Multispectral Data Fusion for Robotic Reconnaissance and Mapping

Petra Kocmanova

1

, Ludek Zalud

2

, Frantisek Burian

2

and Tomas Jilek

2

1

Institute of Geodesy, Brno University of Technology, Veveri 331/95, Brno, Czech Republic

2

CEITEC, Brno University of Technology, Technicka 3082/12, Brno, Czech Republic

Keywords: Data Fusion, Sensory Head, Range Camera, CCD Camera, Thermal Imager.

Abstract: The aim of the paper is to describe the data-fusion from optical sensors for mobile robotics reconnaissance

and mapping. Data are acquired by stereo pair of CCD cameras, stereo pair of thermal imagers, and TOF

(time-of-flight) camera. The fusion is realized by means of spatial data from a TOF camera to ensure

”natural” representation of a robot’s environment; thus, the thermal and CCD camera data are comprised in

one stereo image presented to a binocular, head-mounted display. The data acquisition is performed using a

sensor head, which is placed on an Orpheus-X3 robot; both the head and the robot were developed by our

working group. After the geometrical calibration of each sensor, the positions of the sensors in 6DOFs are

computed. The corresponding data from the CCD camera and the thermal imager are subsequently

determined via homogeneous and perspective transformations. The result consists in an image containing

aligned data from the CCD camera and the thermal imager for each eye. TOF camera calibration and its

impact to the precision of fusion is described. Although the fusion is used for two different tasks –

automatic environment mapping and visual telepresence, the utilised calibration and fusion algorithms are,

in principle, the same.

1 INTRODUCTION

The described calibration and data-fusion algorithms

may be used for two purposes: visual telepresence

(remote control) under extremely wide variety of

visual conditions, like fog, smoke, darkness, etc.,

and for multispectral autonomous digital mapping of

the robot’s environment.

The method uses a combination of „classical“

cameras working in visible spectrum with thermal

imagers working in 7-14um spectrum. Each of them

has certain advantages and disadvantages.

Modern visible-spectrum cameras offer a very

good overview of the situation with high resolution.

Their image representation is the most intuitive for

the operator. On the other hand the dynamic range of

them is much lower than the one of a human eye.

They also do not work in complete darkness, cannot

see through fog or smoke.

Thermal imagers became widely available during

the last couple years, when their price was reduced

significantly. The main advantages - they can

percept in fog, at least for short distances, they are

also almost unaffected by visible light, so it does not

matter how the scene is illuminated (complete

darkness, point light sources, …). The main

disadvantages – they offer significantly lower pixel

resolution comparing to standard cameras, they are

still significantly more expensive and the image

offered is not so intuitive to the operator, since it

basically corresponds to temperatures of the objects.

So it seems valuable to combine these two

Figure 1: Orpheus robots (from left) – Orpheus Hope, Oprheus-AC2, Orpheus-AC2, Orpheus-X3.

459

Kocmanova P., Zalud L., Burian F. and Jilek T..

Multispectral Data Fusion for Robotic Reconnaissance and Mapping.

DOI: 10.5220/0005060504590466

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 459-466

ISBN: 978-989-758-040-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

imagers into one image. Nowadays several

companies provide combined CCD – thermal

imagers, but their approach is simplistic – the

images are only geometrically aligned, so because of

parallax the images do not correspond exactly for

most cases. Furthermore the used CCD cameras are

typically of low quality and with limited field of

view. So these solutions are not appropriate for

telepresence in rescue robotics.

The technique was studied by our team in the

past (Zalud, 2005), but as the sensory prices

decreased and TOF cameras matured, the technique

now may be done more advanced. In this article we

introduce a technique for visual spectrum data and

thermal imager data alignment with help of data

from TOF camera. The TOF camera measures a

distance of an object, while corresponding pixels are

found on color camera and thermal imager. Each of

the sensors has to be calibrated for geometrical

errors, mutual position and orientation is found and

used to make the correspondence calibrations.

This is done for two stereo-pairs of cameras, so

the resulting image may be presented to head-

mounted display with stereovision support, so the

operator has a very good spatial representation of the

surrounding under any visibility conditions.

It has to be pointed out the sensors on the

sensory head will not be used only for this

technique, in parallel we also develop SLAM

technique with similar texture-mapping algorithms.

2 HARDWARE

2.1 Orpheus-X3

The Orpheus-X3 is an experimental reconnaissance

robot based on the Orpheus-AC2 model made by our

team to facilitate the measurement of chemical and

biological contamination or radioactivity for military

purposes (Fig. 1). The Orpheus-X3 offers the same

drive configuration as its predecessor, namely the

four extremely precise AC motors with harmonic

gears directly mechanically coupled to the wheels;

this configuration makes the robot very effective in

hard terrain and enables it to achieve the maximum

speed of 15 km/h. The main difference consists in

the chassis, which is not designed as completely

waterproof but consists of a series of aluminum

plates mounted on a steel frame of welded L-

profiles. This modular structural concept makes the

robot markedly more versatile, which is a very

important aspect in a robot made primarily for

research activities. Furthermore, the device is

equipped with a 3DOF manipulator for the sensory

head. The manipulator, again, comprises very

powerful AC motors combined with extremely

precise, low backlash harmonic drive gearboxes by

the Spinea company. The presence of such precise

gearboxes can be substantiated by several reasons,

mainly by the fact that the robot will be used not

only for telepresence but also for mobile mapping

and SLAM. As currently planned, the robot’s only

proximity sensor will be the TOF camera placed on

the sensory head.

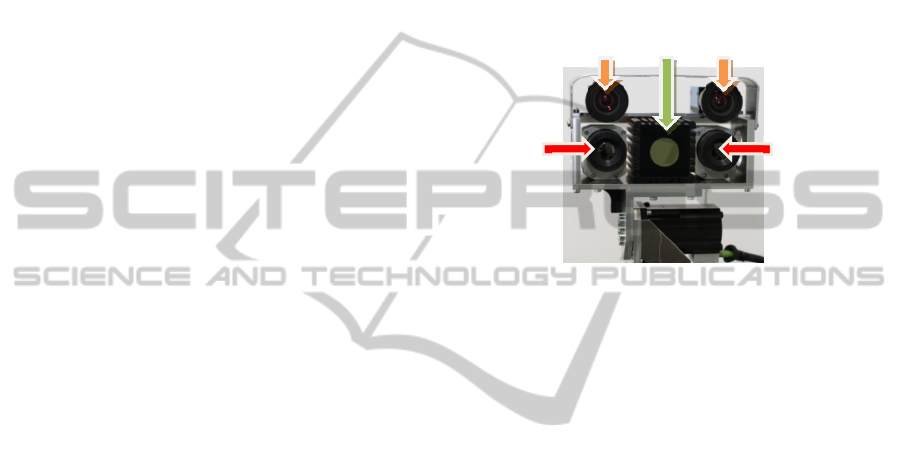

Figure 2: The sensory head. 1 – the tricolor CCD cameras,

2 – the thermal imagers, 3 – the TOF camera.

2.1.1 Sensory Head

The sensory head containing five optical sensors is

shown in Fig. 2.

Two tricolor CCD cameras (see 1 in Fig. 2).

TheImagingSource DFK23G445 with 1280x960

pixels resolution, max refresh rate 30Hz, and

GiGe Ethernet protocol. A Computar 5mm 1:1.4

lens is used.

Two thermal Imagers (see 2 in Fig. 2).

MicroEpsilon TIM 450 with a wide lens,

382x288 pixels resolution, temperature resolution

of 0.08K, a USB output.

One TOF camera (see 3 in Fig. 2). A Mesa

Imaging SR4000 with the range of 10m, 176x144

pixels resolution, an Ethernet output. The field of

view is 56˚(h) x 69˚(v).

From the preceding text we can conclude, the

fields-of-view (FOVs) of the sensors are similar.

The largest FOV captures TOF camera, which is

required for simultaneous use of stereovision and

thermal stereovision. The main disadvantage of the

used TOF camera is its low number of pixels (spatial

resolution). In relation to the CCD cameras is about

10 times lower in one axis and in relation to thermal

imagers, it is 2 times lower.

1

1

2

2

3

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

460

3 SENSOR CALIBRATION

PROCEDURE

The reasons for the sensory head calibration are

following:

Simultaneous use of all five sensors leads to

necessity of determination translations and

rotations among cameras.

Absolute range precision guaranteed by the

manufacturer for range camera is ± 15 mm, but

only for the central 11 × 11 pixels. According to

our experience, range measurement is less precise

- for details see (Kocmanova, 2013)

Temperature shift in color-coded thermal images

(about 1.5K) must be resolved for simultaneous

use of 2 thermal imagers.

With respect to the previous description,

calibration of the sensory head consists of the

following parts (see Fig. 3): range calibration,

temperature calibration, calibration of intrinsic and

extrinsic parameters.

Figure 3: Calibration scheme for all sensors.

3.1 Range Calibration

Range calibration of the TOF camera is detailed

described in (Kocmanova, 2013). Improvement of

range accuracy is evident from Fig. 4. Range

accuracy was tested in 4 regions (see Fig. 5) that are

defined by manufacturer (SR4000, 2011).

3.2 Temperature Calibration

The microEpsilon TIM 450 low quality thermal

imagers were used for this application. The main

reason for this was the low price and very small

dimensions. Although the temperature resolution

(0.08K according to the datasheet) is relatively

sufficient, the absolute precision of 2K can be

defined as poor.

Figure 4: MSE of measured distance for all regions of

TOF camera before and after calibration.

Figure 5: Image division of TOF camera into the region by

accuracy.

In our application, we use two identical thermal

imagers for stereovision. The temperatures are

“expressed“ by colour-coding. In most cases, the

range of colors displayed is quite small (couple

of K). To provide the most relevant data to the

operator, it is important to use the narrowest

temperature range possible, because the more

different are the colors representing the nearby

temperatures, the better the visual perception is. But

as it was already mentioned, the temperature shift

between the two cameras may be - and indeed often

is during the first 30 minutes of operation - in the

order of Kelvins. This may cause unwanted color

shift between the left and right images (Fig. 6).

Figure 6: The temperature shift in the color-coded left and

right thermal images provided by the TIM450 cameras:

the calculated temperature shift is 1.5K. The grayscale

coding (upper row); the thermal-red coding (bottom row).

MultispectralDataFusionforRoboticReconnaissanceandMapping

461

The algorithm to solve this problem is as follows: A

temperature histogram of the left and right images is

made, and the cross-correlation (Eq. 1) function is

calculated. The maximum on the resulting function

corresponds to the actual mutual temperature shift

between the cameras, and therefore we then shift the

temperatures in one of the matrices.

hc

i

ikrhistilhistkcc

0

))(_*)(_()(

where hist_l and hist_r are the temperature discrete

histograms of the left or right thermal image

respectively, and hc is the histogram dimension.

3.3 Calibration of Intrinsic and

Extrinsic Parameters

An interesting problem was to find a material from

that a pattern would be clearly identifiable in the

images of all sensors. For opaque body, the sum of

surface reflectivity and emissivity equals to 1

(Bartl). To create a calibration plate it is necessary to

select two materials with significantly different

emissivity (i.e. also reflectivity). If the emissivity of

both materials isn´t sufficiently different, it is

possible to increase the contrast between materials

by heating one of them.

There are various options to find sufficiently

contract materials. In (Luhmann, 2010) authors

create plane test field that consists of wooden board

with 57 small lamps that warm up when switched on

and test field based on a metal surface with coded

and uncoded circle target points created using self-

adhesive foil. In (X.Ju, 2005) plane with heated

circle target was used for calibration of thermal

imager and color camera stereo pair, and in

(Prakash, 2006) a pair of thermal imagers was

calibrated with checker-board pattern heated by a

flood lamp.

We proposed checkerboar calibration plate. First

version of calibration was from aluminum plate (low

emissivity, high reflectivity) and self-adhesive foil

(high emissivity, low reflectivity). This board had a

problem with high reflectivity of aluminum base.

Second version was aluminum plate with laser-

cut pattern coated by anodizing behind that was

aluminum plate chipboard covered by black matte

foil. Final version is 2mm thin laser-cut aluminum

plate with active heating (see Fig. 7)

Calibration of intrinsic and extrinsic parameters

is based on (Zhang, 1999) and is realized as follows:

the first step consisted in edge extraction, the second

was the initial calibration of intrinsic and extrinsic

parameters, and the last stage of the calculation

included nonlinear optimization (which minimizes

the sum of the squares of the re-projection errors

including the determination of distortion). The

mathematical model is detailed described in (Zalud,

2013, SSRR).

Figure 7: The calibration target: the left and right CCD

cameras (up), the TOF camera intensity image (center),

the left and right thermal imagers (down) camera.

4 DATA FUSION PROCESS

Image transformations are applied for data fusion.

The range measurements of the TOF camera can be

displayed into images of CCD cameras and thermal

imagers using spatial coordinates. The procedure is

outlined in the diagram below (see Fig. 8). The input

data include the range measurement, the image

coordinates of all sensors, and the results of the

previous calibration.

The spatial coordinates X, Y, Z are computed

according to Eq. 2 and 3, where d is the measured

distance, x

c

, y

c

are the calibrated TOF image

coordinates, and f is the focal length of the TOF

camera. The homogeneous transformation is

determined by Eq. 4, where R

[3×3]

is the rotational

matrix, t

[3×1]

is the translation vector, and X', Y', Z'

are the spatial coordinates of the second sensor. The

image coordinates of the TOF camera in the next

frame x

c

',y

c

' are computed according to perspective

projection (see Eq. 5), where f' is the focal length of

the second sensor.

22

cos arctan cos arctan

cc

c

yx

Zd

f

fx

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

462

c

Zx

X

f

,

c

Zy

Y

f

Figure 8: Image transformation scheme.

1

10

1

'

'

'

Z

Y

X

tR

Z

Y

X

'

''

'

Z

Xf

x

c

'

''

'

Z

Yf

y

c

According to the identical (ID) points of the TOF

camera transformed into the frames of the CCD

camera and the thermal imager, the thermal image

can be displayed into the CCD image and vice versa.

The main objective of this paper is to calculate

and verify the accuracy of heterogeneous sensor data

fusion. We will focus on the weakest point of data

fusion i.e. range camera.

4.1 Influence of Distance Error on

Data Fusion Precision

The first investigated problem is influence of

objective point accuracy (or more precisely range

accuracy) on data fusion. Therefore, we determined

pixel differences caused by TOF camera radial

distance error for both CCD cameras and thermal

imagers. We simulated distance error for 2

significant image points: point on optical axis of the

TOF camera, point on the edge of the region 3 (see

Fig. 5) lying on the x-axis. Measured distances in the

region 4 have very low reliability, therefore this

region isn´t considered. The range of the radial

distance simulation is the same as detection range of

TOF camera i.e. 0.1 – 10.0 m.

The effect of distance error is not significant for

data fusion if transformed image coordinate

differences (CCD cameras and thermal imagers) not

exceed 0.5 pixel. For simulation we used values

Figure 9: Scheme of data fusion: up – TOF and CCD data

fusion; centre - TOF and thermal data fusion; down - CCD

and thermal data fusion.

based on distance error from range calibration. It is

also important to judge the usefulness and impact of

the range calibration. Distance error before

calibration 41 mm and after calibration 14 mm was

used for point on optical axis (reg. 1). Analogously

46 mm and 18 mm for point on the edge of reg. 3.

Figs. 10, 11 and Tab. 1 show effect of pixel error

in transformed images caused by distance error.

Graphs for point on the edge of reg. 3 have the same

character as Figs. 10 and 11. The numerical

difference is apparent from Tab. 1. For point on the

edge of reg. 3 are pixel error slightly higher than

point on optical axis (reg. 1). Distance error is

insignificant for radial distance greater than

approximately 2.5 m for CCD cameras before range

calibration and approximately 1.5 m for CCD

cameras after range calibration. Analogously to

thermal imagers, approximately 1.5 m before

calibration and 1 m after calibration.

Rangemeasurementandimage

coordinatesofTOFcamera

Spatial coordinates

Homogeneoustransformation

Perspectiveprojection

Correctionofprincipalpoint

Displayingoverlappingimages

MultispectralDataFusionforRoboticReconnaissanceandMapping

463

Figure 10: Image coordinate differences Δx caused by

distance error for point on optical axis of TOF camera.

Figure 11: Image coordinate differences Δy caused by

distance error for point on optical axis of TOF camera.

Table 1: Image Coordinate Differences 0.5 Pixel Cased By

Distance Error.

Distance

error

Image

coord.

Radial distance at that

pixel error causes by

distance error is 0.5 pixel

[m]

CCDl CCDr

TH.

l

TH.

r

Point

on

optical

axis

41 mm

before

calibration

x

2.43 2.49 1.30 1.34

y

2.40 2.40 – –

15 mm

after

calibration

x

1.48 1.51 0.79 0.81

y

1.45 1.45 – –

Point

on the

edge

of

reg. 3

46 mm

before

calibration

x

2.61 2.94 1.44 1.53

y

2.64 2.64 – –

18 mm

before

calibration

x

1.64 1.84 0.90 0.97

y

1.65 1.65 – –

Influence of low resolution of TOF camera is the

second investigated problem. The same 2 points and

same distance range as in previous section are used

for the simulation.

4.2 Influence of TOF Camera Low

Resolution on Data Fusion

Precision

Error 0.5 pixel in the image of TOF camera cause an

error of image coordinate x for CCD cameras

approximately 5 pixel (see Figs. 12, 14) and for

thermal imagers approximately 1.5 pixel (see Figs.

12, 14).

Figure 12: Image coordinate differences Δx caused by shift

of TOF image coordinate x of 0.5 pixel for point on optical

axis of TOF camera.

Figure 13: Image coordinate differences Δy caused by shift

of TOF image coordinate x of 0.5 pixel for point on optical

axis of TOF camera.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

464

Figure 14: Image coordinate differences Δx caused by shift

of TOF image coordinate x of 0.5 pixel for point on the

edge of reg. 3.

Figure 15: Image coordinate differences Δy caused by shift

of TOF image coordinate x of 0.5 pixel for point on the

edge of reg. 3.

Error of image coordinate y is insignificant for

thermal imagers that are in the same height as TOF

camera and for CCD cameras only for points near

the optical axis of TOF camera (see Figs. 13 and

15). Influence of low resolution of TOF camera is

significant for points remote from optical axis (see

Fig. 13). Range calibration significantly improves

precision of CCD image coordinate y in this case

(see Fig. 15).

4.3 Influence of the TOF Image Radial

Distance on Data Fusion Precision

The third simulated effect was the influence of the

TOF camera image radial distance on data fusion

precision. The simulation comprised the error of 0.5

pixel in the TOF camera image coordinates and the

values of this error after the data fusion in images of

the CCD cameras and thermal imagers depending on

TOF image radial distance.

Figure 16: Image coordinate differences Δx caused by 0.5

TOF pixel error in dependence on the TOF image radial

distance.

Figure 17: Image coordinate differences Δy caused by 0.5

TOF pixel error in dependence on the TOF image radial

distance.

Different camera resolution values appear fully

in this simulation. The error of 0.5 pixel in the TOF

camera image causes, in the image coordinates x, y,

the error of approximately 5 pixels for the CCD

cameras and 1.5 pixels for the thermal imagers (see

Fig. 16, 17). Furthermore, the influence of low

resolution of the TOF camera slightly increases

depending on the TOF camera radial distance.

5 CONCLUSION AND FUTURE

WORK

Although the methods presented in this research

report are sufficiently applicable, stable, and reliable

(see Fig. 18), our research on the telepresence and

mapping subsystem of CASSANDRA is still far

from complete. The challenge we are currently

facing is to facilitate seamless combination of visual

telepresence and digital maps to form an augmented

reality system. The system should be able to add

map information to the “real-time” telepresence

MultispectralDataFusionforRoboticReconnaissanceandMapping

465

image so that the operator could see data such as the

temperatures through a robot that is not equipped

with a thermal imager; furthermore, it should also

facilitate the vision through or behind objects, and

perform other operations.

The CASSANDRA system is obviously also

intended to work outdoors, where other challenges

are waiting. We have already integrated a Velodyne

scanner as well as a high-precision RTK GNSS in

one of our robots, and thus we can build also

outdoor maps. We are currently working on several

supporting systems for outdoor telepresence.

Figure 18: Octree multispectral map of interior with data-

fusion.

ACKNOWLEDGEMENTS

This work was realised in CEITEC – Central

European Institute of Technology with research

infrastructure supported by the project

CZ.1.05/1.1.00/02.0068 financed from European

Regional Development Fund and by the Technology

Agency of the Czech Republic under the project

TE01020197 "Centre for Applied Cybernetics 3".

REFERENCES

P. Kocmanova and L. Zalud, “Spatial Calibration of TOF

Camera, Thermal Imager and CCD Camera”. In:

Mendel 2013: 19th International Conference on Soft

Computing. Brno: Brno University of Technology,

Fakulty of Mechanical Engineering, 2013, s. 343-348.

ISBN 978-80-214-4755-4.

SR4000 Data Sheet, MESA Imaging AG. Rev. 5.1, 2011.

J. Bartl and M. Baranek, “Emissivity of aluminium and its

importance for radiometric measurement”.

Measurement science review.

T. Luhmann, J. Ohm, J. Piechel and T. Roelfs, “Geometric

Calibration of Thermographic Cameras”. In:

International Archives of Photogrammetry, Remote

Sensing and Spatial Information Sciences 2010, vol.

XXXVIII, pp. 411-416.

X. Ju, J.-C. Nebel, J. P. Siebert, H. Gong, Y. Cai and J.-P.

Chatard,” 3D thermography imaging standardization

technique for inflammation diagnosis”. Proceedings of

the SPIE. 2005, vol. 5640, pp. 266-273.

S. Prakash, P. Y. Lee and T. Caelli,” 3D Mapping of

Surface Temperature Using Thermal Stereo”. 2006

9th International Conference on Control, Automation,

Robotics and Vision. IEEE, 2006, pp. 1-4.

Z. Zhang,”Flexible camera calibration by viewing a plane

from unknown orientations”. Proceedings of the

Seventh IEEE International Conference on Computer

Vision. IEEE, 1999, vol. 1, pp. 666-673.

L. Zalud and P. Kocmanova,”Fusion of Thermal Imaging

and CCD Camera-based Data for Stereovision Visual

Telepresence”.In: SSRR 2013: 11th IEEE

International Symposium on Safety Security and

Rescue Robotics, pp.1-6.

L. Zalud, F. Burian, L. Kopecny, P. Kocmanova (2013).

Remote Robotic Exploration of Contaminated and

Dangerous Areas, International Conference on

Military Technologies, pp 525-532, Brno, Czech

Republic, ISBN 978-80-7231-917-6.

L. Zalud, (2005). ORPHEUS – Reconniaissance

Teleoperated Robotic System. In: 16th IFAC World

Congress. pp. 1-6, Prague, Czech Republic.

D. Lichti, D.-Rouzaud: Surface-dependent 3D range

camera self-calibration. In: Proceedings of SPIE

Three-Dimensional Imaging Metrology, Vol. 7239,

2009, pp. 72390A-1-72390A-10.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

466