Sensor Monitoring in an Industrial Network

Experimental Tests for Computer Supported Education

Bruna Salles Moreira, Jaidilson Jó da Silva, Angelo Perkusich and José Sérgio da Rocha Neto

Department of Electrical Engineering, Federal University of Campina Grande, Aprigio Veloso Street,

Campina Grande, Paraiba, Brazil

Keywords: Sensor Monitoring, Industrial Network, Computer Supported Education.

Abstract: The integration of field level and higher communication is expanding and ensuring ideal conditions for open

networks in process automation at industry. For a better knowledge on the referred networks, some

experiments were developed to ensure a better comprehension on how they work and application

possibilities. The experimental tests with industrial network using a PLC (Programmable Logic Controller)

based computer education, allows the electrical engineering students perform experiments on-line by a

remote laboratory for the study of industrial automation process.

1 INTRODUCTION

Nowadays with the development of information

technology, communication between devices and the

use of standardized mechanisms, open and

transparent have become key concepts in automation

technology, especially in today's industrial

environment. The integration of field level and

higher communication is expanding and ensuring

ideal conditions for open networks in process

automation at industry, as it happens with the

combination of AS-Interface and PROFIBUS

(PROFIBUS Association, 2006).

For a better knowledge on the referred networks,

some experiments were developed to ensure a better

comprehension on how they work and application

possibilities. For the experiments, were analyzed the

behavior of sensor networks with AS-I, the devices

were linked by the PROFIBUS network and

controlled by the PLC S7-300 from Siemens. The

whole system was configured by the STEP7

software from Siemens as well. A teaching

supervisory platform was implemented in the

software LabVIEW, and it provided students an

online system monitoring.

2 INDUSTRIAL NETWORKS

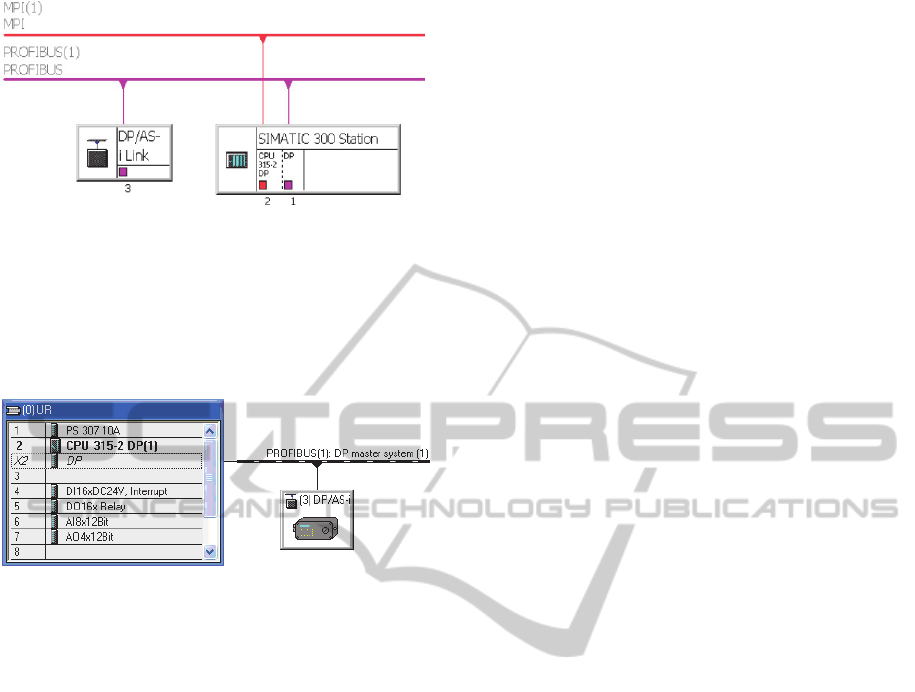

In Figure 1 is presented the system in study,

illustrating the devices and networks linking them.

For a better comprehension of the networks, their

operation is explained in this section.

Figure 1: Simple diagram scheme of the system in study.

2.1 Profibus

PROFIBUS, an acronym for Process Field Bus, is an

open industrial communication network, used

mainly to make the connection of digital controllers

with sensors/actuators (the field level to cell level)

for both high-speed data transmission and special

communication services. By being an open pattern,

its independence of the manufacturer and of

specification is guaranteed by norms EN50170 and

EN50254. Therefore, devices from different

manufacturers can communicate without any

adjustment in their respective interfaces. Figure 2

374

Salles Moreira B., Jó da Silva J., Perkusich A. and da Rocha Neto J..

Sensor Monitoring in an Industrial Network - Experimental Tests for Computer Supported Education.

DOI: 10.5220/0004930303740379

In Proceedings of the 6th International Conference on Computer Supported Education (CSEDU-2014), pages 374-379

ISBN: 978-989-758-020-8

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

presents a diagram with the PROFIBUS application

areas, emphasizing the communication profile, the

application used and the standard cycle time for each

level.

Figure 2: Diagram showing application areas of

PROFIBUS.

The PROFIBUS-DP (Decentralized Periphery) is

an optimized variation with high-speed connection

and low cost. Suitable for the factory floor, where

there is a large volume of information and the

necessity of high speed communication to events is

quickly treated (PROFIBUS Association, 2006). It

uses a transmission technology RS-485 or optic

fiber, making transmissions at rates from 9.6 kbit/s

to 12 Mbit/s.

2.2 AS-I

AS-I, an acronym for Actuator Sensor Interface, is a

standardized network system (EN 50295) for

industrial communication and open to the lowest

level of automation and came to meet certain

requirements defined from the experience of

members founders and to supply the market which

hierarchical level is the bit-oriented (Siemens,

2010). The AS-I was designed to complement the

others systems and make it easier and faster

connections between sensors and actuators with their

respective controllers (Siemens, 2008).

The AS-I is a master-slave type network with

cyclic data capture. It has a master device, capable

of controlling the entire network, reading by cycle

all other integrated devices to it, called slaves. The

AS-I master performs various tasks such as network

boot, identification and diagnosis of the slaves and

transferred data analysis (Lian, 2003). Also, usually

communicates with a controller (PLC or PC) to

receive control configuration of AS-I, report errors,

to address new slaves, among other tasks (Becker,

2002).

Slaves are passive devices, so they may have

access to the network when the master makes a

request and data transfer from slave to slave is only

possible through the master. Slaves can be

connected to four sensors or actuators, which have

their values read/written cyclically by the master.

There are intelligent sensors that have an AS-I chip

integrated, allowing direct coupling to the cable.

There are also slaves who work with analog values,

but these need four cycles of the network so that a

read/write is complete (Siemens, 2008).

For proper exchange of information between the

master and slave, the slaves receive a unique address

that will identify them (Lian, 2003).

2.3 DP/AS-I Link

The DP/AS-I Link creates an interface between AS-I

and PROFIBUS-DP networks. It operates as a

common DP slave and as the master of AS-I

network. Like others DP slaves, requires a DP

master. It has its principle of operation similar to any

other gateway device, where the protocols of the

systems in question are converted (Siemens, 2000).

The DP/AS-I Link is used to perform the exchange

of the sensors and actuators of AS-I network to the

PROFIBUS-DP network (Siemens, 1995). At the

system analyzed on the experiment, it is used the

DP/AS-I Link from Siemens and its image is

visualized in Figure 3.

Figure 3: Image of the DP/AS-I Link from Siemens.

3 EXPERIMENTAL PLATAFORM

The devices connected by the system networks are

presented in this section. Their data acquisition

procedure is explained as well as their functionality

in the experimental platform.

3.1 PLC S7-300

The Programmable Logic Controller (PLC) S7-300

is a modular system used in centralized or

distributed applications. Its modular nature allows a

SensorMonitoringinanIndustrialNetwork-ExperimentalTestsforComputerSupportedEducation

375

quick and easy expansion, with the possibility of

adding 32 modules of various types, divided into I/O

modules, communication modules and function

modules.

A control system based on a S7-300 is basically

composed by the expansion modules, power supply

and CPU. The CPU is accessed by a Multi Point

Interface (MPI) port, which does the whole setup

and configuration. In addition, some CPUs have a

second communication interface, as PROFIBUS-DP

or serial point-to-point (Siemens, 1998).

3.2 Sensors and Modules

The sensors that were used in the experiment were

inductive and photoelectric.

The photoelectric sensor has a transmitter circuit

responsible for the emission of a light beam and an

infrared receiver circuit responsible for receiving the

beam. Light can be reflected or interrupted by an

object, detecting it and triggering the sensor.

At the system analyzed, it is used one of VF AS-

I OS1K-VF-AS-I series, from Sense, that can be

seen in Figure 4.

Figure 4: Image of the photoelectric sensor VF AS-I from

Sense.

The inductive proximity sensor is an electronic

device that detects the approach of metal parts. The

electromagnetic field generated by a high-frequency

resonant coil installed on the sensing face, suffers

interference when a metal part approaches, and the

signal variation is compared to a standard signal,

enabling the output stage.

Two inductive sensors were used, a Pentakon

PS15 + UI + AS-I series from Sense, illustrated in

Figure 5, and a Bero 3RG4613-3WS00 series from

Siemens illustrated in Figure 6.

Two modules make part of the system, an AS-I

connector module with four outputs, identified by

M12 4AR 3RG9001-0AB00, and an AS-I connector

module with two inputs and two outputs, identified

by M12 2E/2AR 3RG9001-0AC00.

Figure 5: Image of the inductive sensor Pentakon PS15 +

UI + AS-I VF AS-I from Sense.

Figure 6: Image of the inductive sensor Bero 3RG4613-

3WS00 series from Siemens.

4 EXPERIMENTAL RESULTS

By the use of the growing and useful computational

tools to increase the method of learning, students are

experiencing a better integration with the real

platforms. In the developed experiment, some

procedures had been done to reach the desired

results for analysis and a successful comprehension.

The steps taken and the results are presented in this

section.

4.1 Experiments

For a better comprehension of the devices and

networks presented, experiments were made with

some theory explanation and a step guide in order to

monitor the sensors attached to the network and to

analyze the Ladder language program configured in

the PLC by the STEP 7 software, which is

developed by Siemens.

Using the resources of STEP 7 software, it was

possible to see how the network was configured as

well as the devices, sensors and modules were

configured and addressed on the network.

A network scheme with the addressed elements

linked to MPI and PROFIBUS, could be seen on the

NetPro as it appears in the Figure 7.

CSEDU2014-6thInternationalConferenceonComputerSupportedEducation

376

Figure 7: Representation of connections on NetPro.

On HW Config, a list of the hardware

components could be seen with their configuration at

the station and the respective input (I) and output

(Q) address. The image of the hardware address

organization can be seen in Figure 8.

Figure 8: Representation of hardware list on HW Config.

The monitoring is used to identify the condition

of the variables when the device changes of state,

and these states help to understand the logic of

control elaborated in the Ladder code. The

configured code in the PLC is seen in

LAD/STL/FBD Program blocks, where the online

monitoring is also possible, and allows the user to

know which inputs and outputs are activated when

the sensors and modules work, as well as the blocks

data.

The Ladder is a simple programming language

based on blocks. The inputs and outputs of the

sensors are referenced as they are configured. The

code is divided in networks to simplify the

understanding. This implementation eliminates the

necessity of adding new electronic devices to the

hardware.

After the configuration of the system in the

STEP 7, a human/machine interface was

implemented by the software of National

Instruments: LabVIEW, so that it simulates an

industrial environment via the sensors connected to a

hybrid industrial network, originated from the ASI

and PROFIBUS-DP’s networks and using the PLC,

with STEP 7 software.

OPC (OLE for process control) is a standard

interface between numerous data sources and

sensors on a factory floor to HMI/SCADA

applications, application tools, and databases. The

OPC Foundation defines the standards that allow

any client to access any OPC-compatible device.

The OPC Specification was based on the OLE,

COM, and DCOM technologies developed by

Microsoft for the Microsoft Windows operating

system family. The specification defined a standard

set of objects, interfaces and methods for use in

process control and manufacturing automation

applications to facilitate interoperability (Halvorsen,

2012).

In virtue of a network using the OPC server, the

LabVIEW communicates with the PLC. In order to

connect the LabVIEW with the OPC tags, it’s

created an I/O Server, which automatically updates

the LabVIEW with the tag’s values in a specific rate.

It’s required to create shared variables that are

similar to OPC tags and obtain native access in the

LabVIEW to PLC data.

LabVIEW is a platform and development

environment for a visual programming language

from National Instruments. The graphical language

is named "G". The execution is determined by the

structure of a graphical block diagram on which the

programmer connects different function-nodes by

drawing wires. These wires propagate variables and

any node can execute as soon as all its input data

become available. LabVIEW programs/subroutines

are called virtual instruments (VIs). Each VI has

three components: a block diagram, a front panel,

and a connector panel (Halvorsen, 2012).

LabVIEW Remote Panels turns the application

into a remote laboratory, where the created HMI

with the purpose of manage and evaluate the

industrial plant is fully accessible by the remote

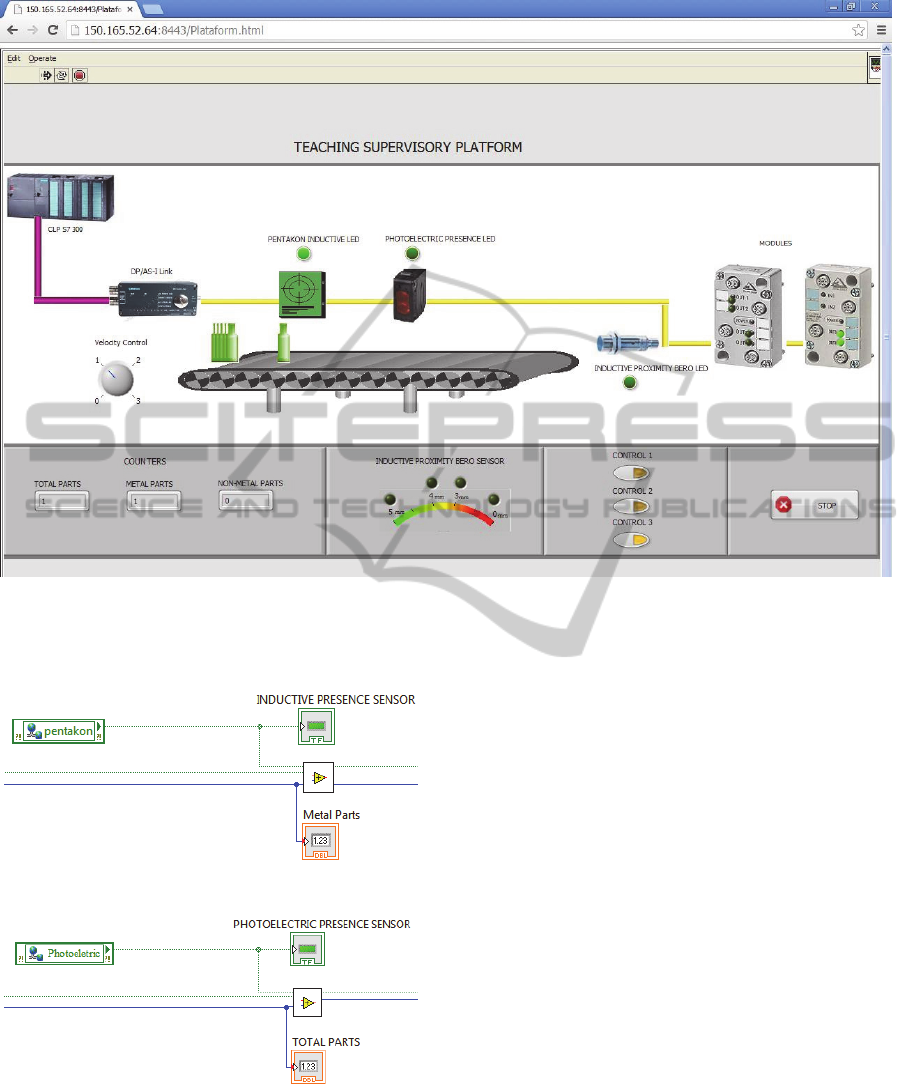

user. The interface designed with LabVIEW and

used in a web browser is presented in Figure 9.

4.1.1 Pentakon Inductive Sensor Monitoring

To check the variable values in Pentakon inductive

sensor, a piece of metal was passed in front of it and

the LED associated with this sensor is activate and

metal parts counter is incremented in the interface

implemented in LabVIEW. The code in language G

can be seen in Figure 10.

4.1.2 Photoelectric Sensor Monitoring

With the photoelectric sensor, any object could be

used to test its operation, passing it front and

ensuring no interference from others. On the HMI

built in LabVIEW, the LED associated with this

sensor is activated and total parts counter is incre-

SensorMonitoringinanIndustrialNetwork-ExperimentalTestsforComputerSupportedEducation

377

Figure 9: Online monitoring interface.

mented. Figure 11 illustrates it as implemented in

the program.

Figure 10: Code of the increment of metal parts counter.

Figure 11: Code used for the increment of the total parts

counter.

4.1.3 Bero Inductive Sensor Monitoring

The operation of the inductive Bero sensor could be

seen approaching a metal part gradually. According

to the proximity of which a metal object is the

sensor will generate combinations of bits "1" and "0"

which will enable different outputs of the PLC

according to the object proximity.

The inductive Bero sensor is the end of the

conveyor belt and is monitored by the LED panel

located at the bottom center of the VI, indicating the

proximity of a metallic object of this sensor,

progressively completing the lights of LEDs as the

object approaches going Green (5mm) through to

yellow (4mm) and orange (3mm), to red when the

contact part with the sensor occurs.

4.1.4 Remote Laboratory

A remote laboratory is defined as a computer-

controlled laboratory that can be accessed and

controlled externally over some communication

medium (National, 2006). In this paper, a remote

laboratory is an experiment, demonstration, or

process running locally on a LabVIEW platform but

with the ability to be monitored and controlled over

the Internet from within a Web browser using the

interface in Figure 9.

The acquisition is still occurring on the host

computer however the remote user has the total

control. Other users can report their Web browser to

CSEDU2014-6thInternationalConferenceonComputerSupportedEducation

378

the same URL to monitor the application in progress

but only one client can control the application at a

time. At any time during this process, the operator of

the host machine can assume control of the

application back from the client currently in control

functionality.

5 CONCLUSIONS

In this paper are presented the advisability of using

technology tools for auxiliary the process of distance

learning, for example, a hypertext which simulates

(emulates) a virtual laboratory for realization of on-

line experiments.

The discussed experiments attempted to report to

the students the concepts involved in this paper

using the computer as a main tool for performing

and analyzing experiments.

The innovative use of technology applied to

education, and more specifically, the distance

education, must be supported by a philosophy of

learning which provides the students the opportunity

to interact, to develop joint projects, to recognize

and respect different cultures and to build

knowledge.

By the use of the LabVIEW software, students

could follow the progress of sensor’s activity as well

as the network communication process. The code

used the processed data to build control logic to

perform varied tasks and analysis. This showed how

suitable is the system with different applications and

approached the student to the real industrial

automation process.

Also, the flexibility of iteration between students

and teacher provided by technology tools establishes

a new dynamic of teaching. The students can better

organize your questions and subjects under study

and they have the initiative to find their answers.

ACKNOWLEDGEMENTS

The authors would like to thank the CNPq for

financial support and everyone from the LIEC

(Electronic Instrumentation and Control Laboratory-

UFCG) who supported the development of this

work.

REFERENCES

Becker, R.; Müller, B.; Schiff, A.; Schinke, T.; and

Walker, H., 2002. AS-Interface - The Automation

Solution. AS-International Association, Germany.

Halvorsen, P. H. 2012. OPC and Real-Time Systems in

LabVIEW.

Lian, S.C.P. 2003. AS-i Master Bus Controller. Thesis

submitted to the School of Information Technology

and Electrical Engineering, The University of

Queensland, June.

National Instruments, 2006. “Distance-Learning Remote

Laboratories using LabVIEW”; available from <

http://www.ni.com/white-paper/3301/en/> accessed

December, 2013.

PROFIBUS Association, 2006. Profibus – Technical

Desciption.

Siemens, 1995. Distributed I/O System DP/AS-I Link.

Manual. 3

rd

edition.

Siemens, 1998. Manual. S7-300 Programmable Controller

Hardware and Installation. 2

nd

edition.

Siemens, 2000. Manual. SIMATIC NET PROFIBUS

Networks.

Siemens, 2008. System Manual. AS-Interface/AS-Isafe.

Siemens, 2010. Reference Manual. AS-Interface - IO Link

- Profibus. Industrial Controls.

SensorMonitoringinanIndustrialNetwork-ExperimentalTestsforComputerSupportedEducation

379