The Front Velocity Approach in the Modelling of

Simulated Moving Bed Process (SMB)

Anderson L. J. Bihain

1

, Antônio J. da Silva Neto² and Leôncio D. T. Câmara

2

1

Department of Mathematics, UNIPAMPA Federal University of Pampa, Bagé, Rio Grande do Sul, Brazil

2

Department of Mechanical Engineering and Energy, IPRJ-UERJ Polytechnic Institute of the

State University of Rio de Janeiro, Nova Friburgo, Rio de Janeiro, Brazil

Keywords: Simulation Moving Bed, Inverse Problems, Modelling and Simulation, Chromatography.

Abstract: The Simulated Moving Bed (SMB) is a countercurrent and continuum process that presents a high

separation efficiency. It has been extensively applied in the separation of the petrochemical compounds, in

the enantiomeric separation of racemic drugs, and in other mixtures that are difficult to separate. Currently

the models used to predict the mass transport along chromatographic columns consist of systems of partial

differential equations that presents a high computational cost. To modeling SMB process the novel approach

Front Velocity is presented. This consists of ordinary differential equations and do not utilize adsorption

isotherms, and therefore it is not necessary to perform equilibrium experiments, which are common

procedures in classical modeling. The first stage of the research work was to characterize the

chromatographic column, where the Random constraint window (R2W) algorithm was employed associate

to a kinetic mass transfer equation of the new approach in the solution of the inverse problem. With the

parameters obtained in the characterization of the chromatographic column, the SMB process simulation

was performed, obtaining the separation profiles of the studied compounds. To validate the model

developed, the simulated results were compared with experimental data of enantiomeric separation of the

Ketamine, also confronted with the simulations obtained from classical models. The results show that the

Front Velocity model has a reasonable agreement with experimental data. Likewise showed similar results

to those separation profiles obtained by classical modeling using partial differential equations, requiring

computational cost about twenty times smaller.

1 INTRODUCTION

The adsorption and reaction process are adopted

extensively by the food industry, textile,

petrochemical, chemical and pharmacological

(Gomes et al., 2002).

Therefore, many studies have been carried out

with the aim of improve and create new separation

techniques, and discover new substances to be used

in the separation of a range of products (Zaijun et

al., 2011).

Currently there are a variety of technical

separation, among them, the Simulated Moving Bed

(SMB), created in the sixties by the Universal Oil

Products (Broughton, 1961). This process stands out

for being a powerful tool to separate compounds that

are very difficult to separate, as when the difference

of affinity between the molecules is very small.

Another positive point is that processes operates

continuously requiring less solvent than batch

chromatography (Gal et al., 2005). The potential of

this chromatography tool has been evidenced by

means of high number of studies and publications of

the academic community.

The development of SMB separation processes

requires a thorough study, since is necessary to

determine some operating conditions such as the

flow rate in each section, feed concentration and the

switch time of the position of the currents

(Gonçalves, 2008). The determination of the

operational conditions can become a very costly to

the operator of the equipment.

To resolve this issue many authors has been

formulated math models capable of predicting the

SMB process of separation with statistically

acceptable errors compared to experimental data.

According to (Antos and Seidel-Morgenstern, 2001),

two different approaches, the discrete (mixed cells)

5

Bihain A., Silva Neto A. and Câmara L..

The Front Velocity Approach in the Modelling of Simulated Moving Bed Process (SMB).

DOI: 10.5220/0005009400050011

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 5-11

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

and continuous (dispersion) models can model

chromatographic columns. Currently, the models

used by the researchers are robust and efficient, but

they require a numerical treatment of partial

differential equations, which carries a high

computational cost.

In order to get a new math model to predict the

profiles of separating compounds of a mixture

submitted to a chromatographic separation by SMB

adsorption process, the new approach called Front

Velocity is proposed.

This approach does not require equilibrium

experiments, does not need application of adsorption

isotherms for characterizing the components

involved in the process, and is compost for ordinary

differential equations.

To validate the proposed model, it was applied in

the separation of the enantiomers of ketamine

anaesthetic (Santos, 2004; Santos et al., 2004) and

the results were compared with those obtained by

conventional models.

2 THEORY

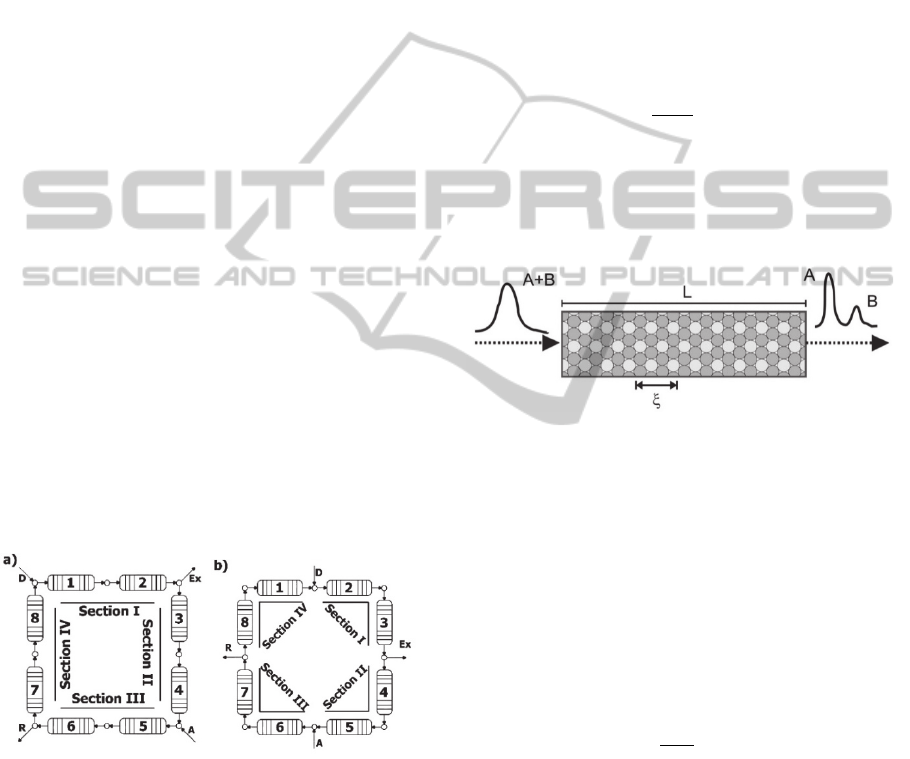

The SMB process used by Santos in the separation

of enantiomers of racemic Ketamine consists of

eight chromatographic columns connected in series,

divided two by two per section. Each column has

0.77 cm diameter and 20 cm in length as shown in

Figure 1. The more retained enantiomer (R) is

collected in the extract (Ex), while the least adsorbed

enantiomer (S) is collected in the raffinate (R).

Figure 1: SMB process with two chromatography columns

per section.

In the stationary and mobile phases were used,

respectively, MCTA (microcrystalline cellulose

acetate) and ethanol. (Santos et al., 2004) also used a

HPLC (High Performance Liquid Chromatography)

column, where was injected ketamine samples for

calibration and determination of purity. The HPLC

column used has 0.46 cm in diameter and 20 cm in

length.

To represent the mass transfer, which occurs

inside one chromatography column, during a

separation process, the Front Velocity new approach

was developed. This establishes that convection is

the dominant phase in the solute transport along the

chromatographic column. The Front Velocity is a

discrete model (mixed cells), where the flow rate

determines the liquid phase advances along the

column. The rate at which the liquid phase

percolates the porous column (v), is the ratio

between volumetric flow rate of the mobile phase

through the porous medium is described by Equation

1,

.

(1)

where, , and

represent the volumetric flow

rate, porosity and the total area of the porous

column, respectively (these data are obtained

experimentally).

Figure 2: Chromatographic column of length L, and

volume control length ξ.

To perform the calculation of the mass transfer,

the chromatographic column was divided into

control volumes (mixed cells) of length ξ, that

moves along the column with the same speed as the

eluent, as can be seen in Figure 2.

The necessary time to move the liquid phase

along each control volume is obtained from

Equation 2, where is the total volume of the

column and is the number of mixed cells.

∆

.

.

(2)

To perform the calculation of the mass transfer in

the chromatography process SMB, the equations

with lumped mass transfer parameter kinetics (Eqs.

3, 4) assumes that equilibrium is achieved

everywhere at all times, so that the effects of axial

dispersion and the mass transfer resistance were

disregarded. Kinetic equations of mass transfer has

been successfully employed in chromatographic

processes (Câmara, 2014; Bihain et al., 2012).

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

6

ξ

.

.

(3)

ξ

.

.

(4)

,

, ,

,

, and represent the

concentration of compound in the liquid phase at

the column, the concentration of compound in

the solid adsorbent phase at the column, the

maximum adsorption capacity, the mass transfer

kinetic parameter of adsorption, the mass transfer

kinetic parameter of desorption and the time,

respectively. These equations (3, and 4) are applied

in all mixture cells (Antos and Seidel-Morgenstern,

2001) and solved numerically utilizing a fourth-

order Runge-Kutta method with a time step equal to

10–5 implemented in Fortran90.

The SMB process consists of four sections (Fig.

1), each on with different volumetric flow rate,

influenced by two input streams and two output

streams (feed, desorbent, extract, and raffinate). To

calculate the mass transfer in each column, first is

necessary determine those volumetric flow rate and

after incorporate the mass balance at the entrance of

each column. After each change in the

configuration of the streams (Fig. 1), the new mass

balance of solutes at the nodes has to be

recalculated.

As the SMB has two streams of input and two

output, the overall flow is necessarily written by

Eq.5.

(5)

To calculate the flow rates in each section and

the mass balance for the first column of each

section, equations 6-9 are used.

Section I:

,

.

.

(6)

Section II:

,

(7)

Section III:

(8)

.

.

(9)

Section IV:

,

(10)

, , , and represent the desorbent, Extract,

Feed, and Raffinate stream, respectively. is the

inlet concentration (concentration at the inlet of the

first column of each section), is the concentration

at the last column of each section, and is relative to

the compound mixture (eg in the case of the racemic

compounds, is R or S).

3 RESULTS AND DISCUSSION

3.1 Characterization of the

Chromatographic Column

A preview and important step in SMB

chromatography process is the characterization of

the columns, through of determination of the lumped

mass transfer parameter kinetics (

, and

).

These parameters determine the rate of adsorption

and desorption of molecules between the liquid and

solid phases.

Table 1: Lumped mass transfer parameters obtained from

the application of the inverse tool, R2W.

S enantiomer R enantiomer

0,00218857 0,00247352

0,05430671 0,02700426

0,04030017 0,09159742

n 505 505

29,567 29,567

R

*

2,54E-05 1,87E-06

*Is the sum of squares of the residuals between the simulation and

experimental data.

(Santos et al., 2004) via an analysis in a High

Performance Liquid Chromatography (HPLC)

system obtained the separations profiles of the

enantiomers of the Ketamine. To determine

,

and

parameters, the retention times

(experimental) observed in the chromatogram

(Santos et al., 2004) resulting from chromatographic

pulse in a HPLC analysis system were used in this

study. These data were combined with mass transfer

equations (Eq.3, and Eq.4) and with the inverse tool,

Random Restricted Window (R2W) (Câmara and

Silva Neto, 2008). The results can be seen on the

table 1. The R2W is considered a simple stochastic

inverse method, which uses a search algorithm with

a random distribution.

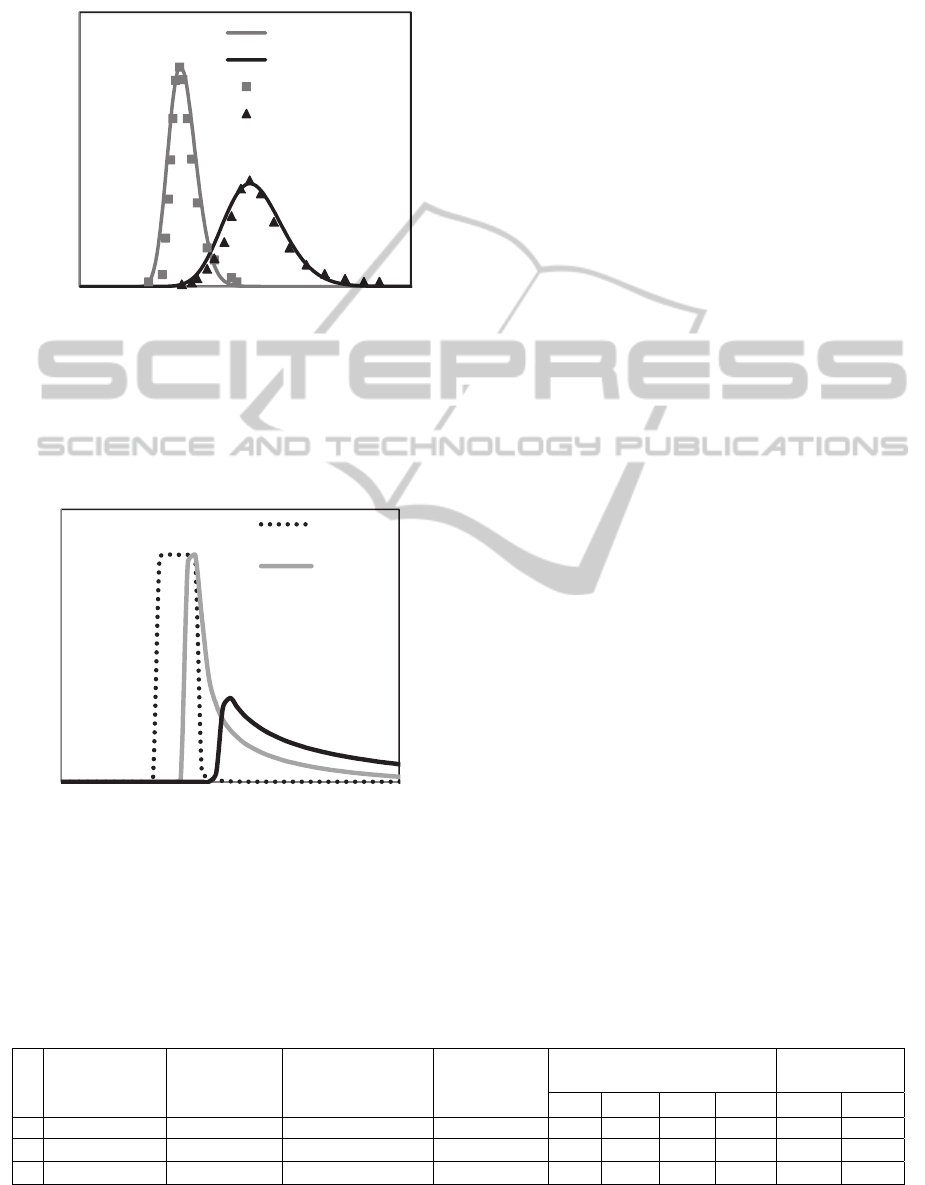

In Figure 3, it is remarkable the good correlation

between the experimental data (chromatogram), and

TheFrontVelocityApproachintheModellingofSimulatedMovingBedProcess(SMB)

7

the simulation performed with Front Velocity

approach.

Figure 3: Chromatogram of racemic ketamine injection in

the analysis column packed with MCTA; anhydrous

ethanol as mobile phase, flow rate 0.25 mL/min, loop

20, the solution concentration 1.5 g/l. Results simulated

with Front Velocity approach, compared to the

experimental data.

Figure 4: Variation of the maximum adsorption capacity

of the adsorbent phase.

15/,30/

,300,10,005/.,2

0,01/.

In a theoretical analysis performed to one

chromatographic pulse as can be seen in figure 4, is

observed that the novel approach presented in this

work has potential to represent the resistance to

mass transfer as well as the saturation of the

adsorbent phase (rectangular peak). The

chromatogram of the simulation also shows a peak

tailing, which is a behaviour observed in the

literature with the use of adsorption isotherms.

Therefore, the characterization of a chromatography

column cannot be linked exclusively with the

isotherm application, but also with mass transfer

kinetic equations.

3.2 SMB Continuous Process

With the data obtained (Table 1) in the

chromatographic column characterization stage, the

SMB was performed under the experimental

conditions (table 2) that were determined by (Santos

et al., 2004). The kinetic equations (Equations 3-4)

and mass balance equations (Equations 6-9) were

applied to each column of the SMB to simulate

separation of the enantiomers of the ketamine,

allowing the results were compared with those

obtained by (Santos et al., 2004; Santos, 2004).

The equations used in the modeling of the LMS

in this work, were solved numerically utilizing a

fourth-order Runge-Kutta method, and implemented

in Fortran 90. The total simulation time to SMB was

approximately 1.5 minutes on a computer with Intel

Core i5 processor (2.3 GHz) with a time step equal

to 10

. The number of mixed cells (divisions of the

columns) in each section is determinate by

volumetric flow rate (figure 1), and it is around 300-

1000 equilibrium stages as can be seen in tables

Table 3.

The differential partial equations of the

dispersive equilibrium model used by Santos et al.

(2004), were solved by public subroutine PDECOL

(Madsen and Sincovec, 1979), which implements

the finite element method for spatial discretization

and the ordinary differential equations were solved

by GEARIB time integrator (Hindmarsh, 1976). The

total simulation time was about 4 hours, using an

Table 2: Operation condition evaluations according to solvent consumption, productivity, and purity.

Feed

Concentration

Switch time

(seconds)

Solvent

consumption

(L/g rac.)

Productivity

(q.rac./D.kg)

Volumetric flow at the

streams (min

)

Purity (%)

Ext. Raff. Feed

S R

1 1.5 1500 2.67 10.65 0.47 0.43 0.18 1.10 99.83 99.71

2 2.5 1500 1.6 17.75 0.47 0.43 0.18 1.10 99.84 99.71

3 5 1500 1.46 19.79 0.44 0.39 0.1 1.10 99.99 99.90

0

0,002

0,004

0,006

0,008

0,01

0,012

0 204060

Concentration(g/L)

Time(min)

S‐FrontVelocity

R‐FrontVelocity

S‐Experimental

R‐Experimental

0

2

4

6

8

10

12

14

16

18

0 20406080

Conc.(g/L)

Time(min)

qm=0.1

g/L

qm=5g/L

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

8

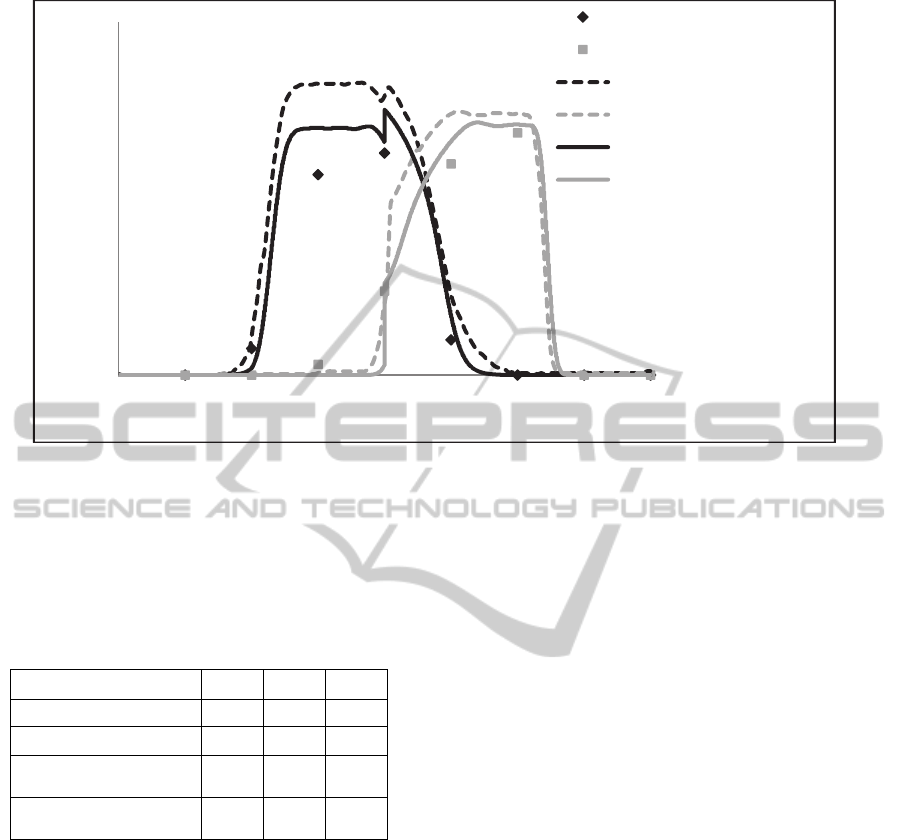

Figure 5: SMB evolution of S enantiomer concentration in the extract stream over time (transient), under experimental

condition 1.

Figure 6: SMB evolution of R enantiomer concentration in the raffinate stream over time (transient), under experimental

condition 1.

Intel Pentium IV (2.4 GHz) processor, with a time

step equal to 10

. Each column has been divided

only into 30 elements.

The good correlation between the simulation

using the Front Velocity approach, and the classical

model used by (Santos et al., 2004), over the time in

the separation process can be seen in Figures 4, and

5. In addition, a comparison with the experimental

data in the extract and raffinate streams can be

visualized, where there is a small deviation between

the simulated and experimental data while the

process is still in the transient. When the process

achieves the pseudo steady-state is reached a better

fit.

Table 3: Number of mixed cells of the columns per

section.

SMB Sections Number of control volumes

Section I 322

Section II 562

Section III 437

Section IV 932

Figure 7 shows the concentration profiles of each

enantiomer over the columns when the SMB reaches

steady state. The good representation of the new

approach is observed due to correlation with

experimental data, and may be noted that Front

Velocity achieves a slightly better fit compared with

(Santos et al., 2004) simulations.

0

0,1

0,2

0,3

0,4

0,5

0,6

0 100 200 300 400 500 600 700 800

Concentration(g/L)

Time(min)

Exp.Santos

FrontVelocityaverage

FrontVelocitysim.

average

Santossimulation

average

0

0,1

0,2

0,3

0,4

0,5

0,6

0 100 200 300 400 500 600 700 800

Concentration(g/L)

Time(min)

Exp.Santos

FrontVelocity

simulation

FrontVelocityaverage

Santossimulation

average

TheFrontVelocityApproachintheModellingofSimulatedMovingBedProcess(SMB)

9

Figure 7: SMB evolution of R enantiomer concentration in the raffinate stream over time (transient).

The solvent consumption, productivity, and

purity showed in table 4 were calculated with the

novel approach proposed in this work. These results

are very similar to experimental values (Table 2).

Table 4: The solvent consumption, productivity, and

purity calculated with Front Velocity approach.

Experimental condition 1 2 3

Raffinate purity (S) % 97.72 98.84 99.89

Extract purity (R) % 99.70 99.93 99.99

Productivity

(q.rac./D.kg)

10.63 17.63 19.49

Solvent consumption

(L/g rac.)

2.66 1.61 1.47

4 CONCLUSIONS

A set of programs for continuous simulation of SMB

process, and also to characterize the

chromatographic column was developed and used

under the new proposed idea of modeling the pulse

experiment to determine the kinetic constants of

mass transfer with mass transfer kinetic equations,

instead of performing equilibrium experiments and

combining them with some kind of adsorption

isotherm. This procedure satisfactorily performed

the separation of the enantiomers of the anaesthetic

ketamine at SMB. The R2W algorithm was effective

in determining the parameters of adsorption,

desorption, and the maximum adsorption capacity of

the adsorbent phase (

,

,

).

The concentration profiles of the simulations

proved to be consistent with the SMB process, and

the simulated profiles of enantiomers were similar to

the experimental data, showing a slightly more

suiting behaviour in relation to the experimental data

than the classical modeling as the model adopted by

(Santos et al., 2004).

The results showed the potential of Front

velocity in the prediction of the SMB separations. In

a shortest time than classical models this approach

performs a full simulation of the separation in a

SMB process. The low computational cost is due the

use the ordinary differential equations in this

approach that requires less parameters than classical

models, furthermore, the ease of implementation and

analysis, and the need to know just few operational

data of the real problem. Another relevant fact is no

be necessary performing equilibrium experiments to

characterize the chromatographic column.

ACKNOWLEDGEMENTS

The authors acknowledge the financial support from

UERJ, CNPq and CAPES.

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

012345678

Concentration(g/L)

Columns

Renantiomer

Senantiomer

RenantiomerSoaressim.

SenantiomerSoaressim.

EnantiomerR‐FrontVelocity

EnantiomerS‐FrontVelocity

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

10

REFERENCES

Antos, D. and Seidel-Morgenstern, A. (2001). Chemical

Engineering Science, 56, 6667.

Bihain, A. L. J., Silva Neto, A. J., Santiago, O. L., Afonso,

J. C., Câmara, L. D. T. The front velocity modelling

approach in the chromatographic column

characterization of glucose and fructose separation in

SMB. Trends in Chromatography, v. 7, p. 33-41,

2012.

Broughton, D. B. (23 May 1961). EUA Patent Nº

US002985589.

Câmara, L. D. and Silva Neto, A. J. (2008). Inverse

Stochastic Characterization of Adsorption Systems by

a Random Restricted Window (R2W) Method.

International Conference on Engineering

Optimization (ENGOPT). Rio de Janeiro - RJ.

Câmara, L. D. Stepwise Model Evaluation in Simulated

Moving-Bed Separation of Ketamine. Chem. Eng.

Technol. 2014, 37, No. 2, 301–309.

Gal, G., Hanak, L., Argyelan, J., Strbka, J., Szanya, T.,

Aranyi, A., & Temesvari, K. (2005). Simulated

Moving Bed (SMB) Separation of Pharmaceutical

Enantiomers. Hungarian Journal of Industrial

Chemistry, 33, pp. 23-30.

Gomes, P. M., Figueirêdo, R. M. and Queiroz, A. J.

(2002). Caracterização e Isotermas de Adsorção de

Umidade da Polpa de Acerola em Pó. Revista

Brasileira de Produtos Agroindustriais, 4(2), pp. 157-

165.

Gonçalves, C. V. (2008). Separação do Racemato N-Boc-

Rolipram pelo Processo Cromatografico de Leito

Movel Simulado Utilizando Fase Estacionaria Quiral

Tris-(3,5-dimetilfenilcarbamato de celulose)

Suportada em Silica. Campinas: UNICAMP: Doctoral

thesis.

Hindmarsh, A. (1976). Preliminary Documentation of

GEARIB - Solution of Implicit Systems of Ordinary

Differential Equations with Banded Jacobian. Report

UCID - 30130.

Madsen, N. K. and Sincovec, R. F. (1979). PDCOL:

General Collection Software for Partial Differential

Equations. ACM Trans. Math. Software, 5, pp. 326 -

351.

Santos, M. A. (2004). Separação dos Enantiômeros do

Anestésico Cetamina por Cromatografia Contínua em

Leito Móvel Simulado. Campinas: UNICAMP:

Doctoral thesis.

Santos, M. A., Veredas, V., Silva JR, I. J., Correia, C. R.,

Furlan, L. T. and Santana, C. C. (2004). Simulated

Moving-Bed Adsorption for Separation of Racemic

Mixtures. Brazilian Journal of Chemical Engineering,

21(01), pp. 127-136.

Zaijun, L., Xiulan, S. and Junkang, L. (2011). Ionic Liquid

as Novel Solvent for Extraction and Separation in

Analytical Chemistry. Chemical Engineering

Applications and Perspectives, pp. 154-180.

TheFrontVelocityApproachintheModellingofSimulatedMovingBedProcess(SMB)

11