Modeling and Performance Optimization of a Direct Injection Spark

Ignition Engine for the Avoidance of Knocking

Michela Costa, Ugo Sorge, Paolo Sementa and Bianca Maria Vaglieco

Istituto Motori, CNR, Via Marconi, 4, 80125, Naples, Italy

Keywords: CFD Optimization, 3D Engine Model, GDI Spark Ignition Engine, Control, Knocking.

Abstract: The paper applies simulation techniques for the prediction and optimization of the thermo-fluid-dynamic

phenomena characterising the energy conversion process in an internal combustion engine. It presents the

development and validation of a 3D CFD model for a GDI optically accessible engine operating either

under stoichiometric homogeneous charges or under overall lean mixtures. The model validation is realized

on the ground of experimental measurements of the in-cylinder pressure cycle and of the available optical

images. The model comprehends properly developed sub-models for the spray dynamics and the spray-wall

interaction. This last is particularly important due to the nature of the mixture formation mode, being of the

wall-guided type. In the stoichiometric mixture case, the possible occurrence of knocking is also considered

by means of a sub-model able to reproduce the pre-flame chemical activity. The CFD tool is finally

included in a properly formulated optimization problem aimed at minimizing the engine specific fuel

consumption with the avoidance of knocking. The optimization, performed through a non-evolutionary

algorithm, allows determining the best engine control parameters (spark advance and start of injection).

1 INTRODUCTION

Present work has the primary purpose of showing

how a properly developed simulation tool may be of

importance for the prediction of the behaviour of a

complex system as a gasoline direct injection (GDI)

spark ignition engine, hence for the choice of the

optimal control parameters of its actual operation.

The well-established role of computational fluid

dynamics (CFD) as a tool for the analysis of thermo-

fluid-dynamic systems is further confirmed by its

application in the design phase of energy conversion

systems, and, in particular, of internal combustion

engines. Simulation analyses allow running a virtual

prototype of a certain propulsion system and testing

various geometric configurations or control

parameters within time and costs absolutely

negligible if compared with the corresponding

characterization at the test bench. Just the increasing

complexity of modern engines, consequent the large

number of parameters that govern their operation,

and the need to respond to higher and higher

performance targets, may justify the importance of

appropriate calculation tools able to describe the

relevant phenomenology, especially in the phase of

design and prototype development (Carling, 2010).

The use of rigorous methods of decision-making,

such as optimization methods, coupled with modern

tools of numerical simulation, on the other hand, is

today very effective to reduce costs, improve

performance and reliability and shorten the time to

market of technical systems and components. In fact,

numerical procedures may be used to generate a

series of progressively improved solutions to the

optimization problem, starting from an initial one,

until a given convergence criterion is satisfied

(Thévenin, 2008). In this perspective, automatic

searching methods may strongly reduce the time

needed for computational engine optimization

effected through parametric analyses.

The state of the art of computational models and

optimization methods for internal combustion engine

development can be found in the book by Shi, Ge

and Reitz (2011): engine optimization through

parametric analysis is compared with optimizations

realised through non-evolutionary methods or

evolutionary methods. Several examples are

provided.

In the present paper, the development of a

simulation model able to predict both the mixture

formation and the combustion processes occurring

within the combustion chamber of a high

484

Costa M., Sorge U., Sementa P. and Vaglieco B..

Modeling and Performance Optimization of a Direct Injection Spark Ignition Engine for the Avoidance of Knocking.

DOI: 10.5220/0005040204840496

In Proceedings of the 4th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2014),

pages 484-496

ISBN: 978-989-758-038-3

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

performance GDI engine working under a mixed

mode boosting (Alkidas, 2007) is described. The

mixed mode boosting consists in a stoichiometric

charge operation at high load and a lean charge

operation at the lower loads and speeds (Oh and

Bae, 2013, Park et al., 2012). The 3D engine model

validation, indeed, is shown with reference to both

these conditions. The main feature of the engine

under study is the optical accessibility to the

combustion chamber, which allows also collecting

images of the in-cylinder spray evolution and flame

development. In a certain relevant operating

condition, the possibility of occurrence of abnormal

combustions is also analysed, in particular with

reference to the phenomenon of spontaneous

ignition arising in the so-called end-gas zone, not yet

reached by the flame front initiated by the spark

plug. The developed simulation tool is finally

applied to realize the best choice of the engine

governing parameters for the operation with the

lower fuel consumption and the avoidance of

knocking.

The work description follows the steps described

below:

- experimental set-up and campaign;

- development and validation of a 3D model for

sprays issuing from new generation high pressure

GDI injectors;

- formulation and validation of a 3D model for the

simulation of the whole operating cycle of a GDI

engine;

- validation of a sub-model for the prediction of

the knocking occurrence.

- reduction of the specific fuel consumption and

avoidance of knocking under a stioichiometric

charge operation.

2 EXPERIMENTAL APPARATUS

The experimental apparatus employed for the

collection of data to be used for the validation of the

3D engine model includes the following modules:

the spark ignition engine, an electrical

dynamometer, the fuel injection line, the data

acquisition and control units, the emission

measurement system and the optical apparatus.

A GDI, inline 4-cylinder, 4-stroke, displacement

of 1750 cm

3

, turbocharged, high performance engine

is the object of the present study. The engine is

equipped either with a Bosch 7-hole injector located

between the intake valves and oriented at 70° with

respect to the cylinder axis, or with a Magneti

Marelli 6-hole injector, mounted in the same way.

Mixture formation is realized in the wall guided

mode, being the piston head properly shaped to

direct the spray and vapour cloud towards the top of

the cylinder and the spark plug. The engine is

equipped with a variable valve timing (VVT) system

in order to optimize the intake and exhaust valves

lift under each specific regime of operation. The

engine is not equipped with after-treatment devices.

Details are reported in Table 1.

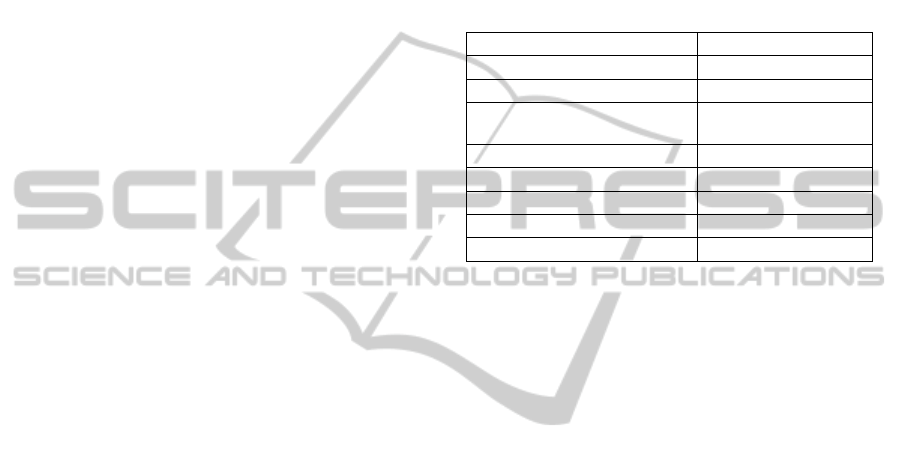

Table 1: Characteristics of the engine under study.

Unitary displacement [cm

3

] 435.5

Bore [mm] 83

Stroke [mm] 80.5

Air supply Exhaust gas

turbocharger

Max. boost pressure [bar] 2.5

Valve timing Int. and Exh. VVT

Compression ratio 9.5:1

Max. power [kW] 147.1 @ 5000 rpm

Max. torque [Nm] 320.4 @ 1400 rpm

An electrical dynamometer allows the operation

under both motoring and firing conditions, hence

detecting the in-cylinder pressure data and exploring

the engine behaviour under stationary and simple

dynamic conditions.

An optical shaft encoder is used to transmit the

crank shaft position to the electronic control unit.

The information is in digital pulses, the encoder has

two outputs, the first is the top dead centre (TDC)

index signal with a resolution of 1 pulse/revolution,

and the second is the crank angle degree marker

(CDM) 1pulse/0.2degree. Since the engine is 4-

stroke, the encoder gives as output two TDC signals

per engine cycle. In order to determine the right

crank shaft position, one pulse is suppressed via the

dedicated software.

A quartz pressure transducer is installed into the

spark plug to measure the in-cylinder pressure with a

sensitivity of 19 pC/bar and a natural frequency of

130 kHz. Thanks to its characteristics, a good

resolution at high engine speed is obtained. The in-

cylinder pressure, the rate of heat release and the

related parameters are evaluated on an individual

cycle basis and/or averaged over 300 cycles.

The tests presented in this paper are carried out

at the engine speed of 1500 rpm. The absolute intake

air pressure remains constant at 1300 mbar, the

temperature is 323 K. Two operating conditions are

considered for the 3D model validation, whose

control parameters are summarised in Table 2. The

first, hereafter indicated with the letter L, is

characterized by an overall lean charge; the second

ModelingandPerformanceOptimizationofaDirectInjectionSparkIgnitionEnginefortheAvoidanceofKnocking

485

one has a stoichiometric charge, and is indicated

with letter S. Start of injection (SOI) and start of

spark (SOS) are expressed in crank angles before the

top dead centre (BTDC). The injection pressure is

equal to 6 MPa in the lean case, to 15 MPA in the

stoichiometric case. Commercial gasoline is

delivered through the 7-hole Bosch injector. Intake

valve opening (IVO), intake valve closing (IC),

exhaust valve opening (EVO) and exhaust valve

closing (EVC) are all reported in the table caption

after (A) or before (B) the relevant dead centre

(TDC or bottom dead centre, BDC).

Table 2: Operating conditions considered for the 3D

model validation. IVO@13°ATDC, IVC@52° ABDC,

EVO@20° BBDC, EVC@15° BTDC.

SOI

[°BTDC]

SOS

[°BTDC]

A/F

p

inj

[MPa]

Overall lean charge

(L)

70 13

21.5

6

Stoichiometric

charge (S)

307 19

14.7

15

(a)

(b)

Figure 1: Polar diagrams for the (a) lean burn and (b)

stoichiometric case of validation.

The polar diagrams of Figure 1 summarises the

synchronization of injection, ignition and valve

timing for the cases L and S. The injection occurs

entirely during the intake stroke in the S case,

entirely in the compression stroke in the L case.

Their length is comparable, although the delivered

fuel amount is greater in the S case, due to the

different injection pressure.

Three different operating conditions are instead

employed with the aim of studying the knocking

occurrence in the engine under study. The 92 RON

fuel is here delivered through the Magneti Marelli 6-

hole injector, with governing parameters as reported

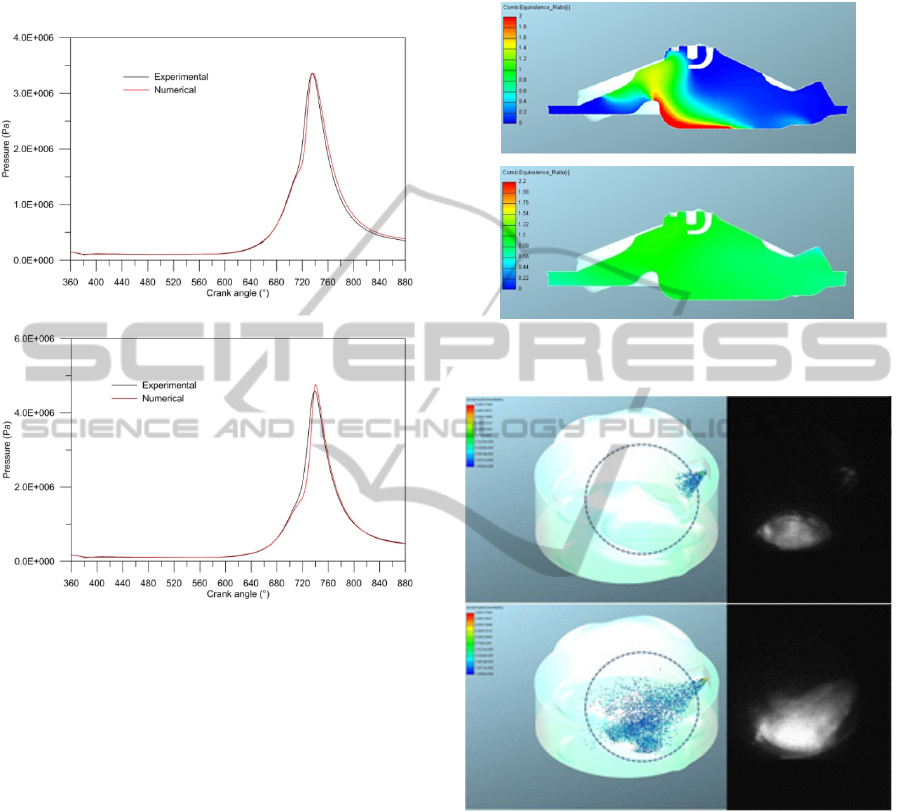

in Table 3. Figure 2 shows the in-cylinder pressure

in the cases of Table 3. In particular, Figure 2a

reports the average over 300 consecutive cycles in a

no-knocking situation, Figure 2b and 2c represents

the instantaneous pressure curves corresponding to

the 150th cycle of 300 consecutive ones in an

incipient knocking case and a knocking case,

respectively. In Figure 2b and 2c the pressure traces

show the typical ripples of knock, whose intensity

increases as the spark advance is increased.

Table 3: Operating conditions considered for study of the

knocking occurrence. IVO@22° BTDC, IVC@17°ABDC,

EVO@5° BBDC, EVC@TDC.

SOI

[°BTDC]

SOS

[°BTDC]

A/F

p

inj

[MPa]

No knocking

case

200 20

14.7

10

Incipient

knocking case

200 25

14.7

10

Knocking case 200 30

14.7

10

2.1 Optical Apparatus

The engine under study is optically accessible.

Imaging measurements are performed by means of

the optical experimental set-up shown in Figure 3.

The optical accesses are realized in the engine head,

as reported in Figure 3.b. A customised protective

case for an endoscopic probe, equipped with an

optical sapphire window (5 mm diameter), is

installed in the engine head in the 4th cylinder. This

system allows investigating an area including the

spark and the gasoline spray through an endoscope

exhibiting a viewing angle of 70°. The field of view

is centred in the combustion chamber

perpendicularly to the plane identified by the axes of

the cylinder and the injector, hence perpendicular to

the plane of tumble motion. The endoscopic probe is

coupled with two high spatial and temporal

resolution CCD cameras. The first is an intensified

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

486

cooled CCD camera (ICCD). It is equipped with a

78 mm focal length, f/3.8 UV Nikon objective.

(a)

(b)

(c)

Figure 2: In-cylinder pressure in the (a) no knocking, (b)

incipient knocking and (c) knocking case and 5-30 kHz

band pass filter.

The ICCD has an array size of 512x512 pixels and a

16-bit dynamic range digitization at 100 kHz. The

optical apparatus allows a spatial resolution of

approximately 0.19 mm/pixel. Its spectral range

spreads from UV (180 nm) until visible (700 nm).

The ICCD operates at a digitizer offset of about

230 counts, but the dark noise fluctuation in the

background is much smaller, less than 50 counts.

Dark noise and photon statistical noise are both

small compared with the measured intensity. The

second camera is a digital CCD colour camera

equipped with a 50 mm focal length, f/3.8 Nikon

lens (Figure 3.a). Its spectral range spreads from 400

to 700 nm and it allows performing a 2D flame

visualization. The spatial resolution for this other

optical assessment is of about 0.19 mm/pixel.

The gasoline injection phase is characterized

through the ICCD camera and an intense strobe

lamp, which is introduced in the spark location

through a fiberoptics. For all the optical

measurements, the synchronization between the

cameras and the engine is made by the crank angle

encoder signal through a unit delay.

Figure 3: Sketch of the experimental setup for optical

investigation and detail of the combustion chamber: a)

CCD for 2D two colour technique, b) ICCD for UV-

Visible acquisition.

3 SPRAY SIMULATION

The analysis of the models available in the literature

for the simulation of sprays generated by new

generation GDI injectors, carried out in order to

identify any inadequacies and issues for potential

improvement, has highlighted the need for the

development of a sub-model suitable of being used

in different operating conditions of a modern GDI

engine. In fact, already in the GDI exclusive

operation with homogeneous charges, namely in

what could be called the first generation GDI

engines, a crucial role was played by the interaction

between the spray of injected fuel and the air

ModelingandPerformanceOptimizationofaDirectInjectionSparkIgnitionEnginefortheAvoidanceofKnocking

487

turbulent motion within the combustion chamber.

The complex phenomena of penetration, transport

and evaporation of gasoline had to be carefully

controlled in order to allow the desired

homogeneous preparation of the mixture and the

minimization of anomalies such as the presence of

liquid particles on the walls or any localized

thickening of fuel deposits (Stan, 2000, Zhao, 2001).

In the new generation GDI engines, based on the so-

called mixed mode boosting, the concentration of

fuel vapor in the combustion chamber may be

differentiated at the medium loads in order to create

a zone with air-fuel ratio stoichiometric or slightly

rich in the vicinity of the spark plug, and lean in the

vicinity of the cylinder walls. Globally, the mixture

ratio can be lean (lean burn). At higher loads, and at

all loads and higher speeds, the engine may be

operated in a stoichiometric homogeneous mode.

The control of the formation process of the air-fuel

mixture, therefore, is an objective of great interest,

as detrimental in ensuring flame stability, reduction

of produced pollutants and high combustion

efficiency.

The 3D sub-model able to simulate the dynamics

of the gasoline spray issuing from the considered

injector is here developed in the context of the

software AVL Fire

TM

, in such a way to simulate

preliminary experiments performed by mounting the

injector and delivering sprays in an optically

accessible vessel. The followed approach is the

classical coupling between the Eulerian description

of the gaseous phase and the Lagrangian description

of the liquid phase. The governing equations are

here not reported for the sake of brevity; the

interested reader may refer to the book by Ramos

(Ramos, 1989). The train of droplets inserted in the

computational domain in correspondence of the

injector holes exit section suffers various concurring

effects as it travels. Details of the model are given in

the paper by Costa et al. (2012). Here it is only

worth pointing out that the droplets break-up

phenomenon is simulated according to the sub-

model of Huh-Gosman (1991), whose constant C

1

(regulating the break-up time) is adjusted in a tuning

procedure. The effects of the turbulent dispersion on

the droplets dynamics is simulated through the sub-

model by O’Rouke (O’Rouke and Bracco 1980), the

coalescence through the sub-model by Nordin

(2001), the evaporation through the sub-model by

Dukowicz (1979).

Initial size of droplets at the nozzle exit section,

is considered as variable according to a probabilistic

log-normal distribution, whose expected value is

given by the following theoretical diameter, where

f

is the gasoline surface tension,

g

the surrounding

gas density, u

rel

the relative velocity between the fuel

and the gas, C

d

a constant of the order of the unity

(indeed taken equal to the unity), and the parameter

* deriving from the hydrodynamic stability

analysis and indicating the dimensionless

wavelength of the more unstable perturbation to the

liquid-gas interface at the injector exit section:

*

2

2

relg

f

dth

u

CD

(1)

The variance of the distribution, , is another sub-

model parameter to be properly tuned.

The model tuning is effected through an

automatic procedure developed by authors, that

solves a single objective optimization problem. In

other words, instead of resorting to a search of the

values of the constants by trial and error, i.e. for

successive approximations, an optimization problem

is set-up, where the Nelder - Mead Simplex

algorithm (Nelder and Mead, 1965) is used to reduce

the error between the results of the numerical

computations and the experimental measurements

relevant to the penetration length. The automatic

procedure allows obtaining a model of high

"portability", i.e. such to be applied as it is to

different operating conditions, or even to sprays

generated by different injectors.

The tuning procedure is hereafter described.

Experimental tests are reproduced by simulating the

spray dynamics within a domain reproducing in size

and shape the used confined vessel. At each

injection pressure, the log-normal distribution of the

initial droplet size at the injector exit section is built

starting from the value of chosen in the design of

experiments (DOE) space and the value of the

expected value computed according to eq. (1). The

distribution profile is transferred to the Fire

TM

spray

sub-model, that also receives the value of C

1

from

the DOE space. The model performs the spray

computation in the interval of time needed to inject a

given mass of gasoline (according to the

experimental measurements), and furnishes, as an

output, the penetration length of the jets

compounding the spray. The error between the

numerically computed penetration length, as

averaged over the six (or seven) jets, and the

experimentally measured one is minimized by the

Simplex algorithm. The objective function is defined

as :

n

i

inumiex

C

tltlObj

1

2

,

1

, (2)

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

488

where n represents the number of discrete

instants of time in which the injection interval of

time is subdivided, t

i

is the i

th

instant of time, and

l

ex

(t

i

) and l

num

(t

i

) the values, respectively, of the

experimentally measured and the numerically

computed penetration length at t

i

. The

experimentally measured penetration length, indeed,

is evaluated by means of a smoothing spline passing

through the actual measurements points in the time-

length plane.

Some results of the developed spray sub-model,

in its application to the 7-hole Bosch injector, are

summarised in Figure 4, where the comparison

between the experimentally measured penetration

length (of one of the seven jets compounding the

spray) and the numerically computed one (as

averaged over the seven jets) is reported for two

different injection pressures.

The prediction capability of the sub-model is

demonstrated by the really satisfactory agreement

between numerical and experimental data under all

the injection pressures.

01.53

Time (ms)

0

0.04

0.08

0.12

Penetration length (m)

p

inj

= 6 MPa

01.53

Time (ms)

0

0.04

0.08

0.12

p

inj

= 15 MPa

Figure 4: Numerical (continuous line) and experimental

(dashed line with dots) penetration lengths of the GDI

spray in a confined vessel at various injection pressures.

Moreover, the developed model also proves being

satisfactory in its application to the Magneti Marelli

6-hole injector, as demonstrated in the paper by

Costa et al. (2014).

As previously mentioned, in the considered

engine, mixture formation occurs in a wall guided

mode, with the spray directed towards a properly

shaped cavity on the piston head, which makes for

the spray droplets and vapour cloud to move in the

proximity of the spark plug. The spray wall

impingement, therefore, plays a fundamental role.

This is the reason why particular care is devoted to

account for the phenomena consequent the impact,

namely the droplets fragmentation, sticking, rebound

and evaporation as a consequence of the heat

transferred from the hot piston wall to the droplets,

which contributes to the latent heat of vaporization.

The sub-model proposed by Kuhnke (2004) is

preferred to the one by Mundo et al. (1995).

4 3D ENGINE MODEL

The formulation of the 3D engine model is carried

out within the AVL Fire

TM

environment, although

the choice of the software is not binding. As

previously mentioned, the simulation model of the

working cycle of the GDI engine object of study is

based on the coupling between the balance equations

of mass, momentum and energy for the gaseous

phase, written according to the Eulerian approach,

and the Lagrangian treatment of the liquid phase.

The mass of gasoline that at each crank angle

undergoes the phase change from liquid to vapor, in

each computational cell, constitutes a source term

for the mass balance equation of the gas phase. The

whole 4-stroke cycle is simulated. Boundary

conditions for the 3D model are obtained from test

bench data.

The discretization of the computational domain

corresponding to the cylinder and the intake and

exhaust ducts of the considered engine is made

through the pre-processing module Fame Engine

Plus (FEP) of the AVL Fire

TM

code, with part of the

domain discretized “manually” to increase the mesh

regularity and assure stability of computations.

Figure 5 shows a computational grid relevant to

the closed valve period, where one may note the care

devoted in the discretisation of the zone surrounding

the spark plug. The nose in the piston head is also

visible on the bottom left of the figure, in opposite

position to the injector location, that is on the right.

Figure 5: Computational grid at TDC.

The combustion process in the developed engine

model is simulated through the Extended Coherent

Flamelet Model (ECFM) (Colin et al., 2003), NO

formation follows the Zeldovich’s mechanism

(Zeldovich et al., 1947). The ECFM model is

properly tuned to well catch the in-cylinder pressure

curve by acting on the initial flame surface density

and the flame stretch factor. The validation consisted

in a preliminary verification of the results

independency upon the grid size, as well as in the

calculation of the motored cycle. For the sake of

ModelingandPerformanceOptimizationofaDirectInjectionSparkIgnitionEnginefortheAvoidanceofKnocking

489

brevity, further details of the validation procedure of

the 3D model are here not reported.

The interested reader may refer to the paper by

Allocca et al. (2012).

(a)

(b)

Figure 6: Numerical-experimental comparison between

the in-cylinder pressure under (a) lean burn and (b) in the

stoichiometric case.

Figure 6.a shows the comparison between the

measured pressure cycle (averaged over 300

consecutive cycles) and the cycle calculated

numerically in the lean burn case of Table 2. The

injection begins 70° BTDC and has duration of 18°;

SOS takes place 13° BTDC. Figure 6.b represents

the comparison between the calculated and the

measured pressure cycles in the stoichiometric case

of Table 2. In both the situations the numerical-

experimental agreement is really satisfactory.

The different characteristics of the mixture

formation process in the two considered cases L and

S are well highlighted in Figure 7, where the

equivalence ratio distribution of the charge on a

plane passing through the spark plug is drawn at the

time of spark ignition. The mixture inhomogeneity

of the case L is determined by the late injection. In

the stoichiometric case, the early supply of gasoline

leaves enough time to the perfect mixing of vapour

with the surrounding air. The charge stratification of

the L case is not optimal, since a rich zone appears

on the piston head, in correspondence of the nose.

Figure 7: In-chamber equivalence ratio on a plane passing

through the spark plug at SOS: (a) case L; (b) case S.

Figure 8: Comparison between numerically computed

(left) and experimentally collected images of the spray

(right) at two crank angles ASOI, for the Case S.

Information concerning the spray evolution within

the combustion chamber can be deduced from

Figure 8, where the numerically computed spray and

the experimentally collected images are represented

for two crank angles after SOI in the S case. The

developed numerical model well reproduces the

droplet dynamics and impingement on the piston

wall, which is moving towards the TDC.

Further confirmation of the good predictive

capability of the numerical model is given by Figure

9, which represents the propagation of the flame

(b)

(a)

6°ASOI

16°ASOI

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

490

front in the stoichiometric mixture in the times

immediately following the initiation of combustion,

a comparison made possible due to the optical

accessibility of the engine under study. In particular,

three different angular positions after the ignition are

considered. It must be kept into account that the

experimental image represents the flame as averaged

over the optical path, while the numerical image

represents the flame surface density on a plane

passing through the spark plug. The slight shift of

the flame toward the exhaust valves, on the left side

of the figure, is well reproduced numerically.

Figure 9: Flame front in the stoichiometric case:

experimental (left) and numerical (right) at various times.

Figure 10: Injected and evaporated gasoline mass in cases

L and S.

As an example of the type of results suitable of

being obtained through the developed numerical

model, one may look at Figure 10, where the trends

of the mass of fuel injected and of the mass of fuel

evaporated are reported in the two conditions S and

L. The evaporation in the case L is not complete at

the crank angle of spark advance, and continues

during combustion, being enhanced by the

Figure 11: CO mass fraction in cases L and S.

Figure 12: NO mass fraction in cases L and S.

consequent increase of the in-chamber temperature.

The production of the main pollutants can instead be

discussed with reference to Figure 11 and 12. A

greater production of carbon monoxide is observed

in the case L due to the incomplete combustion

process. Reduced NO amount are evident, due to the

lower combustion temperature. Definitely, the here

considered lean burn case cannot be considered

optimal, but is susceptible of improvement through a

different choice of the injection strategy or spark

advance.

5 KNOCKING PREDICTION

The study of operating conditions for which

abnormal combustions occur is carried out with

reference to the knocking phenomenon, namely to

situations in which a part of the mixture, before

being invested by the flame front ignited by the

spark plug reaches conditions that promote its

spontaneous ignition. The self-ignition of a fuel-air

mixture is the result of a series of pre-flame or low

temperature reactions, which lead to the start of the

combustion process without the intervention of an

external source of ignition, but through the

formation of not stable products of partial oxidation

(peroxides, aldehydes, hydroperoxides, etc.) and the

ModelingandPerformanceOptimizationofaDirectInjectionSparkIgnitionEnginefortheAvoidanceofKnocking

491

release of thermal energy. When the energy of the

exothermal chemical reactions exceeds the amount

of heat transferred from the reagent system to the

external environment, self-ignition takes place. As a

result, the temperature of the mixture increases,

rapidly accelerating the subsequent oxidation

reactions. The speed of the pre-flame reactions, of

chain type between highly reactive compounds, can

be reduced through the introduction in the fuels of

small quantities of additives, which hinder the

formation of radicals acting as chain propagators

(Leppard, 1991, Li et al., 1994).

The simulation of the process of self-ignition of

an air fuel mixture can be performed at different

levels of approximation. A model that has proved

being successful in predicting both spatially and

temporally the occurrence of self-ignition, and that,

at the same time, does not require excessive

computational time, is the so-called Shell model,

developed by Halstead et al. (1977). It comprehends

the start of combustion, with the break-up of the

carbon-hydrogen bond and its development through

the formation of oxygenated products.

The main advantages deriving from the use of a

reduced scheme with respect to what could be a

detailed kinetic scheme, consist precisely in the

identification of groups of radicals or radicals that

lead to the branching of the reaction chains or to

simple propagation of linear type, and in the

possibility to follow the variation in time of the

concentration of these radicals. Other kinetic

mechanisms developed subsequently to the Shell,

have a number of reactions and species involved

much higher, which makes of little interest their use

within numerical simulations on multidimensional

complex domains (Griffiths et al., 1994).

The Shell model is here used in the so-called

end-gas zone, namely in the volume of mixture not

yet reached by the flame front. The combustion

process resulting from the spark ignition is

calculated using a flamelet model, as already pointed

out in the previous paragraph.

Introducing the hydrocarbon RH, namely the fuel

of composition CxHy, the Shell model is constituted

by the following chemical reactions:

primary initialization

*2

2

RORH

pre-flame propagation

PRR **

BRR **

QRR **

BRQR **

branching

*2RB

linear and quadratic termination

NRR *

NRR *2

where the letter P indicates the reaction products

(CO

2

, H

2

O), B and Q, respectively, represent

branching agents and generic intermediate species.

With the term NR are indicated not reacting

compounds created at the end of the pre-flame

reactions.

Into detail, the model contemplates the start of

combustion, with the breaking of the chains of

carbon-hydrogen fuel and the formation of radicals

R*, and its development through the formation of

oxygenated products. As already mentioned, the

species that have a similar role in the pre-flame

kinetics are treated uniquely, as if they were a single

entity.

The numerical 3D model is first adapted to

reproduce the no knocking condition of Figure 2.a,

then the spark advance is increased twice, each of 5°

crank angle, according to Table 3.

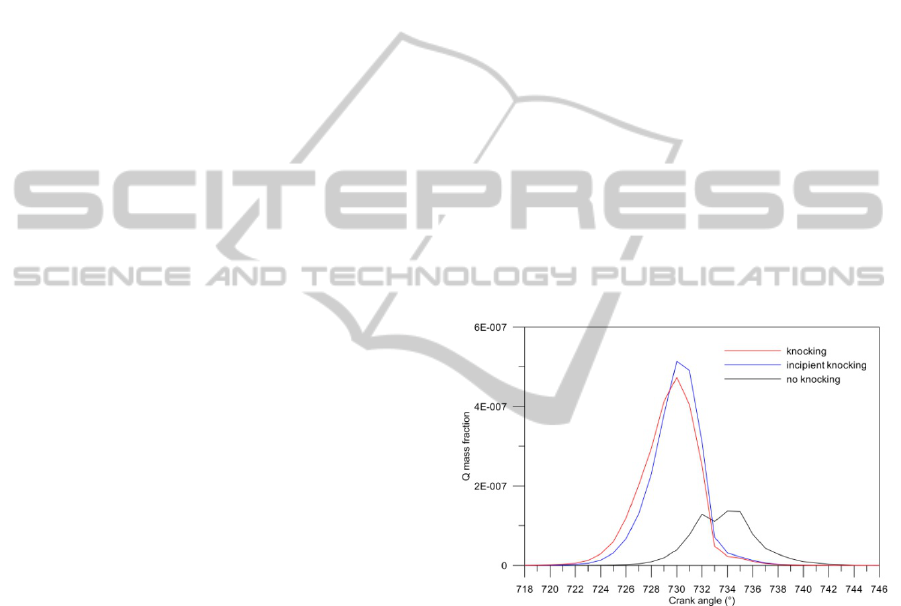

Figure 13: Q formation in the combustion chamber in the

three cases of Table 3.

Figure 13 shows the in-chamber formation of Q for

the three considered cases and well highlights that

with more advanced ignition a more rapid formation

of this group of species occurs. The location of the

maximum value of the Q concentration at the crank

angle of 729° (9° after top dead center, ATDC) is in

excellent agreement with the experimental data of

Figure 2, in particular with the start of oscillations of

the knocking case of Figure 2.c. The Shell model

also allows drawing the distribution of the

intermediate Q in the combustion chamber, that may

help in highlighting the zone where the knocking

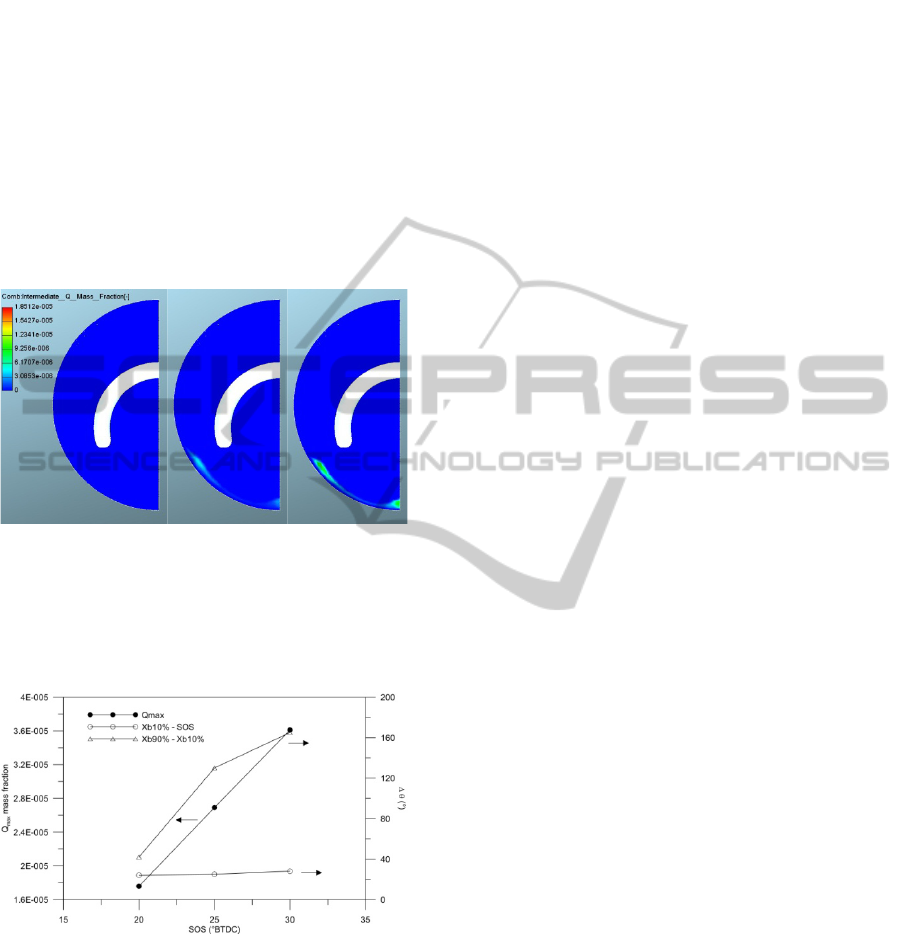

occurrence is the most probable. Figure 14

represents, in the three situations of Table 3, the

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

492

distribution of Q on a plane perpendicular to the

cylinder axis (the one at which the maximum mass

fraction of the species Q is attained) at the crank

angle of knocking occurrence, namely 729°. Due to

the symmetry assumption, only half plane is plotted.

One may note the greater chemical reactivity in the

area of the end-gas located at the bottom of the

figure, on the side where injector is mounted.

The shaped nose on the piston head, in fact,

appears clearly in the figure. The species Q,

therefore, can be used as an index of probability of

knocking occurrence. The Shell model, therefore,

allows both the spatial and temporal localization of

the phenomenon of self-ignition in the end-gas zone.

(a) (b) (c)

Figure 14: Spatial distribution of the intermediate species

of the pre-flame reactions on the plane orthogonal to the

cylinder axis of maximum concentration 9° after TDC for

the (a) no knocking, (b) incipient knocking and (c)

knocking case.

Figure 15: Maximum local value of species Q, flame

initiation angle and flame development angle a function of

SOS.

Finally, Figure 15 represents the maximum local

value of the Q mass fraction as a function of SOS,

together with the angles measuring the interval of

flame initiation and flame propagation. These may

be quantified by the interval of crank angle

comprised between SOS and

10%

and the interval

between

10%

and

90%

, respectively.

10%

is the

crank angle where the 10% of the mixture is burnt,

while

90%

is the crank angle where the 90% of the

mixture is burnt. It is clear that by increasing the

spark advance both the flame initiation and the

flame propagation get slower. The greatest intervals

needed for flame initiation and development at the

highest spark advance, hence the unfavourable

conditions of temperature and pressure at spark

timing, give the mixture enough time to self-ignite in

the end-gas zone.

Based on the afore described calculations and on

the analysis of experimental data, one may define

criteria for knocking occurrence, either based on the

evaluation of the in-cylinder amount of the Q

species, or on the more traditional evaluation of the

pressure gradient in the p- (pressure-crank angle)

plane, where a threshold value can be established

below which the engine operates regularly

(Heywood, 1988). By following this second route,

and in agreement with the experimental data, the

value of dp/d=3.5 was fixed as threshold for the

knocking occurrence.

6 ENGINE OPTIMIZATION

Although GDI engine are characterised by lower in-

cylinder temperatures with respect to port fuel

injection (PFI) engines, knocking occurrence

remains an important issue, especially in

approaching the design of a new engine prototype

and with the aim of defining the control parameters

leading to the best engine performance.

A method is here proposed to explore the DOE

space of the engine control variables, based on the

coupling between the CFD engine model and an

optimization algorithm able to point out the

condition of maximum power output (the objective

function is the maximum integral of pressure in the

pressure-volume plane in the closed valve period)

and simultaneously avoid the occurrence of the

knocking phenomenon. The start of injection (SOI)

and start of spark (SOS) are the input parameters of

the formulated optimization problem, whose flow

chart is represented in Figure 16.

A proper DOE space defines the acceptable

limits of these variables. The engine speed, air-to-

fuel ratio and valve timing are kept constant. The

optimization algorithm, here chosen as the Simplex,

runs the 3D engine model towards the optimal

solution. Computed pressure cycles that do not

satisfy the imposed constraint on the pressure

derivative, defined at the end of paragraph 5, are

discharged from the optimization results. This

ModelingandPerformanceOptimizationofaDirectInjectionSparkIgnitionEnginefortheAvoidanceofKnocking

493

Figure 16: Flow chart of the optimization problem.

approach is preferred to the use of the previously

presented Shell model in the 3D code, in order to

avoid an excessive increase of the computational

time to limits unreasonable for an optimization

process.

Table 4: Cases computed with the optimization tool at

different SOI and SOS imposed and corresponding

dp/d

max

values.

Id

SOI

[°BTDC]

SOS

[°BTDC]

dp/d

max

∫pdv

2 126 40

8.08 272.40

9 122 12

5.38 277.59

15 130 12

3.31 274.44

The obtained results exhibiting the highest value of

the objective function are presented in Table 4 and

in Figure 17.

Table 4 summarises the value of the input

variables SOI and SOS, the objective function and

the maximum value of the pressure derivative in the

p- plane, evaluated in the interval of crank angles

ranging between SOS and 10° ATDC.

Figure 17: Computed in-cylinder pressure cycles for the

three cases of Table 4.

Figure 17 represents the in-cylinder pressure cycles

in the closed valve period, for the IDs of Table 4.

Case indicated with ID=2 is characterised by a really

high pressure gradient, as shown in Figure 17.

Therefore it must be discharged. The other cases

have comparable power output, but also ID=9 must

be not considered due to the adopted constraint on

the knocking occurrence. ID=15 is, therefore, the

optimal solution, with the SOS of ID=9 (knocking

condition), but a SOI occurring 130° BTDC. This

shows a favourable effect of advancing injection on

knocking occurrence.

7 CONCLUSIONS

Mixing control is fundamental in internal

combustion engines. It assures flame stability,

reduction of pollutants, improved combustion

efficiency, reduced size and greater lifetimes of

combustors.

Achievement of optimal charge conditions at all

the engine loads and speeds in modern gasoline GDI

spark ignition engines is undoubtedly a challenging

task, especially if the so-called mixed mode boosting

is to be realized, with homogeneous stoichiometric

or rich mixtures at the higher loads, and stratified

lean mixtures at the lower ones. This is the reason

why fully automatic procedures to be used in the

phase of definition of the engine governing

parameters are strongly demanded.

Present work aims at presenting a 3D numerical

model able to reproduce the in-cylinder processes of

a high performance GDI engine. The model includes

a sub-model for the spray dynamics tuned through

an automatic procedure on the ground of an

experimental campaign conducted in an optically

accessible vessel, as well as a proper spray-wall

impingement sub-model that accounts for the heat

transferred from the wall to the liquid deposits of

fuel.

The considered engine has the head of a

commercial 1750 cm

3

automotive power system, but

is optically accessible due to properly made

modifications to the piston and engine block. This

allows capturing images of both the in-cylinder

mixture formation and combustion processes.

The developed 3D engine model is shown to well

reproduce the in-cylinder thermo-fluidynamics

under both stoichiometric and lean charges. It allows

determining with very good accuracy the whole

pressure cycle over the 4-stroke period, as well as

the flame propagation within the combustion

chamber. This highlights any inadequacy of the

mixture formation process that may cause

incomplete or unstable combustions.

A simplified model for the pre-flame reactions is

also considered in the end-gas zone of the

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

494

combustion chamber, not yet reached by the

principal flame front, in order to detect the possible

occurrence of knocking through numerical

simulations.

Under proper operating conditions, computations

show a good agreement with experiments as regards

the knocking onset and its temporal location. The

spatial position being the most probable for

knocking is also highlighted. The chemical reactivity

in the zone not yet reached by the flame front

increases as the spark advance is increased, also as a

consequence of the greatest time needed for flame

initiation consequent the lower in-chamber value of

temperature and pressure at spark timing.

According to the performed analysis, a criterion

is established to individuate the knocking occurrence

from the pressure cycle trend.

The developed model is finally included within

an optimization problem aimed at maximizing the

engine power output by proper choice of the

injection strategy and the time of spark ignition with

the avoidance of knocking.

The described simulation approach may be

employed in the phase of engine design to reduce the

time-to-market of new technologies. If reliable

experimental data available for engines of analogous

configurations for validation are missing, the

proposed approach may even furnish qualitative

information useful for the development of control

strategies.

REFERENCES

Alkidas, A. C., 2007. Combustion advancements in

gasoline engines, Energy Conversion and

Management, Vol. 48, pp. 2751–2761.

Allocca, L., Costa, M., Montanaro, A., Sementa, P., Sorge,

U., Vaglieco, B.M., 2012. Characterization of the

Mixture Formation Process in a GDI Engine Operating

in Stratified Mode, 12th Triennial Int. Conf. on Liquid

Atomization and Spray Systems, Heidelberg.

Carling, R. W., 2010. Predictive Simulation of

Combustion Engine Performance in an Evolving Fuel

Environment, Sandia National Laboratories.

Colin, O., Benkenida, A., Angelberger, C., 2003. 3D

Modeling of Mixing, Ignition and Combustion

Phenomena in Highly Stratified Gasoline Engines, Oil

& Gas Science and Technology – Rev. IFP Energies

Nouvelles, Vol. 58, pp. 47-62.

Costa, M., Sorge, U., Allocca, L., 2012. CFD optimization

for GDI spray model tuning and enhancement of

engine performance, Advances in Engineering

Software, Vol. 49, pp. 43-53.

Costa, M., Marchitto, L., Merola, S.S., Sorge, U., 2014.

Study of mixture formation and early flame

development in a research GDI engine through

numerical simulation and UV-digital imaging, Energy,

doi: 10.1016/j.energy.2014.04.114.

Dukowicz, J.K., 1979. Quasi-steady droplet change in the

presence of convection, informal report Los Alamos

Scientific Laboratory, Los Alamos Report LA7997-

MS.

Griffiths, J.F., Hughes, K.J., Schreiber, M., Poppe, C.,

Dryer, F.L., 1994. A unified approach to the reduced

kinetic modeling of alkane combustion, Combustion

and Flame, Vol. 99 (3-4), pp. 533-540.

Halstead, M.P., Kirsch, L.J., Quinn, C.P., 1977. The auto-

ignition of hydrocarbon fuel at high temperatures and

pressures-fitting of a mathematical model, Combustion

and Flame, Vol. 30, pp. 45-60.

Heywood, J.B., 1988. Internal Combustion Engine

Fundamentals, New York: McGraw-Hill.

Huh, K.Y., Gosman, A.D., 1991. A phenomenological

model of diesel spray atomisation, International

Conference on Multiphase Flows, Tsukuba, Japan.

Kuhnke, D., 2004. “Spray Wall Interaction Modeling by

Dimensionless Data Analysis”, PhD thesis,

Technische Universität Darmstadt.

Leppard, W.R, 1991. The autoignition chemistries of

octane-enhancing ethers and cyclic ethers: A motored

engine study, SAE Paper 912313.

Li, H., Prabhu, S., Miller, D., Cernansky, N., 1994.

Autoignition Chemistry Studies on Primary Reference

Fuels in a Motored Engine, SAE Tech. Paper 942062.

Mundo, C., Sommerfeld, M., Tropea, C., 1995. Droplet-

Wall Collisions: Experimental Studies of the

Deformation and Breakup Process, International

Journal of Multiphase Flows, Vol. 21(2), pp. 151-173.

Nelder, J. A., Mead, R., 1965. A simplex method for

function minimization, Computer Journal, Vol. 7, pp.

308–313.

Nordin, W.H., 2001. Complex Modeling of Diesel Spray

Combustion, Thesis (PhD), Chalmers University of

Technology.

Oh H. C., Bae C. S., 2013. Effects of the injection timing

on spray and combustion characteristics in a spray-

guided DISI engine under lean-stratified operation,

Fuel, Vol. 107, pp. 225–235.

O’Rourke, P.J., Bracco, F.V., 1980. Modeling of Drop

Interactions in Thick Sprays and a Comparison with

Experiments, IMECHE, London.

Park, C. Kim, S., Kim, H. Moriyoshi, Y., 2012. Stratified

lean combustion characteristics of a spray-guided

combustion system in a gasoline direct injection

engine, Energy, Vol. 41, pp. 401-407.

Ramos, J. I., 1989. Internal Combustion Engine

Modelling, CRC Press.

Stan, C., 2000. Direct injection systems for spark-ignition

and compression-ignition engines, SAE Publication.

Shi, Y., Ge, H. W., Reitz, R. D., 2011. Computational

Optimization of Internal Combustion Engines,

Springer-Verlag. London.

Thévenin, D., Janiga, G. (Eds.), 2008. Optimization and

Computational Fluid Dynamics, Springer-Verlag.

Berlin Heidelberg.

ModelingandPerformanceOptimizationofaDirectInjectionSparkIgnitionEnginefortheAvoidanceofKnocking

495

Zeldovich, Y.B., Sadovnikov, P.Y., Frank-Kamenetskii,

D.A., 1947. Oxidation of Nitrogen in Combustion,

Translation by M. Shelef, Academy of Sciences of

USSR, Institute of Chemical Physics, Moscow-

Leningrad.

Zhao, H., Ladommatos, N., 2001. Engine Combustion

Instrumentation and Diagnostics, SAE Int. Inc..

SIMULTECH2014-4thInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

496