Fuzzy Control of a Sintering Plant

Marco Vannocci

1

, Valentina Colla

1

, Piero Pulito

2

, Michele Zagaria

2

, Vincenzo Di Mastromatteo

2

and Marco Saccone

2

1

PERCRO Laboratory, Scuola Superiore Sant’Anna, Via Alamanni 13D, San Giuliano Terme (Pisa), Italy

2

ILVA S.p.A., Strada Statale Appia Km 648, Taranto, Italy

Keywords:

Fuzzy Control, Expert Systems, Sinter Plant.

Abstract:

Within an integrated steelwork, the industrial priorities in the automation of the sinter plant comprise stable

production rate at the highest productivity level and classical control scheme may fail due to the complexity

of the sinter process. The paper describes an approach exploiting a fuzzy rule-based expert system to control

the charging gates of a sinter plant. Two different control strategies are presented and discussed within an

innovative advisory system that supports the plant operators in the choice of the most promising action to do

on each gate. Through the proposed approach the operators are supported by the system in the control of the

plant: through a suitable exploitation of real-time data, the system suggests the most promising action to do,

by reproducing the knowledge of the most expert operators. Thus, this approach can also be used to train new

technicians before involving them in the actual plant operations. The performance of the strategies and the

goodness of the system have been evaluated for long time in the sinter plant of one of the biggest integrated

steelworks in Europe, namely the ILVA Taranto Works in Italy.

1 INTRODUCTION

Within a steelwork, the sintering process is a central

operation in the production cycle: the treatment is

basically a high temperature process that starts from

raw materials mixture (such as fine iron ores) and

produces a particular form of agglomerate material

known as sinter, which is one of the material fed to the

blast furnace in order to produce the pig iron, which is

subsequently refined in the steel shop to produce the

liquid steel.

The sintering process is articulated into a series

of standard operations. A first preliminary task is the

acceptation and the storage of the iron-bearing raw

materials in the ore stockyard followed by the crash-

ing and the screening of these raw materials. Then,

the following phases which are more specific of the

sintering process can be pointed out: (I) raw mate-

rials are mixed together with water and then granu-

lated into a pseudo-particles in a rotary mixer drum

and then stocked in a feed hopper; (II) after the hop-

per, the moistened mix passes through the charging

gates and it is accumulated just before a leveler that

strips out the exceeding material; thus the moistened

mixture is charging as a layer onto continuously mov-

ing pallet-cars called “strand”; (III) after the ignition

of the material close to the charging zone, the burn-

ing process is propagated by chemical reaction thanks

to the air sucked through the strand by the so-called

wind boxes, that are depressurised air ducts mounted

below the strand; (IV) at the end of the strand the so-

lidified agglomerate is broken within a crusher and

cooled within a cooler strand; (V) finally the cooled

material is conveyed to a second crusher in order to

obtain a suitable size of the particles of the final sin-

ter.

The overall process must be controlled in order to

ensure that all the mix is burned just earlier than being

discharged into the crusher. The points at which the

flame front reaches the base of the strand are called

“burn-through points” (BTPs). Thus, among the aims

of the control process of the plant, two of them are

of considerable interest and can be summarized as

follows: to ensure that the BTPs are aligned in the

transversal direction of the strand and to ensure that

this alignment happens just earlier than the discharge.

As a matter of fact, a uniform flame front is guaran-

teed to the former condition while the latter one op-

timizes the production capacity of the plant. In fact

there is an evident waste of productivity of the plant

68

Vannocci M., Colla V., Pulito P., Zagaria M., Di Mastromatteo V. and Saccone M..

Fuzzy Control of a Sintering Plant.

DOI: 10.5220/0005082400680075

In Proceedings of the International Conference on Fuzzy Computation Theory and Applications (FCTA-2014), pages 68-75

ISBN: 978-989-758-053-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

if the BTPs occur too early compared to the end of the

process; analogously, the quality of the sinter lowers

if the burning process is not completed before the dis-

charge and this fact negatively affects the production

rate of the overall steel plant and the following pro-

duction stages.

Predictive capabilities have been used to develop

control schemes controlling the speed of the strand.

In (Kanjilal and Rose, 1986) the prediction of the

waste gas temperature is used to manipulate the strand

speed, while in (Hu and Rose, 1997) the same vari-

able is controlled using a process model identified

from the observed data. A different perspectiveis pre-

sented in (Arbeithuber et al., 1995), where the control

scheme tries to keep the temperature distribution at

the end of the plant on a pre-defined curve in order to

yields a target BTP. Also in this case the manipulated

variable is the strand speed.

The new approach presented in the paper is based

on fuzzy rule-based expert systems and exploits the

charging gates as controlled variables. Two different

control strategies will be presented and discussed as

well as an innovative advisory system that supports

the plant operators in the control of the plant.

The paper is organized as follows. Section 2 de-

scribes the two control strategies while the advisory

system is presented in Section 3. Section 4 presents

the results of the on-the-plant tests and the Section 5

is devoted to the conclusion.

2 CONTROL STRATEGIES

Some mathematical models have been developed

in order to cope with the dynamic of the sinter-

ing process in an analytical way. A first attempt

has been made in (Young, 1977) while a differ-

ent perspective has been developed in (Augustin

et al., 1995) and (de Castro et al., 2012). A

different approach based on multiple-valued logic

is the core of the present paper and concepts of

fuzzy sets (Zadeh, 1965), fuzzy control (Lee, 1990)

(Pedrycz, 1989) (Passino and Yurkovich, 1998) and

expert systems (Jackson, 1998) (Durkin, 1998) are

used to develop the strategies and to build the advi-

sory system.

2.1 Overview of the Sintering Machine

The transversal direction of the strand can be divided

into four segments denoted by A, B, C and D. Each of

them covers the overall length of the machine and it

is about one meter wide, so that they cover the overall

Figure 1: Sketch of the macro-zones A,B and C of the

plant.

23 24 25 26 27 28

C

Figure 2: Sketch of the grid of thermocouples.

width of the strand. Regarding the longitudinal direc-

tion, three differentmacro-zonescan be pointed out as

depicted in Figure 1 and described in the following:

• charging zone (A) at the very beginning of the

strand;

• permeabilities zone (B) after the ignition hood at

the 3

rd

wind box;

• burn-through points zone (C ) at the end of the bed

covering a wide area of about 48 m

2

.

Within the macro-zone A the feed hopper, 6

charging gates and 6 infrared sensors can be found,

while the permeability sensors, which take 4 differ-

ent permeability measurements along the transversal

direction of the strand and that are indicated in the

following as K

A

, K

B

, K

C

, K

D

, are located within the

macro-zone B. Finally, in the last zone (C ) a regular

grid of thermocouples has been installed, such as de-

picted in Figure 2 that measures 24 temperature val-

ues: among them, the maximum one of each segment

is the associated BTP, thus finally there are 4 BTP val-

ues indicated as BTP

A

, BTP

B

, BTP

C

, BTP

D

.

From the point of view of the plant operational

practice, it would be advisable that the maximum

value of temperature is reached for all the segments

in correspondenceto approximatelythe same distance

from the strand end, as this implies that the sintering

process is quite homogeneous in all the portions of

the strand itself.

A preparatory statistical analysis conducted on

historical data coming from the plant has put

into evidence that the transversal alignment of

FuzzyControlofaSinteringPlant

69

BTP

A

, .. ., BTP

D

is related to a specific configuration

of K

A

, ..., K

D

. Thus, the idea behind the strategies is

to control the charging gates in order to obtain the

suitable permeability configuration in the macro-area

B.

Indeed, as the permeability configuration is sup-

posed to be symmetric, the difference between the

external permeabilities (K

A

, K

D

) and the internal ones

(K

B

, K

C

) can leads to crucial information about the

suitable configuration to be obtained.

Thus, in order to pursue such investigation, the

following 4 permeability ratios (K

r

) have been de-

fined:

(r

1

,r

2

,r

3

,r

4

)

T

=

K

A

K

D

,

K

B

K

C

,

K

A

K

B

,

K

D

K

C

T

. (1)

2.2 Description of the Strategies

Two control strategies have been designed, which

both aim at maximizing the increase of the average

permeability. The first strategy (‘a’) takes into ac-

count only this target; the second one (‘b’) takes also

into account the stress on the actuator and tries to min-

imize the movement of each gate, namely, if more

actions involving different gates are equally physi-

cally feasible, this latter strategy suggests the action

that produces the minimum displacement of the gates

from their current position.

Variables and symbols for both strategies are sum-

marized in Table 1 and a description of the first strat-

egy (‘a’) is the following:

1. Gates and Infrared Indices: the gate and the in-

frared values are normalized using its operative

limits (G

min

, G

max

, IR

min

, IR

max

);

2. Control Coefficients: four control coefficients

that express the contribution of each couple of

gates (i.e. 1,2 - 2,3 - 4,5 - 5,6) on each segment of

the bed are computed using the above indices;

3. Action Indices: four “action-indices” that con-

tain the information about the operations to per-

form on each couple of gates (e.g. a value less

than zero indicates that the gates of a couple need

to be closed) are computed and limited between

suitable thresholds (c

min

, c

max

);

4. Targets Computation: four different target per-

meability profiles, namely 4 different vectors of

4 entries each, are obtained using the permeabil-

ity ratios K

r

; the i-th element of the i-th vector is

obtained by imposing K

target

K

i

(i) = K

t

(i)while the

other elements are calculated using K

r

; the equa-

tions (2) show the computations for the first (i= 1)

profile:

K

target

K

1

(1)

def

= K

target

A

= K

t

(1) ≡ K

A

(2a)

K

target

K

1

(2)

def

= K

target

B

= K

target

A

/r

3

(2b)

K

target

K

1

(3)

def

= K

target

C

= K

target

B

/r

2

(2c)

K

target

K

1

(4)

def

= K

target

D

= K

target

A

/r

1

(2d)

where the relation (2a) concern the imposed ele-

ments (i = 1), while the formulas (2b)-(2d) con-

cern the computed elements of the profile;

5. Gaps Between Current and Target: for each

target profile the gaps between the current pro-

file and the target is evaluated, obtaining 4 dif-

ferent vectors of 4 entries each that are computed

according to the following equations, where i =

1,..., 4:

K

gaps

K

i

(1) = K

A

− K

target

K

i

(1) (3a)

K

gaps

K

i

(2) = K

B

− K

target

K

i

(2) (3b)

K

gaps

K

i

(3) = K

C

− K

target

K

i

(3) (3c)

K

gaps

K

i

(4) = K

D

− K

target

K

i

(4) (3d)

6. Control Amount for Each Couple of Gates: for

each vector of gaps the control amount values to

be applied on each couple of gates is calculated by

obtaining four vectors with four elements each;

7. Calculate the Feasibility: for each target profile

a feasibility coefficient is computed informing if

the related action on the couple of gates are phys-

ically feasible or not (e.g. it is required to close a

gate that it is already completely closed);

8. Calculate the Increase of the Average Perme-

ability: for each target profile the gains of the

average values are evaluated in order to use these

values as performance indicators; each of them is

related to a vector of control amount values so that

the better the control on the gates the higher will

be the index.

9. Select the Actions: among some target profile all

equally physically feasible, it is selected the one

which optimizes the performance indicator gain-

ing the four control amount values denoted by u

12

,

u

23

, u

45

and u

56

.

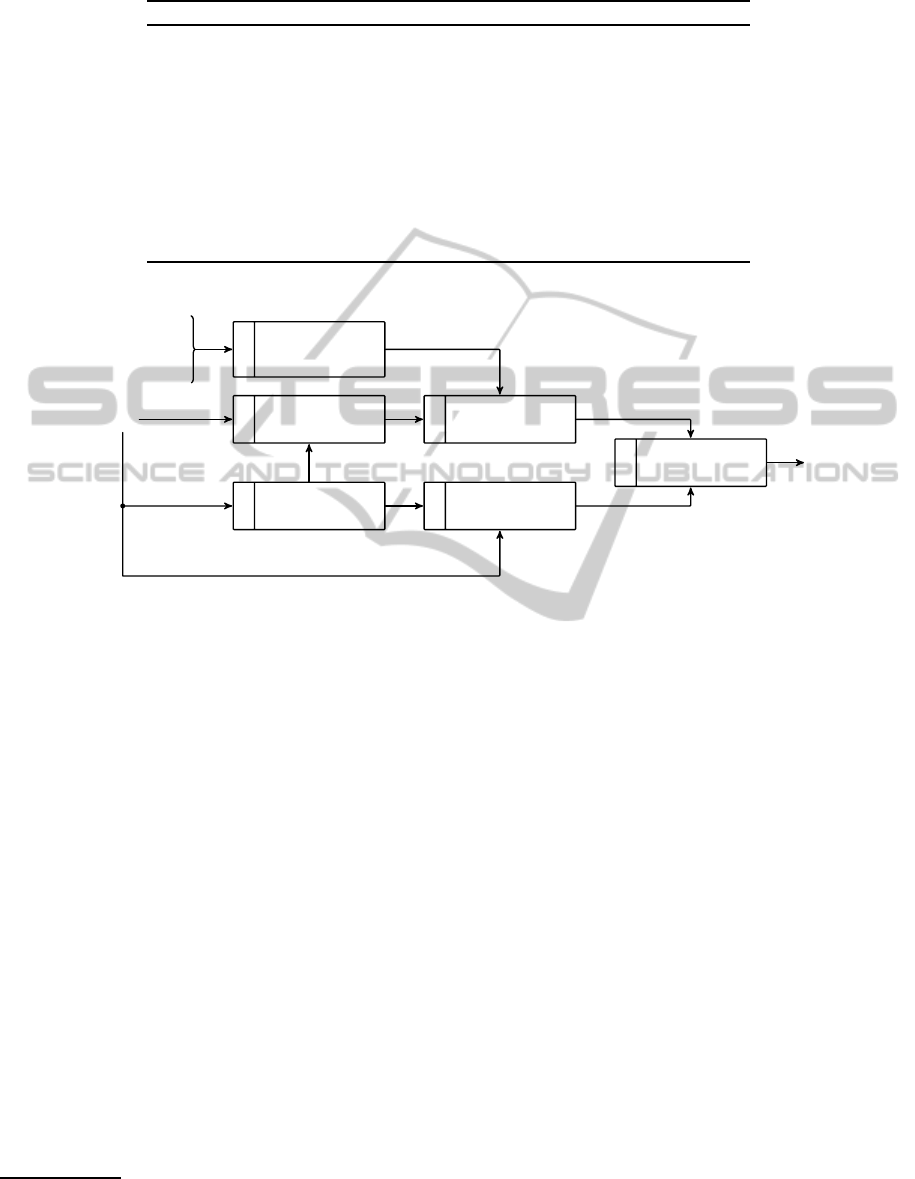

In Figure 3 the conceptual diagram of control strategy

‘a’ is reported.

The description of strategy ‘b’ is similar to the one

of the strategy ‘a’ where the point 8 is modified as

follows:

8. Calculate the Stress on the Actuator: for each

target profile, the stress produced on the actuator

is evaluated by summing the overall gaps of the

FCTA2014-InternationalConferenceonFuzzyComputationTheoryandApplications

70

Table 1: Symbols used within the control strategies.

Symbol Meaning

†

G

t

Opening percentage of the gates

IR

t

Measure of the height of the sinter bed along the transversal direction

K

t

Permeability values i.e. K

t

=(K

1

, .. ., K

4

)

T

≡(K

A

, . .., K

D

)

T

K

r

Permeability ratios i.e. K

r

≡ (r

1

,r

2

,r

3

,r

4

)

T

K

target

K

i

Permeability values computed using K

r

by imposing

K

target

K

i

(i) = K

t

(i), i = 1,. .., 4

G

min

,G

max

Working range limits of the gates

IR

min

, IR

max

Minimum and maximum allowed height of the sinter bed

c

min

, c

max

Suitable thresholds

Y Selected control actions

†

where (·)

t

means that the values are taken at the current time instant i.e. they are on-line values.

G

t

, G

min

, G

max

IR

t

, IR

min

, IR

max

c

min

, c

max

1

2

3

calculate

indices

K

t

5

calculate

gaps

6

7

control and

feasibility

9

select

actions

u

12

u

23

u

45

u

56

4

calculate

target

⋆

8

calculate incr.

of av. perm.

⋆

Also use K

r

as input

Figure 3: Conceptual scheme of the first control strategy.

profile

1

in order to use these values (one for each

target profile) as performance indicators; each of

them is related to a vector of control amount val-

ues so that the better the control on the gates the

lower will be the index.

Thus, the conceptual diagram of the second con-

trol strategy is analogous to the one of the strategy ‘a’

except for the block number 8.

3 ADVISORY SYSTEM

The new value of the gates, required to reach the tar-

get permeability profile, can be computed through the

following relations:

G

new

(1) = G

t

(1) + 0.5u

12

, (4a)

G

new

(2) = G

t

(2) + 0.5u

12

+ 0.5u

23

, (4b)

G

new

(3) = G

t

(3) + 0.5u

23

, (4c)

G

new

(4) = G

t

(4) + 0.5u

45

, (4d)

G

new

(5) = G

t

(5) + 0.5u

45

+ 0.5u

56

, (4e)

G

new

(6) = G

t

(6) + 0.5u

56

(4f)

1

In fact, the gaps are related to the distance between the

current and the desired position of the gates.

where the coefficient of each term has been set heuris-

tically using the knowledge of the technicians’ exper-

tise.

Comparing the new values of the gates with the

current values, the advisory system is able to provide

information about the actions to be performed on all

of the charging gates. The actions are also related

to a rank number in order to inform about the most

promising of them.

The advisory system is an expert system (ES)

founded on multiple-valued logic with a rule base that

reproduce the knowledge of the plant operators. Thus

the system belongs to the larger family of the Fuzzy

Rule-Based Expert Systems (FRBES) (Geyer-Schulz,

1995).

The system is designed using the zero-order Tak-

agi-Sugeno-Kang (TSK) model (Takagi and Sugeno,

1985) where the j-th fuzzy rule (R

j

) of the form “IF

hpremisei THEN hconclusioni” is given by:

R

j

: IF (x is A

i

) AND/OR (y is B

i

) THEN z

j

= c

j

(5)

where x and y are the inputs, A

i

and B

i

are fuzzy sets

and c

j

is a crisp adjustable parameter.

The system evaluates each rule (implication) col-

lecting together the results (aggregation) in order to

FuzzyControlofaSinteringPlant

71

Table 3: Characteristic parameters µ and σ of the linguistic terms.

FIS

1,3,4,6

FIS

2,5

DG DGN DG DGSx DGDx

NEG −1,0.34 −1,0.34 −1,0.34 −1, 0.34 −1,0.34

NUL 0,0.1 0,0.1 0,0.16 0,0.14 0,0.13

POS 1,0.34 1,0.34 1,0.34 1,0.34 1,0.34

Table 4: Rules for the FIS

1,3,4,6

.

DGN is NEG DGN is POS DGN is NUL

DG is NEG −1 0 −1

DG is POS 0 1 1

DG is NUL 0 0 0

produce a unique output fuzzy set. The crisp value

extracted from this fuzzy set (defuzzification) repre-

sents the output of the entire inference process.

The aggregation and the defuzzification tasks can

be merged in a unique operation in the TSK model as

follows:

z =

N

∑

j=1

w

j

c

j

N

∑

j=1

w

j

, with w

j

= F(µ

i

,ν

i

) (6)

where N is the number of rules, w

j

is the firing

strength of the j-th rule (i.e. the “degree of truth” of

the hpremisei), F is the method that implements the

AND operator (F is a t-norm) or the OR operator (F

is a t-conorm), µ

i

is the membership degree of x to A

i

and ν

i

is the membership degree of y to B

i

.

The system is composed of 6 specialized fuzzy

inference systems (FISs), one for each gate (FIS

i

,

i = 1,. .. ,6), whose inputs are the differences ∆G

i

=

G

new

(i) − G

t

(i) (after a proper normalization stage

forcing any crisp input to lie in the range [−1,1]).

Moreover, ∆G

2

is in input to both the FIS

1

and the

FIS

3

as additional input as well as ∆G

5

is in input to

both the FIS

4

and the FIS

6

. These additional gaps will

be denoted by the DGN term within the rules.

The FIS

2

has ∆G

1

and ∆G

3

as additional inputs

as well as the FIS

5

receives ∆G

4

and ∆G

6

. These

additional gaps will be denoted, respectively, by the

DGDx and DGSx terms within the rules. Table 2 sum-

marizes the inputs of each FIS.

Table 2: Inputs of each fuzzy inference system.

∆G

1

∆G

2

∆G

3

∆G

4

∆G

5

∆G

6

FIS

1

• •

FIS

2

• • •

FIS

3

• •

FIS

4

• •

FIS

5

• • •

FIS

6

• •

The inputs of the FIS

1,3,4,6

are 2 linguistic vari-

ables, while the inputs of the FIS

2,5

are 3 linguistic

variables. For each input variable, 3 linguistic terms

(i.e. fuzzy sets) are defined: ‘Negative’(NEG), ‘Null’

(NUL) and ‘Positive’ (POS). The membership func-

tions of all the fuzzy sets are bell-shaped functions

whose parameters (µ,σ) have been heuristically set as

described in Table 3.

The rule bases for the systems have been obtained

after fruitful discussions with the plant operators and

considering also the operative practices of the opera-

tors too.

All the rules for the FIS

1,3,4,6

are shown in Table 4

while in Table 5 to 7 are shownthe rules for the FIS

2,5

.

In all the rule bases the numerical value of the out-

put means that the gate must be closed (− 1) or opened

(1) or, finally, that no operation must be performed on

the gate (0). The

∏

(x,y) = x∗ y operator is the t-norm

that implements the AND connection of each rule and

the relation (6) is used to defuzzify the inferred output

fuzzy set.

4 EXPERIMENTAL RESULTS

Two different scenarios have been considered for the

plant tests. The first one (“short period scenario”)

takes into account a period of 4 hours using the strat-

egy ‘a’ for the first 2 hours and the strategy ‘b’ during

the last 2 hours.

Some characteristic conditions can be highlighted

during the tests within this scenario: (a) no stoppage

of the strand occurred; (b) the percentages of lime and

limestone within the mix were fixed; (c) the ratio be-

tween the speed of the drum feeder and the speed of

the strand was constant; (d) the moisture of the mix

was kept as constant as possible.

The qualitative results of the first session showed

that the strategy ‘a’ leads to an actual increment of

the average permeability and thus to a better yield of

FCTA2014-InternationalConferenceonFuzzyComputationTheoryandApplications

72

Table 8: Time intervals of the long period tests.

Test number Duration (h) Time interval Control Strategy

1 12 Day 1 (from 00:00 to 12:00) Technicians Expertise

2 12 Day 1 (from 12:00 to 00:00) ‘a’

3 12 Day 2 (from 00:00 to 12:00) Technicians Expertise

4 12 Day 2 (from 12:00 to 00:00) ‘b’

5 12 Day 3 (from 00:00 to 12:00) Technicians Expertise

6 12 Day 3 (from 12:00 to 00:00) ‘a’

7 12 Day 4 (from 00:00 to 12:00) ‘b’

Table 5: Rules for the FIS

2,5

when DGSx is POS.

DGSx is POS

DGDx is DGDx is DGDx is

NEG POS NUL

DG is NEG 0 0 −1

DG is POS 0 1 0

DG is NUL 0 0 0

Table 6: Rules for the FIS

2,5

when DGSx is NUL.

DGSx is NUL

DGDx is DGDx is DGDx is

NEG POS NUL

DG is NEG 0 −1 −1

DG is POS 1 0 1

DG is NUL 0 0 0

Table 7: Rules for the FIS

2,5

when DGSx is NEG.

DGSx is NEG

DGDx is DGDx is DGDx is

NEG POS NUL

DG is NEG −1 0 0

DG is POS 0 0 1

DG is NUL 0 0 0

the plant: this can be assessed considering the lower

Internal Return Fines (IRFs) consumption and thus a

lower wet coke consumption.

During the tests, the plant operators confirmed

that: (i) the actions proposed by the system have been

always fully safe despite the change of the operational

conditions in which each decision has been taken;

(ii) the operations have been always coherent with the

personnel’sexpertise. Thus, in the short period the ad-

visory system proved to behave according to the best

practice of the operators. Therefore, it is expected

that, in the long period, the automatic implementation

of such system will lead to improvement of the pro-

cess performances with a reduction of the operators’

effort.

The second scenario (“long period scenario”) con-

siders a period of 84 hours and compares the sys-

tem behavior during intervals when one of the devel-

oped control strategies was applied to intervals when

none of them was used and the plant was controlled

by exploiting only the expertise of the plant techni-

cians. The detailed description of each period of time

is summarized in Table 8.

The long period of eighty-four hours is the best

one that can be obtained minimizing the external in-

fluences such as, for example, a different chemical

composition in the mix caused by a different Blend

Iron Ore (BIO) in the mix. In Taranto, in fact, the typ-

ical amount of BIO is of 160000-180000 tonnes and

they are used within the mix during a typical period

of five days. Thus, the tests have been performed after

a suitable stabilization period after the change of the

BIO. Moreover, during the first day of the long period

test a significant stoppage of the strand occurred. In

order to take this fact into account, the results have

been computed by using only the data deriving from

a stable condition of the process (i.e. about 90 min.

after the restart).

Let ∆S be the amount of the produced sinter (in

tonnes), σ

C

the specific coke consumption (i.e. the

amount of the coke consumption - measured in Kg

- per tonne of produced sinter) and σ

IRF

the spe-

cific IRF production (i.e. the amount of produced

IRFs production - measured in Kg - per tonne of pro-

duced sinter); 3 significant Key Performance Indica-

tors (KPIs) can be defined as follows (where (·)/h

means “per hour”):

KPI

1

i.e. Sinter Production =

∆S

h

, (7a)

KPI

2

i.e. Wet Coke Consumption =

σ

C

h

, (7b)

KPI

3

i.e. IRF Production =

σ

IRF

h

. (7c)

In order to evaluate the goodness of the results the

trends of the KPIs have been evaluated. In particular,

the IRFs production that can be related directly to the

yield of the plant through the following equation:

Yield(%) = 100− 0.1σ

IRF

. (8)

The results of the long period tests are numerically

described in Table 9: using the strategy ‘a’ an aver-

age increment of the produced sinter and an average

FuzzyControlofaSinteringPlant

73

Table 9: Experimental results.

Control Strategy KPI

1

KPI

2

KPI

3

Expertise 4.25 -0.019 6.60

Strategy ‘a’ 2.38 -0.236 -6.75

Expertise -6.25 0.208 4.66

Strategy ‘b’ 1.45 -0.062 -2.50

Expertise -1.18 0.048 2.17

Strategy ‘a’ 3.92 -0.015 -0.43

Strategy ‘b’ -5.76 -0.231 -0.93

Expertise (mean) -1.06 0.08 4.48

Strategy ‘a’ (mean) 3.15 -0.13 -3.59

Strategy ‘b’ (mean) -2.16 -0.15 -1.72

reduction of the coke consumption as well as of the

IRFs production have been gained. The strategy ‘b’,

on the other hand, led to comparable results regarding

the coke consumption and the IRFs production, but

caused an average decrement of the productivity.

During both the short and the long period tests the

opinions of the technicians have been taken into ac-

count in order to evaluate the practical goodness of

the strategies as well as the KPI’s variations.

The behaviour most frequently used by the plant

experts was very similar to that of the strategy ‘b’ and

in contrast with the strategy ‘a’. Indeed, the strat-

egy ‘a’ takes into account only the average perme-

ability and whenever a variation of the gates posi-

tion is required in order to improve the permeabil-

ity, the variation is reported to the gates. This leads

to frequent variation in the gates positions and some-

times in abrupt changes. The technicians, on the other

hand, use a more conservative approach that tends to

perform slight modification in the gates position and

rarely abrupt changes.

Summing up the results of the tests of the two

control strategies: strategy ‘a’ gives better automatic

results, but it is less coherent to the technicians’

standard operating practice, thus they can experience

higher efforts in order to follow the plant behavior

when this control strategy is applied. Strategy ‘b’

leads to fairly good results, but it is more coherent

to the standard operating practice.

Finally, it can be noticeable that the advisory sys-

tem has been designed to be improved through its use,

as the overall software system supports data collec-

tion and analysis. After a longer period of use it will

be possible to refine the performances of the proposed

system using the same statistical parameters that sup-

plied the system.

5 CONCLUSION

A new approach based on fuzzy rule-based expertsys-

tems and a new advisory system to control the charg-

ing gates of a sinter plant is presented. Two new con-

trol strategies have been developed and tested on the

field.

Strategy ‘a’ is more invasive within the process

operational conditions, as it aims at maximizing the

productivity without any kind of trade-off. It can be

used when the plant is characterized by lower produc-

tivity (e.g. the plant is restarted after a stoppage): in

these cases the greater the control amount, the shorter

the time elapsed before reaching fair operating condi-

tions.

On the other hand, strategy ‘b’ is more conser-

vative, as it aims at maximizing the productivity but

considers also the stress on the gates’ actuators and

produces less perturbation in the operating conditions

with respect to the other strategy. It can be used when

the plant is characterized by higher productivity and

the machine shows a higher sensitivity to the changes

on the gates.

Real-time tests are still ongoing at the sintering

plant of ILVA S.p.A. (Taranto Works, Italy) and satis-

factory results confirm the goodness of the automatic

control system.

Future work will deal with the development of a

new strategy combining the strong points of the two

developed ones. In detail, this strategy can select au-

tomatically the use of the strategy ‘a’ during the lower

productivity phase of the plant switching on the other

strategy (‘b’) during the phase with high productiv-

ity and vice-versa. In this way a single strategy can

take the best advantages from the two developed ones

achieving good results during all the production phase

of the plant.

ACKNOWLEDGEMENTS

The work described in the present paper was devel-

oped within the project entitled ”New measurement

and control techniques for total control in iron ore

sinter plants” ToSiCo (Contract No. RFSR-CT-2009-

00001) that has received funding from the Research

Fund for Coal and Steel of the European Union. The

sole responsibility of the issues treated in the present

paper lies with the authors; the Commission is not re-

sponsible for any use that may be made of the infor-

mation contained therein.

REFERENCES

Arbeithuber, C., J¨orgl, H. P., and Raml, H. (1995). Fuzzy

control of an iron ore sintering plant. Control Engi-

FCTA2014-InternationalConferenceonFuzzyComputationTheoryandApplications

74

neering Practice, 3(2):1669–1674.

Augustin, M., Arbeithuber, C., and J¨orgl, H. P. (1995).

Modeling and simulation of an iron ore sinterstrand.

In EUROSIM, pages 873–878.

de Castro, J. A., Sazaki, Y., and Yagi, J. (2012). Three

dimensional mathematical model of the iron ore sin-

tering process based on multiphase theory. Materials

Research, 15(6):848–858.

Durkin, J. (1998). Expert Systems: Design and Develop-

ment. Macmillan Publishing Company.

Geyer-Schulz, A. (1995). Fuzzy Rule-Based Expert Systems

and Genetic Machine Learning. Physica-Verlag.

Hu, J. Q. and Rose, E. (1997). Predictive fuzzy control ap-

plied to the sinter strand process. Control Engineering

Practice, 5(2):247–252.

Jackson, P. (1998). Introduction to Expert Systems. Addison

Wesley, 3rd edition.

Kanjilal, P. P. and Rose, E. (1986). Application of adaptive

prediction and control method for improved operation

of the sintering process. Ironmaking and Steelmaking,

13(6):289–293.

Lee, C. C. (1990). Fuzzy logic in control systems: Fuzzy

logic controller - parts 1 and 2. IEEE Transactions on

Systems, Man and Cybernetics, 20(2):404–435.

Passino, K. M. and Yurkovich, S. (1998). Fuzzy Control.

Addison Wesley.

Pedrycz, W. (1989). Fuzzy Control and Fuzzy Systems. Re-

search Studies Press Ltd.

Takagi, T. and Sugeno, M. (1985). Fuzzy identification of

systems and its applications to modelling and control.

IEEE Transactions on Systems, Man and Cybernetics,

15(1):116–132.

Young, R. W. (1977). Dynamic mathematical model of

a sintering process. Ironmaking and Steelmaking,

4(6):321–328.

Zadeh, L. A. (1965). Fuzzy sets. Information and Control,

8:338–353.

FuzzyControlofaSinteringPlant

75