Proposal of Electronic Tag for Monitoring Environmental Conditions

During Product Transportation

Mikhaylov Dmitry, Smirnov Alexander, Khabibullin Timur, Froimson Mikhail, Zuykov Alexander,

Sychov Nikolay, Grigorenko Andrey and Tolstaya Anastasia

Youth Engineering Centre of the National Research Nuclear University “MEPhI”, Kashirskoye shosse 31,

Moscow, Russian Federation

Keywords: Environmental Conditions Monitoring, Temperature Registration, Tag.

Abstract: The present invention is directed to an electronic tag for monitoring transportation of goods over long

periods of time. It provides monitoring of all data regarding environmental conditions (for example, if an

item should not be stored at more than some critical temperature, but had remained the entire time at just

below the critical temperature, this also might be of interest). The tag reading device can communicate with

the tag via a wired or wireless interface to transmit the data about conditions violations and display this

information on its screen or forward it further to a PC or to a local area network. The paper provides the

information about choice of the required for the system electronic components, tag, tag reading device,

system software, monitoring methods, additional options, and system testing. The tag temperature

registration accuracy is ± 0.5

0

C.

1 INTRODUCTION

Delivery logistics is one of the most risky periods of

many products’ lifetime. A lot of products or

components have serious restrictions on the

environmental conditions, e.g., on temperature

(drugs, food), humidity (electronic components),

vibration (electronic devices, fragile objects), etc.

For example, period of validity of medicinal agent

depends on physical, chemical and biological

processes therein. These processes are greatly

influenced by humidity, light intensity, pH, and

temperature. (Kazakova O., 2010; Register of

medicines of Russia radar RLS+, 2004) As such, the

problem of monitoring conditions during product

transportation and delivery exists.

Some conventional solutions exist, such as

placing drugs in special cases with almost constant

temperature, placing electronic components in

vacuum packets, etc., but a mechanism for

monitoring the transportation conditions is still of

great need.

There are a number of such mechanisms –

temperature sensors in the containers for

transporting medications, humidity papers that

change color when humidity restrictions are

violated, etc. (Temperature recorder DS1921L-F51,

et., 2014; Disposable temperature indicators

WarmMark, 2013; Temperature recorders (loggers),

2012). Several papers have been devoted to this

issue – they may be considered as analogs of the

proposed monitoring device called BBT (Wang

Jiahan, 2011; Chen-Ming, 2012; Meng Xian-Yao,

2009; Wang Keliang, 2010; Chenxia Yun, 2009).

However, all of the conventional solutions have a

number of limitations.

For example, container temperature monitoring

systems do not guarantee that the temperature

restrictions are not violated when the medications

are taken out of the container and placed in a

warehouse. Humidity monitors cannot give any

information about the time and duration of violation

of storage and transportation conditions. Finally, in

some cases they have low memory.

Another important sphere is transportation and

storage of unstable chemical substances such as

hydrogen in a liquid form. ( Saturation Properties for

Hydrogen – Pressure Increments)

Accordingly, there is a need in the art for a more

reliable and robust system and method for

monitoring environmental conditions during

transportation of goods.

239

Dmitry M., Alexander S., Timur K., Mikhail F., Alexander Z., Nikolay S., Andrey G. and Anastasia T..

Proposal of Electronic Tag for Monitoring Environmental Conditions During Product Transportation.

DOI: 10.5220/0004987002390247

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 239-247

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

2 SYSTEM FOR MONITORING

ENVIRONMENTAL

CONDITIONS

The invention addresses the need for monitoring

environmental condition during the transporting of

goods.

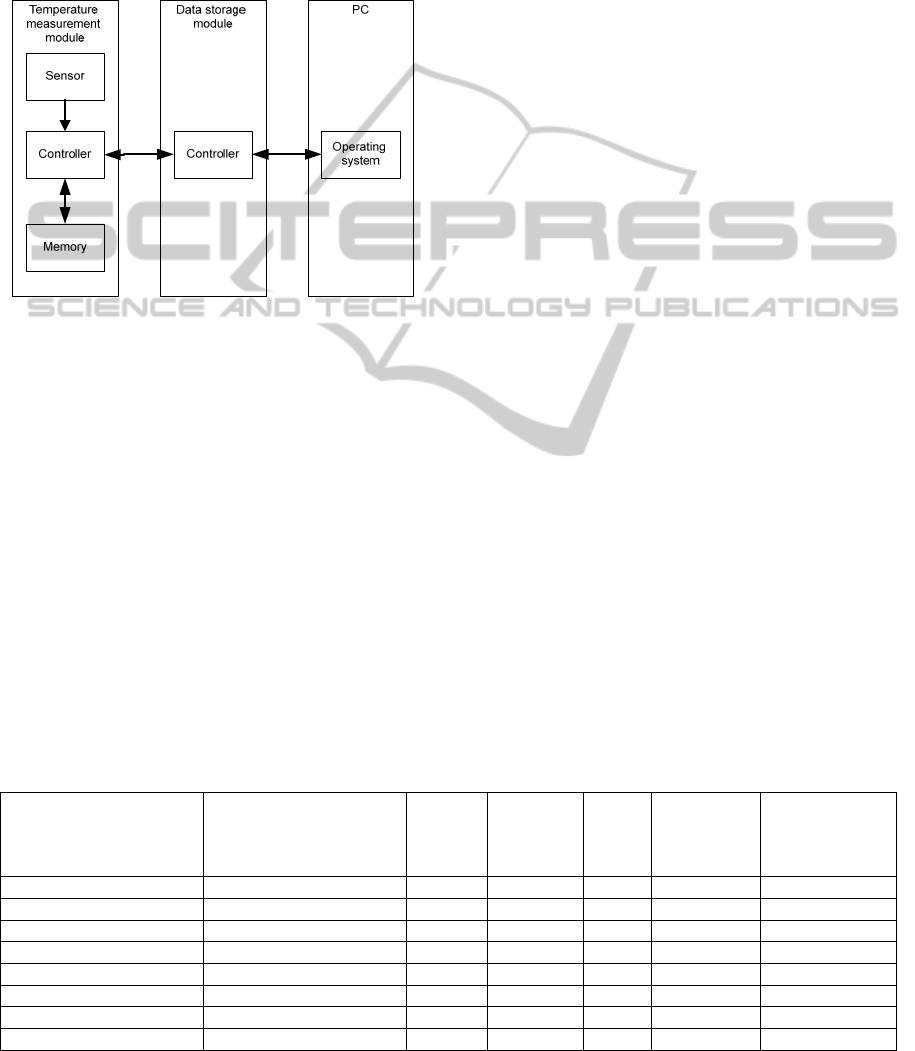

Figure 1: General system scheme.

The solution includes a thin electronic tag with

autonomous power, and a tag reading device as well

as special software for a personal computer (PC)

(Fig. 1).

2.1 Choice of the Required Electronic

Components

2.1.1 Microcontrollers

Consider the basic specifications (see Table 1) of

controllers that can be used for a proposed system.

The chip is selected according to these specifications

and the presence of temperature sensor in

microcontroller.

According to Table 1 microcontrollers

STM32F100C4T6B and MSP430F2101IPW28 for

data collection module and temperature monitoring

module respectively. The main parameters

influencing the choice were amount of memory,

processor speed and power consumption.

2.1.2 Non-volatile Memory

EEPROM (Electrically Erasable Programmable

Read-Only Memory) 24aa128

(24AA128/24LC128/24FC128, 2004) is a tag non-

volatile memory for temperature data storage.

EEPROM 24aa128 allows the following temperature

ranges: industrial: -40°C to +85°C; automotive: -

40°C to +125°C. In comparison with Flash

EEPROM 24aa128 has longest storage time, lower

power consumption in sleeping mode and while

recording, more rewriting cycles.

2.2 Tag

The tag should be slim enough to be inserted into a

product’s box or a container before sealing. The

BBT tag monitors the environmental conditions with

particular sensors (for example, temperature sensor,

humidity sensor, pressure sensor, accelerometers,

some combination of these, etc.) and logs all

detected violations of the monitored conditions with

timestamps into its non-volatile memory.

Alternatively, all data regarding environmental

conditions during the transportation and delivery can

be monitored. For example, if the item should not be

at more than some critical temperature, but had

remained the entire time at just below the critical

temperature, this also might be of interest.

The system operates in the following way (by the

example of temperature registration). The

monitoring tag records temperature inside the

monitored volumes in the range of minus 20°C to

Table 1: Basic specifications of microcontrollers (LPC1111FHN33, 2014; STM32F100x4, 2012; ATtiny13A, 2012;

ATmega48/V, 2011; MSP430F2101IPW, 2004; PIC16F676, 2014; PIC12F509, 2009; PIC10F200, 2013).

Microcontroller Core

Price

(RUB)

Flash-

memory

(kb)

RAM

(kb)

Processor

speed

(MIPS)

Energy

consumption in

optimal mode

(mА)

LPC1111FHN33 ARM 32-bit Cortex M0 100 8 2 40 8

STM32F100C4T6B ARM 32-bit Cortex-M3 78 16 4 30 8

AtTiny13A Atmel 8bit 70 1 0.064 20 11

atmega48 Atmel 8bit 80 4 0.5 20 11

MSP430F2101IPW28 TI 16bit MSP430 70 8 0.5 16 3

PIC16F676 PIC16 8bit 60 2 0.22 5 0.4

PIC12F509 PIC12 8bit 60 2 0.041 5 0.4

PIC10F200T PIC10 8bit 40 0.25 0.016 1 0.2

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

240

50°C with pre-mechanical (LED) alarm temperature

points 0°C, 2°C, 8°C, 10°C, 15°C, 25°C, and

documentation of the entry in the non-volatile

memory. Quantitative values of temperature

registered in the calendar view and in real time form

in temperature-time schedules are sent to a personal

computer using a special USB-device. The software

should allow recounting total affecting temperature

into heat calories.

The tag provides the following operation modes:

sleep mode – thermo-sensor is not active,

there is no registration and the tag is ready to

receive commands to turn on;

operating mode – thermo-sensor is active, the

tag powered by the starting device is working

in the recording mode. Registered data are

stored in non-volatile memory in encrypted

state and until reading the information is

stored in an inaccessible area of the memory;

LEDs triggering on 0°C, 2°C without counting

temperature calories.

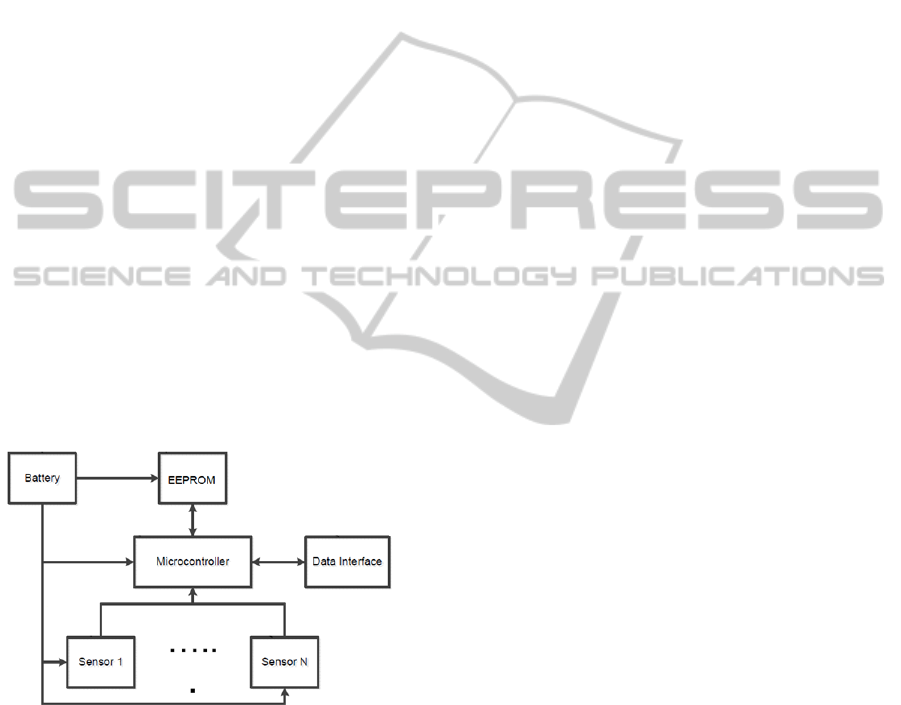

The tag includes the following components

shown in Figure 2.

A battery is a “tablet” battery of any radius (or

custom manufactured to an arbitrary shape). The

type of battery is chosen by the expected drain of the

device and its lifetime. If a wireless channel is used,

and the tag is expected to function about 2-3 years, a

lithium element battery is applied.

Figure 2: A schematic diagram of the tag.

If only a wired interface is used and the tag

lifetime is about half a year, a less expensive NiCd

battery can be implemented. Alternatively, a super-

capacitor also can be applied. Typical battery

parameters are 1.6-3.3 V, 50 mA maximum output

current, 150 mAh. The battery parameters can be

sacrificed, for example, if a smaller tag is needed

(and other reduced parameters are acceptable, such

as fewer measurements per unit time).

Non-volatile memory is used to store a tag log of

the monitored conditions (temperature, humidity,

etc). The log typically contains:

tag serial number;

tag-related data (i.e., a tag activation time, tag

manufacturing date, etc.).

The log data entries can be, for example:

TIMESTAMP1 – SENSOR1 MEASURE1 –

SENSOR2 MEASURE1 … – SENSOR N

MEASURE1

TIMESTAMP2 – SENSOR1 MEASURE2 –

SENSOR2 MEASURE2 … – SENSOR N

MEASURE2

A microcontroller (MCU) is used to:

acquire data from the sensors;

store the data into non-volatile memory;

acquire data from non-volatile memory;

send data via data interface.

The non-volatile memory can be embedded into

the microcontroller.

Sensors can be an integrated circuit or other kind

of device, with digital or analog output that converts

any physical parameter (temperature, humidity,

pressure, etc.) into voltage (analog) or code (digital).

This can be a thermocouple (a temperature sensor

based on the Seebeck effect (Encyclopedia of

Physics, 1998)), a humidity sensor (capacitive,

resistive or any other type), a pH sensor of any kind

(based on potentiometer, ion-sensitive field-effect

transistor, or on any other principle), an

accelerometer and a gyroscope (such micro-

electromechanical systems, capacitive

accelerometers, etc.), etc.

The sensors measure the value with the required

accuracy and should stay alive under any possible

conditions during the transportation. The sensors can

be embedded into the microcontroller.

A data interface is a communication channel

between the tag and the devices around it. The data

interface can be either wired or wireless.

A wireless data interface allows for

communicating with the tag during the entire period

of delivery, sending commands, reprogramming the

tag, reading data, etc. It is very helpful for different

logistic operations. The whole shipment might be

thrown away, if the tag data shows that the required

environmental conditions had been seriously

violated.

The main disadvantage is that it consumes a lot

of battery power and it significantly increases the

cost of the device. A wired interface, on the other

hand, does not allow communicating with the tag

when it is “in the box.” It can only be activated,

placed with the goods, and checked to see what was

going on with the shipment when it is unpacked. The

advantage is that it is less expensive.

ProposalofElectronicTagforMonitoringEnvironmentalConditionsDuringProductTransportation

241

Both interfaces could be implemented inside the

processor (there are processors with the wireless

communication features) or by using an external

interface controller. The wireless interface can use

either an open or proprietary protocol. The wired

interface can be custom made, I2C, SPI, SD,

iButton, etc.

Consider the temperature monitoring module

(Figure 3).

Figure 3: Temperature monitoring module.

The system is likely to be the least expensive one

(less than 1$ per unit in 1000-pieces shipment), the

lowest active drain (hundreds of mA in active

mode), the lowest frequency (in most cases, 32 kHz

as the main clock is sufficient), the lowest pin-count

(if an external non-volatile memory is not used and

the communication interface is wired, it can even be

an 8-pin integrated circuit).

2.3 Tag Reading Device

The tag reading device can communicate with the

tag via a wired or wireless interface to transmit the

data about conditions violations and display this

information on its screen or forward it further to a

PC or to a local area network (LAN).

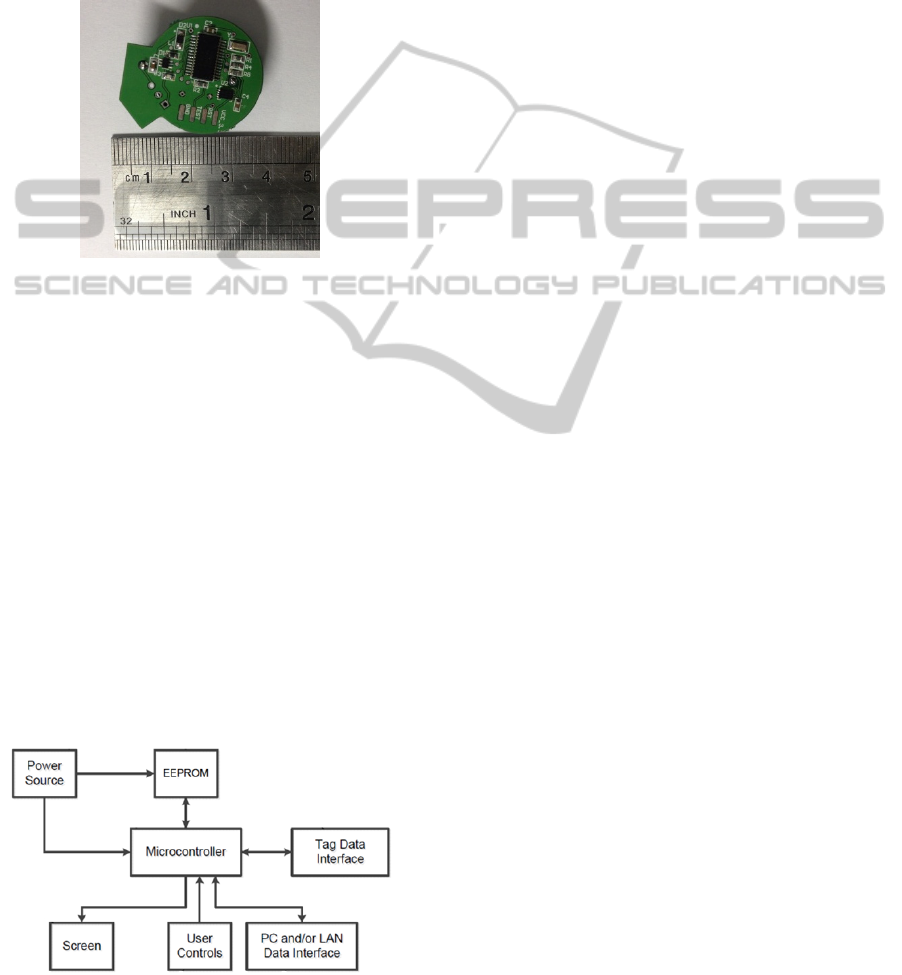

The reader includes the following components

shown in Figure 4.

Figure 4: A schematic diagram of the reader.

A power source is a standard battery form-factor

(AA, AAA, one or more), can be a re-chargeable

battery, can be an accumulator cell (replaceable or

not). The power source can be a super-capacitor.

The battery can be charged via AC/DC (alternating

current/direct current) adapter, DC/DC adapter, USB

connection or wirelessly, by vibration or through by

heat (thermocouple).

The non-volatile memory is used to store data

from tags, so its capacity is at least:

N * TagRAMCapacity,

where N is the number of tags the reader obtains

data from.

The non-volatile memory can have its file

system, based on commonly used (FAT, NTFS,

etc.), or based on proprietary standards.

The microcontroller acquires data from tags via a

tag data interface and stores it in the non-volatile

memory. The microcontroller monitors user controls

and performs certain actions (read tags, calibrate

time, etc.). The microcontroller obtains data from

the memory and sends the data via PC/LAN

interface.

The tag data interface is an interface compatible

with the tag's data interface. A screen is used to

output information to the user. The screen can be

very small (1 or 2 inches diagonal) to minimize the

reader's overall size or the screen can be rather large

(about 10 inches in diagonal) to maximize usability.

The screen can be combined with a touch panel

based on any technology (resistive, capacitive,

infrared, SAW, etc.) that plays a part of user

controls. The screen can also have some display

connection (HDMI, DVI, VGA, DisplayPort, etc.) to

the external display.

User controls are any buttons, touch screen

menus or triggers. The buttons can have pre-defined

functions (i.e., read tag, clear non-volatile memory,

set tag’s clock, etc.), or the buttons can be used to

navigate through the device's menu (Up, Down,

Forward, Back).

PC and/or LAN interface is used to translate data

from non-volatile memory to computer or computer

network. The interface can be wired or wireless. For

example, USB, Ethernet, Wi-Fi, Bluetooth, etc. can

be used. In addition, the memory can be embedded

into the microcontroller.

Consider the reading device (Figure 5).

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

242

Figure 5: Reading device.

2.4 Monitoring Methods

If the tag measures data periodically, the tag only

needs to store the activation time. If the tag logs only

the times of violation of the allowed conditions, the

timestamps are used.

The amount of non-volatile memory is

determined by a predicted number of measurements

taken during the tag’s lifetime and the size of the

measurements. For example, if a temperature is

monitored (about 12 bits per measurement is

needed) and the measurement is taken once a

minute, then a one-year-long log will take up about

780 Kbytes of memory.

If only violations (for example if temperature is

higher than 10

0

C or lower than – 5

0

C) are stored,

then the additional 6 bytes of timestamps for each

measure are used resulting in a total of 60 bits per

measure. However, the conditions are expected to be

within normal range during most of the

transportation time. Thus, much less data is actually

stored in the memory.

A rough guideline is that if conditions are logged

every minute or so, then about 1 Mb per one sensor

installed on the tag per one year of its lifetime is

needed. Another concept of logging environmental

conditions that significantly reduces the amount of

used memory is not to log the measure every minute,

but to store the “overall violation” data instead.

For example, a parameter should stay at or below

A1, but it was violated and the value was A2 at one

of the measures and then, returned to normal on the

next measure. The measure is periodic and the time

between two measures is D. Therefore, in the worst

case, the duration of violation was about 2*D. The

overall violation can be estimated as:

(A2 – A1) * 2 * D

– the violation value multiplied by the duration

of the violation. Such estimate can be used to decide

if the product can still be used, but it will not store

the information of when a particular violation had

occurred.

The two of the above methods can be combined.

For example, the tag can know every time that it is

passed from one company in the delivery chain to

another via a wireless interface, so it can log data as

follows:

OVERALL VIOLATION ON DELIVERY

STAGE 1 (an ID can be used to determine which

company had delivered the goods at specific stage,

this ID can be transferred when the next

transportation stage begins)

OVERALL VIOLATION ON DELIVERY

STAGE 2

…

OVERALL VIOLATION ON DELIVERY

STAGE N.

This technique can significantly reduce the

amount of memory used compared with every-

minute-logging, but still lets the final recipient of the

cargo or the insurance company know the specific

stage of delivery when the conditions were violated.

2.5 Software

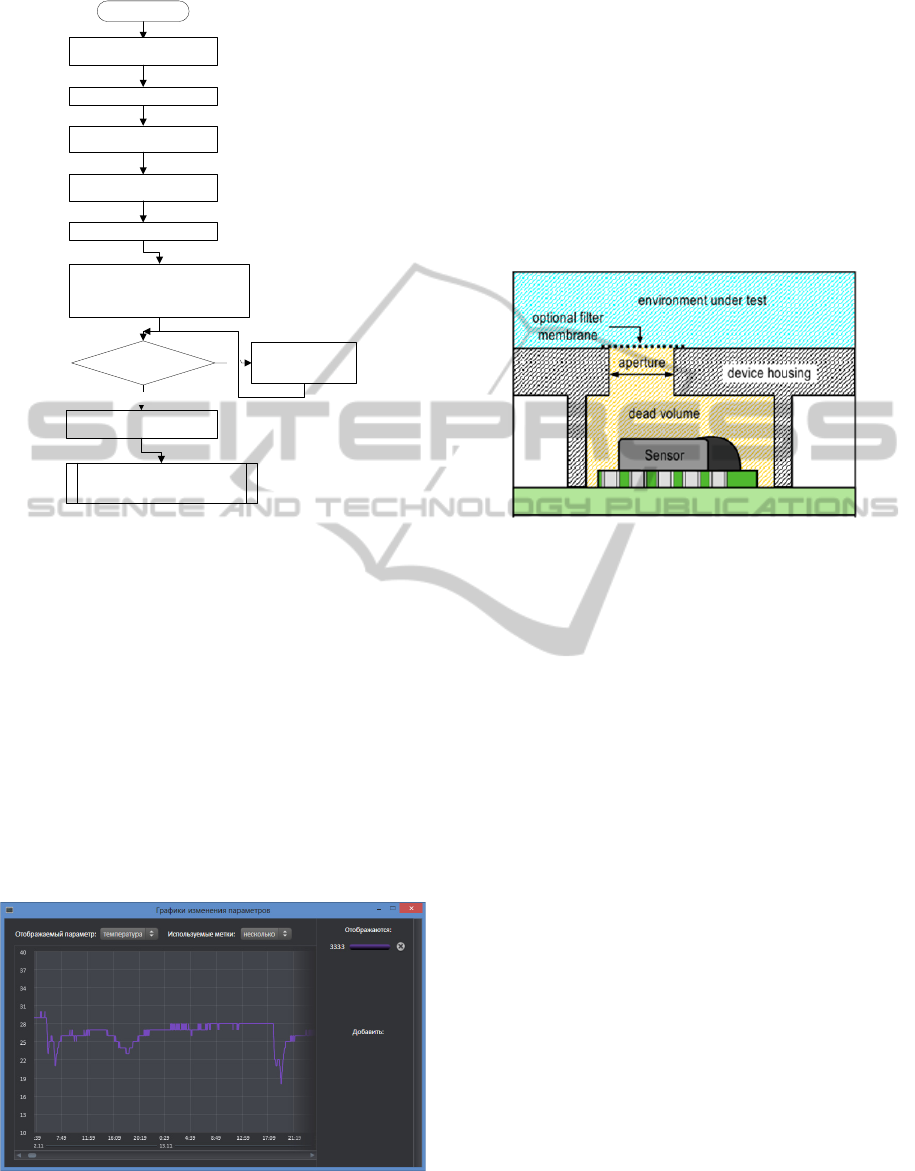

As a part of the proposed temperature monitoring

system the special software has been developed. The

algorithm of data acquisition module`s software

performance is shown in Figure 6 and the algorithm

of temperature monitoring module`s software is

presented in Figure 7.

Figure 6: Algorithm of main cycle of data collecting

module`s software.

ProposalofElectronicTagforMonitoringEnvironmentalConditionsDuringProductTransportation

243

Start

System of controller

clock setting

I2C bus initiation

Analog-to-digital

converter initiation

Data acquisition

interface initiation

Timer initiation

Reading of current state of the

temperature monitoring

module from EEPROM

Module

is initiated and

active?

Transition to a

low power mode

No

Controller clock setting

from RTC

Yes

Processing of commands

from data collecting module

Figure 7: Algorithm of temperature monitoring module`s.

2.6 Testing

2.6.1 Sensors

The performance of the system with one temperature

sensor was tested using a logic analyzer LeCroy

Logic Studio 16 (LogicStudio™ 16 Channel Logic

Analyzer, 2010). The tag was subjected to changing

temperatures, obtaining the data. After they were

read by the reader and transmitted to the PC, the data

was analyzed by the software.

Obtained by the temperature monitoring module

data can be analyzed in graphical interface of PC

software as it is shown in Figure 8.

Figure 8: Temperature curve.

The testing of the tag accuracy was carried out

using a sealed chamber with zero thermal gradient.

The pre-calibrated tag was placed inside the

chamber in which the temperature was changed

every five minutes. The tag accuracy is ± 0.5

0

C.

The linearity of the sensors allow after assembly

to make a temperature measurement and store in the

tag`s memory the difference between the measured

temperature and the temperature obtained from the

reference sensor.

To increase the sensor accuracy it is proposed to

make the tag`s body in a way, shown in Figure 9.

Figure 9: Proposed tag`s body (SHT21, 2011).

The testing of the humidity monitoring is now

underway that is why the testing results are not

presented in this paper.

2.6.2 Battery

For battery testing the battery with capacity I = 225

mA/h was taken. The aim was to check its life-time

depending on the reference frequency (frequency of

requests to tag). The results are shown in Table 2.

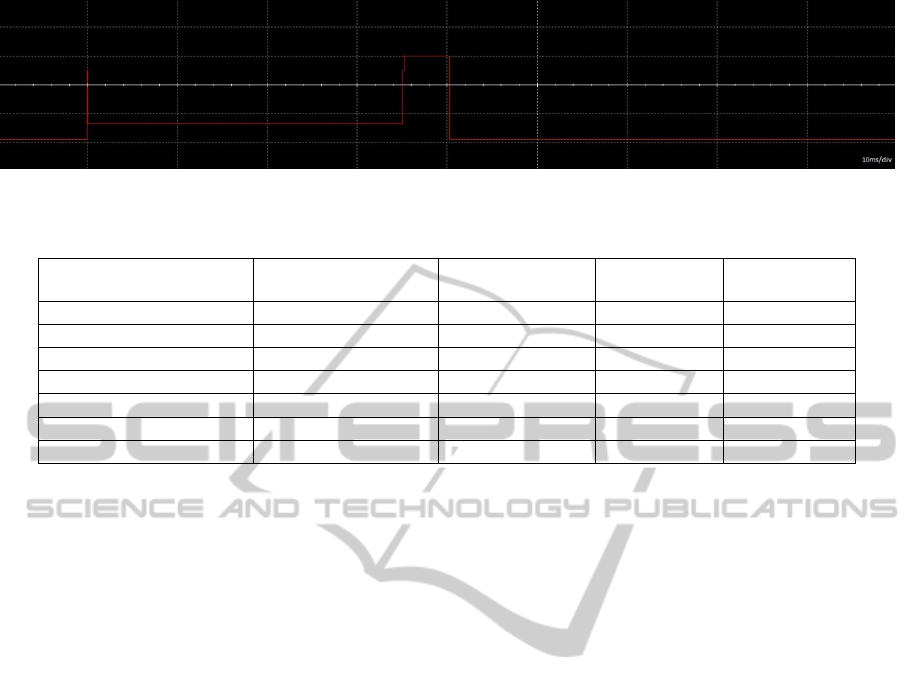

Battery consumption diagram is shown in Figure 10.

2.7 Additional Options

As an option, an integration value of the violation

condition over time can be stored.

In general, the tag can be used multiple times. A

mechanism for charging tag’s battery, erasing tag’s

non-volatile memory and calibrating tag’s clock is

provided. Memory damp can be performed as a

command received via the data interface. Battery

replacement can be performed if the tag’s body has

an appropriate battery slot.

Battery recharging can be performed, if the tag

has a charging socket on it and a battery controller

integrated circuit on the tag (this function can also

be performed by the processor). The tag can also be

recharged wirelessly using the alternating magnetic

fields. Thus, the tag can be hermetically sealed.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

244

Figure 10: Battery power consumption diagram.

Table 2: Battery testing parameters and life-time.

T

(reference frequency) I (mА/h) Operation time (s)

Operation

time (h)

Operation time

(days)

0.001 34.4500000000000 23512.34 6.53 0.27

0.01 3.5350000000000 229137.20 63.65 2.65

0.1 0.4435000000000 1826381.06 507.33 21.14

1 0.1343500000000 6029028.66 1674.73 69.78

10 0.1034350000000 7831004.98 2175.28 90.64

100 0.1003435000000 8072271.75 2242.30 93.43

1000 0.1000343500000 8097218.61 2249.23 93.72

The tag’s body is manufactured from plastic or

polymer. The microcircuit that records the

temperature changes is contacting the tag`s body by

means of dielectric layer placed between the

microcircuit and tag`s body providing maximum

accuracy of temperature changes.

Tag’s clock calibration is performed via the tag’s

data interface. If required the data in the tag can be

encrypted by either symmetric or asymmetric

encryption scheme.

In order to increase battery life (particularly in

case of the wireless connection), the tag can be

programmed to turn on (and start recording and

listening for wireless commands) after a certain

period of time, as opposed to immediately after

being manufactured. Alternatively, the tag can turn

on when it detects a specific event (e.g., using a

magnetic switch/sensor).

The tag itself can be a system, distributed in

space. For example, sensors can be located in

different parts of the cargo container and the

electronic components can be located in one place,

connected (wired or wirelessly) to the sensors,

decreasing the overall cost of the system.

Electronic components with memory can be

located in a container lock, thus giving an

opportunity to log not only the environmental

conditions, but also the physical access to the

container. Low-power wireless solutions such as

Bluetooth 4.0 can significantly increase the usability

of the system. The tag data records can be accessed

not only from a specialized reader, but also from a

smart-phone, a tablet PCs, etc. This simplifies the

cargo check procedures and eliminates the need of

using specialized reader – all functionality of the

reader can be implemented in a smart-phone/tablet

PC application.

Tags can have one sticky surface covered by a

non-sticky film to prevent it from being covered

with dirt or dust, so the tag can be easily attached to

any surface. The tags (housing) can be made of a

semi-flexible printed circuit board (PCB) to be fixed

on non-flat surfaces. The tag itself can be made

flexible, e.g., using flexible mounting surfaces, such

as mylar, as housing, to make it suitable for

complex-shaped shipping and mail envelopes.

After the cargo is delivered to the warehouse, the

tags can be used in sorting and accounting processes

using additional shipment data stored in the tag’s

memory. Inserting a beeper inside the tag can help in

finding the items inside the non-automated

warehouses.

Figure 11 illustrates a tag life time flow chart.

The tag is manufactured, activated and placed inside

package (goods). The tag can be activated wirelessly

(using tag wireless interface) after it has been placed

inside the package. During transporting of the

package the tag data can be read via the tag wireless

interface. After transportation the tag is extracted

from the package and the tag data is read by the tag

reader. If needed, the data can be compressed for

storage and/or transmittal.

The tag can be implemented as a PCB module

that can be mounted (using soldering or sockets)

with other PCBs. Also, tag readers can be

implemented as stationary modules on checkpoints

ProposalofElectronicTagforMonitoringEnvironmentalConditionsDuringProductTransportation

245

of logistics to perform control automatically.

Figure 11: A life cycle of the tag.

Furthermore, the tags can have two power

sources – a direct current power source, such as a

battery, and one or more inductive coils to be

powered wirelessly, which is useful for reading data

from tags with exhausted batteries.

The tags can be synchronized with other

machines, such as robots or warehouse machinery,

via a wired or a wireless interface or through the

reader, via wired or wireless interface, to perform

goods rejection automatically. Also, the tags and/or

readers can use wired or wireless interfaces to

upload data to the Internet and to a remote server to

perform online state checks.

3 CONCLUSIONS

The tag monitors the environmental conditions with

particular sensors and logs all detected violations of

the monitored conditions with timestamps into its

memory. The tag reading device can communicate

with the tag via a wired or wireless interface to

transmit the data about conditions violations and

display this information on its screen or forward it

for storage.

As competing systems for monitoring

environmental parameters during transportation

HygroBouton (Proges-Plus company, 2014) and

Hygrochron (TERMOCHRON Elin – Russia (Elin,

2014)). Table 3 presents main specifications of the

above monitoring systems.

Table 3: Comparison of systems for monitoring

environmental conditions during transportation.

HygroBouton Hygrochron BBT

Temperature

range

-20/+85°C -20º/+85ºC -40/+86ºC

accuracy ± 0.5°C ± 1°С ± 0.5°C

Humidity

range

0-100 % 0-100 % 0-100 %

accuracy ± 5% ±1% ± 0.5%

Vibration

monitoring

- - Not limited

accuracy - - 2mg

Reader Needed Needed Not needed

The study is underway to improve the accuracy of

registered temperature and developing conditions for

providing monitoring of humidity, “lab on a chip”

chemical analysis and vibration. Moreover, humidity

monitoring accuracy and performance is being

tested.

In order to reduce the energy consumption and

increase the life-time of the tag the study will also

focus on development of the software for data

compression as well as its processing before

transmitting the data array to the PC.

REFERENCES

Kazakova O., 2010. Storage temperature of medicinal

agents. Extract. Moscow pharmacy №8 (197).

Register of medicines of Russia radar RLS+, 2004.

Doctor. Yearbook 2004 \ 7. LLC-2004 RLS. 960 pages

– 1 electron. wholesale. Disc (CD-ROM).

Temperature recorder DS1921L-F51, DS1921L-F52,

DS1921H-F5, DS1921Z-Fб, 2014. Rainbow

Electronics, official web-site. URL:

http://www.rtcs.ru/news_detail.asp?id=106.

Disposable temperature indicators WarmMark, 2013.

Intex, official web-site. URL: http://warmmark.ru.

Temperature recorders (loggers) (-40 ... +85) °C,

Comparative table of specifications, 2012. Engineer

technologies, official web-site. URL: http://

gigrotermon.ru/?find_cat=12.

Wang Jiahan, Qin Jianwang, 2011. Design and

development of intelligent terminal of special cargo

monitoring system. International Conference on

Transportation, Mechanical, and Electrical

Engineering (TMEE). Pages: 485 – 488.

Chen-Ming, Chin-Chung Nien, Jia-Liang Liao, Yu-Chee

Tseng, 2012. Development of wireless sensor module

and network for temperature monitoring in cold chain

logistics. IEEE International Conference on Wireless

Information Technology and Systems (ICWITS).

Meng Xian-yao, Meng Song, Han Xin-jie, 2009.

Optimization on Handling and Temperature Control

System of Product/Chemicals Carrier. International

Conference on Measuring Technology and

Mechatronics Automation. ICMTMA '09. (Volume:

2). Pages: 865 – 868.

Wang Keliang, Zhao Li, Liang Shoucheng, Sun Lijing,

2010. The parameters optimization of Lowered

Temperature and Gathering-Transportation technology

in Putaohua Oilfield. Asia-Pacific Power and Energy

Engineering Conference (APPEEC). Pages: 1 – 3.

Chenxia Yun, Shouyuan Chen, He Wang, Chini, M.,

Zenghu Chang, 2009. Temperature feedback control

for long-term carrier-envelope phase locking.

Conference on Lasers & Electro Optics & The Pacific

Rim Conference on Lasers and Electro-Optics.

CLEO/PACIFIC RIM '09. Pages: 1 – 2.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

246

Saturation Properties for Hydrogen – Pressure Increments.

National Institute of Standards and Technology. NIST

Standard Reference Data. URL: http://webbook.

nist.gov/cgi/fluid.cgi?Action=Load&ID=C1333740&

Type=SatT&Digits=5&PLow=.5&PHigh=1.5&PInc=.

1&RefState=DEF&TUnit=K&PUnit=atm&DUnit=kg/

m3&HUnit=kJ/mol&WUnit=m/s&VisUnit=uPa*s&S

TUnit=N/m.

LPC1111FHN33, 2014. NXP Semiconductors, official

web-site. URL: http://www.ru.nxp.com/products/

microcontrollers/cortex_m0_m0/lpc1100/LPC1111FH

N33.html.

STM32F100x4, STM32F100x6, STM32F100x8,

STM32F100xB, 2012. STMicroelectronics. URL:

http://www.st.com/web/en/resource/technical/docume

nt/datasheet/CD00251732.pdf.

ATtiny13A, 2012. Atmel Corporation. URL: http://

www.atmel.com/ru/ru/Images/doc8126.pdf.

ATmega48/V, ATmega88/V, ATmega168/V, 2011. Atmel

Corporation. URL: http://www.atmel.com/images/

doc2545.pdf.

MSP430F2101IPW, 2004. Texas Instruments

Incorporated. URL: http://pdf.datasheetcatalog.net/

datasheets2/56/564429_1.pdf.

PIC16F676, 2014. Basic specifications. Microchip,

official web-site. URL: http://www.microchip.ru/d-

sheets/40039.htm:PIC16F676:1x1.

PIC12F509, 2009. Data Sheet. Microchip Technology Inc.

URL: http://ww1.microchip.com/downloads/en/

DeviceDoc/41236E.pdf.

PIC10F200, 2013. Data Sheet. Microchip Technology Inc.

URL: http://ww1.microchip.com/downloads/en/

DeviceDoc/40001239E.pdf.

PJSRV05W-4LC, 2011. Data Sheet. PANJIT

semiconductor. URL: http://archive.espec.ws/files/

PJSRV05W-4LC.pdf.

24AA128/24LC128/24FC128, 2004. Microchip

Technology Inc. URL: http://www.microchip.ru/

cdrom/ww1.microchip.com/downloads/en/DeviceDoc/

21191M.pdf.

Encyclopedia of Physics, 1998. – Moscow: Great Russian

Encyclopedia. – Volume 2, Volume 5.

SHT21 sensor, 2011. EasyElectronics.ru. URL:

http://we.easyelectronics.ru/part/datchik-temperatury-

i-vlazhnosti-sht21.html.

LogicStudio™ 16 Channel Logic Analyzer, 2010. Data

Sheet. LeCroy Corporation. URL: http://www.prist.ru/

produces/pdf/LeCroy_LogicStudio_Datasheet.pdf.

Hygro Bouton – Température Humidité, 2014.

Téléchargez la documentation. PROGESPLUS. URL:

http://proges.com/ftp/plugandtrack/Products_Data_Sh

ets/Fr/Thermo%20Bouton.pdf.

Elin, 2014. Thermochron iButton. URL: http://

www.elin.ru/Thermochron.

ProposalofElectronicTagforMonitoringEnvironmentalConditionsDuringProductTransportation

247