicsandDevices

186