Mixing and Combustion of Turbulent Coaxial Jets

An Application of Computational Fluid Dynamics to Swirling Flows

Teresa Parra

1

, Ruben Perez

1

, Miguel A. Rodriguez

1

, Artur Gutkowski

2

, Robert Szasz

3

and Francisco Castro

1

1

Department of Energy and Fluid Mechanics, University of Valladolid, Paseo del Cauce 59, 47011 Valladolid, Spain

2

Department of Heat Technology and Refrigeration, Technical University of Lodz, Lodz, Poland

3

Energy Division, Lund University, Lund, Sweden

Keywords: CFD, Swirl Number, Recirculation Zones, Burner.

Abstract: The aim of this research is gaining an insight into flow patterns in swirling burners. These are suitable for

lean mixtures, because of procuring the fix position of the flame. The interaction of the two reactive

confined swirling jets leads to the formation of complex patterns which are not well understood. In the

present study, these flow patterns are numerically investigated using Reynolds Averaging Navier-Stokes

(RANS) equations for the flow and a Probability Density Function is used for modelling the combustion.

Two swirl numbers were characterised: 0.14 and 0.74. Strong swirling annular jets are responsible of an

inner recirculation zone. Low swirling flows produce poorer mixture and wide flame fronts whereas strong

swirling flows are precursors of mixing enhancement and thing flame fronts.

1 INTRODUCTION

The paper is focused on studying the flow pattern of

the flame for low and high swirl number. Swirling

flows let burn lean mixtures near the flammability

limits and produce low emissions.

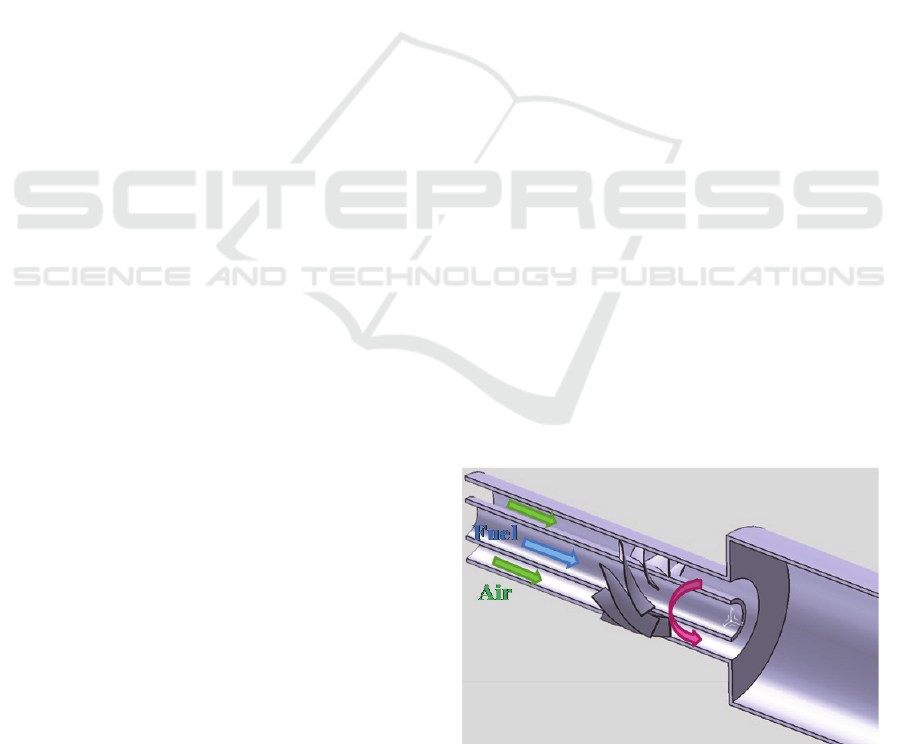

The simplest burners are based on the interaction

of two confined coaxial jets. Annular jet goes

through a swirler that gives azimuthal component to

the flow. The exit of the two coaxial nozzles to the

chamber with an expansion ratio of four in area

produces the separation of the annular boundary

layer. The swirling annular jet is responsible for the

radial pressure gradient. For swirl numbers over 0.6,

there is reverse flow in the centre of the chamber.

The benchmark of Roback and Johnson (Roback,

1983) is the set up chosen to study the influence of

the swirler. This burner has two coaxial nozzles that

discharge into a test chamber. Figure 1 shows and

scheme of the burner and table 1 presents a summary

of the main dimensions and operation conditions of

this test case.

The swirler is a certain number of fixed vanes

located in the annular nozzle. The change of the

trailing edge angle modifies the Swirl number of the

annular jet. This paper is devoted to study the flow

pattern of the flame for low and high swirl numbers.

Figure 1: Scheme of the Roback-Johnson swirling burner.

The definition of Swirl number is the ratio of

azimuthal momentum and axial momentum. The

clear classification of low and high swirl numbers is

related to the flow pattern.

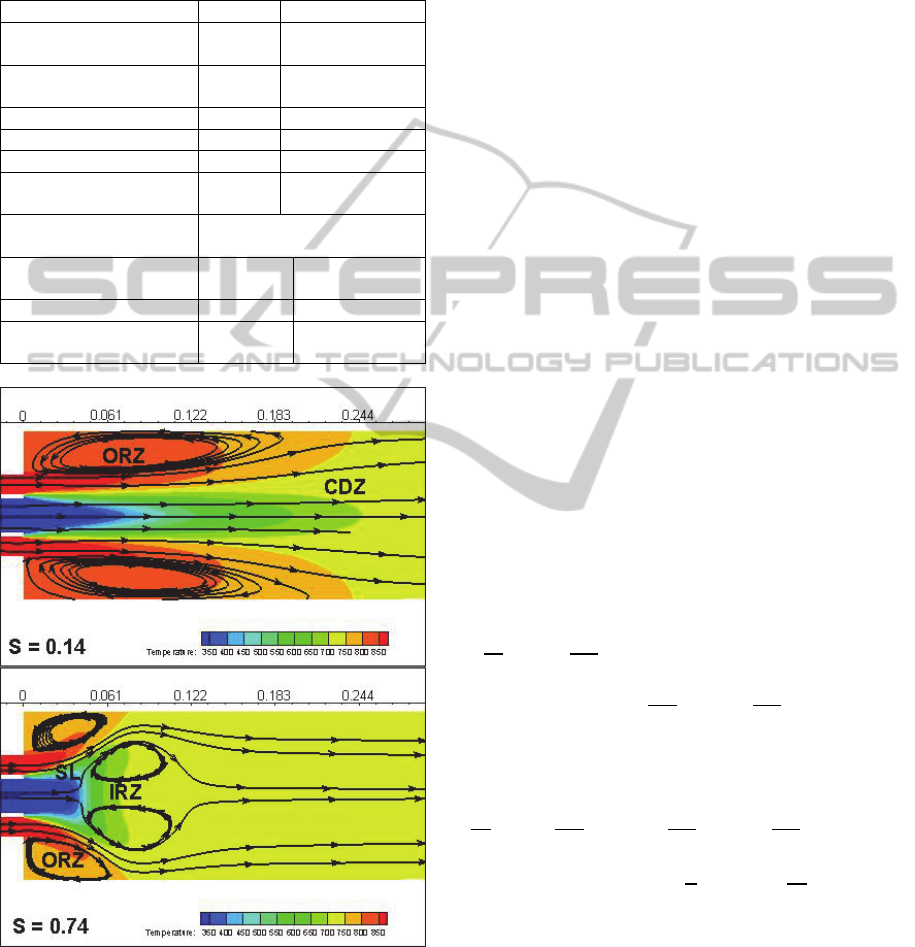

Low-swirl injector (S < 0.6) produces in the test

chamber a Central Divergence Zone (CDZ), a Shear

Layer (SL) and an Outer Recirculation Zone (ORZ).

Whereas high-swirl injectors are precursors of an

Inner Recirculation Zone (IRZ), a Shear Layer (SL)

545

Parra T., Perez R., Rodriguez M., Gutkowski A., Szasz R. and Castro F..

Mixing and Combustion of Turbulent Coaxial Jets - An Application of Computational Fluid Dynamics to Swirling Flows.

DOI: 10.5220/0005009005450550

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 545-550

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

and an Outer Recirculation Zone (ORZ), (García-

Villalba, 2006

a

; García-Villalba 2006

b

). See figure 2

for details of the described flow pattern.

Table 1: Dimension details, boundary conditions and fluid

properties.

Fuel Oxidizer

Injection Central

Nozzle

Annular Nozzle

Nozzles' diameter

inner-outer (mm)

0-25 31-59

Composition CH

4

22% O

2

78% N

2

Temperature (K) 300 900

Velocity (m/s) 0.66 1.54

Turbulence intensity

(%)

12 7.5

Specific Heat(J/kg/K) Polynomial function of

temperature

Thermal Conductivity

(W/m/K)

0.0332 0.0242

Viscosity (kg/m/s) 1.087.10

-5

1.7894.10

-5

Molecular Weight

(kg/kmol)

16.04303 28.996

Figure 2: Contours of temperature in the longitudinal

plane and stream lines to locate recirculation zones for non

reactive cases.

The interest for swirling burners is based on their

low emissions and the possibility to burn lean

mixtures, (Parra, 2014; Parra 2015).

2 NUMERICAL MODEL

The three dimensional domain has the following

spatial resolution: ~d/190 in the test chamber,

~d/40 in the central nozzle and ~d/46 in the

annular nozzle, being d the diameter of the chamber,

diameter of central nozzle and difference of

diameters of the annular nozzle respectively, and

the dimension of the cell. To sum up, the

computational domain has around 10 million

hexahedral cells. The mesh is decomposed to be

solved in parallel being the criterion the minimum

number of cells in the interface to save

computational time associated to information

transfer.

Navier-Stokes equations for transient,

incompressible, turbulent and reactive flows were

solved using Total Variation Diminishing. Pressure-

Velocity coupling was PISO. Multigrid resolution

improves the performance towards the full

convergence.

Anisotropy of the swirling flow makes difficult

to model the turbulence. The chosen model was

RNG k-ε model dominated by the swirl. Because it

considers source term R

ε

based on the strain tensor,

(Versteeg, 1995). Its conservation equations are

described in equations (1) and (2).

(1)

(2)

Enhanced wall treatment is used as turbulence

treatment near the walls, hence the mesh was

generated for y

+

= 1.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

546

2.1 Combustion Model

A suitable approach for turbulent non premixed

reacting flows is to use the mixture fraction defined

as a function of local mass fraction and their

corresponding in the combustible and oxidizer jets.

,

,

,

(3)

Local thermodynamic properties are predicted

from the mixture fraction distribution. Hence the

hypothesis of infinite Damköhler number is

assumed, that is instantaneous chemical reaction

after mixing is achieved, (Kuo, 1986). This method

let estimate intermediate species without solving a

detailed mechanism of reaction.

The code solves the transport equations for both

mixture fractions

̅

and the variance ′

as proposed

by Jones (Jones, 1982):

̅

̅

̅

(4)

′

′

̅

(5)

with

, C

g

and C

d

values equal to 0.7, 2.86 and 2

respectively.

The use of the Probability Density Function

(PDF) p(f) converts the time averaged mixture

fraction and variance,

̅

and ′

, into the

instantaneous mixture fraction f. The PDF can be

calculated assuming equilibrium or measured from

experiments. Finally, local temperature and

composition are evaluated as equation 6 where

∅

.represents either temperature or mass fractions.

∅

∅

(6)

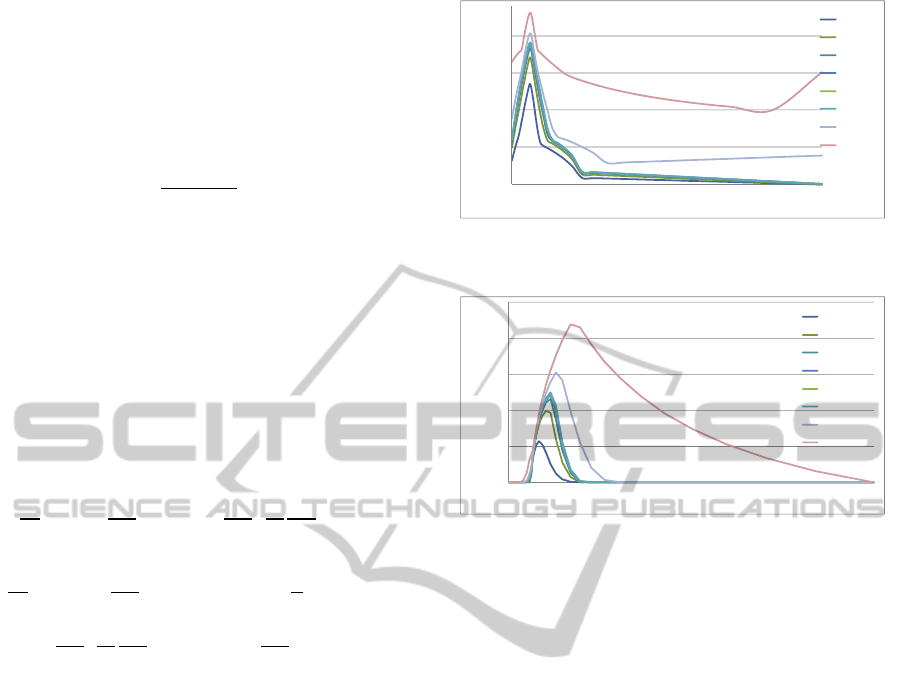

Figures 3 and 4 show the sample for temperature

and carbon monoxide at different scaled heat loss

(HL) or gain (HG) as well as adiabatic flames

obtained from experimental data and used for

simulations.

Figure 3: Tabulated temperature based on mixture fraction

and scaled heat loss-gain.

Figure 4: Tabulated CO mole fraction based on mixture

fraction and scaled heat loss-gain.

3 INFLUENCE OF SWIRL

NUMBER

In this section the flames for swirl numbers 0.14 and

0.74 are presented. Figure 5 depicts the mean

mixture fraction, as well as the volumes of null axial

velocity. Since the recirculation zones are composed

by negative values of axial velocity, these

isovolumes identify the boundaries of the

recirculation zones. Swirl = 0.14 presents a large

ORZ and lacks the IRZ. Whereas Swirl no. = 0.74

has a smaller ORZ and a central IRZ.

From the mixture fraction contours illustrated in

Figures 5, it is clear the higher gradients of any

variable are produced upwind of the IRZ. But for

Swirl no. 0.14, the mixture fraction gradient is lower

and the mixing region larger.

Figures 6 show the mixture fraction variance

whose local maxima correspond with the region with

high reaction rate. Swirl no. 0.14 has a larger

reaction zone than that of swirl no. 0.74. It is clear

the IRZ produces the blockage of the fuel jet, hence

it is forced to be deflected and mixed with the

annular jet. Also, the IRZ is mainly composed by

products of reaction that keep thermal conditions

adequate for ignition of the fresh mixture.

300

800

1300

1800

2300

00.20.40.60.81

MeanTe m p e r at u r e

MeanMixtureFraction

HL=‐48%

HL=‐19%

HL=‐8%

HL=‐3%

HL=‐1%

Adiabatic

HG=20%

HG=80%

0

0.05

0.1

0.15

0.2

0.25

0 0.10.20.30.40.50.60.70.80.9 1

MoleFractionofCO

MeanMixtureFraction

HL=‐ 48%

HL=‐ 19%

HL=‐ 8%

HL=‐ 3%

HL=‐ 1%

Adiabatic

HG=20%

HG=80%

MixingandCombustionofTurbulentCoaxialJets-AnApplicationofComputationalFluidDynamicstoSwirlingFlows

547

It is said that a flame with M shape tends to be

instable, whereas a flame with V shape is more

stable.

Figure 5: Longitudinal contours of Mean Mixture Fraction

for different swirl numbers. Grey shadows are the iso-

volume of null axial velocity.

Figure 6: Longitudinal contours of Mean Fraction

Variance. Grey shadows are the isovolume of null axial

velocity.

Figures 7 present the radial profiles of axial

velocity for non reactive and reactive cases and both

swirl numbers: 0.14 and 0.74. Simulations without

reactions are validated with the experimental results

provided by Palm (Palm, 2006).

Reactive cases (RXN) produce higher axial

velocities than non reactive cases (noRXN) because

there is a reduction of density in the reaction

products and there is mass conservation.

a)

b)

c)

d)

Figure 7: Radial profiles of axial velocities for different

sections. a) Z = 5mm, b) Z = 50mm, c) Z = 100 mm and d)

Z = 300 mm Experimental values from (Palm, 2006) for

no reactive case.

Negative axial velocities in the periphery of the

chamber are associated with the ORZ while these for

radial position near zero are involved with the IRZ.

‐0.5

0

0.5

1

1.5

2

2.5

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.02 0.04 0.06 0.08

S=0.14noRXN

S=0.14RXN

S=0.74noRXN

S=0.74RXN

EXP_Palm

Tª[K]

R[m]

Vz[m/s]

R[m]

Z=5mm

‐0.5

0

0.5

1

1.5

2

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.020.040.060.08

S=0.14noRXN

S=0.14RXN

S=0.74noRXN

S=0.74RXN

EXP_Palm

Tª[K]

R[m]

Vz[m/s]

R[m]

Z=50mm

‐0.4

‐0.2

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.02 0.04 0.06 0.08

S=0.14noRXN

S=0.14RXN

S=0.74noRXN

S=0.74RXN

Tª[K]

R[m]

Vz[m/s]

R[m]

Z=100mm

0

0.2

0.4

0.6

0.8

1

1.2

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.02 0.04 0.06 0.08

S=0.14noRXN

S=0.14RXN

S=0.74noRXN

S=0.74RXN

Tª[K]

R[m]

Vz[m/s]

R[m]

Z=300mm

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

548

It is clear the IRZ is higher for no reactive case than

for the reactive one for swirl 0.74.

a)

b)

c)

d)

Figure 8: Radial profiles of temperature for different

sections. a) Z = 5mm, b) Z = 50mm, c) Z = 100 mm and d)

Z = 300 mm.

Figures 8 present the radial profiles of

temperature for non reactive case to analyse the

mixing, and reactive case.

For reactive cases, the maximum variance is

observed for S=0.14, whereas for S=0.74 the flame

is more compact in longitudinal direction with

smaller difference of the local maxima. Hence, the

flame is prone to instabilities with low Swirl

numbers.

For reactive cases, the maximum variance is

observed for S=0.14, whereas for S=0.74 the flame

is more compact in longitudinal direction with

smaller difference of the local maxima. Hence, the

flame is prone to instabilities with low Swirl

numbers.

4 CONCLUSIONS

Computational Fluid Dynamics has been used to

study the interaction of two reactive confined

coaxial jets. Annular swirling jet was generated with

a swirl generator composed by 8 flat plates located

in the annular nozzle. Averaged fluid field for no

reactive case was validated with experimental results

provided by Palm (Palm, 2006). Inner and outer

recirculation zones where identified.

Low and high swirl injectors have been

simulated and their pattern flow was contrasted.

Numerical simulation uses PDF for combustion

model and RNG k-ε turbulence model. These were

found in this study to be suitable for turbulent swirl

dominated flows.

Low swirling injectors does not promote the

fluid to turn over near the centre of the chamber,

resulting larger mixing zones with weak gradients of

temperature and species' mass fractions.

Large swirling flows promote the formation of a

vortex bulb near the axis of the chamber. The

presence of the IRZ is a precursor of a smaller ORZ.

The lead stagnation point of the inner

recirculation zone is responsible of deflecting the

flame front and increases the mixing upstream of its

lead stagnation point.

ACKNOWLEDGEMENTS

The author thankfully acknowledges the Spanish

Ministry of Science and Innovation for the financial

resources in the framework of the project reference

ENE2011-25468.

0

200

400

600

800

1000

1200

1400

1600

1800

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.020.040.060.08

S=0.14noRXN S=0.14RXN

S=0.74noRXN S=0.74RXN

Tª[K]

R[m]

Tª[K]

R[m]

Z=5mm

0

200

400

600

800

1000

1200

1400

1600

1800

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.02 0.04 0.06 0.08

S=0.14noRXN S=0.14RXN

S=0.74noRXN S=0.74RXN

Tª[K]

R[m]

Tª[K]

R[m]

Z=50mm

0

500

1000

1500

2000

2500

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.020.040.060.08

S=0.14noRXN S=0.14RXN

S=0.74noRXN S=0.74RXN

Tª[K]

R[m]

Tª[K]

R[m]

Z=100mm

0

500

1000

1500

2000

2500

3000

‐0.08 ‐0.06 ‐0.04 ‐0.02 0 0.020.040.060.08

S=0.14noRXN S=0.14RXN

S=0.74noRXN S=0.74RXN

Tª[K]

R[m]

Tª[K]

R[m]

Z=300mm

MixingandCombustionofTurbulentCoaxialJets-AnApplicationofComputationalFluidDynamicstoSwirlingFlows

549

We acknowledge PRACE for awarding us access

to resource Curie-GENCI@CEA based in France

and MareNostrum@BSC based in Spain. Ref.

2010PA1766

REFERENCES

García-Villalba M., Fröhlich J. and Rodi W. 2006

a

Identification and analysis of coherent structures in the

near field of a turbulent unconfined annular swirling

jet using large eddy simulation- Physics of Fluids

(1994-present) 18:5, 055103

García-Villalba M., and Fröhlich J. 2006

b

. LES of a free

annular swirling jet–Dependence of coherent

structures on a pilot jet and the level of swirl.

International journal of heat and fluid flow 27:5, 911-

923

Jones W., Whitelaw J., 1982. Calculation Methods for

Reacting Turbulent Flows: A Review. Combustion

and Flame vol. 48 pp1-26.

Palm R., Grundmann S., Weismuller M., Saric S., Jakirlic

S., Tropea C., 2006. Experimental characterization and

modelling of inflow conditions for a gas turbine swirl

combustor. International Journal of Heat and Fluid

Flow 27 924–936.

Parra T., Vuorinen V., Perez R., Szasz R. and Castro F.

2014. Aerodynamic characterization of isothermal

swirling flows in combustors. International Journal of

Energy and Environmental Engineering 5:85

Parra-Santos M. T., Mendoza-Garcia V., Szasz R. Z.,

Gutkowski A. N., Castro-Ruiz F. 2015. Influence of

swirling on the aero-thermodynamic behaviour of

flames. Combustion Explosion and Shock Waves

Accepted for publication on 23/5/14.

Kuo K., 1986. Principles of Combustion. John Wiley and

Sons.

Roback R., Johnson B.V. 1983. Mass and momentum

turbulent transport experiments with confined swirling

coaxial jets, NASA CR-168252

Versteeg H. K., Malalasekera W. 1995. Computational

Fluid Dynamics, The finite volume method.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

550