Seam Tracking Control of Welding Robotic Manipulators Based on

Adaptive Chattering-free Sliding-mode Control Technology

Youmin Hu

1

, Jie Liu

1

, Bo Wu

1

and Ming-Feng Ge

2

1

School of Mech. Sci. and Eng., Huazhong University of Science and Technology, Luoyu Rd 1037, Wuhan, China

2

College of Automation, Huazhong University of Science and Technology, Luoyu Rd 1037, Wuhan, China

Keywords:

Seam Tracking Control, Chattering-free, Adaptive Sliding-mode Control (ASMC), Welding Robotic Manipu-

lator, Large-scale Structure Component.

Abstract:

A novel adaptive sliding mode control (ASMC) algorithm is derived to deal with seam tracking control prob-

lem of welding robotic manipulator, during the process of large-scale structure component welding. The

controllers robustness is verified by the Lyapunov stability theory, and the analytical results show that the pro-

posed algorithm enables better high-precision tracking performance with chattering-free than classic sliding

mode control (SMC) algorithm.

1 INTRODUCTION

Large-scale structure component holds a large pro-

portion in the large engineering machinery, with a

very high importance. As main bearing component,

its connection mode is mainly composed of welding

parts. Therefore, the welding quality directly affects

the performance of the large-scale structure compo-

nent, to some extent, determines the overall quality of

the engineering machinery product itself, and the cost

of the production.

Figure 1: Manual welding is still dominated and adopted

(Provided by Weihua Group in Henan, China).

Unfortunately, manual welding is still dominated

and adopted in the manufacturing of the large-scale

structure component, as shown in Figure 1 above.

Currently, welding robotic automation improves the

welding quality, increases productivity and sets men

free from unhealthy, monotonous and poor working

conditions in industrial areas, as illustrated in Figure

2.

Figure 2: Welding robot in crane welding production line

(Provided by Nucleon (Xinxiang) Crane Co., Ltd in Henan,

China).

However, due to its main characteristic is big size

and large tonnage, it leads to difficulties in the pro-

cess of robotic welding. For example, the beam of

large crane is about 100 meters long. And the large-

scale structure component has diverse forms of weld

seams, such as flat, vertical and horizontal, which

would form welding residual deformation, such as

flexural deformation, distortion, waves of panel, etc.

In general, the robotic welding process of large-scale

structure component in the large engineering machin-

ery is more difficult, and needs higher technical re-

quirements than in the general structure component.

In order to overcome or restrain various uncertain

influences, caused by the large-scale structure compo-

nents weld seam, on welding quality, it is promising

to develop and improve intelligent technologies for

welding robots (Chen and Lv, 2014). Among these

417

Hu Y., Liu J., Wu B. and Ge M..

Seam Tracking Control of Welding Robotic Manipulators Based on Adaptive Chattering-free Sliding-mode Control Technology.

DOI: 10.5220/0005055104170420

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 417-420

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

intelligent technologies, tracking control of robotic

manipulators has a great of attention. Tracking con-

trol is needed to make each joint track a desired tra-

jectory as close as possible. Many control algorithm

such as computer torque method (Craig, 1989), opti-

mal control (Ruderman, 2014), adaptive control (Slo-

tine and Li, 1987), variable structure control (VSC)

(Cao and Ren, 2012), neural networks (NNs) (Yan

and Wang, 2012) and fuzzy system (Cruz and Mor-

ris, 2006) have been proposed to deal with this robotic

control problem. However, robotic manipulators are

highly nonlinear, highly time-varying and highly cou-

pled. Moreover, there always exists uncertainty in the

system model such as external disturbance, parame-

ter uncertainty, sensor errors and so on, which cause

unstable performance of the robotic system (Guo and

Woo, 2003).

In this paper, a novel adaptive sliding mode con-

trol (ASMC) algorithm is derived to deal with seam

tracking control problem of welding robotic manipu-

lator, during the process of large-scale structure com-

ponent welding. Its well known that classic sliding

mode control (SMC) will cause chattering, which is

a crucial disadvantage to the stability of the system,

making the controller designing become extremely

troublesome. The controllers robustness is verified by

the Lyapunov stability theory, and the analytical re-

sults show that the proposed algorithm enables better

high-precision tracking performance with chattering-

free than classic SMC.

The layout of the paper is as follows. Section 2

presents the dynamic model of welding robotic ma-

nipulator, and some relevant properties are discussed.

In Section 3, a novel adaptive sliding mode controller

is developed and analyzed for the tracking control of

welding robotic manipulators. Simulation examples

are given to demonstrate the performance of the pro-

posed controller in Section 4. Finally, we offer brief

conclusions and suggestion for further research.

2 DYNAMIC MODEL OF

WELDING ROBOTIC

MANIPULATORS

In general, the dynamic model of the 3-link welding

robotic manipulator is given as follows

M(q) ¨q+C(q, ˙q) ˙q+ g(q) + d(t) = u, (1)

where M(q) = M

T

(q) ∈ R

3×3

is the symmetric pos-

itive definite inertia matrix; q ∈ R

3

denotes the joint

position vector; C(q, ˙q) ∈ R

3×3

is the Coriolis and

centrifugal torques; g(q) ∈ R

3

is the vector of gravita-

tional torques; d(t) ∈ R

3

denotes the bounded distur-

bance; and u ∈ R

3

represents the torque input vector.

Several fundamental properties of the robot model

(1) can be obtained as follows.

Property 1. The matrix

˙

M(q) − 2C(q, ˙q) is skew sym-

metric matrix, i.e.,

x

T

˙

M(q) − 2C(q, ˙q)

x = 0, ∀x ∈ R

3

.

Property 2. For arbitrary x, y ∈ R

3

, we get that

M(q)x+C(q, ˙q)y+ G(q) = Y(q, ˙q, x, y)θ,

where Y(q, ˙q, x, y) denotes the regression matrix, θ is

the constant unknown parameter vector.

Property 3. The unknown disturbance d(t) is as-

sumed to be unknown, but bounded, i.e., kd(t)k < η.

3 CONTROLLER DESIGN

3.1 Adaptive Sliding Mode Controller

The objective of designed controller is to drive the

joint position q to the desired trajectory position q

d

.

First we define the tracking error as following:

˜q = q − q

d

. (2)

Let the sliding surface

s =

˙

˜q+ β ˜q, (3)

where β = diag[β

1

, β

2

, β

3

] in which β

i

is a positive

constant.

The objective of controller can be achieved by

choosing the control input u, so that the sliding sur-

face satisfies the sufficient condition (Slotine and Li,

1989; Slotine and Li, 1991). Let the reference state

˙q

r

= ˙q− s = ˙q

d

− β ˜q, (4)

and

¨q

r

= ¨q− ˙s = ¨q

d

− β

˙

˜q. (5)

Then the control law u is designed as

u =

ˆ

M(q) ¨q

r

+

ˆ

C(q, ˙q) ˙q

r

+ ˆg(q) − K

r

sgn(s)

α

, (6)

where

ˆ

M(q),

ˆ

C(q, ˙q) and ˆg(q) are the estima-

tions of M(q), C(q, ˙q) and g(q) respectively; K

r

=

diag[K

r11

, K

r22

, K

r33

] is a diagonal positive definite

matrix; sgn(s)

α

is defined as

sgn(x)

α

=

|x

1

|

α

sign(x

1

), |x

2

|

α

sign(x

2

), |x

3

|

α

sign(x

3

)

T

,

(7)

and x ∈ R

3

, 0 < α < 1.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

418

Then combining system (1) with the control law

(6), we can conclude

[

ˆ

M(q) −

˜

M(q)](˙s+ ¨q

r

) + [

ˆ

C(q, ˙q)−

˜

C(q, ˙q)](s+ ˙q

r

)+

ˆg(q) − ˜g(q) + d(t) =

ˆ

M(q) ¨q

r

+

ˆ

C(q, ˙q) ˙q

r

+ ˆg(q)−

K

r

sgn(s)

α

,

(8)

where

˜

M(q) =

ˆ

M(q) − M(q),

˜

C(q) =

ˆ

C(q) −C(q) and

˜g(q) = ˆg(q) − g(q). Thus system (8) becomes

M(q) ˙s+C(q, ˙q)s+ d(t) =

˜

M(q) ¨q

r

+

˜

C(q, ˙q) ˙q

r

+

˜g(q) − K

r

sgn(s)

α

.

(9)

By using property 2, since the matrixes M(q),

C(q, ˙q) and g(q) are linear in terms of the manipulator

parameters, system (9) can be written as

˜

M(q) ¨q

r

+

˜

C(q, ˙q) ˙q

r

+

˜

G(q) = Y(q, ˙q, ˙q

r

, ¨q

r

)

ˆ

θ, (10)

and therefore

M(q) ˙s+C(q, ˙q)s+d(t) = Y(q, ˙q, ˙q

r

, ¨q

r

)

˜

θ−K

r

sgn(s)

α

.

(11)

Based on the properties above, the adaptation law

is designed as following:

˙

ˆ

θ = −ΓY

T

s. (12)

3.2 Stability Analysis

Considering the following Lyapunov function candi-

date for system (11)

V =

1

2

s

T

M(q)s+

1

2

˜

θ

T

Γ

−1

˜

θ, (13)

where θ is a 3-dimensional vector containing the un-

known manipulator and load parameters,

ˆ

θ is its esti-

mate, and

˜

θ =

ˆ

θ− θ denotes the parameter estimation

error vector. According to the property 1, Equation

(11) and (12), the derivative of the chosen Lyapunov

function can be derived as:

˙

V = −s

T

d(t) − s

T

K

r

sgn(s)

α

.

By using property 3, we can conclude

˙

V ≤ kskkd(t)k − λ

min

(K

r

)ksk

α+1

≤ kskη− λ

min

(K

r

)ksk

α+1

= −ksk(λ

min

(K

r

)ksk

α

− η).

(14)

Then we have the following theorem.

Theorem 1. For system (1) under controller (6) and

(12), if λ

min

(K

r

) > 0, 1 > α > 0 and Γ > 0, the system

trajectory will converge to the neighborhood of s = 0

as

ksk ≤

η

λ

min

(K

r

)

1

α

(15)

in finite time.

Proof. Notice that when (15) holds, from (14), we

can conclude

˙

V ≤ 0. Then by the finite time stabil-

ity theory, the neighborhood (15) can be reached in

finite time. This completes the proof.

4 SIMULATION

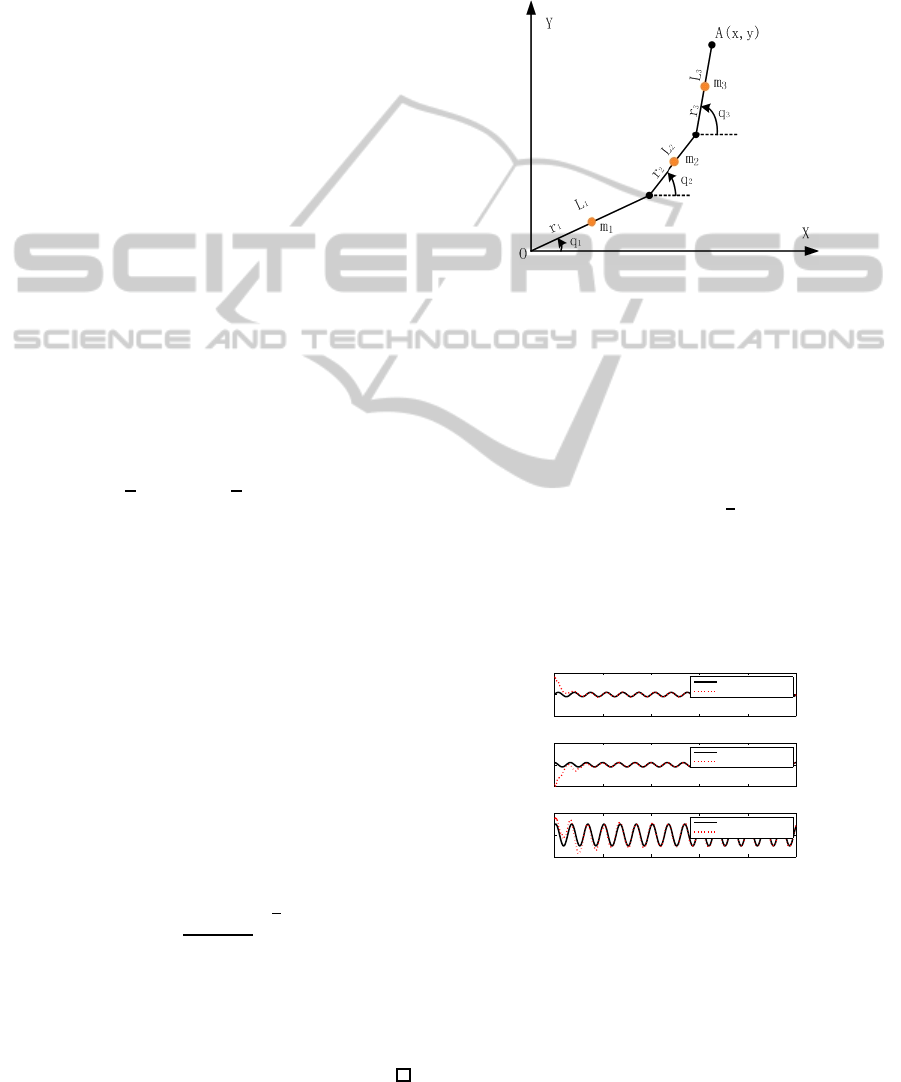

Simulation is performed by using a 3-link non-linear

planer robot manipulator, as shown in Figure 3, which

dynamic model is derived by methods in (Spong and

Vidyasagar, 2008).

Figure 3: A 3-link robot manipulator.

The robotmanipulatorsparameter values are m

1

=

0.5kg, m

2

= 1.5kg, m

3

= 1.3kg, l

1

= 1m, l

2

= 1m,

l

3

= 1m, r

1

= 0.5m, r

2

= 0.5m, and r

3

= 0.5m. The

moment of inertia are i

1

= 2kg· m

2

, i

2

= 2kg· m

2

, and

i

3

= 2kg · m

2

. The initial conditions of the robot ma-

nipulator are given as q

1

(0) = 8, q

2

(0) = −9, q

3

(0) =

1.5, ˙q

1

(0) = 8, ˙q

2

(0) = −9, and ˙q

3

(0) = 1.5. The

reference signals are given by q

d1

= sin(3πt), q

d2

=

cos(3πt), and q

d3

= sin(3πt +

1

3

π). The bounded

disturbance is selected as d

1

(t) = 5sin(t), d

2

(t) =

2.5cos(t), d

3

(t) = 5sin(2t).

Besides, the parameter α in Equation (6) is set as

α = 0.6, and the gain K

r

in Equation (6) is designed

as K

r

= diag[300, 300, 300].

0 2 4 6 8 10

−10

0

10

time(s)

Angle response

Ideal position signal 1

Position tracking 1

0 2 4 6 8 10

−10

0

10

time(s)

Angle response

Ideal position signal 2

Position tracking 2

0 2 4 6 8 10

−2

0

2

time(s)

Angle response

Ideal position signal 3

Position tracking 3

Figure 4: Ideal position signal and position tracking output.

The simulation results above show that the de-

signed chattering-free ASMC can enable the abil-

ity of tracking control of the 3-link nonlinear planer

robot manipulator under various disturbances. Fur-

thermore, the proposed control algorithm doesnt re-

quire the precise dynamic model of the robot manip-

ulator.

SeamTrackingControlofWeldingRoboticManipulatorsBasedonAdaptiveChattering-freeSliding-modeControl

Technology

419

0 2 4 6 8 10

−10

0

10

time(s)

Angle response

Position tracking error 1

0 2 4 6 8 10

−20

0

20

time(s)

Angle response

Position tracking error 2

0 2 4 6 8 10

−1

0

1

time(s)

Angle response

Position tracking error 3

Figure 5: Position tracking output error.

0 2 4 6 8 10

−100

0

100

time(s)

Angle velocity response

Ideal position velocity signal 1

Position velocity tracking 1

0 2 4 6 8 10

−100

0

100

time(s)

Angle velocity response

Ideal position velocity signal 2

Position velocity tracking 2

0 2 4 6 8 10

−50

0

50

time(s)

Angle velocity response

Ideal position velocity signal 3

Position velocity tracking 3

Figure 6: Ideal position velocity signal and position velocity

tracking output.

0 2 4 6 8 10

−100

0

100

time(s)

Angle velocity response

Position velocity tracking error 1

0 2 4 6 8 10

−100

0

100

time(s)

Angle velocity response

Position velocity tracking error 2

0 2 4 6 8 10

−50

0

50

time(s)

Angle velocity response

Position velocity tracking error 3

Figure 7: Position velocity tracking output error.

5 CONCLUSIONS

We have proposed a novel chattering-freeASMC con-

troller for the seam tracking control of robotic manip-

ulator. And the proposed algorithm is more practical

than the traditional SMC controller. Besides, the sim-

ulation results have shown that the ability of the track-

ing control under various disturbances. In the end, a

challenging work for further research is to perform

the proposed algorithm in the seam tracking control

during the process of practical welding, and verify its

effectiveness.

ACKNOWLEDGEMENTS

The work here is supported by the National Natural

Science Foundation of China (No. 51175208), the

State Key Basic Research Program of China (NO.

2011CB706803), the Fundamental Research Funds

for the Central Universities (No. 2013ZZGH001).

REFERENCES

Cao, Y. C. and Ren, W. (2012). Distributed coordinated

tracking with reduced interaction via a variable struc-

ture approach. IEEE Transaction on Automatic Con-

trol, 57(1):33–48.

Chen, S. B. and Lv, N. (2014). Research evolution on

intelligentized technologies for arc welding process.

Jounal of Manufacturing Processes, 16:109–122.

Craig, J. J. (1989). Introduction to Robotics. Addison-

Wisley, 2nd edition.

Cruz, E. A. M. and Morris, A. S. (2006). Fuzzy-ga-based

trajectory planner for robot manipulators sharing a

common workspace. IEEE Transaction on Robotics,

22:613–624.

Guo, Y. Z. and Woo, P. Y. (2003). Adaptive fuzzy sliding

mode control for robotic manipulators. In 42nd IEEE

Conference on Control, Maul, Hawaii, USA.

Ruderman, M. (2014). Tracking control of motor drives us-

ing feedforward friction observer. IEEE Transactions

on Industrial Electronics, 61(7):3727–3735.

Slotine, J. E. and Li, W. (1987). On the adaptive control

of robot manipulators. The international journal of

robotics research, 6(3):49–59.

Slotine, J. E. and Li, W. (1989). Composite adaptive control

of robot manipulators. Automatica, 25:509–519.

Slotine, J. E. and Li, W. (1991). Applied Nonlinear Control.

The publishing company, Prentice Hall.

Spong, M. W. and Vidyasagar, M. (2008). Robot dynamics

and control. John Wiley & Sons.

Yan, Z. and Wang, J. (2012). Model predictive control for

tracking of underactuated vessels based on recurrent

neural networks. IEEE Journal of Oceanic Engineer-

ing, 37(4):717–726.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

420