Development of 3D Simulation System for Multi-Axis Turn-Mill

Machining

Hong-Tzong Yau, Jhih-Long Chen, Bing-Rau Yu and Tsan-Jui Yang

Advanced Institute of Manufacturing with High-Tech Innovations, National Chung Cheng University, Chia-Yi, Taiwan

Keywords: NC Simulation, Turn-Mill Machining, Material Removal, Solid Model.

Abstract: This paper proposes a 3D simulation system for multi-axis turn-mill machining. With the diversification of

technology products, traditional three-axis machining has been unable to meet the needs of existing

industries. Multi-axis machining system with high processing efficiency and accuracy has gradually become

the mainstream, and is widely used to produce high-value-added products, such as aerospace components

and medical devices. Since multi-axis machining hardware is very expensive, how to ensure the generation

of correct NC paths and avoid machine collisions from happening become important challenges. In this

paper, the triangular mesh model is used to represent the cutter, machine parts and materials. The actual

movement of the machine can be simulated after G codes are parsed. For the material removal, taking

processing speed into consideration, this paper proposes a hybrid simulation mechanism including 2D

intersection, Z-map and Boolean operations. This proposed method can obtain better result in terms of

processing efficiency and machining precision. At the same time, collision detection is used to find

interference between tools and machines. Using experiments, this paper demonstrates a variety of turn-mill

machining examples to verify the feasibility of the proposed method.

1 INTRODUCTION

Recently, computer numerical control (CNC) multi-

axis milling machine has become a main approach

for maching complex objects. The advantages of

multi-axis milling include efficiency, accuracy and

cost-effectiveness. The multi-axis milling machine is

more suitable for milling complex free-form

surfaces than the traditional 3-axis milling machine.

Moreover, it can provide better surface quality and

less surface roughness. However, after milling, most

mechanical components still require turning,

grinding, drilling and tapping. Therefore, part

moving, mounting and tool calibration need to be

repeated in the subsequent procedures.

In order to overcome this bottleneck, a CNC

turn-mill machine provides a more complete

solution. The advantages of the CNC turn-mill

machine include shortened machining time,

increased production, and decreased cost.

With the improvement of CAD/CAM

technology, intellegent or smart machine is growing

vigorously. The intelligent monitoring and

interactive 3D machining simulation can increase

the added values of NC machines. However, a

voxel-based rendering is used in most simulation

software. This kind of rendering is inefficient

because it needs much memory space and computing

power to provide accurate visualization. In this

paper, a polygon-based representation model with Z-

map and Boolean operations is proposed to simulate

the practical machining process in the turn-mill

machine.

The aim of this paper is to propose a 3D

simulation system for multi-axis turn-mill

machining. After loading the machining parameters

and NC paths, the simulated workpiece, tooling

turret and cutter can be generated automatically.

With 3D collision detection, the simulation can be

carried out more intuitively in different kinds of

machining situations.

2 LITERATURE SURVEY

2.1 NC Simulation

Real-time simulation for virtual machining process

is an important key, and pre-processing and good

hardware are necessary to enhance the performance

717

Yau H., Chen J., Yu B. and Yang T..

Development of 3D Simulation System for Multi-Axis Turn-Mill Machining.

DOI: 10.5220/0005039907170724

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 717-724

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

efficiency (Kerning, 2010). Generally, NC

simulation can mainly be categorized into three

approaches. The first approach uses direct Boolean

intersection of solid models to calculate the volume

of material removal during machining (Huang,

1995). This approach is theoretically capable of

providing accurate NC simulation, but this method

has the drawback of expensive computation. The

second approach uses spatial partitioning

representation to represent a cutter and work-piece

(Kim, 2006). In this approach, a solid object is

decomposed into a collection of basic geometric

elements, which includes Z-map, voxel and ray

representation. Voxel and Octree (Jang, 2000) is

another popular 3D decomposition approach which

is used to develop NC simulation system. However,

the disadvantages of Voxel and Octree are mainly

the high memory requirement and poor boundary

accuracy. The third approach uses discrete vector

intersection (Chang, 1991). Discrete vector method

is one of the most efficient methods in NC

simulation. Z-map simulation can be classified as a

special case of discrete vector method. However,

this method does not directly generate a solid model

for the machined part and is not suitable for cases

with dramatic normal changes during simulation.

2.2 Z-map Simulation

For Z-map machining simulation, the larger grid size

will lead to faster simulation speed but poor

accuracy. On the contrary, smaller grid size can

improve the simulation result but resulting in low

efficiency. (Lee, 2002) proposed enhanced Z-map

method which can satisfy the requirements of

efficiency and accuracy. Some algorithms (Maeng,

2003~2004) calculate the intersection of cutter swept

volume and work-piece, and adjust its z value to

achieve the simulation results. (Cai, 2010) presented

a general simulation methodology based on a Z-map

model of work-piece for predicting surface

topographic features and roughness formed in the

finish milling process. (Tsai, 2013) calculated mesh

position and z coordinates of tool scanning surface

according to tool path and initial tool scanning

boundary in reducing the long computation time.

This method can simulate not only straight line and

arc but also nonlinear path, like helical and spline

curves.

2.3 Boolean Operation

The difference set of Boolean calculation is widely

used in CAD/CAM and reverse engineering and is

considered to be able to achieve the purpose of

accurate material removal. About the type of

computation, (Tayebi, 2011) assort them into four

different categories: exact arithmetic methods,

approximate arithmetic methods, interval

computation methods and volumetric methods. (Mei,

2013) described a simple and robust algorithm for

triangular mesh Boolean operators; their method can

deal with both manifold and non-manifold cases.

(Wang, 2011) presented a new approach to compute

the approximate Boolean operations of two freeform

polygonal mesh solids efficiently with the help of

Layered Depth Images. (Reqiuicha, 1985) explored

the boundary condition and merge of solid model,

including dealing with coplanar issues.

2.4 Collision Detection

The main concept of collision detection is to test the

intersection of bounding volumes of objects. If there

is no collision between bounding volumes of objects,

it means that there is no collision for measured

models and does not need further interference tests.

(Chan, 2003) proposed an algorithm which can

specifically define the axis-aligned bounding box of

an object. (Hutter, 2007) added triangular mesh

information into bounding volume hierarchy to

increase the effectiveness of collision detection.

(Curtis, 2008) extended the above mentioned

method and simplify the detection rules to accelerate

calculation efficiency.

3 RESEARCH METHOD

This paper presents a 3D simulation system for

multi-axis turn-mill machining. In the machining

simulation system, the main consideration is the

simulation efficiency. In order to obtain the balance

between efficiency and accuracy, this paper uses the

mainstream triangular mesh model as our basis

format to represent the work-piece. And in our

machining simulation algorithm of material removal,

we propose a hybrid mechanism to choose among

the algorithms of Deformation of Intersection Point

(DIP), Z-map and Boolean. The system will

automatically determine the appropriate algorithm

according to the different machining processes. For

example, DIP is for turning process, Z-map is for

milling process and Boolean takes all situations that

Z-map can't handle, like drill or chamfer. The blue

arrow in Figure 1 shows it can support the

deformation of DIP and Z-map. Besides, the DIP

and Z-map are also of mutual assistance. That's why

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

718

our system can handle the mixed case of turning and

milling process. Additionally, to increase the

simulation value and ensure the machining accuracy

of the tool-path, the system will detect the collisions

between tools and the machine in the whole

simulation process.

Figure 1: Flow chart of our simulation process.

4 ENVIRONMENT

CONSTRUCTION

4.1 Parameter Setting

First, the program will load the related files and

parameters before the machining simulation starts.

The detailed descriptions of each of these files are as

follows:

1. Initial parameters of program: material types,

jaw types and G30 coordinates of origin.

2. NC file: data of NC path.

3. Material file: User-defined 2D point group of

raw material block.

4. Jaw file: User-defined 2D point group of jaw.

5. File of process and parameter: name of

processes, parameter of tools and of tool colours.

4.2 Work-piece Construction

Based on the 2D plane concept of a turning machine,

the system will draw the material profile on a 2D

plane. Then we use the polar coordinates to rotate

material profile 360 degrees on the Z axis and build

the triangular mesh model. Users can adjust the

mesh density to their needs. The material shape is

drawn by users. However, the system will

automatically determine the mesh size of the

material model by considering the follow-up

deformation and the situation of the NC code. The

following figure shows a cylindrical material was

made by this method.

Figure 2: Work piece shown in triangular grid.

5 SIMULATION OF MATERIAL

REMOVAL

5.1 Deformation of Intersection Point

(DIP)

In turning simulation process, we can get several

intersections by each step using vertical line,

horizontal line or every connected line of two NC

points. As long as with correct orders of the NC path

track, we can get the 2D shape’s point group after

deformation. Furthermore by revolving the original

point group 360 degrees, we can create the 3D space

points after the material removal. The line-line

intersection equation of this paper is as follows:

There are two line equations L1 and L2 in the 2D

space. Two points on the line of segment L1 are

(x1,y1), (x2,y2). The other points on the line of

segment L2 are (x3,y3), (x4,y4). The intersection

points of two segment lines are as follows:

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(1)

,

,

(2)

If the two lines are parallel, then

0

(3)

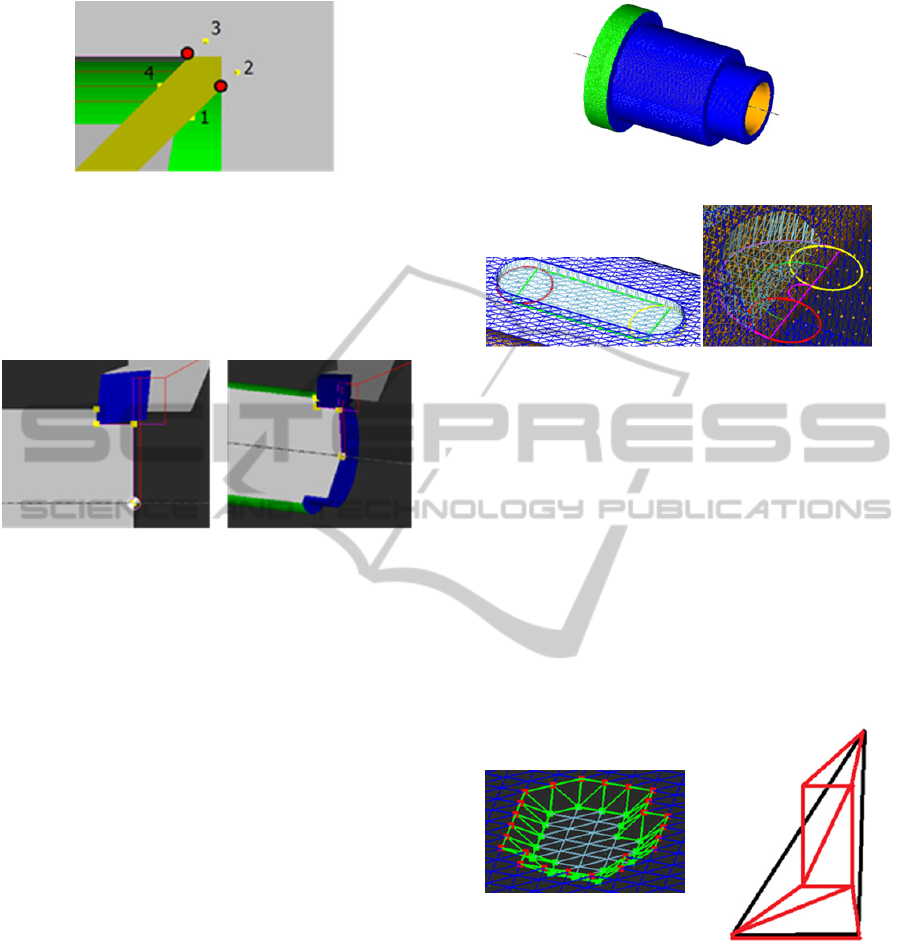

In Figure 3, the points in order 1,2,3,4 are points of

the tool shape. The program will determine the point

is taken or not, based on if it is inside or outside. If it

is inside then it is taken, if not find the intersection

point with the other points of the tool shape.

Developmentof3DSimulationSystemforMulti-AxisTurn-MillMachining

719

Figure 3: Illustration of deformation algorithm.

Figure 4 is the result of turning simulation.

In Figure 4(a), it is a simplified schematic drawing

showing the intersection points and the deformation

result of turning. In Figure 4(b), we show the result

of simulation with a tilted angle.

(a) (b)

Figure 4: The result of turning simulation.

5.2 Z-map

Z-map is the second method of material removal in

simulation in this paper. The Z-map method has one

advantage: it does not break up the mesh model. It

has been widely used in 3-axis milling simulation.

The main principle is changing the depth of point

group of the mesh to get simulation results of

material removal by the path of the sweeping tool. In

implementation, our research uses Tree data

structure to accelerate the search efficiency. Along

the cutter movement, the G01 NC segment will be

divided into three areas: Circle A (red), Circle B

(yellow), and Rectangular C (blue). In real situation,

path is continuous. When the mesh grids are marked

under these three areas and ready for deformation,

the system only deals with the parts of Circle B and

Rectangular C. Figure 5 is a mesh model and we use

it’s triangular grid endpoints to establish the Z-map.

Figure 6 shows the tool is moved linearly during the

simulation. Figure 7 shows the tool is moved in an

arc during the simulation. Marked sections of grid

are Circle A(red), Circle B(yellow) and fan-shaped

C(pink), and we only need to deal with B and C.

In general, if we only use the Z-map to push grid

points, it is difficult to keep the accuracy in

simulation. Just like Figure 8, the only thing one can

Figure 5: Mesh model for Z-map.

Figure 6: Straight path.

Figure 7: Circular path.

do is to increase the grid density to approximate the

real machining results. Hence, we propose the

concept of “grid folding” as shown in Figure 9. It is

using the idea of taking apart one grid into five grids.

In the middle there will be two segments of sharp

boundary generated intersection points. When the Z-

map pushes the grids with a flat end-mill, the

boundary grids need to be “extended” by the

additionally generated intersection points. At this

moment, using the intersection points as folding

points, we can obtain the sharp edges in the

boundary. Figure 9 shows that the required accuracy

can be reached using this method.

Figure 8: Inaccuracy

situation.

Figure 9: Grid

folding.

The actual test results are as follows, Figure 10(a) is

the result of the original grid, and Figure 10(b) is the

result after grid folding. Using such method, we can

get the good simulation result without the increase

of grid density by subdivision.

In the simulation of the mixed case of turning

and milling, the Z-map method can be further

extended by combining the use of polar coordinates

transferred to the Y axis and the C axes. The polar

coordinates can be “flattened out” as in Figure 11(b),

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

720

(a) (b)

Figure 10: The results before and after.

the simulation is performed by the Z-map, and the

result is then “folded back” as in Figure 11(a).

Figure 12 shows the simulation result using this

extended Z-map approach.

(a) (b)

Figure 11: The results of “folded back” and “flattene

d

out”.

Figure 12: Simulation results.

5.3 Boolean Operation

Boolean operation plays an important role in

geometric processing, which aims to obtain union,

subtraction and intersection of geometric models.

Theoretically, an accurate material removal model

may be obtained through the Boolean operation. But

the drawback is expensive computational loading.

For machining simulation, the required efficiency

may not be achieved. The purpose of this paper is to

achieve the material removal simulation process, and

therefore only consider the difference operator. Here,

we implement a simple and robust Boolean

algorithm proposed by (Mei, 2013); the operational

flowchart of difference operators is as follows:

Step 1: Roughly search the candidate intersection

triangle-pairs by bounding box detection and

removal of coplanar triangle-pairs with plane

projection algorithm.

Step 2: Compute the intersection line for each pair

of triangles. Merge all the segments into a loop as

expansion boundary.

Step 3: Split cutter and work-piece according to the

intersection loop.

Step 4: Decide seeds on both cutter and work-piece.

Execute region growing method to define removal

part based on mesh topology.

Step 5: Merge all the sub-surfaces which are defined

as “reserve” to form a new model.

Since the using Boolean operators must pay a higher

cost, if we simply use Boolean operators as a way to

remove the material, it will result in inefficient

simulation with a higher cost. Therefore, in general,

Z-map will be considered as the first method for

deformation. The timing of using Boolean is when

the Z-map fails to generate correct deformation. In

this system Boolean is mostly used for drilling and

chamfering editing and other related actions, for

example, reaming of thread or chamfer. Figure 13

and 14 indicate drilling and chamfering examples

where Boolean operations are used.

Figure 13: Drilling.

Figure 14: Chamfering.

In addition, in drilling there could be a special case

of coplanar problem and we have a special process

to deal with it. For example, Figure 15 is the drilling

case we used. Using NC path points to exclude the

grids and the lines on the co-plane, there will be no

incorrect intersection lines during the process of

Boolean. This can help avoid mistakes and prevent

Boolean failure from happening.

Figure 15: The drilling case has co-planar situation.

Developmentof3DSimulationSystemforMulti-AxisTurn-MillMachining

721

6 SIMULATION OF TURN-MILL

PROCESS

The main purpose of this work is to construct 3D

simulation of turn-mill process. In addition to

adopting triangular mesh model to represent every

work-piece, we also create realistic tools and turrets

for the simulation of the turn-mill process. This

includes different characteristics of turning and

milling machines so it can be widely used in various

practical planning situations. In this section we will

show actual industry examples and demonstrate the

feasibility of the proposed system.

6.1 Emulated Turret Construction

In the beginning, this paper mentioned that we hope

to create an emulated turn-mill machine. Therefore,

our goal is to construct turrets and tools based on

real machine information as much as possible. The

database of tool and turrent (STL files) was provided

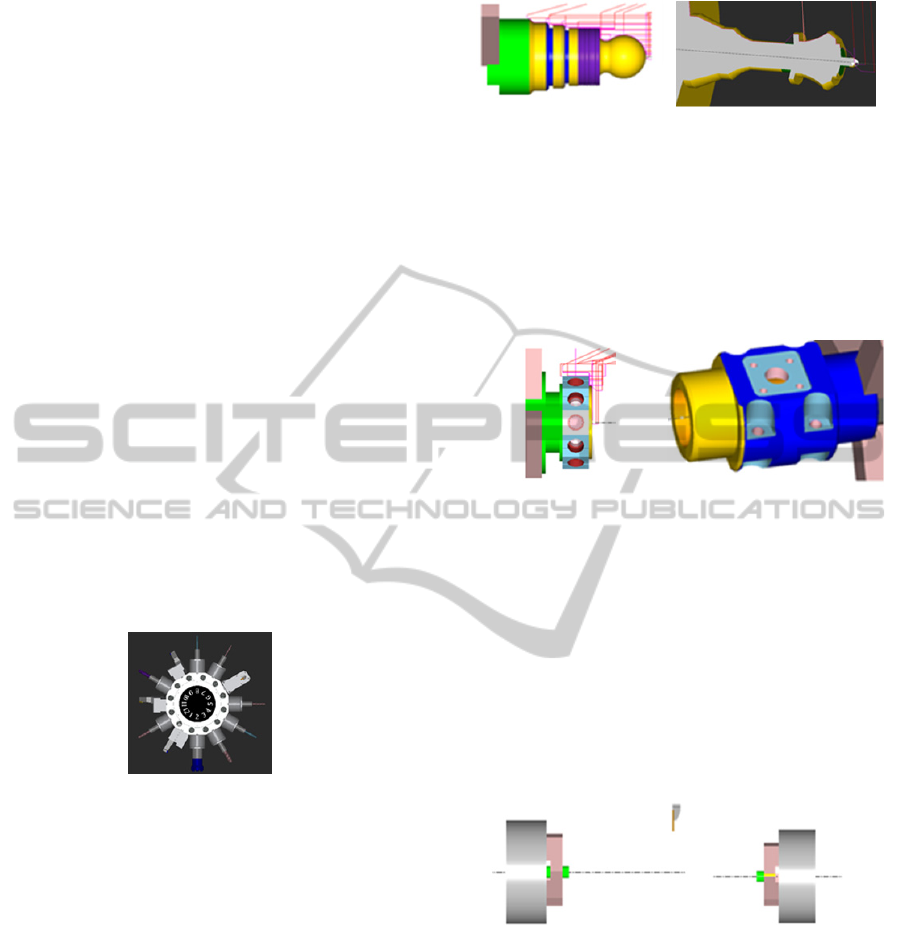

by a CNC factory. Figure 16 shows that if the user

opens turret viewing function, he can examine the

turret at the front view (or any views). This will help

the user easily check the tools one by one by rotating

the tools counter-clockwise.

Figure 16: The realistic turret.

6.2 Turning

The first part of this software development is turning.

This system not only includes outside turning and

inside turning, but also circular and screw cutting

paths. Unlike other general lathe simulation software

which provides only 2D turning simulation, this

system provides true 3D simulation using triangular

solid meshes. This not only provides realistic

material removing process, but also is very useful

for 3D collision detection between work-piece and

machine structures including turrets. Figure 17 and

18 show two such examples.

6.3 Milling

The second important part of this software

development is milling. At the end of each turning

Figure 17: Result 1.

Figure 18: Result 2.

process, this system will convert the object into a

triangular mesh for Z-map or Boolean simulation.

Most milling simulations are performed using the Z-

map method. Boolean operations are employed for

chamfering or other complex functions such as

drilling or internal threading. Figure 19 and 20 are

other two difficult simulation cases.

Figure 19: Results.

Figure 20: Results.

6.4 Sub-spindle

Most turn-mill machines often come with a sub-

spindle. Therefore, our system also adds a sub-

spindle module, making this simulation more

versatile. Figure 21 shows machining the work-piece

under the spindle and the subsequent sub-spindle

clamping of the work-piece. Simulations carried out

in the sub-spindle need to consider the reversed

cutting directions.

Figure 21: Work piece is moved from main spindle to sub-

spindle.

6.5 Cylindrical Interpolation/Polar

Coordinate Interpolation

This paper also deals with special G code commands

(G07.1, G12.1). This method is discussed in section

5.2. It can also be applied to the sub-spindle module.

Figure 22 and 23 are simulation results of polar

cases.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

722

Figure 22: Polar case 1.

Figure 23: Polar case 2.

6.6 Hybrid Turning/Milling/Drilling

In this work, combination of different machining

processes need to be considered, for example, from

turning to milling and then to turning, or from

milling to turning and then to milling. These

changes tend to disrupt the original data structure of

the system. We overcome this problem by recording

the accumulated profile of the turning process,

which can be converted to a solid triangular mesh

anytime. In the subsequent process of milling or

drilling, Boolean operation can be used to obtain the

final geometry. A turning/drilling/turning case is

shown in Figure 24.

(a) the work-piece is turned in positive spindle

(b) move to the sub-spindle, and turn again

(c) the work-piece is drilled

(d) the work-piece is turned again to obtain the final

result

(a)positive spindle(turning) (b)sub-spindle(turning)

(c) sub-spindle(drilling) (d) final results

Figure 24: Different steps of simulation.

6.7 Collision Detection

Collision detection is a very important function in

turn-mill simulation. We can use the collision

detection function to verify whether the NC path is

correct or not, so we can avoid significant damage

because of the collision between the tool and

machine before machining. In this paper, we use

three steps to do collision detection. First, we record

the bounding box of tool when we create the tool

database, then we use an AABB tree to filter

collision components in the simulation. Finally, we

use mesh intersection algorithm to detect collision

components. We display the collision detection by

changing the colour of the collision components to

red to warn the user. Figure 24 (a) shows the

collision result between tool and jaws. Figure 24(b)

shows the collision result between tool and work-

piece.

(a)Tool and jaw

interference

(b) Tool and work-piece

interference

Figure 25: Two different situations of interference.

7 DISCUSSION

Complete turn-mill machining simulation has been

presented in the previous sections. This paper

demonstrates that turn-mill machining simulation is

possible through the integration of 2D Intersection,

Z-map and Boolean algorithms with balanced

efficiency and accuracy. In this section, will discuss

the problems encountered during the simulation

process and their solutions. First, for the turning

simulation, this work achieves the desired result by

2D intersection calculation. The surface of the work-

piece will be deformed according to the intersection

profile. Then, the turned profile is rotated 360

degrees to construct a 3D solid mesh. The result

shows that this method is feasible, robust and highly

efficient. For the milling simulation, this paper

removes materials by the Z-map algorithm. The Z-

map method can provide an excellent simulation

result similar to the Boolean operation but with

better efficiency. Meanwhile, this paper also extends

the Z-map method into polar coordinates system to

simulate turn-mill machining. Furthermore, the

work-piece must be subdivided and then deformed

in order to achieve the simulation of material

removal. It can predict that the system performance

will decrease due to huge polygon data after long

time milling simulation. Thus, polygon merge is

Developmentof3DSimulationSystemforMulti-AxisTurn-MillMachining

723

necessary during the simulation process. Further, the

Z-map can’t perform the drill function to remove

materials due to its algorithm limitation. The

Boolean operation is the only solution to simulate

drilling operation.

The difference set of Boolean can be used to

remove material from the original object.

Theoretically, Boolean operation can produce

precise machining results. However, its drawback is

that Boolean calculation needs higher computation

cost and will decrease performance during

simulation. In addition, coplanar contacts between

the cutter and work-piece are quite common during

the simulation. For the surface-based model

representation, coplanar issue is still a challenge.

8 CONCLUSIONS

The main contribution of this paper is the simulation

of turn-mill machining in 3D with accuracy and

efficiency. Triangular mesh model is used to

represent the cutter and work-piece, including

tooling turret and clamp. The advantage of turn-mill

machining is that it can shorten processing time,

increase productivity, reduce storage space, and

maintain accuracy. The turn-mill process is usually

complicated and involves multiple cutters and

spindles. The danger and cost of collision is high,

therefore accurate and efficient simulation of the

process becomes critical. To achieve this purpose

and balance between efficiency and precision, this

paper proposes a hybrid simulation method by

combining DIP, Z-map and Boolean operations. The

software will determine the appropriate material

removal method according to the NC instructions. In

the simulation processing, in order to check if the

path is correct or not, mesh collision detection

algorithm is used to find out interferences. For the

future work, first, this research will focus on the

improvement of Boolean operation. The efficiency

of Boolean operation is still a bottleneck of

simulation. In addition, the Boolean operators still

need to exclude some special cases such as coplanar

in advance to ensure the success of the simulation.

In the future, this work will also be extended to the

on-line turn-mill simulation/monitor by integrating

the simulation software with a PC-based controller.

REFERENCES

Kerning P., Yuanyuan, X., 2010, “Real-Time Boolean

Operation for NC Machining in Virtual Simulation”,

International Conference on Computer Application

and System Modeling.

Huang, Y. and Oliver, J. H., 1995, “Integrated Simulation,

Error Assessment, and Tool Path Correction for Five-

Axis NC Milling”, Journal of Manufacturing Systems.

Kim, Y. H. and Ko, S. L., 2006, “Improvement of Cutting

Simulation using the Octree Method”, The

International Journal of Advanced Manufacturing

Technology.

Jang, D., Kim, K. and Jung, J., 2000, “Voxel-based Virtual

Multi-axis Machining”, Advanced Manufacturing

Technology.

Chang, K. Y. and Goodman, E. D., 1991, “A Method for

NC Tool Path Interference Detection for A Multi-Axis

Milling System”, ASME Control of Manufacturing

Process.

Lee, S. K. and Ko, S. L., 2002, “Development of

Simulation System for Machining Process using

Enhanced Z Map Model”, Journal of Materials

Processing Technology.

Maeng, S. R., Baek, N., Shin, S. Y., and Choi, B. K., 2003,

“A Z-map Update Method for Linearly Moving Tools”,

Computer-Aided Design.

Maeng, S. R., Baek, N., Shin, S. Y., and Choi, B. K., 2004,

“A fast NC Simulation Method for Circularly Moving

Tools in the Z-map Environment”, Proceedings of the

Geometric Modeling and Processing 04.

Cai, Y., Zhen, L. and Xin, P., 2010, “A Geometrical

Simulation of Ball End Finish Milling Process and Its

Application for the Prediction of Surface Topography”,

Mechanic Automation and Control Engineering.

Tsai, J. P., 2013, “A Modified Z-map Computational

Interpolation Algorithm for Surface Machining

Simulation”, Transactions of the Canadian Society for

Mechanical Engineering.

Tayebi, A, G´omez, P. J, Gonz´alez, D. I, Catedra, F.,

2011, “Boolean Operations Implementation over 3D

Parametric Surfaces to be Included in the Geometrical

module of an Electromagnetic Solver”, Proceedings of

the 5th European Conference on Antennas and

Propagation.

Mei, G. and Tipper, C., 2013, “Simple and Robust

Boolean Operations for Triangulated Surfaces”,

Computational Geometry.

Wang, C. L., 2011, “Approximate Boolean Operations on

Large Polyhedral Solids with Partial Mesh

Reconstruction”, IEEE Transactions on visualization

and computer graphics.

Reqiuicha, A. G., and Voelcker, B., 1985, “Boolean

Operations in Solid Modeling: Boundary Evaluation

and Merging Algorithms”, Proceedings of the IEEE.

Chan, C. K., 2003, “Minimum bounding boxes and

volume decomposition of CAD models”.

Hutter, M. and Fuhrmann, A., 2007, “Optimized

Continuous Collision Detection for Deformable

Triangle Meshes”, Fifth International Conference on

Computer Graphics and Computer Vision.

Curtis, S., Tamstorf, R. and Manocha, D., 2008, “Fast

Collision Detection for Deformable Models using

Representative Triangles”,

ACM I3D.

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

724