System Reactivity Components in Cellular Manufacturing Subjected

to Frequent Unavailability of Physical and Human Resources

Sameh M. Saad

1

and Carlos R. Gómez

2

1

Department of Engineering and Mathematics, Sheffield Hallam University, Sheffield, U.K.

2

Department of Materials, Mechanical and Manufacturing, Nottingham University, Nottingham, U.K.

Keywords: Cellular Manufacturing, Internal Disturbances, Simulation.

Abstract: In manufacturing systems, different types of disturbances influence system’s performance. In this paper

those components within a manufacturing cell contributing to maintain a higher performance, despite the

influence of internal disturbances such as machine breakdowns and operator unavailability, are investigated.

Discrete event simulation is used to model the processing and material handling subsystems within a

cellular manufacturing. Experimentation is conducted using a full factorial design and data analysis is

performed using analysis of variance. The results indicated that, in terms of systems reactivity, processing

subsystems aspects such as the skills of the operators, the capacity of the buffers and the duration of

machine set-ups are more efficient in coping with work-in-progress (WIP) resulting from the effect of

disturbances than aspects related to the material handling sub system.

1 INTRODUCTION

In a current economic environment characterised by

increasing uncertainty, manufacturing systems are

more vulnerable to the effects of unpredictable or

random events commonly referred to as

manufacturing disturbances. A particular type of

disturbances includes all the disrupting events

occurring within the limits of manufacturing

systems. These are known as internal disturbances

and are characterised by the limited availability of a

specific resource (Saad and Gindy, 1998). In order

to remain competitive in an environment of

uncertainty, it is necessary for manufacturing

systems to identify those components providing the

system with the capability to efficiently perform

under such disrupting conditions.

Manufacturing systems are determined by a

transformation process where inputs are converted

into outputs by means of an internal process. The

internal process is an assembly of interconnected

components (e.g. machines, material handling

devices and human resources) whose interaction

determines the outcome of the system. A cellular

system is a particular layout configuration of a

manufacturing system where different types of

machines are grouped together according to the

process combination occurring within a family of

parts. Among some benefits of cellular

manufacturing, Williams (1994) reported an

increased efficiency by reducing material handling

and transportation cost. Compared to other layout

configurations such as functional layouts, where

machines are grouped together based on similar

functions, cellular systems offer better results in

terms of work-in-process inventory, particularly

when there are small batches and short run times

involved (Logendran and Talkington, 1997).

Eckstein and Rohleder (1998) claimed that cellular

configurations also offer more advantages in terms

of human issues such as the operator’s learning rate

and the number of workers employed.

Modern manufacturing systems operate under

uncertain conditions originated within the

boundaries of the system; such internal conditions

range from uncertainty about processing times to

uncertainty about resources’ reliability. Having into

consideration that, for a considerable number of

organizations, it is prohibitive to acquire additional

capacity in order to guarantee a safe operation

against uncertainty, the only way for manufacturing

systems to meet deadlines is by using available

resources. Reactivity has been defined as the

capacity if the system to react to internal

disturbances and constitutes a significant aspect

373

Saad S. and R. Gómez C..

System Reactivity Components in Cellular Manufacturing Subjected to Frequent Unavailability of Physical and Human Resources.

DOI: 10.5220/0005038803730384

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 373-384

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

regarding the evolution of manufacturing systems.

Reactivity, according to Ounnar and Ladet (2004),

is achieved by exploiting the flexibility of physical

resources.

On the one hand, processing machines are the

most pervasive physical resources in manufacturing

systems. On the other hand, the human element is

another physical resource mainly associated with

control tasks within such systems. Both types of

resources have received significant research

attention, particularly in issues regarding the

reactivity of manufacturing systems. Regarding

processing machines, one important aspect of system

reactivity is the capability of machines to efficiently

perform despite the presence of frequent

breakdowns, which is one of the most inherent

disturbances within systems’ limits. Dynamic

scheduling, where real time decisions are made in

order to offer a rapid response to disturbances, is one

of the most favoured approaches to cope with

machine breakdowns. Nihat et al. (2006) claimed

that it is possible to reduce the adverse impact of

machine breakdowns by using intelligent scheduling

policies that exploit available information about

sources of uncertainty. They proposed a stochastic

scheduling approach to characterize uncertainty

using probability distributions and generated optimal

policies under different distributional assumptions.

Ounnar and Ladet (2004) investigated reassignment

strategies and proposed a multi-criteria algorithm for

reassigning parts from a broken down machine into

an alternate machine and by considering the best

compromise between the variables time, cost and

machine reliability. Ozmutlu and Harmonosky

(2004) stated that conventional re-routing strategies

become more difficult to achieve as the complexity

of manufacturing system increase; therefore they

proposed a threshold –based selective rerouting

strategy to minimize the mean flow time in a system

with machine breakdowns. Their strategy achieved

superior results compared to other strategies and also

has the advantage of being simpler in its application.

Chen and Chen (2003) recognised that a frequent

rescheduling due to recurrent machine breakdowns

can make the behaviour of the system hard to

predict, reducing the effectiveness of dynamic

scheduling . To avoid this, the authors proposed

adaptive scheduling, which consist in updating the

job ready time and completion time, and the

machine status on a rolling horizon basis; they also

suggested considering machine availability in

generating schedules.

Other approaches to cope with machine

breakdowns look at the improvement of repair times

and facilities in order to reduce machine down time,

the implementation of preventive maintenance

policies to either avoid or reduce failures, the

consideration of wok-in-process inventory buffers as

a safety measure, etc (Buffa, 1972). Taylor et al.

(1982) used network modelling in order to analyse

alternative approaches for maintaining desired

levels of system output in the presence of machine

breakdowns. Hillier and So (1991) analysed the

effects of inter-stage storage on the performance of a

system subjected to machine breakdowns; they

concluded that, in the event of a machine

breakdown, a suitable inter-stage storage capacity

helps to provide parts for downstream machines,

reducing the effect of the disturbance. In a very

unconventional approach Liao and Chen (2004)

proposed maximising set-up time subject to a due

date constraint in order to reduce machine

breakdowns rate.

Concerning the human resource element of

manufacturing systems, aspects particularly related

to the level of skills and the extent of human

resource involvement in manufacturing processes,

have been investigated as determinants of system’s

reactivity.

Concerning the human element, it is clear that

despite increasing automation of manufacturing

systems, the human element is still an essential

component (Hwang et al., 1984). It has been

demonstrated that success in the implementation of

advanced manufacturing technology is due not to

technical failures but to human related issues such as

the capability of workers in terms of skills,

knowledge and attitude (Chung, 1996). In a study

carried out by Kahn and Lim (1998), the authors

found strong evidence that productivity growth was

increasingly concentrated in the more skill-intensive

manufacturing industries. Pagell et al. (2000)

pointed out that a key advantage of skilled workers

is their ability to more easily cope with increasing

complexity and uncertainty; however, the higher

costs associated to high skilled workers and the

dependence upon scarce resources can be

discouraging factors. This may just be the reason

why despite of the existing evidence on the

relationship between productivity and a skilled

workforce, a considerable number of manufacturing

organisations still rely on low skilled workers.

Regarding the fact of manufacturing systems and

their current uncertain environment, the link

between uncertainty and an increased need for more

flexible workers has been established. There is

extensive research focusing mostly on the impact of

human resource practices on the performance of

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

374

manufacturing systems. Among some of the relevant

research, Pagell et al. (2000) suggested that a poorly

developed human resource strategy often leads to

low performance levels in environments of advance

manufacturing technology. Huselid (1995)

investigated the impact of human resource

management practices, such as new skills

acquisition, on corporate financial performance. The

authors suggested that such practices lead to an

improved performance, particularly in terms of

employee turnover and productivity. Similarly,

Jayaram et al. (1999) also investigated the impact of

common human resource practices on a series of

performance measures, namely cost, quality,

flexibility and time. The authors found a strong

positive relationship between employee-skills

related factors and performance. Udo and Ebienfung

(1999) confirmed such relationship by investigating

the impact of human factors, such as employee

training, on performance indicators like ROE,

reduced cost, quick throughput , competitiveness,

control, response, improved condition and quality.

The purpose of this study is to understand how

the key components of a cellular manufacturing

system can contribute to system’s reactivity. In this

section, it has been mentioned that components such

as machines and human workers may possess

particular characteristics or abilities that make them

able to individually contribute to a better system

performance. In this study the technical aspect of

manufacturing systems, represented by machines

and material handling equipment, is combined with

the human aspect in order to identify those features

that provide the system with the capability to

perform under uncertain environments characterised

by frequent machine breakdowns and frequent

operator unavailability.

The objective of this study is achieved by using

discrete event simulation combined with statistical

design of experiments. Simulation has enabled the

representation of a complex manufacturing

environment and a full factorial design of

experiments has made possible the consideration of

the interactions occurring between all the

components within the defined system. As opposed

to other research on the topic of system reactivity,

this study looks at a combination of factors and

different experimental scenarios. This consideration

of a bigger picture enables a better understanding of

system reactivity and the alternative ways to achieve

it.

2 RESEARCH

METHODOLOGIES

2.1 Simulation Model

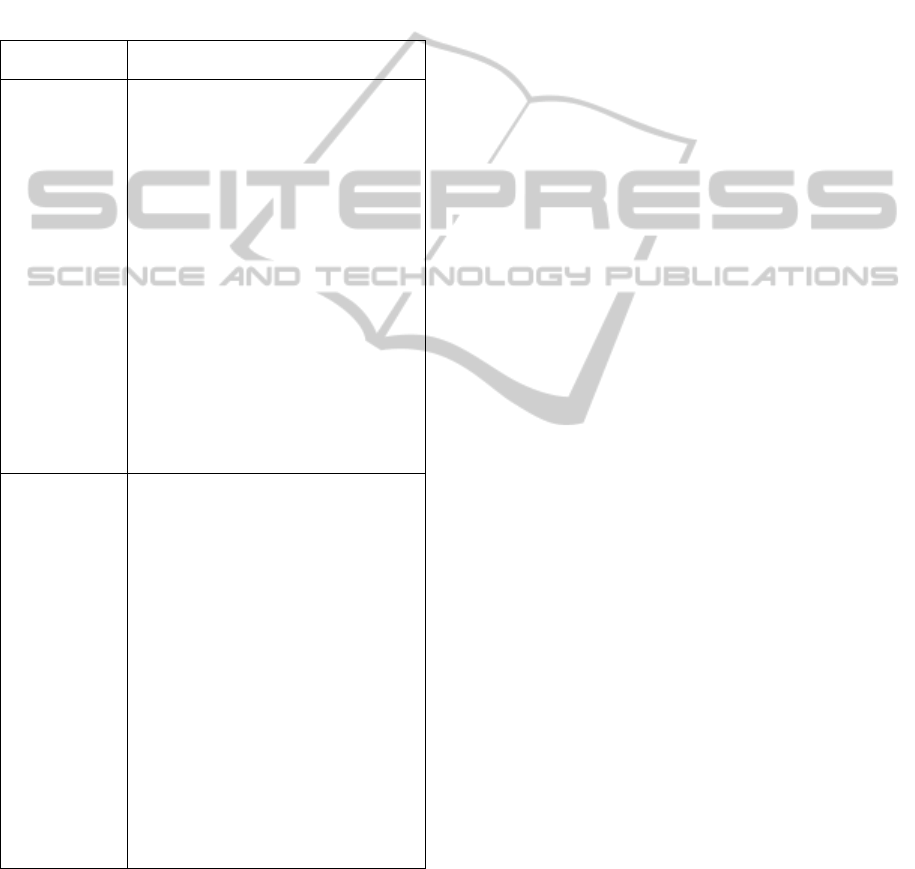

The cellular manufacturing system considered in this

paper consists of nine work centres. Each work

centre is composed of one input buffer, one

machine, and one output buffer. Parts arrive one at

time into the system following a representative

probability distribution. A loading area receives five

different types of parts corresponding to five

different products. As soon as ten parts of a

particular type are available in the loading area,

those parts are pushed into their corresponding

processing route. Each part type follows a specific

processing route with different processing times.

When a batch of parts is delivered to a work centre

the parts are directed into an input buffer first.

Afterwards, a machine operator collects one part

from the input buffer and loads it into the machine

for its processing. The operator stays next to a

machine during the whole machine processing time.

Once the machine finishes processing the part the

operator takes the part and places it into an output

buffer. Both the machine and the operator become

available for the next part to be processed. Parts

placed in output buffers are ready to be taken to the

following work centre along the processing route.

The flow of parts between the work centres is

assisted by an AGV based material handling system.

After parts have gone through all the processes

along the route they are delivered to an unloading

area from where they are subsequently shipped to

customers. The described manufacturing system is

represented in figure 1.

Figure 1: Manufacturing system layout.

Workcentre

1

Workcentre

2

Workcentre

3

Workcentre

6

Workcentre

5

Workcentre

4

Workcentre

7

Workcentre

8

Workcentre

9

Loadingarea

Unloadingarea

AGV

SystemReactivityComponentsinCellularManufacturingSubjectedtoFrequentUnavailabilityofPhysicalandHuman

Resources

375

2.2 Operating Assumptions

The system represented in figure 1 operates under

the following assumptions:

2.2.1 Parts

Parts arrive in the system one at a time and

following an exponential distribution with an

average inter-arrival time of 45 minutes. The

exponential distribution has been selected

because of the existing resemblance between

such distribution and the inter arrival times for

real world systems (Law and Kelton, 2000).

There are five different products involved; each

product with different processing requirements,

i.e. different processing times and routes. Process

routing is fixed for each of the products.

2.2.2 Machines

Each machine represents a specific

manufacturing process within the system; they

can process only one piece at a time.

Although all of the machines are assumed to

follow a normal distribution in both processing

and set up times, the times are different from

each other.

There is a different usage cost per minute

associated with each machine.

Machines do not have any automation level,

therefore each machine do require an operator.

It is assumed that all machines breakdown from

time to time, consequently a different efficiency

level has been predefined for each machine.

When machines fail, repairs are assumed to be

carried out by external personnel (not considered

for the purposes of this research). Machine

repairs are assumed to follow an exponential

distribution with different average times for each

machine.

2.2.3 Buffers

Blocking does not occur.

Buffer capacity is limited; all the buffers have

the same capacity. There is a storage cost per

item per minute associated with the capacity, i.e.

the higher the capacity the higher the storage

cost.

Parts in buffers are prioritized according to FIFO

dispatching rule, i.e. parts are dispatched either

into a machine or vehicle considering a first

come first served rule.

2.2.4 Operators

Operators have different abilities; in

consequence labour cost is associated with the

skill level.

Operators are assumed not to be always

available, therefore different availability

percentages and absence times have been

specified for each operator.

Travelling times for operators have not been

considered.

2.2.5 Automated Guided Vehicle

The material handling system is totally

independent from human operators.

The AGV travels at a constant speed along a

fixed route connecting all the work centres.

Material handling costs are omitted and no

vehicle breakdowns are assumed.

The AGV’s travelling time is determined based

on its speed.

2.3 Model Verification

Model verification can be carried out in three

different and complementary ways: Checking the

code, performing visual checks, and inspecting

output reports (Robinson, 1994). Code checking was

facilitated by the capabilities of the simulation

software, which made possible to interactively check

the coding line by line. Visual checks were

performed by keeping track of parts progressing

throughout the system, allowing the behaviour of all

the components intervening along the process to be

monitored. Additionally, the model was run in an

event-by-event mode in order to complement the

verification process.

This verification procedure made possible to

guarantee that each element within the model would

behave as it was originally intended. The last

method of model verification consisted in checking

the outputs of the main components within the

model; to do so 30 replications, each with a run time

of 400 simulation-hours, were conducted. After

analysing some of the most important system

outputs it was possible to confirm that all the model

components performed according to what had been

defined during the model coding process.

2.4 Model Validation

Model validation provides the confidence during the

experimentation stage and is basically concerned

with the extent to which a certain model is

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

376

representative of a real system. The level of

representation will be judged upon the viability of

making decisions based on the information provided

by the simulation model. Ideally, a model would be

better validated when compared to a real system

(Pidd, 1993); however, models do not always

represent real systems. Because the latter is the case

in the present research, it was not necessary to

compare the model with either empirical data or the

behaviour of a real system (Maki and Thompson,

2006).

Validation techniques are classified in two

groups, namely subjective techniques and objective

techniques. Objective validation-techniques do

require the existence of real systems in order to

establish input-output comparisons between systems.

Subjective techniques, as their name imply, does not

necessarily require the existence of a real system

since they are more dependent on the experience and

“feelings” of its developers (Banks, 1998). The

proposed model has been validated using a

sensitivity analysis as a subjective validation

method. The sensitivity analysis capability is a built-

in feature in Simul8; its function is to test the

assumed probability distributions in terms of how

sensitive the results are to changes in these inputs. A

number of probability distributions particularly

related to machine processing times and set-ups have

been randomly selected to be tested. The sensitivity

analysis confirmed the validity of the assumptions.

3 EXPERIMENTAL DESIGN

The experimental design of this study was concerned

with:

(i) Selecting the response variables;

(ii) Determining the model running time;

(iii) Choosing the experimental factors and

settings; and

(iv) Defining the statistical design of the

experiments.

3.1 Selection of Response Variables

The performance of the investigated manufacturing

system was measured in terms of three

complementary response variables, namely number

of completed parts, manufacturing cost, and average

time in the system.

3.2 Model Running Time

In a simulation model, the total running time

consists of a warming-up period, during which the

model reaches normal operating conditions, and a

run length period, during which the model collects

results. In order to determine the model warm-up

period Welch’s graphical method was used. In this

method, the model will be run several times with

different random number seeds in order to calculate

a mean average of a key output for specific periods

of time, afterwards moving averages are calculated

(Robinson, 1994). For the proposed model, Welch’s

method indicated a minimum warm-up period of 50

hours (Welch, 1983).

On the other hand, the run length period of the

simulation model was determined by means of

another graphical approach described by Robinson

(1994). According to such approach, a minimum run

length period of 220 hours was required to gather

enough data.

3.3 Experimental Factors

Considering that this study has a special interest in

the physical components of manufacturing systems,

the design factors were grouped in aspects

concerning the two main subsystems in the model,

i.e. work centres and the handling of material. See

Table 1 below.

Table 1: Design factors.

Subsystem

Aspect

(Design factor)

Definition

Work centre

The skill level

of operators

It is determined by the

number of different

machines a single

operator can control.

The capacity of

buffers

It is related to the

maximum number of

parts the system is able to

hold.

The duration of

machine

set-ups

It is the time it takes for

machines to switch from

producing one type of

part to producing a

completely different part.

Material

handling

system

The number of

AGVs

It is related to the total

number of material

handling vehicles within

the system.

The speed of

AGVs

It is the distance covered

by material handling

vehicles during a specific

period of time.

The loading

capacity of

AGVs

The maximum number of

parts a material handling

vehicle can transport

between work centres.

SystemReactivityComponentsinCellularManufacturingSubjectedtoFrequentUnavailabilityofPhysicalandHuman

Resources

377

4 MODELS SCENARIOS

In order to reflect the effects of internal disturbances

and taking into consideration technological and

human resources, two different noise factors were

considered, namely an increase of machine

breakdowns and an increase in operator

unavailability. See Table 2 below for a definition of

each disturbance scenario.

Table 2: Internal disturbances.

Disturbance Definition

Machine

breakdowns

The purpose of this scenario is to

identify system components

contributing to maintain a higher

performance when there are recurrent

failures in machines throughout the

system. It is widely known that when

a manufacturing system does not have

the capability to cope with frequent

machine breakdowns, the system will

eventually come to a stop as a result

of increasingly accumulating WIP

inventory.

To simulate this scenario, the

original machine efficiencies, ranging

between 83% and 96%, have been

decreased. The new machine

efficiencies ranging between 60% and

70% have been randomly assigned to

each machine within the system.

Operator

unavailability

In this scenario, the system is subject

to long unavailability periods of

human operators in order to identify

suitable system’s responses. In a

similar way to the previous scenario,

the unavailability of human resources

for long periods of time can

significantly affect performance by

interrupting the production flow along

the system.

To simulate this scenario original

operator availability percentages have

been decreased from a range between

96% and 97% to a range between

91% and 95%. The average absence

time per operator ranges from 480 to

600 minutes. Both availability

percentages and absence times are

randomly assigned to operators.

There is a direct relationship between these two

scenarios given that both are characterised by the

unavailability of a specific resource during a period

of time; however, the aim of each scenario is

different since two different aspects of resource

unavailability are examined. The machine

breakdowns scenario examines the aspect of

frequency of unavailability, whereas the scenario of

operator unavailability examines the aspect of the

duration of resource unavailability.

4.1 Factor Levels and Range

The objective of the experiment is to identify the

factors with a higher influence on the response

variable, it is recommended to keep a low number of

factor levels, with a relatively large range between

levels (Montgomery, 2009). After establishing and

testing a series of ranges for each of the considered

factors, the levels and ranges shown in Tables 3 and

4 were chosen for the factors in the two considered

scenarios.

Note that factor levels are different in both tables

because each table corresponds to a specific scenario

where the effect of a particular disturbance was

analysed before choosing adequate factor levels.

4.2 Number of Necessary Replications

The number of necessary replications for each

simulation scenario was determined by calculating a

maximum error estimate out of a series of initial

model replications. The maximum error estimate

together with a desired error was taken into account

to determine the required number of replications for

each model. According to such calculation, a

minimum of 250 replications per model were

enough to guarantee statistical reliability at a 95%

confidence interval.

4.3 Data Structuring and Analysis

The simulation experiments were conducted

according to a complete factorial experimental

design , which was a suitable design due to the fact

that possible factor interactions needed to be

considered (Mason et al., 2003). Considering that

there were 6 design factors involved, each at two

levels, a 2

6

full factorial design was employed.

Given the high variation in the resulting data related

to the responses cost and time, the original data has

been normalized using a log transformation.

Subsequently an analysis of variance was conducted

to identify the significant factors. Main effects plots

and interaction plots were used to identify factor

levels and factor interactions respectively. Minitab

was the statistical software used to analyse the data

provided by each simulation scenario.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

378

Table 3: Frequent machine breakdowns scenario: Factor levels.

FACTOR DESCRIPTION LEVEL 1 LEVEL 2

A

Operator skills

4 unskilled operators and 2 semi-

skilled operators.

3 semi-skilled operator and 3 skilled

operators

B

Buffer capacity

Buffer capacity of up to 10 parts; cost

per item per minute $0.010.

Buffer capacity of up to 29 parts; cost

per item per minute $0.030.

C

Number of vehicles 1 AGV. 4 AGVs.

D

Vehicle speed Vehicle speed 5 km/hr. Vehicle speed 60 km/hr.

E

Loading capacity of

AGV

3 parts loading capacity. (load/unload

= 0.5 min)

10 pieces loading capacity (load/unload

= 1.2 min)

F

Machine set-ups

duration

Set-up time between 1 and 5 minutes. Set-up time between 20 and 29 minutes.

Table 4: Frequent operator unavailability scenario: Factor levels.

FACTOR DESCRIPTION LEVEL 1 LEVEL 2

A

Operator skills

4 unskilled operators and 2 semi-

skilled operators.

2 semi-skilled operator and 4 skilled

operators.

B

Buffer capacity

Buffer capacity of up to 10 parts; cost

per item per minute $0.010.

Buffer capacity of up to 29 parts; cost

per item per minute $0.030.

C

Number of vehicles 1 AGV. 5 AGVs.

D

Vehicle speed Vehicle speed 5 km/hr. Vehicle speed 80 km/hr.

E

Loading capacity of

AGV

4 parts loading capacity.

(load/unload = 0.5 min)

10 pieces loading capacity (load/unload

= 1.2 min)

F

Machine set-ups

duration

Set-up time between 6 and 10

minutes.

Set-up time between 20 and 29 minutes.

5 ANALYSIS AND RESULTS

5.1 Machine Breakdowns Scenario

The analysis of variance of the results, in terms of

each of the three considered response variables, has

been calculated for this scenario. Tables 5, 6, and 7

show the ANOVA tables for the responses number

of parts, cost, and average time in the system

respectively. Note that the statistical package used to

analyse the results – Minitab – automatically omits

those main factors whose direct contribution to the

response is not significant. For this reason the factor

vehicle speed is not included in Table5 and the

factor loading capacity is not considered in Tables 6

and 7.

Table 5: ANOVA table for the response number of parts.

Source DF SS MS F P

Operators skills 1 0.60567 0.60567 11.03 0.002*

Buffer capacity 1 2.15831 2.15831 39.30 0.000*

Number of vehicles 1 0.00838 0.00838 0.15 0.698

Loading capacity 1 0.11816 0.11816 2.15 0.149

Set up duration 1 0.05766 0.05766 1.05 0.311

Operators skills*Loading capacity 1 0.47699 0.47699 8.69 0.005*

Operators skills*Buffer capacity 1 0.27227 0.27227 4.96 0.031

Operators skills*Number of vehicles 1 0.00296 0.00296 0.05 0.818

Buffer capacity*Number of vehicles 1 0.06154 0.06154 1.12 0.295

Buffer capacity*Loading capacity 1 0.00439 0.00439 0.08 0.779

Buffer capacity*Set up duration 1 0.00152 0.00152 0.03 0.868

Loading capacity*Set up duration 1 0.00197 0.00197 0.04 0.851

Operators skills*Buffer capacity* 1 0.35865 0.35865 6.53 0.014*

Number of vehicles

Buffer capacity*Loading capacity* 1 0.37574 0.37574 6.84 0.012*

Set up duration

Error 49 2.69103 0.05492

Total 63 7.19523

S

= 0.234348 R

-

S

q = 62.60% R

-

S

q(adj) = 51.91%

SystemReactivityComponentsinCellularManufacturingSubjectedtoFrequentUnavailabilityofPhysicalandHuman

Resources

379

Table 6: ANOVA table for the response cost.

Table 7: ANOVA table for the response time.

In Tables 5, 6, and 7, low p-values, at alpha =

0.05, identify those important main factors and

interactions. To make the identification easier,

significant factors and interactions have been

marked with a *. Even though the analysis of

variance identified significant factors and

interactions, it was necessary to confirm their level

of significance by looking at the percentage of

contribution of each factor and factor interaction.

Percentage of contribution is an indication of the

weight of each factor and factor interaction in

relation to the response variable; Percentage of

contribution calculation is part of Minitab’s

capabilities. Table 8 below shows these calculations

of the identified significant factors and interactions

as calculated by Minitab.

See Table 8 for the percentage of contributions

of the important factors and interactions to the

related response variable.

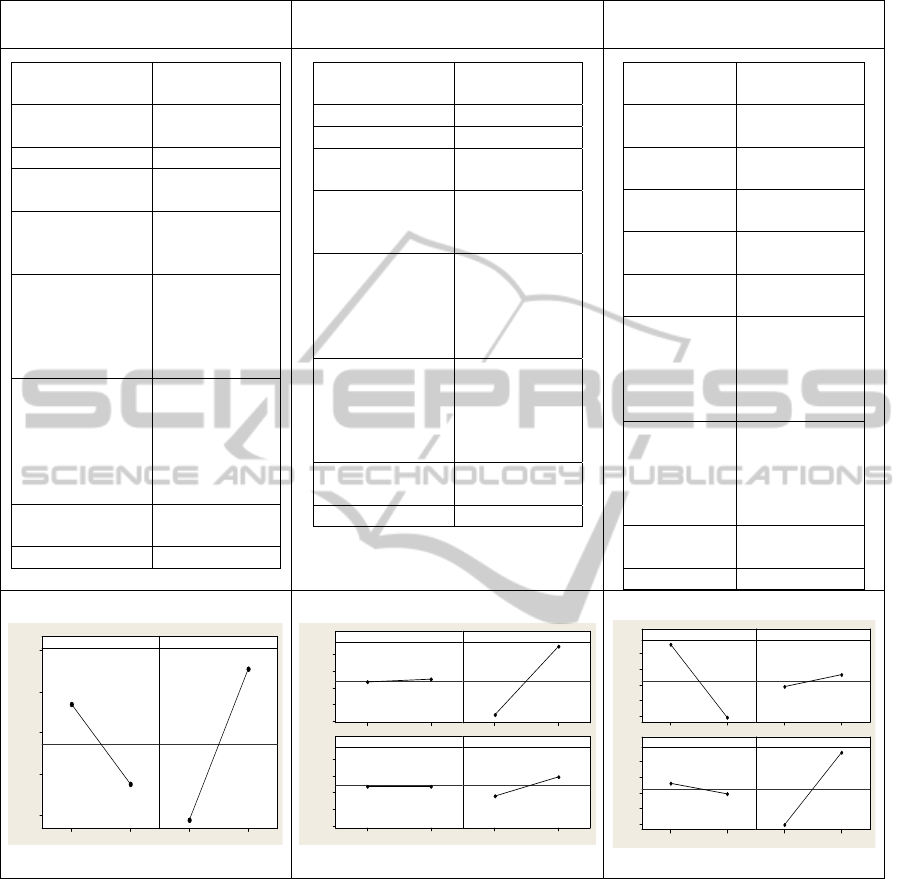

Regarding the response number of completed

parts, the information presented in Table 8 confirms

the results presented previously in Table 5. From

upper left section of Table 8, it can be noticed that

the combined percentage of contribution of the

factors operators’ skills and buffer capacity was of

approximately 39%. Additionally, the contribution

of the two significant interactions adds up to slightly

over 10%. As evidenced by the main effect plot in

the lower left section of Table 8, buffer capacity at

the highest level was the most important factor in

terms of number of completed parts; operators’ skill

at the lowest level was the second important factor.

Concerning the response cost, the percentage

contribution section at the upper middle section of

the table shows that only two out of the four

important factors identified in Table 6 were in fact

significant; those were buffer capacity and set-up

duration, both with a combined percentage

contribution of approximately 98%. Interaction’s

contribution was negligible. The main effect plot at

the lower middle of the table shows that buffer

capacity at its lowest level was the most significant

factor followed by set-up duration at its lowest level.

In relation to the response time in the system, the

percentage contribution section at the upper right

corner of Table 8 confirms that only 2 out of the

originally 4 identified important factors were

actually significant; those were operators’ skills and

set-up duration, both with a combined percentage

contribution of approximately 93%. No significant

interactions were presented. The main effects plot in

the lower right section of Table 8 indicates that the

factor operators’ skills at its highest level and set-up

duration at its lowest level were the only significant

factors in terms of a minimum time in the system.

5.2 Operator Unavailability

Similarly to the previous scenario, Minitab

automatically excluded those insignificant factors in

the analysis of variance, which are presented in

Tables 9, 10 and 11 below.

Table 8: ANOVA table for the response number of parts.

Source DF SS MS F P

Operators skills 1 0.002607 0.002607 1397.28 0.000*

Buffer capacity 1 0.487377 0.487377 261253.72 0.000*

Number of vehicles 1 0.000016 0.000016 8.52 0.005*

Vehicle speed 1 0.000002 0.000002 1.18 0.282

Set up duration 1 0.035603 0.035603 19084.53 0.000*

Operators skills*Buffer capacity 1 0.006888 0.006888 3692.30 0.000*

Operators skills*Number of vehicles 1 0.000022 0.000022 11.69 0.001*

Operators skills*Set up duration 1 0.000383 0.000383 205.40 0.000*

Buffer capacity*Number of vehicles 1 0.000038 0.000038 20.25 0.000*

Buffer capacity*Vehicle speed 1 0.000011 0.000011 5.66 0.022

Buffer capacity*Set up duration 1 0.000389 0.000389 208.40 0.000*

Number of vehicles*Vehicle speed 1 0.000000 0.000000 0.19 0.669

Number of vehicles*Set up duration 1 0.000103 0.000103 55.25 0.000*

Vehicle speed*Set up duration 1 0.000107 0.000107 57.50 0.000*

Operators skills*Buffer capacity* 1 0.000290 0.000290 155.68 0.000*

Set up duration

Buffer capacity*Vehicle speed* 1 0.000013 0.000013 6.93 0.011

Set up duration

Number of vehicles*Vehicle speed* 1 0.000048 0.000048 25.52 0.000*

Set up duration

Error 46 0.000086 0.000002

Total 63 0.533982

S = 0.00136584 R-Sq = 99.98% R-Sq(adj) = 99.98%

Source DF SS MS F P

Operators skills 1 0.0612929 0.0612929 8727.27 0.000*

Buffer capacity 1 0.0013389 0.0013389 190.64 0.000*

Number of vehicles 1 0.0000364 0.0000364 5.18 0.028

Vehicle speed 1 0.0014422 0.0014422 205.34 0.000*

Set up duration 1 0.0597981 0.0597981 8514.42 0.000*

Operators skills*Buffer capacity 1 0.0014947 0.0014947 212.82 0.000*

Operators skills*Number of vehicles 1 0.0002010 0.0002010 28.61 0.000*

Operators skills*Vehicle speed 1 0.0001284 0.0001284 18.28 0.000*

Operators skills*Set up duration 1 0.0030511 0.0030511 434.43 0.000*

Buffer capacity*Number of vehicles 1 0.0000356 0.0000356 5.07 0.029

Buffer capacity*Vehicle speed 1 0.0000016 0.0000016 0.22 0.640

Buffer capacity*Set up duration 1 0.0001578 0.0001578 22.48 0.000*

Number of vehicles*Vehicle speed 1 0.0001291 0.0001291 18.38 0.000*

Number of vehicles*Set up duration 1 0.0003161 0.0003161 45.01 0.000*

Vehicle speed*Set up duration 1 0.0003820 0.0003820 54.39 0.000*

Operators skills*Buffer capacity* 1 0.0000464 0.0000464 6.61 0.014

Number of vehicles

Operators skills*Buffer capacity* 1 0.0002124 0.0002124 30.24 0.000*

Set up duration

Operators skills*Number of vehicles*1 0.0000465 0.0000465 6.61 0.014

Set up duration

Number of vehicles*Vehicle speed* 1 0.0001051 0.0001051 14.97 0.000*

Set up duration

Error 44 0.0003090 0.0000070

Total 63 0.1305251

S = 0.00265012 R-Sq = 99.76% R-Sq(adj) = 99.66%

Source DF SS MS F P

Operator skills 1 72.740 72.740 209.35 0.000*

Buffer capacity 1 50.297 50.297 144.76 0.000*

Number of vehicles 1 3.038 3.038 8.74 0.005*

Loading capacity 1 0.869 0.869 2.50 0.119

Operator skills*Buffer capacity 1 30.792 30.792 88.62 0.000*

Operator skills*Loading capacity 1 2.858 2.858 8.22 0.006*

Error 57 19.805 0.347

Total 63 180.398

S = 0.589452 R-Sq = 89.02% R-Sq(adj) = 87.87%

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

380

Table 9: Significant factors and factors interactions in terms of three response variables; machine breakdowns.

Number of completed parts Cost Time in the system

Model term

Percentage of

contribution

Operators’

skills

8.46 %

Buffer capacity 29.97%

Rest of main

factors

2.3%

Operators’

skills*Loading

capacity

6.66%

Operators’

skills*Buffer

capacity*Numb

er of vehicles

5.01%

Buffer

capacity*Loadi

ng

capacity*Set-up

duration

5.21%

Rest of

interactions

42.39%

Total 100%

Model term

Percentage of

contribution

Buffer capacity 91.27%

Set-up duration 6.67%

Rest of main

factors

0.49%

Operators’

skills*Buffer

capacity

1.29%

Operators’

skills*Set-up

duration

0.07%

Buffer

capacity*Set-up

duration

0.07%

Rest of

interactions

0.14%

Total 100%

Model term

Percentage of

contribution

Operators’

skills

46.96%

Buffer

capacity

1.03%

Vehicle

speed

1.10%

Set-up

duration

45.81%

Rest of

main factors

0.03%

Operators’

skills*Buffe

r capacity

1.15%

Operators’

skills*set-up

duration

2.34%

Rest of

interactions

1.58%

Total 100%

Table 10: ANOVA table for the response cost.

Table 11: ANOVA table for the response time.

1-1

667.3

667.2

667.1

667.0

666.9

1-1

Operators skills

Mean

Buffer capacity

D

a

t

a

M

e

a

n

s

1-1

60000

55000

50000

45000

40000

1-1

1-1

60000

55000

50000

45000

40000

1-1

Operators skills

Mea n

Buffer capacity

Number of vehicles Set up duration

1-1

1700

1650

1600

1550

1500

1-1

1-1

1700

1650

1600

1550

1500

1-1

Operators skills

Mean

Buffer capacit y

Vehicle speed Set up duration

Source DF SS MS F P

Operator skills 1 0.002513 0.002513 390.45 0.000*

Buffer capacity 1 0.492206 0.492206 76469.78 0.000*

Set up duration 1 0.011401 0.011401 1771.32 0.000*

Operator skills*Buffer capacity 1 0.009631 0.009631 1496.23 0.000*

Operator skills*Set up duration 1 0.000157 0.000157 24.41 0.000*

Buffer capacity*Set up duration 1 0.000067 0.000067 10.45 0.002*

Error 57 0.000367 0.000006

Total 63 0.516343

S = 0.00253705 R-Sq = 99.93% R-Sq(adj) = 99.92%

Source DF SS MS F P

Operator skills 1 0.076130 0.076130 4999.58 0.000*

Buffer capacity 1 0.003489 0.003489 229.15 0.000*

Number of vehicles 1 0.000091 0.000091 5.97 0.018

Vehicle speed 1 0.002846 0.002846 186.90 0.000*

Set up duration 1 0.018487 0.018487 1214.06 0.000*

Operator skills*Buffer capacity 1 0.003524 0.003524 231.40 0.000*

Operator skills*Number of vehicles 1 0.000357 0.000357 23.44 0.000*

Operator skills*Set up duration 1 0.000954 0.000954 62.64 0.000*

Number of vehicles*Vehicle speed 1 0.000325 0.000325 21.33 0.000*

Vehicle speed*Set up duration 1 0.000158 0.000158 10.37 0.002*

Error 53 0.000807 0.000015

Total 63 0.107168

S

= 0.00390223 R

-

S

q = 99.

2

5% R

-

S

q(adj) = 99.10%

SystemReactivityComponentsinCellularManufacturingSubjectedtoFrequentUnavailabilityofPhysicalandHuman

Resources

381

Note that in this scenario the models generated by

the analysis of variance were much less complex

than the models in the first scenario, i.e. the models

had fewer terms in each of the considered responses.

The analysis of variance has preliminarily

identified a series of important factors and factor

interactions. By looking at the information presented

in Table 12 it is possible to confirm the real

significance of those factors in terms of the three

considered response variables.

The upper left section in Table 12 indicates that,

in terms of the response number of completed parts,

the only two significant factors were operators’

skills and buffer capacity; both with a combined

percentage of contribution of approximately 68%.

No significant interactions were present. The plot of

main effects in the lower left section shows that

these two factors were both significant at their

highest level.

In the column related to the response variable

cost, the upper middle section of Table 12 shows

that there was only one significant factor out of the

three originally identified factors. The factor buffer

capacity on its own had a percentage of contribution

to the response of approximately 95%. Compared to

this contribution, the other factors together with all

of the interactions cannot be considered significant.

The effects plot in the lower middle of Table 12

indicates that the factor buffer capacity was

significant at its lowest level.

In terms of the response time in the system, the

upper right section of Table 12 indicates that only 2

out of the originally identified important factor were

considerably significant; those were operators’ skills

and set-up duration. No significant factor

interactions were present in the model. The effects

plot in the lower middle section shows that the main

factor operators’ skill was significant to the response

at its highest level, whereas the main factor set-up

direction was significant at its lowest level.

6 DISCUSSION AND FUTURE

WORK

From the results section it can be noticed that,

although the level of significance may differ, the

significant factors are similar in both scenarios.

Regarding the response variable number of

completed parts, in the model with frequent machine

breakdowns the two most important factors were a

high buffer capacity in the first place and low

operators’ skills in the second place. This result

indicates that in a manufacturing environment

characterised by recurrent machine breakdowns a

higher buffer capacity to accommodate the excess of

WIP inventory accumulated during machine down

periods is the most desirable feature. According to

Hillier and So (1991), additional buffer space

reduces the adverse effect of machine breakdowns

and increases the throughput of the line.

Additionally, low skilled operators are more likely

to be dedicated to only one or two machines; this

guarantees the availability of the operator even when

the machine is down.

In the model characterized by a more frequent

rate of operator unavailability, the most important

and second most important factors were high

operators’ skills and high buffer capacity

respectively. In this type of environments, counting

on skilled operators is much more important than

relying on a high buffer capacity because skilled

operators can take on any machine when other

operators are absent during considerable periods of

time. A high buffer capacity, similarly to the

machine breakdowns scenario, contributes to

increase the throughput.

Concerning the response variable cost, both

scenarios indicated low buffer capacity as the most

important factor followed by low set-up duration.

Considering that the different processes along

cellular systems are accountable for WIP inventories

(Srinivasan and Bozer, 1992), an important approach

to keep costs down is to control the levels of costly

WIP inventories along the system. In order to

achieve this, the use of low capacity inter-storage-

areas to limit the size of WIP is an important first

step. In addition, a second important step to control

WIP levels and therefore maintain lower costs in

manufacturing environments characterized by the

temporary unavailability of resources is the

consideration of set-up reduction strategies.

In relation to the response variable time, the two

most important factors in each considered scenario

were high operator skills, in the first place, followed

by low set-up duration. Under a time minimization

criterion, the priority in both scenarios is to keep

parts flowing throughout the system and high skilled

operators, able to handle different processes, are the

solution to maintain a smooth production flow. Set-

up time reduction is also decisive for total

production lead time reduction (Dimitrov, 1990).

Low set-up durations contribute to maintain

production flow by keeping low levels of WIP and

compensating the time lost during periods of

resource unavailability.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

382

Table 12: Significant factors and factor interactions in terms of three response variables; operator unavailability.

Number of completed parts

Cost

Time in the system

Model term

Percentage of

contribution

Operators’

skills

40.31%

Buffer

capacity

27.88%

Number of

vehicles

1.69%

Rest of main

factors

1.17%

Operators’

skills*Buffer

capacity

17.06%

Operators’

skills*Loadin

g capacity

1.59%

Rest of

interactions

10.3%

Total 100%

Model term

Percentage of

contribution

Operators’ skills 0.49%

Buffer capacity 95.33%

Set-up duration 2.21%

Rest of main

factors

0.01%

Operators’

skills*Buffer

capacity

1.86%

Operators’

skills*Set-up

duration

0.03%

Buffer

capacity*Set-up

duration

0.01%

Rest of

interactions

0.06%

Total 100%

Model term

Percentage of

contribution

Operators’

skills

71.04%

Buffer

capacity

3.26%

Vehicle speed 2.66%

Set-up

duration

17.25%

Rest of main

factors

0.12%

Operators’

skills*Buffer

capacity

3.29%

Operators’

skills*set-up

duration

0.89%

Rest of

interactions

1.49%

Total 100%

In both disturbance scenarios, aspects related to the

processing subsystem of the manufacturing cell,

such as the skill level of the operators, the capacity

of buffers and the duration of machine set-up were

determinant to control the level of WIP inventories

within the system, which in turn was translated into

a system’s capacity to maintain a higher

performance. The only aspect related to the material

handling subsystem that appeared to be more

important, particularly for the response time, was the

speed of the vehicle. Similarly to the indentified

significant factors, vehicle speed is strongly linked

with WIP reduction (Srinivasan and Bozer, 1992).

No other of the aspect concerning the material

handling subsystem was considerably significant.

In addition to the consideration of system’s

reactivity, where manufacturing system’s behaviour

under the effect of internal disturbances is analysed,

the effect of external disrupting forces like those

related to the market could also be investigated.

Furthermore, both internal and external disturbances

could be investigated in the context of

manufacturing flexibility. By adopting a more

inclusive approach on the analysis of manufacturing

flexibility and the effect of disturbances, those

particular system components providing the system

1-1

667.0

666.5

666.0

665.5

665.0

1-1

1-1

667.0

666.5

666.0

665.5

665.0

Operator skills

Mean

Buffer capacity

Number of vehic les

D

a

t

a

M

e

a

n

s

1-1

60000

55000

50000

45000

40000

1-1

1-1

60000

55000

50000

45000

40000

1-1

Operator skills

Mean

Buf fer capacity

Vehicle speed Set up duration

1-1

1550

1500

1450

1400

1350

1-1

1-1

1550

1500

1450

1400

1350

1-1

Operator skills

Mean

Buffer capacity

Vehicle speed Set up duration

D

a

t

a

M

e

a

n

s

SystemReactivityComponentsinCellularManufacturingSubjectedtoFrequentUnavailabilityofPhysicalandHuman

Resources

383

with flexibility capabilities under a number of

disrupting situations could be identified. The

identification of such components could lead to a

number of system configurations, especially able to

absorb the effects of several disturbances.

REFERENCES

Buffa, E. S., 1972, Operations Management: Problems

and models, New York, Wiley.

Chen, J. & Chen, F., 2003, Adaptive scheduling in random

flexible manufacturing systems subject to machine

breakdowns. International Journal of Production

Research, 41, 1927-1951.

Chung, C., 1996, Human issues influencing the successful

implementation of advanced manufacturing

technology. Journal of Engineering and Technology

Management, 13, 283-299.

Dimitrov, P., 1990, The impact of flexible manufacturing

systems (FMS) on inventories. Engineering Costs and

Production Economics, 19, 165-174.

Eckstein, A. & Rohleder, T., 1998, Incorporating human

resources in group technology/cellular manufacturing.

International Journal of Production Research, 36,

1199-1222.

Hillier, F. & So, K., 1991, The effect of Machine

breakdowns and interstage storage on the performance

of production line systems. International Journal of

Production Research, 29, 2043-2055.

Huselid, M. A., 1995, The impact of human-resource

management-practices on turnover, productivity, and

corporate financial performance. Academy of

Management Journal, 38, 635-672.

Hwang, S. L., Barfield, W., Chang, T. C. & Salvendy, G.,

1984, Integration of humans and computers in the

operation and control of flexible manufacturing

systems. International Journal of Production

Research, 22, 841-856.

Jayaram, J., Droge, C. & Vickery, S. K., 1999, The impact

of human resource management practices on

manufacturing performance. Journal of Operations

Management, 18, 1-20.

Kahn, J. A. & Lim, J. S., 1998, Skilled labor-augmenting

technical progress in US manufacturing. Quarterly

Journal of Economics, 113, 1281-1308.

Law, A. & Kelton, D., 2000, Simulation Modelling and

Analysis, Singapore, McGraw-Hill.

Liao, C. J. & Chen, W. J., 2004, Scheduling under

machine breakdown in a continuous process industry.

Computers and Operations Research, 31, 415-428.

Logendran, R. & Talkington, D., 1997, Analysis of

cellular and functional manufacturing systems in the

presence of machine breakdown. International Journal

of Production Economics, 53, 239-256.

Mason, R., Gunst, R. & Hess, J., 2003, Statistical design

and analysis of experiments, with applications to

engineering and science, New York, Wiley-

Interscience.

Montgomery, D. C., 2009, Design and analysis of

experiments, Hoboken, NJ, John Wiley & Sons.

Nihat, K., Haldun, A. & Anand, P., 2006, Minimizing

makespan on a single machine subject to random

breakdowns. Operations Research Letters, 34, 29-36.

Ounnar, F. & Ladet, P., 2004, Consideration of machine

breakdown in the control of flexible production

systems. International Journal of Computer Integrated

Manufacturing, 17, 69-82.

Ozmutlu, S. & Harmonosky, C., 2004, A real-time

methodology for minimizing mean flow time in FMSs

with machine breakdowns: threshold-based selective

rerouting. International Journal of Production

Research, 42, 4975-4491.

Pagell, M., Handfield, R. B. & Barber, A. E., 2000,

Effects of operational employee skills on advanced

manufacturing technology performance. Production

and Operations Management, 9, 222-238.

Robinson, S., 1994, Successful Simulation: A Practical

Approach to Simulation Projects, London, McGraw-

Hill.

Saad, S. & Gindy, N.,1998, Handling internal and external

disturbances in responsive manufacturing

environments. Journal of Production Planning and

Control, 9, 760-770.

Srinivasan, M. M. & Bozer, Y. A., 1992, Which one is

responsible for wip - the workstations or the material

handling-system. International Journal of Production

Research, 30, 1369-1399.

Taylor, B. & Clayton, E., 1982, Simulation of a

production line system with machine breakdowns

using network modeling. Computers and Operations

Research, 9, 255-264.

Udo, G. & Ebiefung, A., 1999, Human factors affecting

the success of advanced manufacturing systems.

Computers and Industrial Engineering, 37, 297-300.

Welch, P., 1983. “The statistical analysis of simulation

results.” In The computer modeling handbook, ed. S.

Lavenberg, 268-328. New York: Academic Press.

Williams, D. J., 1994, Manufacturing systems; an

introduction to the technologies, London, Chapman &

Hall.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

384