Dealing with Variations for a Supplier Selection Problem in a Flexible

Supply Chain

A Dynamic Optimization Approach

Akram Chibani

1,2,3

, Xavier Delorme

1,2

, Alexandre Dolgui

1,2

and Henri Pierreval

1,3

1

LIMOS, Laboratoire Informatique, Modelisation et Optimisation des Syst

`

emes,

Complexe Scientifique des C

´

ezeaux, 63173, Aubi

`

ere Cedex, France

2

´

Ecole Nationale Sup

´

erieure des Mines de Saint-

´

Etienne, Institut Henri Fayol,

UMR CNRS 6158, 42023 Saint-

´

Etienne CEDEX 2, France

3

Clermont University, IFMA, Campus des C

´

ezeaux, CS20265, F63175, Aubi

`

ere, France

Keywords:

Supply Chain, Supplier Selection, Flexibility, Adaptation, Genetic Algorithm, Dynamic Optimization.

Abstract:

Supply chains are complicated dynamical systems due to many factors, e.g. the competition between compa-

nies, the globalization, demand fluctuations, sales forecasting. Hence, they must react to changes in order to

adapt quickly its network. In this paper we focus on a two echelon supply chain problem dealing with supplier

selection issue during periods in a highly flexible context. How to select suppliers is the main question we try

to answer in this research. A suggested approach based on dynamic optimization is highlighted to solve this

problem.

1 INTRODUCTION

Dynamic considerations have led researchers to find

suitable models for the supply chain system. Var-

ious factors characterize the changing environment

e.g. arrival of new tasks, suppliers unable to meet

demand increases, delivery breakdowns, customer de-

mand forecasts. For these reasons supply chains must

adapt their networks to cope with these new situations

over time. Notions such as Flexibility and adaptation

have emerged in the literature to deal with changes

that may affect the supply chain. In this context,

Flexibility presents a primordial key to cope with

perturbations that may affect structures of networks.

Thus, supply chains must have ability to synchronize

their networks during the changes. Adaptability is

expressed to deal with problems that may affect the

supply chain. (Lee, 2004) describes adaptability as

the ability to adjust the supply chain’s design to meet

structural shifts in markets and modify the supply net-

work to reflect changes in strategies, technologies and

products.

Supplier selection problem is one of numerous

problems dealing with the structure of the supply

chain. Supplier’s capacity, lead time and various cost

parameters are subject to change over time. Hence

the optimal set of supplier can change from a period

to another. In the literature this kind of problems is

known as Dynamic Supplier Selection Problem. A

great number of conceptual and empirical works have

been published dealing with this problem. However,

this selection must be part of a dynamic approach that

will help to implement the appropriate network. In-

deed, how to adapt supply chain is extremely difficult

to determine in a dynamic market that is constantly

moving and where prices fluctuate over time.

Recently dynamic optimization have been used to

cope with issues that operate in a similar environment

in many sectors. To our knowledge, researches based

on dynamic optimization have been rarely used in a

supply chain context.

This paper seeks to contribute to the configuration

of a two echelon supply chain based on a supplier

selection issue in a flexible context by proposing an

approach based on dynamic optimization that will al-

lows to find the suitable set of suppliers in response to

changes to cope with variations in costs in a changing

environment depending on market developments and

sensitivity.

The rest of this paper is structured as follows. Sec-

tion 2 reviews the existent literature on adaptable and

reconfigurable supply chain issues putting a focus on

supplier selection works. Section 3 describes the main

features of the problem considered. Main contribu-

322

Chibani A., Delorme X., Dolgui A. and Pierreval H..

Dealing with Variations for a Supplier Selection Problem in a Flexible Supply Chain - A Dynamic Optimization Approach.

DOI: 10.5220/0004924603220327

In Proceedings of the 3rd International Conference on Operations Research and Enterprise Systems (ICORES-2014), pages 322-327

ISBN: 978-989-758-017-8

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

tions of the dynamic optimization approach are dis-

cussed in section 4. We conclude the paper by sum-

marizing the most important features of the method

adopted and recommend research directions.

2 RELATED RESEARCH

Several papers have focused on the structure of the

supply chain treating numerous problems. Issues such

as the selection of suppliers and inventory manage-

ment (Kristianto et al., 2012) were addressed to meet

the needs of reconfiguration in the supply chain. (Oh

et al., 2011) highlight a method of reconfiguring the

supply network of an enterprise to cope with flexi-

ble strategies, to illustrate the influence in a dynamic

global market environment on the structure of the sup-

ply chain. They treat in their paper two types of strate-

gies, flexible procurement and flexible manufacturing

in order to evaluate the supply network flexibility in

terms of numerical comparison based on an indica-

tor called ”suitability of the reconfiguration of supply

network”. In their article, (Osman and Demirli, 2010)

propose a bilinear goal programming model solved

by a modified Benders decomposition algorithm for

supply chain reconfiguration and supplier selection in

response to the increased demand and customer sat-

isfaction requirements regarding delivery dates and

amounts. Other researchers have adopted a multi-

agent technology to facilitate the flexibility to handle

reconfiguration issues (Ryu and Jung, 2003).

Among these different works dealing with the

change in the supply chain structure, the supplier se-

lection problem appear like one of the most common

issue in term of change in the network. In the lit-

erature this problem is modeled in two ways: quan-

titative models and qualitative models. In order to

select the best supplier, tangible and intangible cri-

teria are highlighted through papers. (Ghodsypour

and O’Brien, 1998) present a decision support sys-

tem using an integrated analytic hierarchy process

(AHP) and linear programming. (Nazari-Shirkouhi

et al., 2013) presented a Supplier selection and or-

der allocation problem using a two-phase fuzzy multi-

objective linear programming. (Wu et al., 2009) used

an integrated multi-objective decision-making pro-

cess for supplier selection with bundling problem.

Analytic network process (ANP) and mixed integer

programming (MIP) are provided to optimize the se-

lection of supplier. (Deng et al., 2014) solved a sup-

plier selection problem using (AHP) methodology ex-

tended by effective and feasible representation of un-

certain information denoted D-numbers. A (D-AHP)

method is proposed for the supplier selection prob-

lem, which extends the classical analytic hierarchy

process method. (Ding et al., 2005) used an optimiza-

tion via simulation approach using genetic algorithm

for supplier selection issue. Discrete-event simula-

tion is used for performance evaluation of a supplier

portfolio and the genetic algorithm is proposed for op-

timum portfolio identification based on performance

index estimated by the simulation.

Following the adequate set of suppliers for all pe-

riods of supply due to variation of information (e.g.

to quantity shipped at each period, lead time, costs.)

seems interesting. Indeed, suppliers for one period

may not be the best ones for another period. To our

knowledge only one paper focuses on multi period for

supplier selection problem. (Ware et al., 2014) de-

veloped a mixed-integer non linear program to cope

with dynamic supplier selection problem during pe-

riods. This paper is based on a static optimization

and it doesn’t cope with the dynamic market of sup-

ply chain. They do not take into account, for example,

variation of parameters during a period.

As a result, providing a dynamic approach in or-

der to cope with the dynamic aspect of this issue over

time seems interesting. In this paper we propose such

a dynamic approach dealing with cost variation dur-

ing period based on dynamic optimization in order to

select the right set of suppliers after each change.

3 PROBLEM FORMULATION

For sake of clarity we decide in this paper to rely on

a simple problem of a two-echelon supply chain. We

assume that there are two major types of actors: a sin-

gle customer who wants to be delivered a quantity of

one type of product by a set of suppliers. The pro-

duction capacity of all suppliers allows the delivery

of products to the customer.

The notation used of the problem are presented as

follows:

• ∆ : Set of sub-period. δ ∈ ∆ : {1,2,....nδ}

• S : Set of suppliers. s ∈ S : {1,2,....ns}

• k

δ

s

: Maximal capacity of a supplier s at sub-period

δ

• D : Demand of product for a customer

• Cu

δ

s

: Unit cost of one product at supplier s at sub-

period δ

• Ca

δ

s

: Assignment cost for a supplier s at sub-

period δ

The customer can order a quantity of products to a

number of suppliers for a supply in the beginning of

DealingwithVariationsforaSupplierSelectionProbleminaFlexibleSupplyChain-ADynamicOptimizationApproach

323

a period. However, throughout this period, changes

may occur. Unit cost and assignment cost of suppliers

are subject to change over time. Hence, the command

issued at the beginning of a period does not neces-

sarily cope with the most appropriate network to de-

liver the quantity that meets customer requirements.

All decisions times related to suppliers selection will

result in increased costs for the period. However, as-

signment cost at suppliers s become higher, approach-

ing the end of the period.

Each sub-period correspond to the refresh time

of parameters of our problem. The changing nature

of information means that it is possible to adapt the

supply chain after the initial configuration. In other

words, adaptation in this case is trigged to meets the

customer’s request by a set of suppliers with the least

cost.

In this context, decision variables are expressed as

follow:

• V

δ

s

: Supplier assignment at sub-period δ

• Q

δ

s

: Quantity of product shipped from supplier s

at sub-period δ

The formulation (1-5) presents the case where data

is known in advance. Nevertheless, it can be applied

to the case of a single sub-period.

Min Z =

∑

s∈S

∑

δ∈∆

[Cu

δ

s

.Q

δ

s

+Ca

δ

s

.V

δ

s

] (1)

Subject to,

∑

s∈S

Q

δ

s

= D ∀δ ∈ ∆ (2)

Q

δ

s

≤ k

δ

s

.V

δ

s

∀s ∈ S ∀δ ∈ ∆ (3)

V

δ

s

∈ {0,1} ∀s ∈ S ∀δ ∈ ∆ (4)

Q

δ

s

∈ N ∀s ∈ S ∀δ ∈ ∆ (5)

This formulation involves minimizing the total cost

corresponding to unit cost of product at supplier s for

entire sub-period and assignment cost for each sup-

plier for the same period. Eq.2 ensures the satisfac-

tion of the demand at each sub-period. Eq.3 denotes

the capacity restriction for each supplier.

We can prove that this problem is NP-hard con-

sidering a special case of this problem where Cu

s

= 0

and ∆ = {1}. In this case, the problem can reduce

to the formulation (6-8) which corresponds to a knap-

sack problem with a change of variables X

s

= 1 −V

s

.

Min Z =

∑

s∈S

Ca

s

.V

s

(6)

subject to,

∑

s∈S

k

s

.V

s

≥ D (7)

V

s

∈ {0,1} (8)

This formulation correspond to an integer linear

program and thus we could try to solve it with a

solver. However, giver the dynamic nature of data and

taking into account the short time available to solve

this NP-hard problem between the acquisition of the

new costs and the decision of change, an approximate

solution seems to be useful for solving this problem.

4 SUGGESTED APPROACH

4.1 A Dynamic Approach

In the recent years, dynamic optimization has been

successfully used in many areas. Results have demon-

strated the greater ability of this method to deal with

problems subject to various disturbances.

Several definitions related to dynamic optimiza-

tion are proposed in the literature. Among the most

cited, a general definition is given by (Cruz et al.,

2010). According to them, Dynamic optimization

problem is a problem where the objective function or

the restrictions change over time and where the oc-

currence of changes are unknown. The goal of the

issues dealing with dynamic optimization problems is

no longer to locate a stationary optimal solution, but

to track its movement through the solution and time

space as closely as possible (Lepagnot et al., 2010).

Generally there is not much time between two

subsequent decisions time, restarting optimization at

every changes is often undesirable. However, tracking

optima is not enough. Decision taken now affects di-

rectly the future. The lack of visibility known by the

term of ”myopia” does not allows to predict the be-

havior of the models to the end of a given period. In

other words, since the dynamic changes are unknown

beforehand the problem has to be solved over time.

Inventory management and dynamic vehicles

routing problem represent the two most studied in

industry. A dynamic variant of the VRP is that the

rides of different vehicles from a central repository

are represented by cycles whose correspond to cus-

tomers. The dynamic nature of this problem is that

customers can be added or removed unexpectedly

(Pillac et al., 2013). Inventory management problems

are also treated in a dynamic context. Decision re-

lated to this case faces the problem of which quantity

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

324

of products to command to maximize profit and when

we decide to ship this quantity (Bosman, 2007).

Evolutionary Algorithms have been widely used

to solve dynamic optimization. Given the continuous

nature on data in real world, the moving peaks bench-

mark are proposed like test problems to compare the

performance of these evolutionary algorithms. In

our problem sub-periods allow optimization over time

based on a small sequence of period when changes

can occur. Hence, the optimum position may changes

over time, the idea is to follow it in order to decide

how to change the set of suppliers during sub-periods.

The literature review of (Nguyen et al., 2012)

listed approaches dealing with changes in several is-

sues :

• Detecting changes

• Introducing diversity when changes occur

• Maintaining diversity during the search

• Memory approaches

• Prediction approaches

• Self-adaptive methods

• Multi-population approaches

Our algorithm is based on approaches dealing

with memory, introducing and maintaining diversity

and self-adaptive methods. The principle is to use

a population that is constantly conducting research

to explore space research and ensure the diversifica-

tion of solutions. The best optima found are stored in

memory, in order to accelerate the convergence of the

algorithm and follow the optimum whenever a change

appears in the objective function.

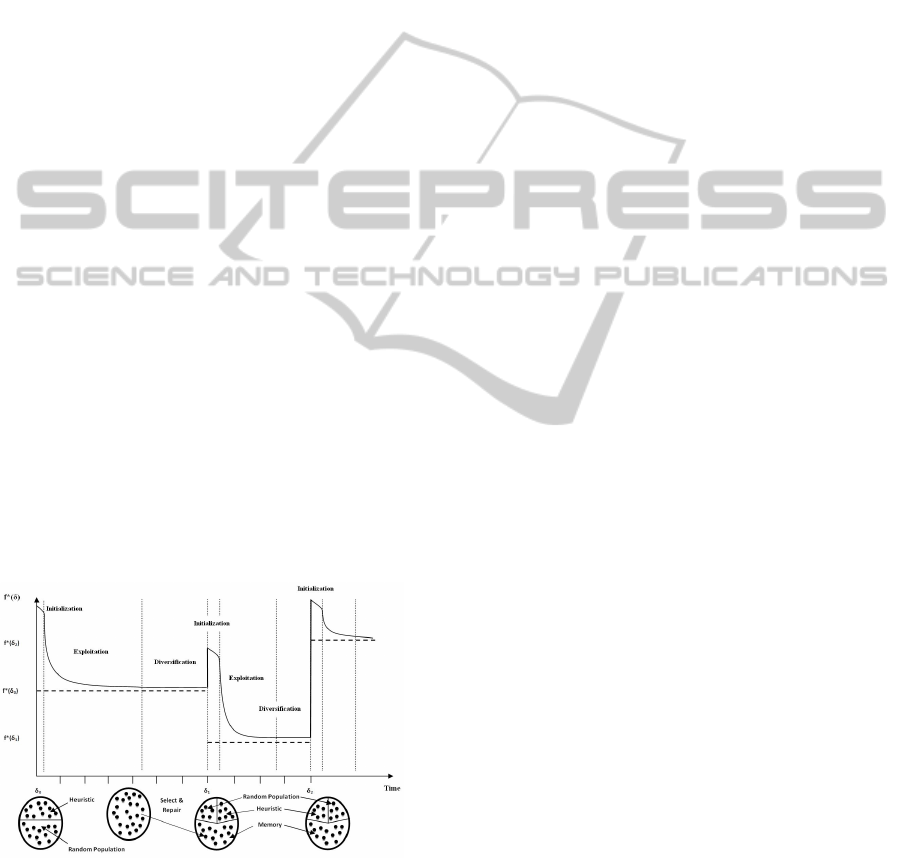

Figure 1: Algorithm behavior during time.

Three main phases are illustrated in Figure 1: Ini-

tialization, exploitation and diversification.

At δ = 0 population is initialized based on two

parts. A first part initialized randomly and the second

is determined using the following heuristic.

G

j

denotes the quantity of the gene j for each in-

dividual. k

j

denotes the capacity of a supplier. D rep-

resents the total demand of the customer. Solutions

are given based on this algorithm.

∀ j ∈ 1...J

R

j

← 0 (9)

P ← D (10)

While (P >

∑

j

R

j

)

j∗ ← argmin

j|G

j

=0

{Cu

j

} (11)

G

j∗

← 1 (12)

R

j∗

← k

j∗

− G

j∗

(13)

P ← P − 1 (14)

End while

While (P > 0)

j∗ ← argmin

j|G

j

>0

{Ca

j

} (15)

Q ← min{R

j∗

,P} (16)

G

j∗

← G

j∗

+ Q (17)

R

j∗

← k

j∗

− G

j∗

(18)

P ← P − Q (19)

End while

An exploitation phase comes after highlighting the

operations of the genetic algorithm. However dur-

ing the sub-period, at some points the convergence

should be nearly finished and an exploration phase is

launched. The purpose of this step is to diversify the

population when it approaches the optimum in order

to use it in the next update of data. In other terms,

in the next optimization. Taking into account these

operations, at δ = 1 initial population is composed of

three parts. A first part which represent the best in-

dividuals from the previous sub period. The second

part represents the solutions derived from the heuris-

tic. And finally, the third part is generated randomly.

This mechanism is true for any time of change during

all the periods of supply.

4.2 A Genetic Algorithm

”Genetic algorithms are search methods based on

principles of natural selection and genetics”. They en-

code the decision variables of a search problem into

”finite-length strings of alphabets of certain cardinal-

ity”. The strings which are candidate solutions to the

search problem are chromosomes, the alphabets are

genes and the values of genes are alleles. (Goldberg,

1989).

Representation Scheme. We started with a pop-

ulation composed of random solution chromosomes

and then evolves via iterations generations. For our

DealingwithVariationsforaSupplierSelectionProbleminaFlexibleSupplyChain-ADynamicOptimizationApproach

325

optimization problem formulated in the last section,

each solution is represented by a chromosome P

i

. G

genes are considered for each chromosome, where ns

is the number of suppliers and it contains the quantity

Q

s

which represent the quantity delivered by a sup-

plier s.

Initialization. The initialization is important in

the performance of any Genetic Algorithm. An

heuristic is used here but usually doesn’t permit to

generate the whole initial population. A random al-

gorithm is thus used to fulfill the population. Each

quantity is assigned randomly in an interval which

meet suppliers capacity without exceeding the total

demand of the customer for each chromosome created

satisfying constraints 2 and 3. Since the optimiza-

tion problem is with non-negative solutions, all genes

are constrained to non-negative integers in the genetic

algorithm, satisfying constraint 5 as a result. When

the population is formed, all chromosomes should be

evaluated by computing their fitness value one at a

time. The evaluation fitness is the same as the opti-

mization model defined in function 1

Selection. The selection of the valuable chromo-

somes that will survive and be passed to the next gen-

eration is extremely important. In our genetic algo-

rithm, fitness proportionate selection is employed. In

this method each individual in the population is as-

signed a roulette wheel slot sized in proportion to its

fitness. We begin by evaluating the fitness f

i

of each

individual in the population. After we calculate the

probability p

i

corresponding to slot size.

Genetic Operations. The genetic operators used

in the proposed genetic algorithm are crossover and

mutation. Generally, among candidates selected for

crossover, we choose chromosomes with probability

p

c

. For our case, we use a simple crossover operation

in which a random crossover point k is determined,

and a second part of the two selected individuals are

exchanged. We use two chromosomes for an adapt-

able crossover to cope with demand constraint. Let’s

denote P1 and P2 the individuals selected for this op-

eration in order to have two offspring E1 and E2. To

fill the genes without exceeding the demand in E1 and

E2, the following formula are used:

∀ j ∈ 1....k

E

1 j

= P

1 j

E

2 j

= P

2 j

(20)

∀ j ∈ k + 1....ns

E

1 j

=

(

h

∑

ns

k+1

P

1 j

∑

ns

k+1

P

2 j

× P

2 j

i

:

∑

ns

k+1

P

2 j

6= 0

∑

ns

k+1

P

2 j

/ns − k : otherwise

(21)

E

2 j

=

(

h

∑

ns

k+1

P

2 j

∑

ns

k+1

P

1 j

× P

1 j

i

:

∑

ns

k+1

P

1 j

6= 0

∑

ns

k+1

P

1 j

/ns − k : otherwise

(22)

Note: Brackets are used for the Rounding of cer-

tain value after the calculation of the quantity for

crossover.

To illustrate the example, we use two chromo-

somes composed from 5 genes corresponding to the

quantities of 5 suppliers. The sum of these quantities

is equal to 50, in our case, referring to the demand D

of the customer. See Figure 2

E

13

= [

P

13

+ P

14

+ P

15

P

23

+ P

24

+ P

25

× P

23

] = 20 (23)

Figure 2: Example of crossover operator.

For the mutation, a transfer of a quantity between

two genes selected randomly is assumed. In addition,

the transmitter gene is randomly selected to provide

the quantity to the other one. Figure 3.

Due to the capacity of suppliers. Individuals are sub-

ject to not deal with the total demand of the customer

after crossover and mutation. For this reason, we have

to repair each solution to cope with the demand con-

straint. In our case, the reparation of our individuals

is inspired from the method that we have defined in

section 4.1 dealing with the proposed heuristic. In-

deed, instructions 9 and 10 are subject to be replaced.

We begin by calculating the residual quantity r

j

which

is equal to the difference between the supplier capac-

ity k

j

and the quantity G

j

(Formula 24). The aim is

to compare the sum of the residual quantity r

j

and P

which present the quantity we dispose for reallocation

(Formula 25). While this quantity exceeds the sum

of r

j

we should choose other suppliers to dispatch

the quantity without exceeding the capacity of the se-

lected supplier. This selection is based on the quan-

tity of product available at the supplier which should

equal to 0 and the cheapest one of them according to

the assignment cost Cu

j

and so on (Formula 11).

∀ j ∈ 1...J R

j

=

k

j

− G

j

: G

j

> 0

0 : otherwise

(24)

P =

∑

j|R

j

<0

− R

j

(25)

∀ j|R

j

< 0 R

j

← 0 (26)

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

326

Figure 3: Example of mutation operator.

5 CONCLUSIONS

In this position paper, we rely on a two echelon sup-

ply chain problem dealing with a supplier selection

issue in order to resolve it based on an Evolutionary

Algorithm adapted to dynamic optimization. Our aim

is to find a response for how to change the set of sup-

pliers during time. Based on the optimum behavior

after each change, we proceed to select suppliers for

each sub-period. Given the dynamic parameters of the

problem and its complexity, the choice of a solver for

the resolution may be inadequate for medium to large

size problems. Hence, the choice to search for an

approximate solution seems appropriate in this case.

For further studies, we are planning to extend and im-

plement the problem to make in consideration more

operations on supply chain related to forecasts of or-

ders, inventories and adding other actors (distributors,

retailers, etc.). An algorithm-based memory that de-

tects changes and keeps the best individuals over time

can converge quickly to the best solution as it was

demonstrated in many Benchmarks. In addition other

approach adapted for dynamic optimization problem,

like anticipation, need to be developed if we want to

take into account further operations in a global supply

chain.

ACKNOWLEDGEMENTS

This research is supported by the European com-

munity related to the region of Auvergne in France,

through the project LABEX IMOBS3. These sup-

ports are gratefully acknowledged.

REFERENCES

Bosman, L. P. (2007). Learning and anticipation in on line

dynamic optimization. Studies in computational intel-

ligence, 51:129–152.

Cruz, C., Gonz

´

alez, J. R., and Pelta, D. a. (2010). Optimiza-

tion in dynamic environments: a survey on problems,

methods and measures. Soft Computing, 15(7):1427–

1448.

Deng, X., Hu, Y., Deng, Y., and Mahadevan, S. (2014).

Supplier selection using AHP methodology extended

by D numbers. Expert Systems with Applications,

41(1):156–167.

Ding, H., Benyoucef, L., and Xie, X. (2005). A simulation

optimization methodology for supplier selection prob-

lem. International Journal of Computer Integrated

Manufacturing, 18(2-3):210–224.

Ghodsypour, S. and O’Brien, C. (1998). A decision sup-

port system for supplier selection using an integrated

analytic hierarchy process and linear programming.

International Journal of Production Economics, 56-

57:199–212.

Goldberg, D. (1989). Genetic Algorithm In Search, Op-

timization And Machine Learning. Addison-Wesley,

Reading, MA.

Kristianto, Y., Gunasekaran, A., Helo, P., and Sandhu, M.

(2012). A decision support system for integrating

manufacturing and product design into the reconfigu-

ration of the supply chain networks. Decision Support

Systems, 52(4):790–801.

Lee, H. L. (2004). The triple-A supply chain. Harvard

business review, 82(10):102–12, 157.

Lepagnot, J., Nakib, A., Oulhadj, H., and Siarry, P. (2010).

A new multiagent algorithm for dynamic continuous

optimization. International Journal of Applied Meta-

heuristic Computing, 1(1):16–38.

Nazari-Shirkouhi, S., Shakouri, H., Javadi, B., and Kera-

mati, A. (2013). Supplier selection and order alloca-

tion problem using a two-phase fuzzy multi-objective

linear programming. Applied Mathematical Mod-

elling, 37(22):9308–9323.

Nguyen, T. T., Yang, S., and Branke, J. (2012). Evolution-

ary dynamic optimization: A survey of the state of the

art. Swarm and Evolutionary Computation, 6:1–24.

Oh, S., Ryu, K., and Jung, M. (2011). Reconfiguration

framework of a supply network based on flexibility

strategies. Computers & Industrial Engineering.

Osman, H. and Demirli, K. (2010). A bilinear goal pro-

gramming model and a modified Benders decompo-

sition algorithm for supply chain reconfiguration and

supplier selection. International Journal of Produc-

tion Economics, 124(1):97–105.

Pillac, V., Gendreau, M., Gu

´

eret, C., and Medaglia, A. L.

(2013). A review of dynamic vehicle routing prob-

lems. European Journal of Operational Research,

225(1):1–11.

Ryu, K. and Jung, M. (2003). Agent-based fractal archi-

tecture and modelling for developing distributed man-

ufacturing systems. International Journal of Produc-

tion Research, 41(17):4233–4255.

Ware, N. R., Singh, S., and Banwet, D. (2014). A mixed-

integer non-linear program to model dynamic supplier

selection problem. Expert Systems with Applications,

41(2):671–678.

Wu, W.-Y., Sukoco, B. M., Li, C.-Y., and Chen,

S. H. (2009). An integrated multi-objective

decision-making process for supplier selection with

bundling problem. Expert Systems with Applications,

36(2):2327–2337.

DealingwithVariationsforaSupplierSelectionProbleminaFlexibleSupplyChain-ADynamicOptimizationApproach

327