Operational Assistance System using 3-DOF Joystick with Reaction

Force Display to Load Transfer Machine in a Plane

Tomoya Kuneguchi

1

, Yoshiyuki Noda

1

, Yukinori Sago

2

and Kiyoaki Kakihara

3

1

Department of Mechanical Systems Engineering, University of Yamanashi, Takeda 4-3-11, Kofu, Japan

2

Department of Mechanical Engineering, Toyohashi University of Technology, Toyohashi, Japan

3

KER Co., Ltd, Toyokawa, Japan

Keywords:

Operational assistance, load transfer machine, 3-DOF Joystick, Reaction Force Display, Obstacles Avoidance.

Abstract:

This paper is concerned with an operational assistance system to a load transfer machine in a plane such

as a manually guided vehicle and a crane without vertical transfer. In the transfer machine, collisions with

obstacles are often occurred by the incorrect operations. Therefore, in order to avoid the obstacles to the

transfer machine, the operational assistance system using 3-DOF(3 Degree of Freedom) joystick with reaction

force display is proposed in this study. The 3-DOF joystick enables operator to manipulate the transfer machine

with back-and-forth, left-and-right, and rotation motions. And, it has motors for presenting the reaction force

on each axis. In this system, the joystick displays the reaction force which consists of the virtual elastic

force and viscosity resistance, which are controlled by PD control gains. By associating the gains in the PD

control with the distance between the obstacles and the transfer object, the joystick operation is constrained

for avoiding the obstacles. The effectiveness of the proposed operational assistance system is verified by the

experiments using the simulator of the transfer machine manipulated by the 3-DOF joystick.

1 INTRODUCTION

A load transfer machine such as a crane and an indus-

trial vehicle is widely used in industry. It is required

to transfer the load efficiently(Sawodny, Aschemann

and Lahres, 2002), (Osumi, Kubo, Yano and Saito,

2010). However, since there are some obstacles in

the transfer space, the operator has to manipulate the

transfer machine to avoid the obstacles. The skill is

required to manipulate the transfer machine. How-

ever, even if the skilled worker operates the transfer

machine, the collisions with the obstacles are often

occurred by the incorrect operation. 30 fatal accidents

by cranes occurred in Japan in 2011, of which fifteen

were the accidents by the incorrect operation(Japan

Crane Association, 2011). Including the unreported

accidents such as a near-miss accident, there are a lot

of accidents by the incorrect operation in the transfer

machines.

In order to operate safety the crane, some op-

erational assistance systems have been proposed in

the previous studies. The sway of the load in

the crane is occurred by the inappropriate opera-

tion. For suppressing the sway of the load, the op-

erational assistance system with the haptic device

was proposed(Yoneda, Arai, Fukuda and Miyata,

1999). The crane operation assistance system using

the augmented reality technology was proposed in the

study(Yi-Chen, Hung-Lin, Shin-Chung and Shang-

Hsien, 2011). In this system, the actual information

of the working environment and the virtual informa-

tion such as building information are integrated and

displayed on the monitor. However, the operational

assistance systems for avoiding the obstacles have not

been proposed in most previous studies as seen from

the above. In one of the previous studies, the oper-

ational assistance system for avoiding the obstacles

using the haptic joystick was proposed(Sato, Noda,

et.al., 2009). However, since the overall size of the

transfer object has not been considered in the sys-

tem, the collision of the obstacles and the edge of the

transfer object might be occurred. Moreover, the de-

sign method of the parameters in the joystick control

system are unclear in the paper. It is desired to de-

sign clearly the operational assistance system using

the haptic joystick with consideration of the overall

size of the transfer object for obstacles avoidance.

Recently, an omnidirectional mobile vehicle has

been developed as a next-generation personal vehi-

cle(Noda, Kawaguchi and Terashima, 2010). This

346

Kuneguchi T., Noda Y., Sago Y. and Kakihara K..

Operational Assistance System using 3-DOF Joystick with Reaction Force Display to Load Transfer Machine in a Plane.

DOI: 10.5220/0005026303460352

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 346-352

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

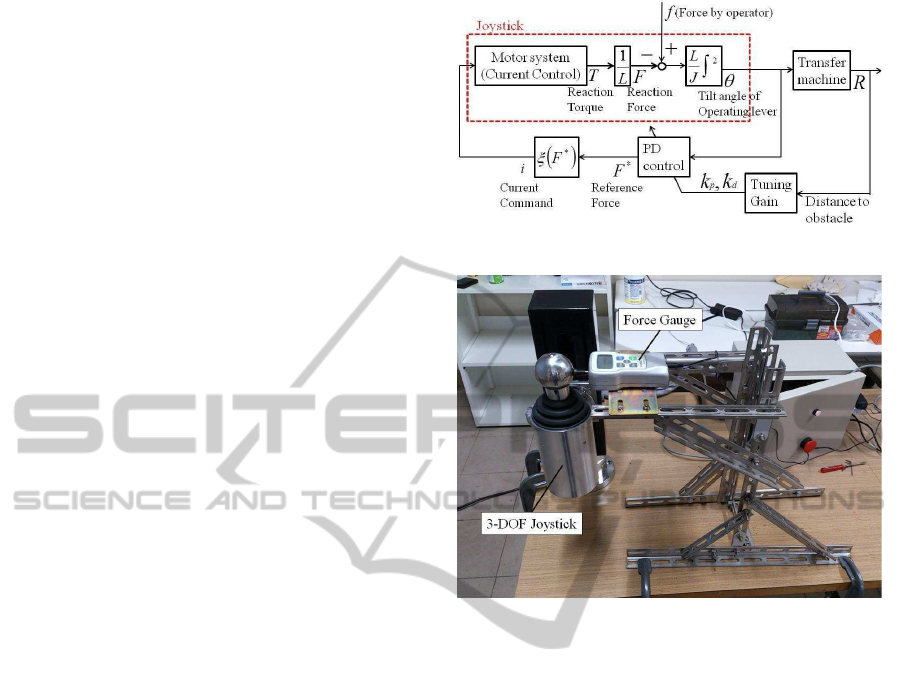

Figure 1: Crane system manipulated by 3-DOF joystick.

vehicle has 3-DOF motion with back-and-forth, left-

and-right, and rotation. However in the previous stud-

ies, the vehicle has been operated by the 2-DOF joy-

stick and switching equipment which switches be-

tween the lateral and the rotation motions. Therefore,

it cannot be transferred freely in a plane. For improv-

ing the operability of the vehicle, 3-DOF operation

device is required. On the other hand, the incorrect

operation will be increased by applying the 3-DOF

joystick. The operation device with high operability

and safety is demanded for the useful transfer ma-

chine with high degree of freedom motion.

Therefore, the present authors are developing the

operational assistance system using 3-DOF joystick

with reaction force display for the load transfer ma-

chine. The example of the application of the develop-

ing operational assistance system is shown in Figure

1. In Figure 1, the operational assistance system is

integrated into the overhead traveling crane system.

The crane system has 3-DOF transfer with back-and-

forth, left-and-right, and rotation. In order to avoid

the obstacles, the joystick operation is constrained dy-

namically by the reaction force display.

In this paper, 3-DOF joystick with the reaction

force displayed on each axis is proposed. In order to

constrain dynamically the joystick operation for the

obstacle avoidance, about 30[N] of the maximum re-

action force can be generated by the servomotors in-

stalled the joystick. Moreover, the operational assis-

tance system using the 3-DOF joystick is proposed

for operating the machine freely and safety. In this

system, the joystick displays the reaction force which

consists of the virtual elastic force and viscosity re-

sistance controlled by PD control gains. Furthermore,

by associating the gains in the PD control with the

distance between the obstacles and the transfer object,

the joystick operation is constrained for avoiding the

Figure 2: Photo of 3-DOF joystick.

Figure 3: Schematic view of 3-DOF joystick structure.

Table 1: Specifications of DC servomotors.

Rating Torque Rating Current

DC Motor (A) 23.3[mNm] 0.49[A]

DC Motor (B) 33.6[mNm] 1.48[A]

obstacles.

The effectiveness of the proposed operational as-

sistance system is verified by the experiments using

the simulator of the transfer machine manipulated by

the 3-DOF joystick.

2 3-DOF JOYSTICK

The photo and the schematic view of the 3-DOF joy-

stick proposed in this study are shown in Figures 2

and 3, respectively. This joystick has three servomo-

tors, and can provide the reaction force to operation of

back-and-forth, left-and-right, and rotation as shown

in Figure 3. The specifications of the installed mo-

tors in the joystick are shown in Table 1. The reaction

force to the back-and-forthoperation can be displayed

OperationalAssistanceSystemusing3-DOFJoystickwithReactionForceDisplaytoLoadTransferMachineinaPlane

347

by increasing the driving torque of the motor through

the reducer and the bevel gear. The reaction force to

the left-and-right operation also can be displayed by

the same structure with the back-and-forth operation.

The tilting angle of the operating lever can be detected

by the rotary encoders attached to the motors. The

motor for displaying the reaction force to the rotation

operation is installed into the operating lever. The re-

action force can be displayed by self-rotating the mo-

tor with the reducer. The rotating angle of the operat-

ing lever can be detected by the hall sensor installed

into the motor. The maximum reaction forces at the

operation point to the back-and-forthand the left-and-

right operations are 30.18[N]. The maximum reaction

torque to the rotation operation is 0.76[mNm]. They

are sufficient to constrain the operation for preventing

the incorrect operation.

3 OPERATIONAL ASSISTANCE

SYSTEM

The operational assistance system which avoid the

collision with the obstacles by the incorrect operation

using the 3-DOF joystick is proposed in this study.

The block diagram of the proposed assistance system

is shown in Figure 4.

In the proposed assistance system, the servomotor

with the current control mode is used. The reaction

torque T is generated by the motor, and the reaction

force F at the operation point is represented by di-

viding the reaction torque T by the length L of the

operating lever. The operating lever is tilted depend-

ing on the error between the reaction force F and the

force f by the operator. Here, J is the inertia moment

about the tilting center to the operating lever, and θ is

the tilting angle of the operating lever. The velocity of

the transfer machine corresponds to the tilting angle θ

of the operating lever. The reaction force F can be in-

creased by increasing the virtual elastic force and the

viscous resistance in the operational assistance sys-

tem. Therefore, the PD control to the tilting angle

θ is constructed for generating the elastic force and

the viscous resistance. Since the PD gains correspond

to the distance between the obstacles and the transfer

object, the reaction forces are increased by approach-

ing the transfer object to the obstacles. The reference

force F

∗

is generated by the PD control, and trans-

formed to the current command i through the function

ξ(F

∗

). The operational assistance system as shown in

Figure 4 is constructed to each operational axis.

Figure 4: Block diagram of operational assistance system.

Figure 5: Measurement of reaction force using force gauge.

3.1 Transform Function between

Current Command to Motor and

Reaction Force

ξ shown in Figure 4 is the function between the reac-

tion force and the current command to the motor. In

design of the function ξ, the relation between the re-

action force and the current command has to be clar-

ified. Therefore, the reaction force at the operation

point is measured by using the force gauge as shown

in Figure 5. The measurement results are shown in

Figure 6. In Figure 6, the markers are the reaction

force measured by the force gauge. The reaction force

cannot be displayed to the small current command.

On the other hand, the reaction force to the current

command over 0.3[A] is increased linearly to the cur-

rent command. The function ξ is designed by the in-

verse function to the measurement data in Figure 6.

However, the inverse function cannot be uniqueness

on the small current command. Therefore, the thresh-

old is set at the reaction force 5[N], and the inverse

function between the reaction force and the current

command is represented as

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

348

0 0.5 1 1.5

0

5

10

15

20

25

Reaction Force F [N]

Current Command [A]

Approximation

Experimental data

Threshold f

b

Figure 6: Relation between reaction force and current.

i =

(

i

a

(F

∗

), (F

∗

> f

b

)

i

a

( f

b

)

f

b

F

∗

, (F

∗

≤ f

b

),

(1)

where f

b

is the threshold, and F

∗

is the reference

force. i

a

is linear approximation of the current com-

mand to the large reaction force. In this study, the

function i

a

is represented as

i

a

(F

∗

) = α

1

F

∗

+ α

0

, (2)

where α

0

= 51.81 and α

1

= 56.04.

3.2 Derivation Method of Shortest

Distance between Obstacles and

Transfer Object

The transfer object varies widely depending on the in-

tended use. In the crane system, a long object such

as a steel beam or a cylindrical container such as a

liquid tank is transferred. Therefore, it is difficult to

recognize the accurate geometry of the transfer ob-

ject automatically. In this study, the transfer object

is replaced by the ellipse including the transfer ob-

ject as shown in Figure 7. Even the long object can

be included reasonably by the ellipse. The ellipsoidal

Figure 7: Transfer object included into ellipse and opera-

tional direction.

Figure 8: Positional relationship between ellipsoidal trans-

fer object and obstacle.

transfer object needs the 3-DOF motion with back-

and-forth, left-and-right, and rotation, and it can be

manipulated by the proposed 3-DOF joystick.

In order to generate the reaction force for the ob-

stacles avoidance, the shortest distance between the

obstacles and the ellipsoidal transfer object is derived

in this section. The relationship between the obstacle

and the ellipsoidal transfer object is shown in Figure

8. In the operational assistance system as shown in

Figure 1, the outline of the obstacles can be detected

by a laser sensor. The shortest distance is selected

from among the detected positional data, R

i

(x

i

,y

i

). At

first in the derivation method of the shortest distance,

the detected positional data on the transfer direction

are picked up as

S

d

= {R

i

(x

i

,y

i

) ∈ S| ax

i

+ b

1

< y

i

< ax

i

+ b

2

,

sgn(x

i

) = sgn(θ

x

),sgn(y

i

) = sgn(θ

y

)}, (3)

where S is the set of the detected positional data, and

S

d

is that on the transfer direction. θ

x

and θ

y

are

the tilting angles of the operating lever on x- and y-

axes, respectively. The linear functions ax

i

+ b

1

and

ax

i

+ b

2

show the tangent lines to the ellipse which

have same slope to the transfer direction of the trans-

fer object. The slope a is represented as

a =

θ

y

θ

x

. (4)

The intercept b

1

and b

2

can be derived from the tan-

gent points of the tangent line and the ellipse. The

distances |R

di

| of the detected positional data on the

transfer direction are calculated as

|R

di

| =

q

x

2

i

+ y

2

i

, ∀R

di

∈ S

d

. (5)

OperationalAssistanceSystemusing3-DOFJoystickwithReactionForceDisplaytoLoadTransferMachineinaPlane

349

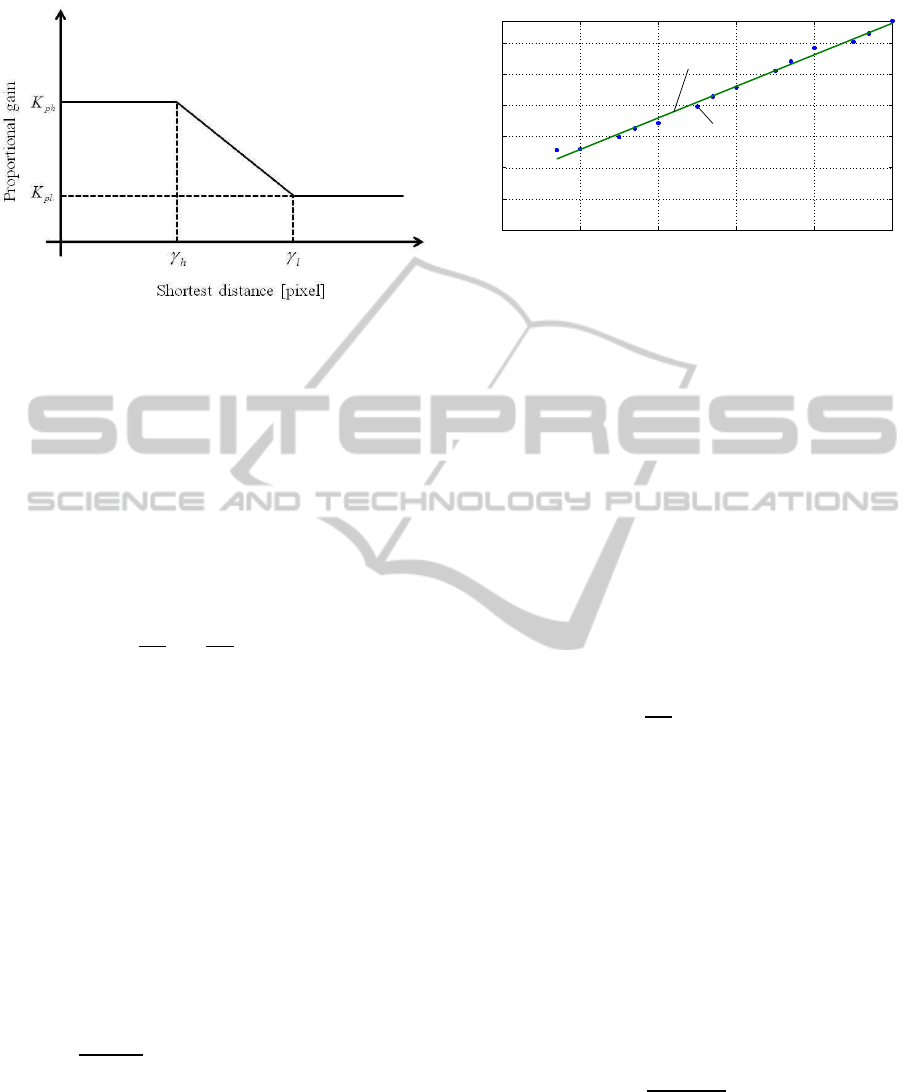

Figure 9: Relation between proportional gain and shortest

distance.

The shortest distance |R|

min

can be derived as

|R|

min

= min|R

di

|. (6)

3.3 Design of Virtual Elastic Force

In the proposed operational assistance system shown

in Figure 4, the reaction force can be represented as

J

i

¨

θ

i

+ K

di

˙

θ

i

+ K

pi

θ

i

= f

i

L, (7)

F

∗

i

=

K

di

L

˙

θ

i

+

K

pi

L

θ

i

, i = x,y, (8)

where F

∗

i

is the reference force on each axis, and K

pi

and K

di

are the proportional gain and the derivative

gain on each axis, respectively. θ

i

is the tilting an-

gle of the operating lever on each axis. In the equa-

tion (8), (K

pi

/L)θ

i

is the virtual elastic force associ-

ated with the proportional gain. The reaction force

is increased by increasing the tilting angle of the op-

erating lever by the effect of the virtual elastic force.

Then, the operating lever is pulled back to the orig-

inal attitude by large proportional gain. Therefore,

the joystick operation is constrained dynamically by

changing the proportional gain. In order to avoid the

obstacles, the relation between the proportional gain

and the shortest distance |R|

min

is represented as

K

pi

=

K

pil

,(|R|

min

> γ

l

)

K

pil

−K

pih

γ

l

−γ

h

(|R|

min

− γ

h

) + K

pih

,

(γ

h

< |R|

min

≤ γ

l

)

K

pih

,(|R|

min

≤ γ

h

), i = x, y,

(9)

where K

pil

is the small proportional gain when the

transfer object is far away from the obstacles. K

pih

is the large proportional gain when the transfer object

is close to the obstacles. γ

l

and γ

h

are the thresholds as

shown in Figure 9. The thresholds have to be satisfied

0 1 2 3 4 5

0

1

2

3

4

5

6

x 10

−3

Propotional Gain

Inertia Moment [kgm

2

]

Experimental data

Linear approximation

Figure 10: Relation between inertia moment and gain.

the following condition.

γ < γ

h

< γ

l

, (10)

where γ is the long axis of the ellipsoidal transfer ob-

ject.

3.4 Design of Virtual Viscous Resistance

As seen from the equation (7), the motion of the op-

erating lever without the viscous resistance (K

di

/L)

˙

θ

i

is the undamped vibration. Therefore, the virtual vis-

cous resistance associated with the derivative gain K

di

is designed for suppressing the vibration. Firstly, the

undamped natural frequency ω

n

can be obtained by

the free vibration of the operating lever which is oc-

curred by K

di

= 0. Then, the inertia moment J is de-

rived as

J =

ω

2

n

K

pi

, i = x,y. (11)

The inertia moment obtained from the above proce-

dure is shown in Figure 10. In this figure, the inertia

moment is increased with increasing the proportional

gain. The backlash of the bevel gear and the reducer

is regarded as the cause of varying inertia moment.

In order to design the derivative gain, the relation be-

tween the inertia moment and the proportional gain is

represented by the linear approximation as

J

(K

pi

)

= β

1

K

pi

+ β

2

, i = x,y. (12)

In this study, β

1

and β

2

are given as 1.012× 10

−3

and

1.570× 10

−3

, respectively.

Using the inertia moment and the proportional

gain, the derivative gain can be derived as

K

di

= 2ζ

q

K

pi

J(K

pi

), i = x,y, (13)

where ζ is the damping ratio. The damping ratio

should be ζ = 1 for realizing the critical damping,

theoretically. However, the noise in the detected an-

gular velocity of the operating lever is amplified by

high derivative gain, and the motion of the operating

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

350

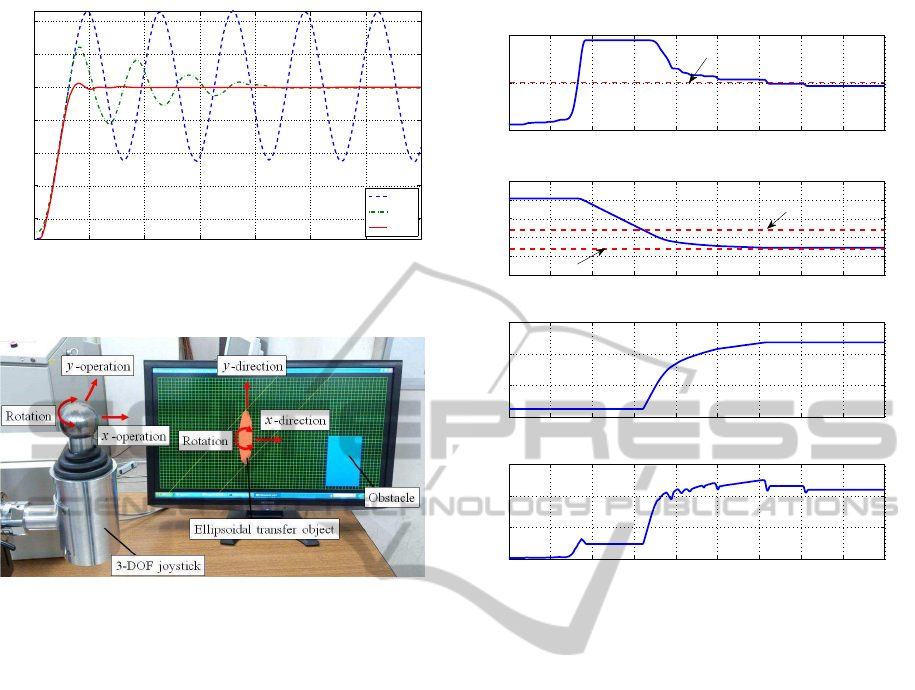

0 0.2 0.4 0.6 0.8 1 1.2 1.4

−40

−30

−20

−10

0

10

20

Time [s]

Joystick Angle[deg]

ζ=0

ζ=0.2

ζ=0.5

Figure 11: Experimental results to motion of operating lever

depended on damping ratio.

Figure 12: Photo of simulator of transfer machine manipu-

lated by 3-DOF joystick.

lever is in unstable. The damping ratio is adjusted in

the range of the damping vibration. In this study, the

damping ratio was determined as ζ = 0.5. The ex-

perimental results to the motion of the operating lever

depended on the damping ratio are shown in Figure

11. It can be seen that the vibration is suppressed by

the damping ratio ζ = 0.5.

4 EXPERIMENTAL VALIDATION

The effectiveness of the proposed operational assis-

tance system is verified by the experiments using the

simulator of the transfer machine manipulated by the

3-DOF joystick. The simulator is shown in Figure

12. The long and short axes of the ellipsoidal transfer

object are 18(pixel) and 4(pixel), respectively. The

thresholds γ

l

and γ

h

for changing the proportional

gain are given as 48(pixel) and 28(pixel). The low

and high proportional gains are K

pxl

= K

pyl

= 0.5 and

K

pxh

= K

pyh

= 5.0, respectively. The threshold γ

h

is

larger than the long axis of the ellipsoidal transfer ob-

ject. Therefore, the joystick operation is constrained

before the obstacle. In order to prevent the motion of

transfer object influenced by the fluctuating hand of

operator, we set up the dead band between the tilting

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

0

5

10

Angle of operating lever [deg]

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

0

20

40

60

80

100

Shortest distance [pixel]

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

0

2

4

6

Proportional Gain

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

0

10

20

30

Reference reaction force [N]

Time [s]

(a)

(b)

(c)

(d)

γ

h

γ

l

Limitation of Dead Band

Figure 13: Experimental results to operation on x-axis.

angle of the operating lever and the command input

to the transfer object. In this study, the dead band is

with in ±5[deg] of the angle of the operating lever.

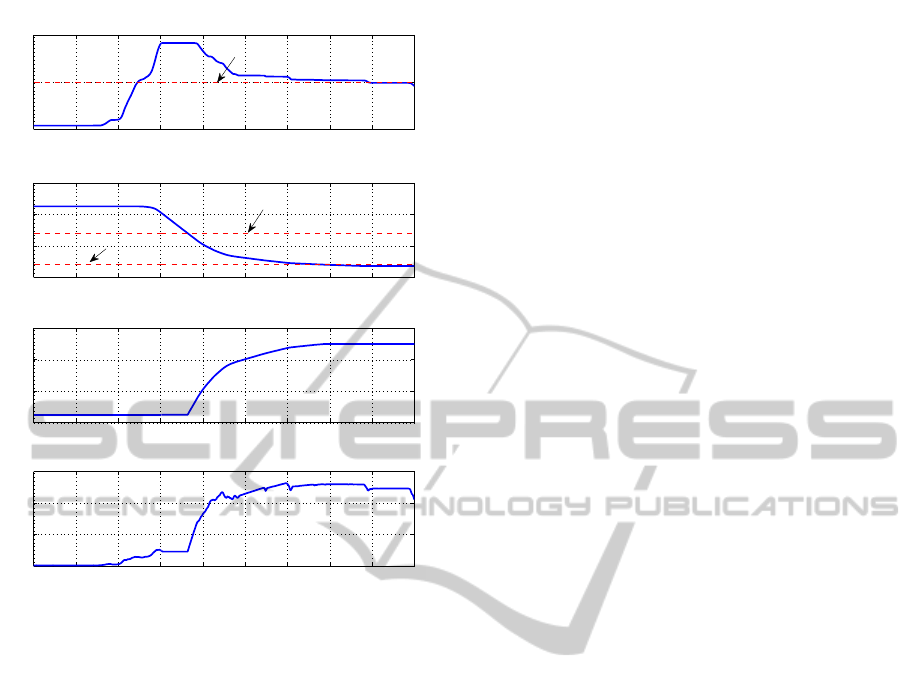

In the experiments, the transfer object is ap-

proached to the obstacle by manipulating the joystick.

The experimental results to the operations on x- and

y- axes are shown in Figures 13 and 14, respectively.

In these figures, (a) and (b) show the tilting angle of

the operating lever and the shortest distance |R|

min

,

respectively. (c) and (d) are the proportional gain K

p

and the reference reaction force F

∗

, respectively. We

assume the reference reaction force as the actual re-

action force displayed on the top of the joystick. In

figures (a), the broken line shows the limitation of the

dead band which the transfer object does not work on

the tilting angle of the operating lever within ±5[deg].

In figures (b), the broken lines show the thresholds for

changing the proportional gains. As seen from these

figures, the reaction force is increased by approaching

the obstacle, and the operating lever is pulled back to

the vertical posture. The tilting angle of the operating

lever is within the dead band, which is 5[deg]. Then,

the transfer object can be stopped before the object as

shown in Figures 13 (b) and 14 (b). Therefore, the

collision avoidance to the obstacle is realized by the

proposed operational assistance system.

OperationalAssistanceSystemusing3-DOFJoystickwithReactionForceDisplaytoLoadTransferMachineinaPlane

351

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

0

5

10

Angle of operating lever [deg]

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

20

40

60

80

Shortest distance [pixel]

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

0

2

4

6

Proportional Gain

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

0

10

20

30

Reference reaction force [N]

Time [s]

Limitation of Dead Band

γ

l

γ

h

(b)

(c)

(d)

(a)

Figure 14: Experimental results to operation on y-axis.

5 CONCLUSIONS

The 3-DOF joystick with reaction force display has

been proposed in this study. The joystick enables the

operator to manipulate intuitively the 3-DOF trans-

fer object on a plane. Furthermore, the operational

assistance system for avoiding the collision with the

obstacles has also proposed by using the 3-DOF joy-

stick. The experiments using the simulator of the 3-

DOF transfer object manipulated by the 3-DOF joy-

stick shows that the proposed operational assistance

system was effective.

In the future works, we will apply the operational

assistance system to the actual transfer machine such

as the crane system.

REFERENCES

Sawodny, O., Aschemann, H., and Lahres, S., ”An auto-

mated gantry crane as a large workspace robot”, Con-

trol Engineering Practice 10, pp.1323 - 1338, 2002.

Osumi, H., Kubo, M., Yano, S., and Saito, K., ”Devel-

opment of tele-operation system for a crane with-

out overshoot in positioning”, Proceedings of 2010

IEEE/RSJ International Conference on Intelligent

Robots and Systems, pp.5799 - 5805, 2010.

Japan Crane Association, http://www.cranenet.or.jp/, 2011.

Yoneda, M., Arai, F., Fukuda, T., and Miyata, K., ”As-

sistance system for crane operation with haptic dis-

play operational assistance to suppress round payload

awing”, Proceedings of International Conference on

Control, Robotics and Automation, pp.2923 - 2929,

1999.

Yi-Chen, C., Hung-Lin, C., Shin-Chung, K., and Shang-

Hsien, H., ”A smart crane operations assistance sys-

tem using augmented reality technology”, Proceed-

ings of 28th International Symposium on Automation

and Robotics in Construction, pp.643 - 649, 2011.

Sato, R., Noda, Y., Miyoshi, T., Terashima, K., Kakihara,

K., Nie, Y., and Funato, K., ”Operational support

control by haptic joystick considering load sway sup-

pression and obstacle avoidance for intelligent crane”,

Proceedings of Annual Conference of the IEEE Indus-

trial Electronics Society, pp.2321 - 2327, 2009.

Noda, Y., Kawaguchi, A., and Terashima, K., ”A mecha-

tronics vision for smart wheelchairs”, Mobile Robots

Navigation, Intech, pp.609 - 628, 2010.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

352