Simplified Closed Form Numerical Approaches to Predict Natural

Rubber Behavior under Sulfur Curing in Standard Rheometer Tests

Marco Brotto

1

, Gabriele Milani

2

and Federico Milani

1

1

CHEM.CO Consultant, Via J.F.Kennedy 2, 45030 Occhiobello (RO), Italy

2

Technical University in Milan, Piazza Leonardo da Vinci 32, 20133 Milan, Italy

Keywords: Rubber Vulcanization, NR, Numerical Model, Kinetic Approach.

Abstract: In this paper, a complex numerical and a simplified mathematical closed form approach with robust kinetic

base are proposed to interpret NR sulfur vulcanization. A preliminary phase of preparation of meta-

rheometer curves from few experimental data may be necessary to have at disposal the whole curve to fit

with the model when experimental data at disposal are a few. Then, on such data (either experimental or

artificially generated) partial reaction kinetic constants characterizing the vulcanization process within the

models proposed are derived. When needed, meta-data are obtained using a direct C2 natural cubic spline

interpolation of the rheometer curve, which proved to fit the experimental data well. Both the presence and

absence of reversion are discussed and how they are reflected in the model calculations. The chemical

schemes, translated mathematically into differential equations systems, are suitably re-arranged to derive

single analytical equations, which represents the crosslinking degree evolution vs time. The parameters of

the single equations may be determined setting the kinetic constants of the chemical model by means of best

fitting in the first model (more complex) and with the direct solution of a non linear system of equations in

the second (simplified) approach. The major improvement of the second procedure here proposed is to

utilize some ad hoc values for the kinetic constants that do not necessarily require an optimization

algorithm, thus by-passing the usage of a least squares minimization routine.

1 INTRODUCTION

Sulphur vulcanization maybe represents the most

popular technique to cure both natural rubber (NR)

and its synthetic counterpart (IR), as well as for

other synthetic rubbers such as polybutadiene (BR),

styrene–butadiene rubber (SBR), nitrile rubber

(NBR), butyl rubber (IIR), and ethylene–propylene–

diene rubber (EPDM), only to indicate the most

important in the market. In general, it is commonly

accepted that vulcanization takes place roughly into

three steps: induction, crosslinking and post

crosslinking. The idea comes from the macroscopic

interpretation of what happens to a sample during

controlled temperature curing conditions in the

rheometer chamber. The rheometer curve, which is

simply the measure of the torque resistance of a

sample subjected to fixed temperature cure at

increasing time, typically exhibits an initial plateau

with low and slightly decreasing torque, a rapid

crosslinks formation with a significant torque

increase and eventually a final degradation, i.e. a

torque decrease, at sufficiently large vulcanization

times, usually denoted with the term “reversion”.

Reversion is a key distinctive aspect of the

vulcanization with sulphur and, from a macroscopic

point of view, consists in a remarkable decrease or

rubber vulcanized properties at the end of the curing

process. It depends on a series of concurring factors,

the most important being rubber type, its structure,

% of double bonds see (Milani and Milani, 2012),

presence of additives, in particular the accelerators,

and co-adjuvants, as well as vulcanization

temperature.

In the paper, two numerical models to interpret

natural rubber vulcanization with reversion are

presented: a complex and a simplified one. Both of

them have robust kinetic base. A preliminary phase

of preparation of meta-rheometer curves from few

experimental data may be necessary to have at

disposal the whole curve to fit with the model when

experimental data at disposal are a few. In this latter

case, meta-data are obtained using a direct C2

natural cubic spline interpolation of the rheometer

141

Brotto M., Milani G. and Milani F..

Simplified Closed Form Numerical Approaches to Predict Natural Rubber Behavior under Sulfur Curing in Standard Rheometer Tests.

DOI: 10.5220/0005013401410147

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 141-147

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

curve, which proved to fit the experimental data

reasonably well. On either experimental or

artificially generated data, two kinetic schemes are

assumed to fit rheometer curves, the first involving 5

kinetic constants, the second only 2. The chemical

schemes, translated mathematically into differential

equations systems, are suitably re-arranged to derive

single analytical equations, which represents the

crosslinking degree evolution vs time. Kinetic

constants of the first model are derived by means of

a best fitting procedure, whereas in the second

model the solution of a two variables non linear

system of equations is needed. The major

improvement of the second procedure here proposed

is avoid the utilization of an optimization algorithm,

which sometimes proved to be not sufficiently

robust. Both models are validated on a wide set of

experimental data available in the literature.

Figure 1: Products and schematic reaction mechanisms of

NR accelerated sulphur vulcanization.

2 META-DATA GENERATION

WITH NATURAL CUBIC

SPLINES

When a few “characteristic” experimental points on

the rheometer curve are available, i.e. when the

entire cure curve is not at disposal, a natural cubic

spline interpolation of the experimental data at hand,

which typically include a few “meaningful” points

may be used to produce a meta-curve approximating

the experimental rheometer one, see (Milani and

Milani, 2014a; Milani and Milani, 2014b). Instead of

MHF the reversion percentage, i.e. the decrease in

the peak torque at the end of the rheometer test, may

be provided.

The fundamental idea behind cubic spline

interpolation is based on the engineer’s tool used to

draw smooth curves through a number of points of

the actual rheometer curve M(t).

Spline interpolation is based on the following

hypotheses:

1) The piecewise function M(t) interpolates all data

points.

2) M(t) together with its first and second derivatives

(M‘(t) and M‘‘(t) respectively) are continuous on the

interval 0-t

max

.

The kernel, Deitel relies on the fitting of known

experimental points at times t1, t2,., tn by means of a

piecewise function of the form:

nnn

tttiftM

tttiftM

tttiftM

tM

11

322

211

(1)

where

i

M

are third degree polynomial defined by

iiiiiiii

dttcttbttatM

23

with

1,,2,1

ni

.

The previous interpolating function has first and

second derivative equal to:

iiii

iiiiii

bttadttMd

cttbttadttdM

26/

23/

22

2

(2)

Assuming that the composite function passes

through experimental points (say that, at ti, the

rheometer curve has a torque equal to

i

M ), it is

continuous with its first and second derivatives

(equal to

'

i

M and ''

i

M in

i

t

respectively) we

obtain 2

n

-2 mathematical conditions from the

passage through points and 2(

n

-2) conditions for

the first and second derivative continuity

respectively.

Total coefficients to set are 4(

n

-1), so that the

number of coefficients exceed equality conditions by

2 equations.

In order to evaluate the degree of vulcanization

t

exp

, see (Milani et al., 2013) and (Sun et al.,

2009), the following relation may be used:

cross-link precursor

form ation

K

0

S

sulphurating

agent

unvulcanized

natural

rubber

X

1

cross-link precursor

(S)

y

X

formation of stable S-S

bond

K

1

X

2

formation of unstable S-S

m ultiple bond

K

2

S*

(S)

1,2

reticulated rubber

(S)

x>2

reticulated rubber

X

1

multiple bond break

K

3

bond break

X

2

single/double bond break

K

4

D'

D

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

142

00

minmax

min

exp

'

TT

T

SS

StS

t

(3)

where:

- M

minT

is the minimum value of torque M(t) during

a cure experiment at temperature T. Before reaching

this minimum value,

t

exp

is considered equal to

zero.

- M

minT0

and M

maxT0

are the minimum and maximum

torque values obtained for a cure experiment at a

temperature T

0

low enough to allow reversion to be

neglected.

In this way, the rheometer curves to fit always

range between 0 and 1, with a maximum torque

sensibly less than 1 for high vulcanization

temperatures.

3 A REFINED FIVE CONSTANTS

KINETIC MODEL

A mechanistic model, already presented in (Milani

et al., 2013), based on a detailed kinetic scheme, is

here recalled. The mathematical solution of the

mechanistic model allows to numerically reproduce

rheometer curves for NR vulcanized with sulfur. The

basic reaction schemes are schematically represented

in Figure 1. Such scheme simplifies well established

chemical interpretations available from the technical

literature, see (Ding and Leonov, 1996; Han et al.,

1998; Leroy et al., 2013).

Adopting for NR the kinetic scheme constituted

by the chemical reactions shown in Figure 1, the

following schematization holds:

*

0

SS

k

'

31

1

*

DXS

k

k

DXS

kk

42

2

*

(4)

In Equation (4),

S

is the uncured polymer,

*

S

the unmatured crosslinked polymer, which evolves

into matured

crosslinked polimer

1

X

+

2

X

, with

1

X

indicating the stable crosslinked part and with

2

X

the unstable part. Part of both

1

X

and

2

X

may

evolve into

D

and

'

D

unvulcanized polymer due to

multiple S-S chains breaks and consequent

backbiting.

4,...,0

K

are kinetic reaction constants.

Here it is worth emphasizing that

4,...,0

K

are

temperature dependent quantities, hence they

rigorously should be indicated as

)(

4,...,0

TK

, where

T

is the absolute temperature. In what follows, for

the sake of simplicity, the temperature dependence

will be left out.

Differential equations associated to chemical

reactions are the following:

(a)

SK

dt

dS

o

(b)

*

210

*

'

SKKSK

dt

dS

(c)

13

*

1

1

XKSK

dt

dX

(d)

24

*

2

2

XKSK

dt

dX

(5)

A closed form solution for the crosslink degree,

intended as

21

XX

, may therefore be

deduced from relations (7). In particular, the

variation of the cure degree as a function of time

t

assumes the following form:

tK

tK

tKK

tKK

tK

tK

e

KKKKK

SKK

e

KKKKK

SKK

e

KKK

K

C

e

KKK

K

C

eCeCXX

0

0

21

21

3

4

30021

020

40021

010

321

2

2

421

1

2

6421

(6)

Having indicated with

2

C

,

4

C

and

6

C

the

following integration constants:

201

00

2

KKK

SK

C

42140

010

4

KKKKK

SKK

C

32130

020

6

KKKKK

SKK

C

(7)

and with

0

S

the initial amount of unvulcanized

polymer, which, as already mentioned, has to be put

equal to 1 when the crosslink percentage

(ranging from 0% to 100%) has to be determined.

SimplifiedClosedFormNumericalApproachestoPredictNaturalRubberBehaviorunderSulfurCuringinStandard

RheometerTests

143

3.1 Starting Point Determination

In order to evaluate kinetic constants of the model

(problem (4)), a non-linear least squares routine -to

fit with the mathematical model normalized

rheometer curves- has to be used, see (Milani et al.,

2013). The utilization of non-linear optimization

algorithms is not always effective, may fail in some

cases in finding the minimum point or may require

an excessive processing time. Two alternative

strategies are possible, the first is to find a

reasonable starting point, intending with the term

reasonable a point sufficiently near the solution of

the least-squares problem. Such procedure is

however not an easy task in this case and the starting

point determination is usually done by attempts,

discriminating the quality of the starting point

looking at the stability of the algorithm. An

alternative is to simplify the kinetic scheme and

compare the results obtained with those provided by

the mathematical solution of problem (4).

4 THE NEW SIMPLIFIED

MECHANISTIC MODEL

PROPOSED

In this section, we propose a novel, simplified but

robust mechanistic model to fit experimental

rheometer curves that do not require the least

squares data fitting, mandatory for solving problem

(4).

According to the chemical reactions reported in

Figure 1, it is possible to analyze the problem by

means of the following simplified kinetic model:

'

'

PP

k

*

*

' PP

k

(8)

Where

21

' KKK

and

43

* KKK

.

Differential equations associated to chemical

reactions are the following:

(a)

PK

dt

dP

'

(b)

''

'

*

PKPK

dt

dP

(c)

'

*

*

PK

dt

dP

(9)

Differential Eq. (9)(a) may be solved

immediately providing

)(tP

as

tK

ePtP

'

0

)(

. The

previous equation may be substituted into Eq. (9) (b)

providing directly a differential equation for

)(' tP

,

which represents the matured polymer as:

tk

eKPPK

dt

dP

'

0

''*

'

(10)

which is solved in closed form finding a general

integral and a particular solution.

The general integral is the following:

tK

g

eCP

*

1

'

(11)

whereas a particular integral is:

*

'

01

'

'

**

*

KK

ee

PeCP

tKKtK

tK

p

(12)

So that the solution of the differential equation under

study is:

*

'

01

'

'

**

*

KK

ee

PeCP

tKKtK

tK

(13)

Assuming that

00'

P

, hence Eq. (13) becomes:

tKKtK

ee

KK

P

tP

**

'

*

0

1

'

'

(14)

Assuming that at t

1

the rheometer curve reaches a

maximum and that at t

2

the reversion percentage is,

say,

R, it is possible to directly evaluate '

K

and

*

K

by means of the solution of a non linear system

of equations (two equations in two variables).

5 MODEL VALIDATION

A full validation of the approach proposed has been

already performed on the 5 kinetic constant model,

considering some experimental data available in the

technical literature, see (Davis et al., 1986), where a

NR blend is vulcanized with sulphur, in presence of

different accelerators at the same curing temperature

(144°C). The accelerators proved, in some cases, to

give the blend an excellent reversion resistance.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

144

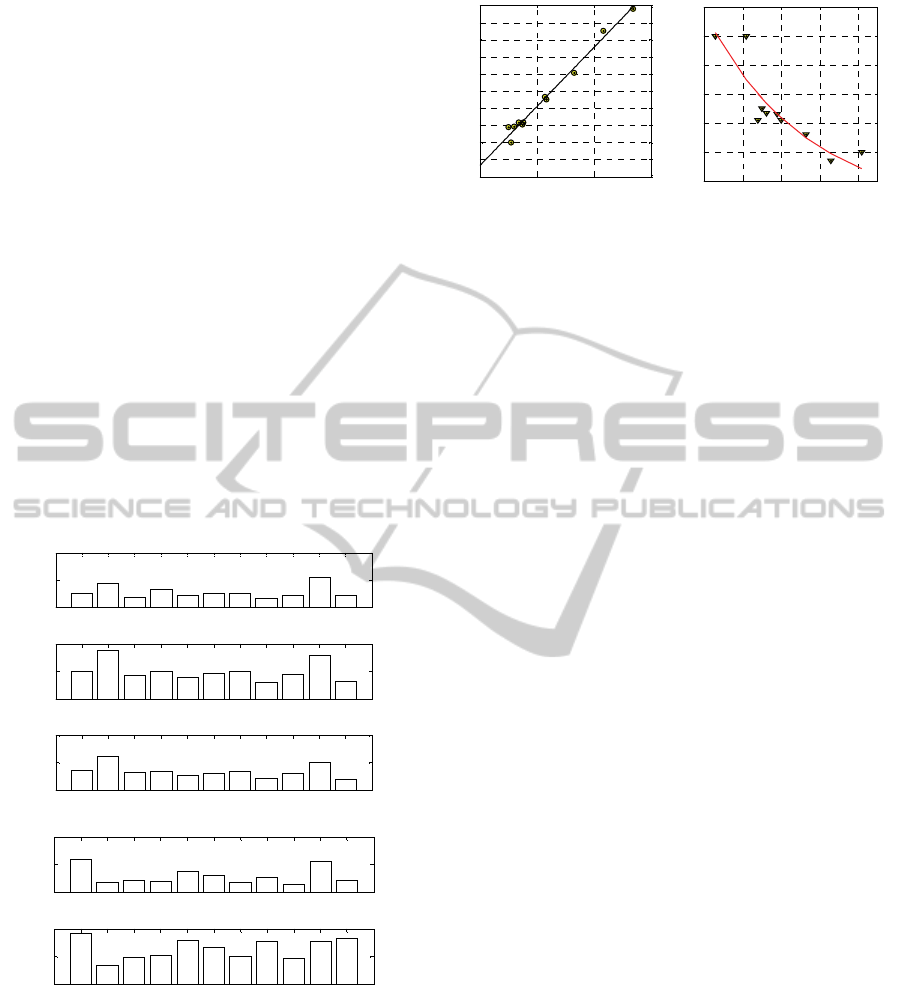

Figure 2: preliminary simplified model validation on data

set 5 of Table 1 and Table 2.

The performance of the accelerators was

comparatively estimated collecting a few rheometer

data, as for instance

2

t

and

90

t

times, reversion %,

total cure time, maximum torque and some

mechanical

properties of the cured specimens, as

elongation at break, ultimate tensile strength and

elastic modulus at 300% of elongation. Information

regarding the behaviour of the blend in the

rheometer chamber is particularly suitable to

calibrate meta data in the first step.

A preliminary validation of the simplified

procedure proposed in this paper is still running and

is under study by the authors. However, first results

obtained on some data sets, see e.g. Figure 2, seem

to confirm a generally satisfactory capability of the

numerical model to fit reasonably well the main

features of the experimental rheometer curves, i.e.

amount of reversion and time needed to achieve an

optimal vulcanization.

When dealing with specific chemical aspects of

the validation, it is possible to compare synoptically

the numerical results obtained in terms of kinetic

constants (5 constants model), see Figure 3, with

reference to the experimental results available, see

Table 1 and Table 2.

Using dialkyldithiophosphates (as ZDBDP) it is

possible to obtain improved reversion resistance, see

(Davis et al., 1986). However, blends containing

such accelerators generally burn slightly on the

surface and this affects their practical use. ZDBDP

with TBBS is a accelerators combination that

decreases drastically the cure time needed, but with

a very short scorch delay. With about a

stoichiometric equivalent by w. of CTP, roughly the

same improvements in the curing rate with very

small reversion may be obtained. Finally, certain

triazine derivatives have been identified as active

accelerators however, increasing their amount in the

blend also with the PSSR accelerator resulted into

superficial burn.

Table 1: Overview of the experimental data utilized to

validate the two-step numerical model (1/2).

Numerical

Test #

1 10 5 6 11 9

Reversion % 19.1 17.1 12.1 9.5 6.5 3.9

M300

[MPa]

15.2 11.8 14.5 14.3 15.0 18.5

UST [MPa] 28.8 27.5 28 27.1 26.0 29.0

UE [%] 517 574 499 510 477 459

Cure time

[min]

25 21.2 36.5 30.0 50.7 29

ODR 144°C

t2 [min] 9.2 4.65 10.5 9.5 10.9 10.5

t90 [min] 21.6 17.4 31.7 25.5 45.8 25.2

Products concentration in phr

PYSSPY 1.0 1.0

MBS 0.25

TBBS 0.6

TSSR 0.7 1.0

MBTS 1.0

Table 2: Overview of the experimental data utilized to

validate the two-step numerical model (2/2).

Numerical Test # 4 8 7 2 3

Reversion % 6.1 9.0 5.7 5.6 6.5

M300 [MPa] 15.5 11.6 16.8 13.0 13.2

UST [MPa] 28.0 25.0 27.1 28.0 28.0

UE [%] 503 544 464 555 550

Cure time [min] 29 43 26 13 24

ODR 144°C

t2 [min] 7.8 15.3 9.5 5.7 14.7

t90 [min] 25 37.6 22.5 12.0 22.0

Products concentration in phr

TSST 0.7

PSSR 1.0 0.5

TSSR 0.5

TBBS 0.2 0.2

ZDBDP 0.76 0.76

CTP 0.72

Finally, plotting the numerical constants found

with the 5 kinetic constants model as in Figure 4 (in

subfigure –a a relationship between K

3

+K

4

and

reversion % is provided whereas in subfigure –b a

relationship between K

1

+K

2

and cure time is shown)

it is very straightforward to conclude that K

3

+K

4

(which follow almost rigorously a straight line for

the reversion) globally gives a quantitative

information on the amount of degradation of cure,

whereas K

1

+K

2

the speed of reticulation. Best fitting

curves reported in Figure 4 may be therefore

0 2 4 6 8 10 12

0

0.2

0.4

0.6

0.8

1

1.2

1.4

Time [min]

Normalized torque M

t

/M

tmax

Coran set-5

Present model solution

Full experimental meta data curve

SimplifiedClosedFormNumericalApproachestoPredictNaturalRubberBehaviorunderSulfurCuringinStandard

RheometerTests

145

extremely useful from a practical point of view to

directly predict the most important parameters of

vulcanization of a rubber blend, i.e. time needed for

curing and expected reversion.

6 CONCLUSIONS

Two kinetic models suitable -to interpret NR

vulcanization in presence of reversion- through the

utilization of the experimental rheometer curve have

been presented. Depending on the level of

complexity of the kinetic model proposed, more

detailed or less precise information on the degree of

curing, as well as on the single and multiple-bond

percentage of resulting links may be retrieved.

However, an increased complexity of the models

results both into the impossibility to deal with

closed-form predicting expressions for the cure

percentage and in complex numerical best fits on

experimental data available to estimate single kinetic

constants representing the chemical scheme adopted.

Figure 3: Synoptic comparison between the partial kinetic

constants obtained in the different cases analyzed

numerically.

Two models of different complexity have been

presented: the first describes in a quite complex way

the vulcanization process and requires the

knowledge of five kinetic constants, the second is

rougher but less complex, needing only the

evaluation of two kinetic constants.

-a -b

Figure 4: –a: Relationship between K

3

+K

4

and reversion

%. –b: relationship between K

1

+K

2

and cure time.

The first approach proved to fit very well

experimental rheometer curves (or meta-curves

deduced numerically from few experimental data

available), but needs expensive and not always

robust best fitting procedures, whereas the second is

less precise but allows the determination of model

constants directly by mean of the solution of a non-

linear equations system into only two variables.

The validation of the simplified model is still

running. In particular, the choice of the two points

into the rheometer curve to select in order to obtain

the best performance of the model (in terms of

fitting) appears the key issue to be investigated.

REFERENCES

ASTM D 2084-81, Annual Book, 1986.

Davis, L.H., Sullivan, A.B., Coran, A.Y., 1986. New

curing system components. In Proc.: International

Rubber Conference IRC 86 – Goeteborg, Sweden ,

vol.2 , p.387-392.

Ding, R., Leonov, I., 1986. A kinetic model for sulfur

accelerated vulcanization of a natural rubber

compound. J. Appl. Polym. Sci., 61, 455.

Han, I.S., Chung, C.B., Kang, S.J., Kim, S.J., Chung,

H.C., 1998. A kinetic model of reversion type cure for

rubber compounds. Polymer (Korea), 22, 223.

Leroy, E., Souid, A., Deterre, R., 2013. A continuous

kinetic model of rubber vulcanization predicting

induction and reversion. Polym. Test., 32 (3), 575.

Milani, G., Milani, F., 2010. A new simple numerical

model based on experimental scorch curve data fitting

for the interpretation of sulphur vulcanization. J. Math.

Chem., 48, 530.

Milani, G., Milani, F., 2012. Comprehensive numerical

model for the interpretation of cross-linking with

peroxides and sulfur: Chemical mechanisms and

optimalvulcanization of real items. Rubber Chem.

Technol., 85 (4), 590.

Milani, G., Leroy, E., Milani, F., Deterre, R., 2013.

Mechanistic modeling of reversion phenomenon in

1 2 3 4 5 6 7 8 9 10 11

0

1

2

# numerical simulation

K

0

[1/min]

Ave rage

Aver age

Average

1 2 3 4 5 6 7 8 9 10 11

0

2

4

# numerical simulation

K

1

[1/min]

Aver age

Aver age

Aver age

1 2 3 4 5 6 7 8 9 10 11

0

2

4

# numerical simulation

K

2

[1/min]

Aver age

Aver age

Aver age

1 2 3 4 5 6 7 8 9 10 11

0

0.1

0.2

# numerical simulation

K

3

[1/min]

Average

Average

Average

1 2 3 4 5 6 7 8 9 10 11

0

0.005

0.01

# numerical simulation

K

4

[1/min]

Average

Aver age

Average

0 50 100 150

0

2

4

6

8

10

12

14

16

18

20

Reversion %

10

3

(K

3

+K

4

) [1/min]

10 20 30 40 50

1

2

3

4

5

6

7

(K

1

+K

2

) [1/min]

cure time [min]

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

146

sulphur cured natural rubber vulcanization kinetics.

Polym. Test., 32, 1052.

Milani, G., Milani F., 2014a. Fast and reliable meta-data

model for the mechanistic analysis of NR vulcanized

with sulphur. Polymer Testing, 33(1), 1.

Milani, G., Milani F., 2014b. Effective closed form

starting point determination for kinetic model

interpreting NR vulcanized with sulphur. Journal of

Mathematical Chemistry, 52(2), 464.

Sun, X., Isayev, A., 2009. Cure kinetics study of unfilled

and carbon black filled synthetic isoprene rubber.

Rubber Chem. Technol., 82(2), 149.

Westlinning, H., 1970. Vulcanization of Rubber with

Aminomercaptotriazines. Rubber Chem. Tech., 43,

1194.

SimplifiedClosedFormNumericalApproachestoPredictNaturalRubberBehaviorunderSulfurCuringinStandard

RheometerTests

147